Polypropylene composition and preparation method thereof

A polypropylene composition and polypropylene technology, applied in the field of polypropylene composition and its preparation, can solve the problems affecting the odor of composite materials, etc., and achieve the effects of low odor and low emission performance, broad application prospects, and low emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

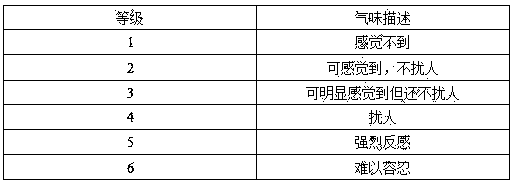

Examples

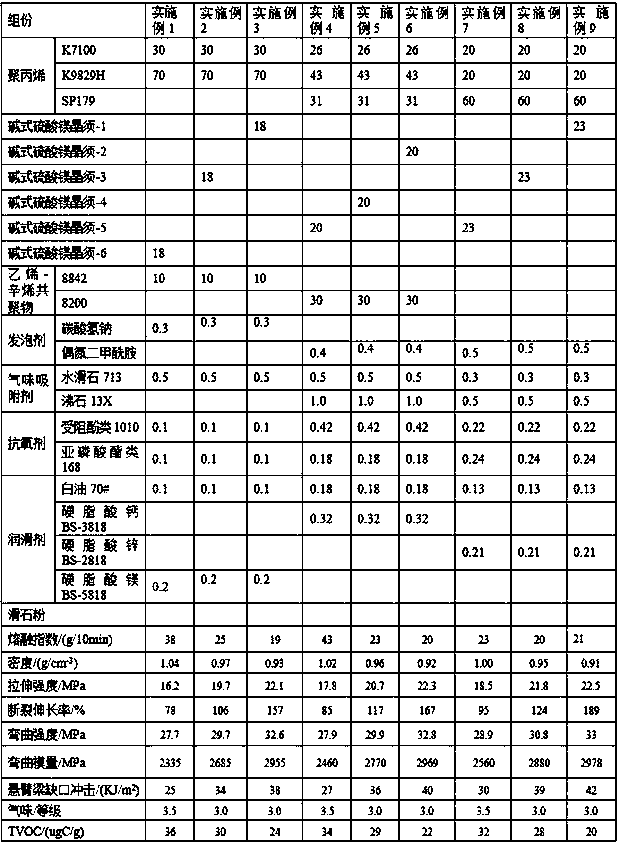

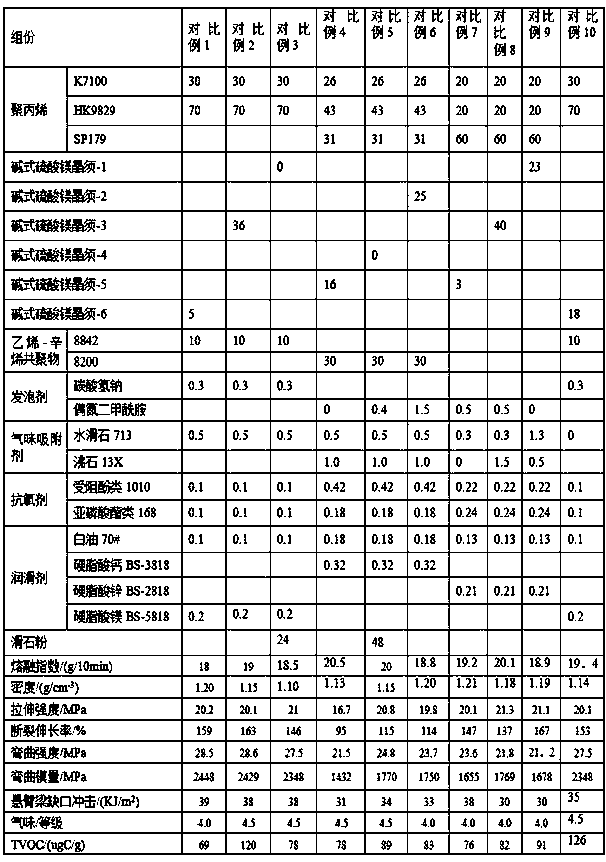

Embodiment 1-9 and comparative example 1-10

[0073] Embodiment 1-9 and comparative example 1-10: the preparation of polypropylene composition

[0074] According to the formula in Table 1, first weigh polypropylene, toughening agent, foaming agent, odor adsorbent and processing aid and add them in a high-speed mixer for 3-5 minutes, wherein the rotating speed of the high-speed mixer is 200 rpm- 300 rev / min; then weigh the basic magnesium sulfate whiskers and add them to the high-speed mixer for 3-5 minutes, wherein the rotating speed of the high-speed mixer is 200 rev / min-300 rev / min; add the above-mentioned mixed materials to the mixture. Perform melt extrusion, granulation, drying, cooling, and packaging in a twin-screw extruder; among them, the twin-screw extruder is a single-vacuum design (that is, a vacuum pump is set in zone 9), and the vacuum degree is required ≤ -0.08bar, the temperature of the twin-screw extruder is 170°C, 200°C, 200°C, 210°C, 210°C, 205°C, 205°C, 205°C, 200°C, 200°C from the feeding section to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com