Lawrence electron accelerator type electrostatic spray gun

A technology of electron accelerator and electrostatic spray gun, applied in the direction of non-gas spraying, etc., can solve the problems of uneven coating thickness, limitation of spraying uniformity, weak divergence of coating particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings and embodiments:

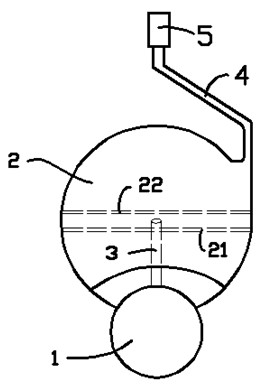

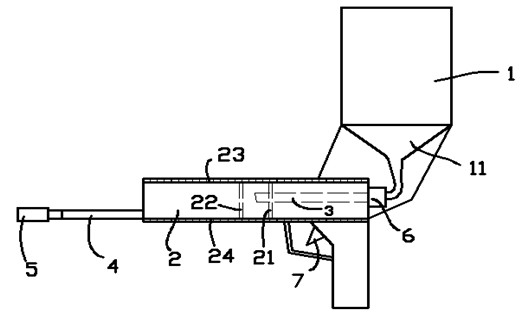

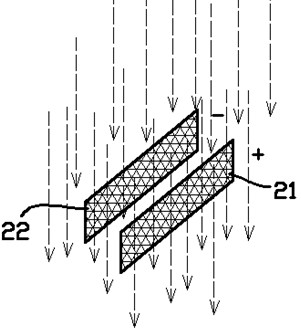

[0017] in figure 1 — image 3 In the illustrated embodiment, the Lawrence electron accelerator type electrostatic spray gun includes a paint container 1, an electrostatic generator 6, a barrel 4, and a switch 7. The main body of the paint container 1 is in the shape of a barrel, and the bottom is a conical funnel. 11. A solenoid valve (simple device, not shown) and an electrostatic generator 6 are connected in series at the bottom through the feed pipe 3 and then connected to an electron accelerator 2; the electron accelerator 2 is in the shape of a horizontal round box, and its upper and lower two The end surface includes a pair of oppositely opposed magnetic poles 23, 24 that can form a uniform magnetic field inside the electron accelerator 2; the electron accelerator 2 includes two metal mesh plates 21 that are parallel to each other and parallel to the uniform magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com