Flat plate micro heat pipe vacuumizing and liquid injection device and method thereof

A technology of flat micro heat pipe and liquid injection device, which is applied in indirect heat exchangers, lighting and heating equipment, etc. It can solve the problems of difficulty in ensuring the accuracy of vacuum degree and liquid filling rate, the difficulty of quantitatively controlling the amount of liquid filling, and large processes. Achieve the effects of automatic and precise injection, low cost, precise vacuum degree and liquid injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

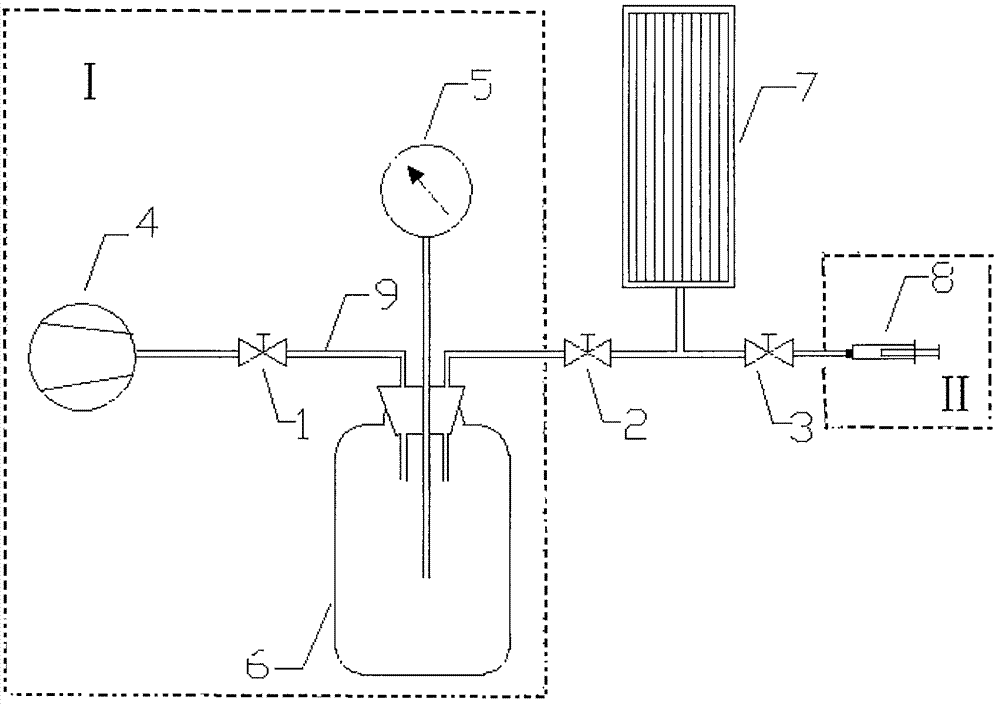

[0019] Such as figure 1 As shown, a flat plate micro heat pipe vacuum liquid injection device is composed of a vacuum pumping part I and a liquid injection part II. The vacuum pumping part I is composed of a vacuum pump 4, a vacuum gauge 5, a gas collecting bottle 6, and a capillary tube 9. 4 is used to evacuate the flat micro heat pipe 7 and the gas collecting bottle 6, and the vacuum gauge 5 is used to observe the degree of vacuum; the liquid injection part II is composed of a syringe 8 and a capillary tube 9, and the liquid is injected into the flat micro heat pipe 7 through the syringe 8 ; The vacuuming hole and the liquid injection hole share the same hole on the flat plate micro heat pipe; during the process of vacuuming and liquid injection, the connection between the plate micro heat pipe and each component is controlled by a manual valve. The flat plate micro heat pipe vacuum liquid injection device provided in this embodiment has simple structure, low cost, high prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com