Patents

Literature

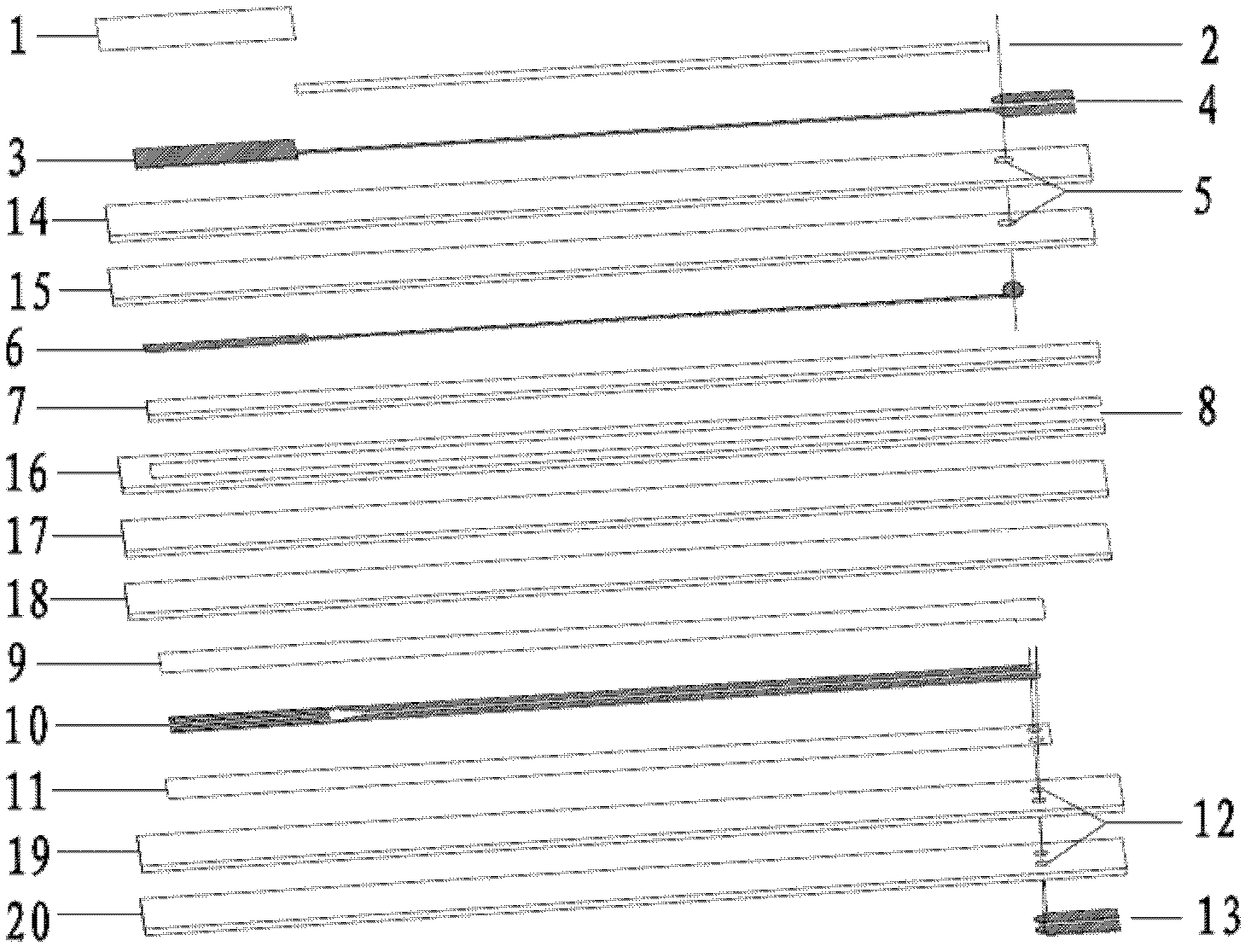

62results about How to "Reduce process error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

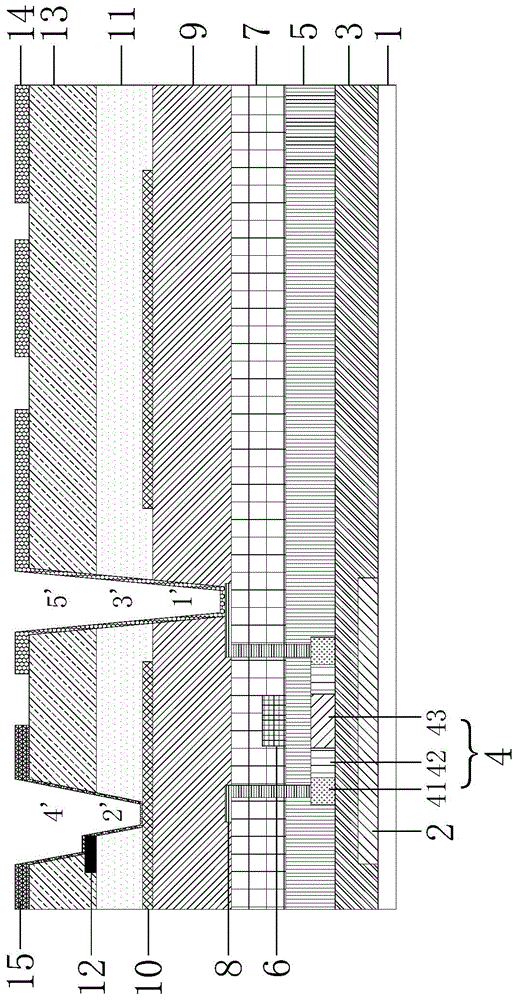

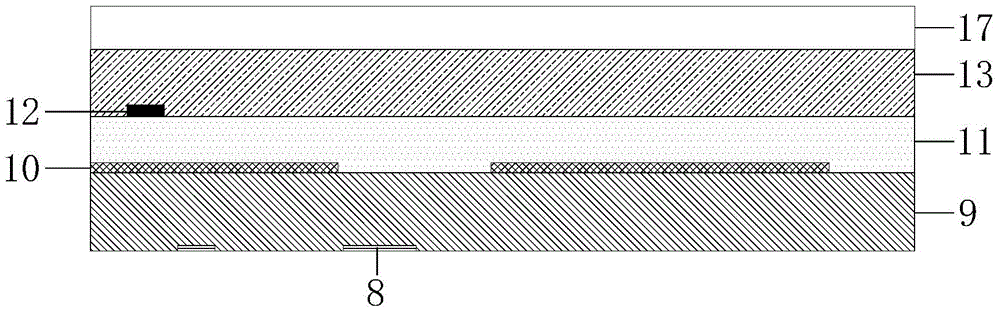

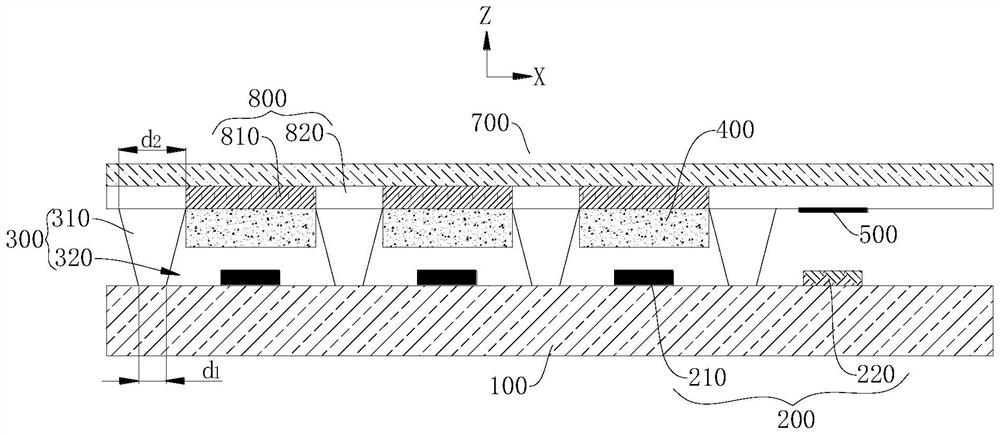

Touch control display device, manufacturing method thereof and electronic equipment

ActiveCN104915052ASimple preparation processReduce process errorSemiconductor/solid-state device manufacturingInput/output processes for data processingData linesDisplay device

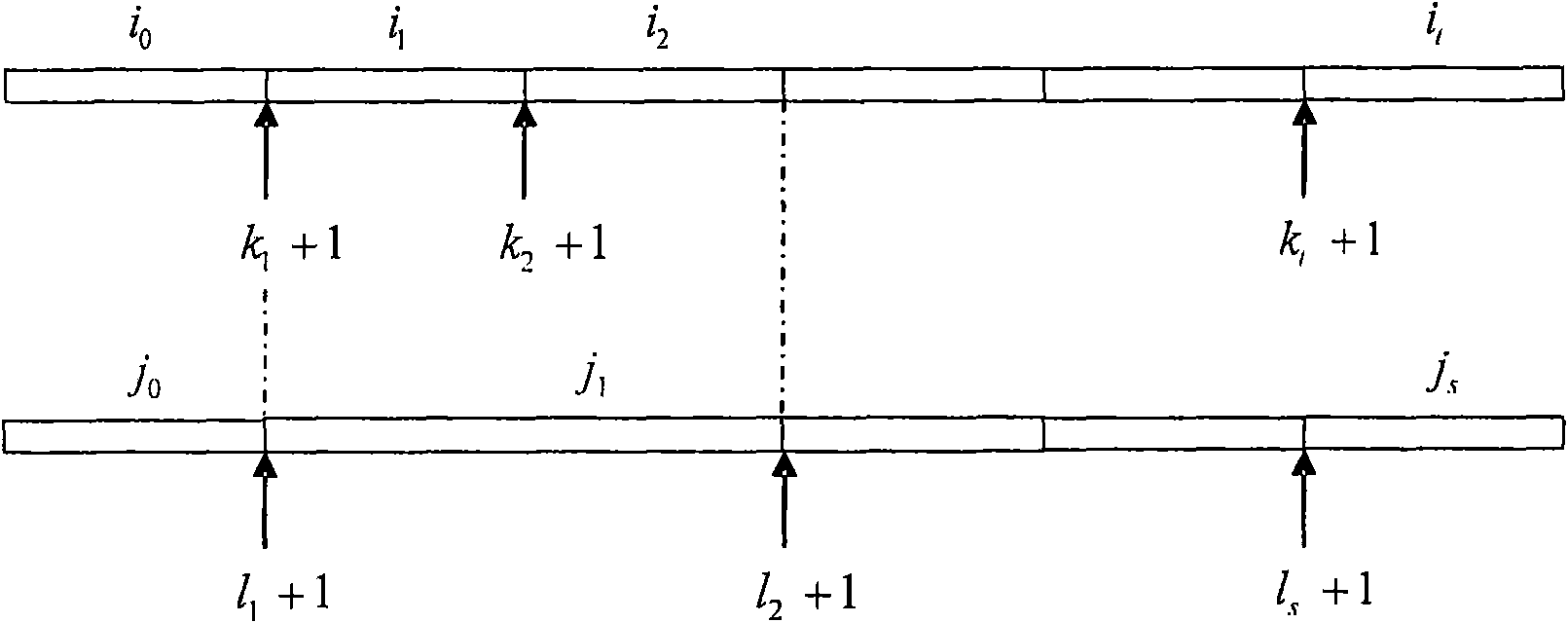

The invention discloses a touch control display device, a manufacturing method thereof and electronic equipment. When the touch control display device is manufactured, a via hole enabling a connecting electrode to be connected with a touch control electrode and a common electrode and a via hole enabling a pixel electrode to be connected with a data line metal layer can be formed through one photolithographic process. Manufacturing technology is simple, technological error is small, production period is short, production cost is low, and production efficiency is improved greatly.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

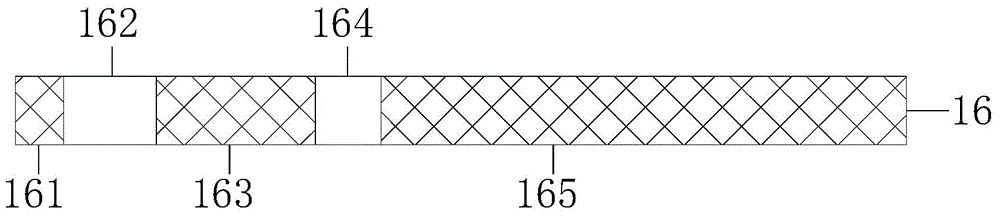

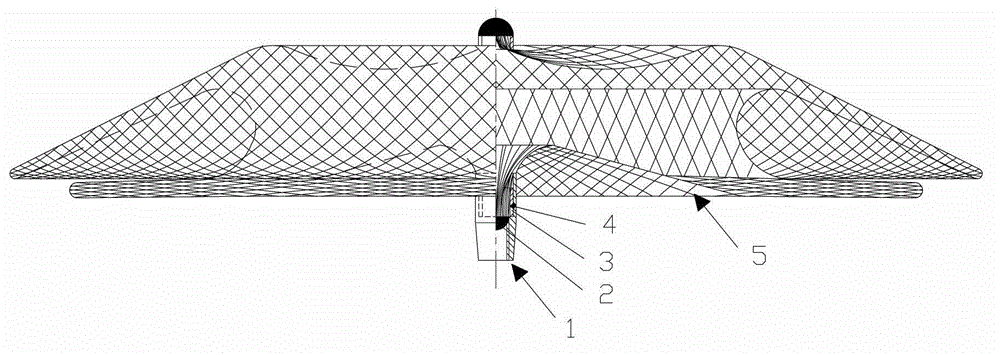

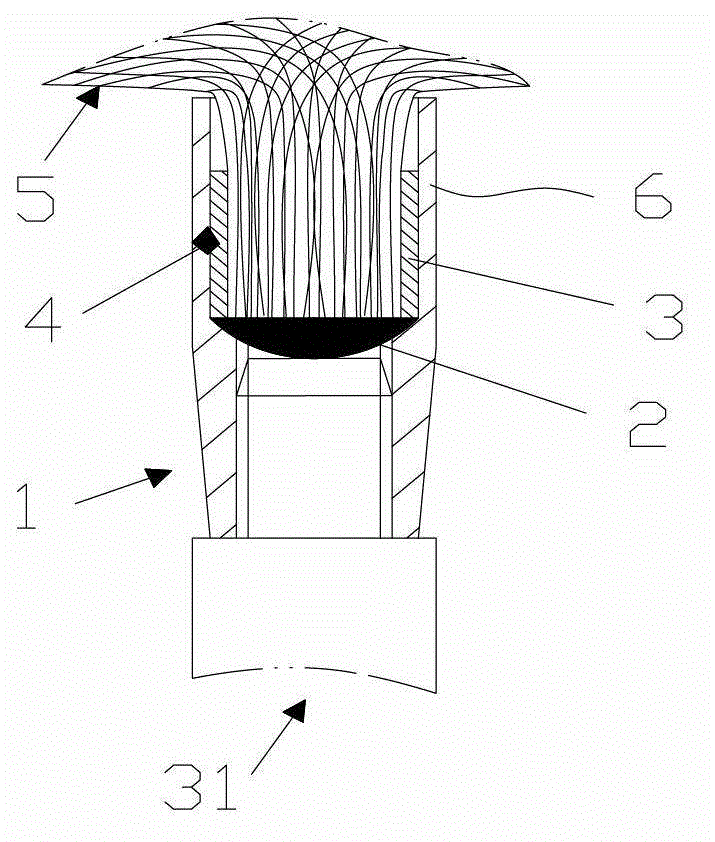

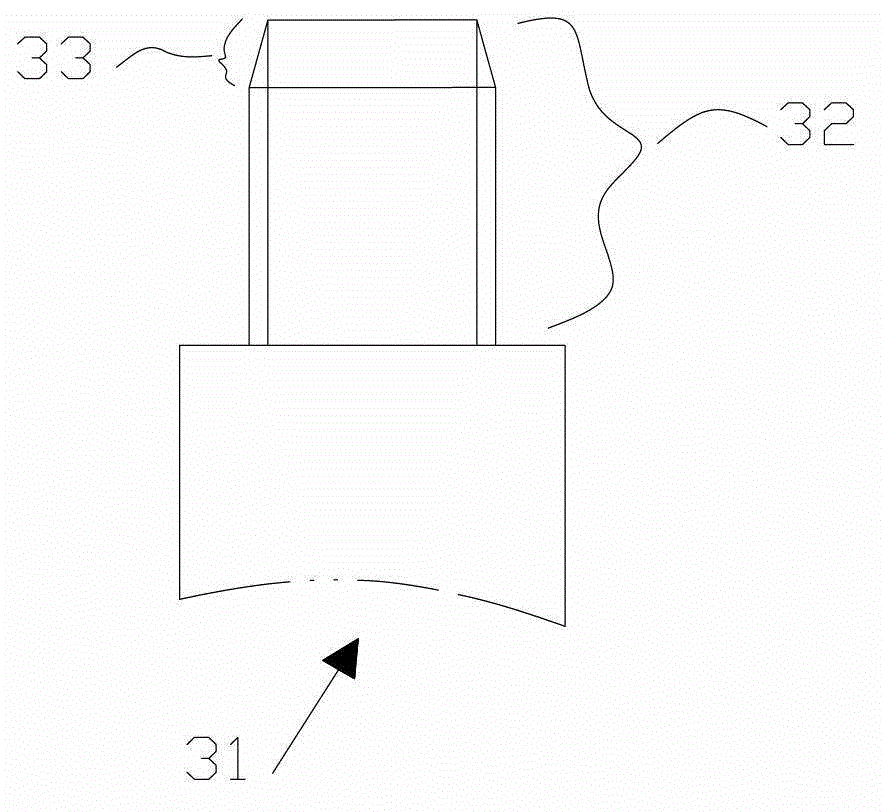

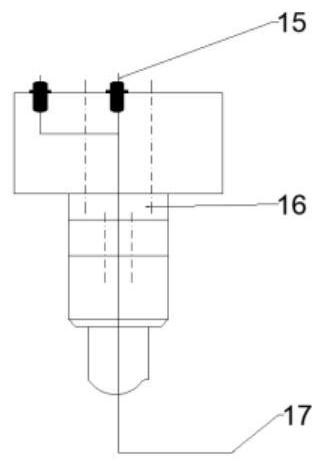

Medical instrument for interventional therapy

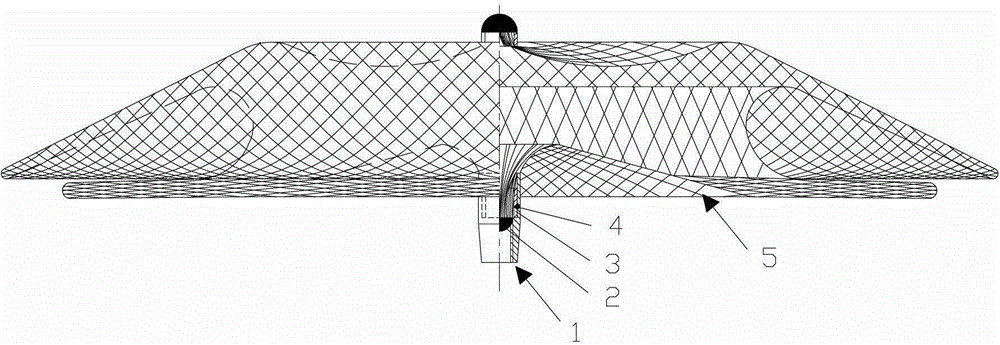

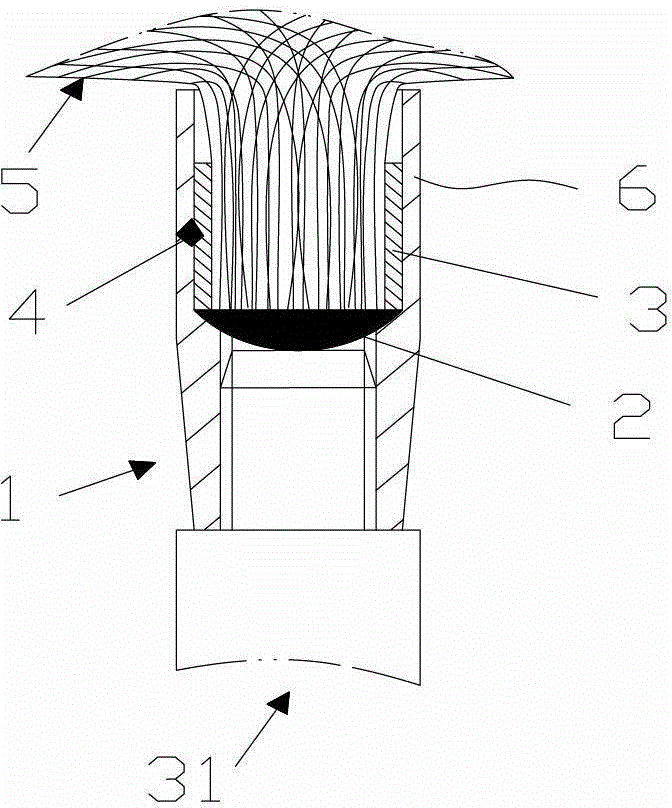

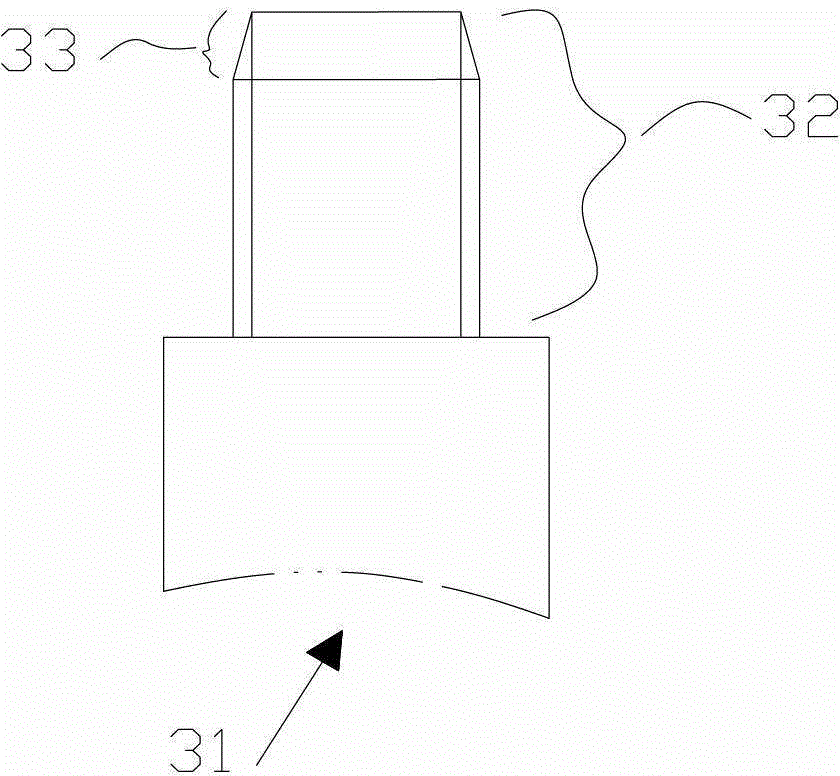

The invention relates to a medical instrument for interventional therapy. The medical instrument comprises at least one fabric body and a fixing and connecting device, wherein each fabric body is composed of a plurality of knitting yarns, and a part of the knitting yarns is provided with knitting yarn fixing ends; and the fixing and connecting device comprises an inner sleeve and an outer sleeve, the inner sleeve is fixed in the outer sleeve, the knitting yarn fixing ends are fixed between the inner sleeve and the outer sleeve, the inner sleeve is completely hollow and two ends of the inner sleeve are open. The medical instrument solves the problems that an existing fixing and connecting device for the fabric body planted into the medical instrument protrudes outwards or protrudes much and the like, so that the outer surface near the fixing and connecting device is flatter, and safe, convenient and controllable threaded connection manner is reserved.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

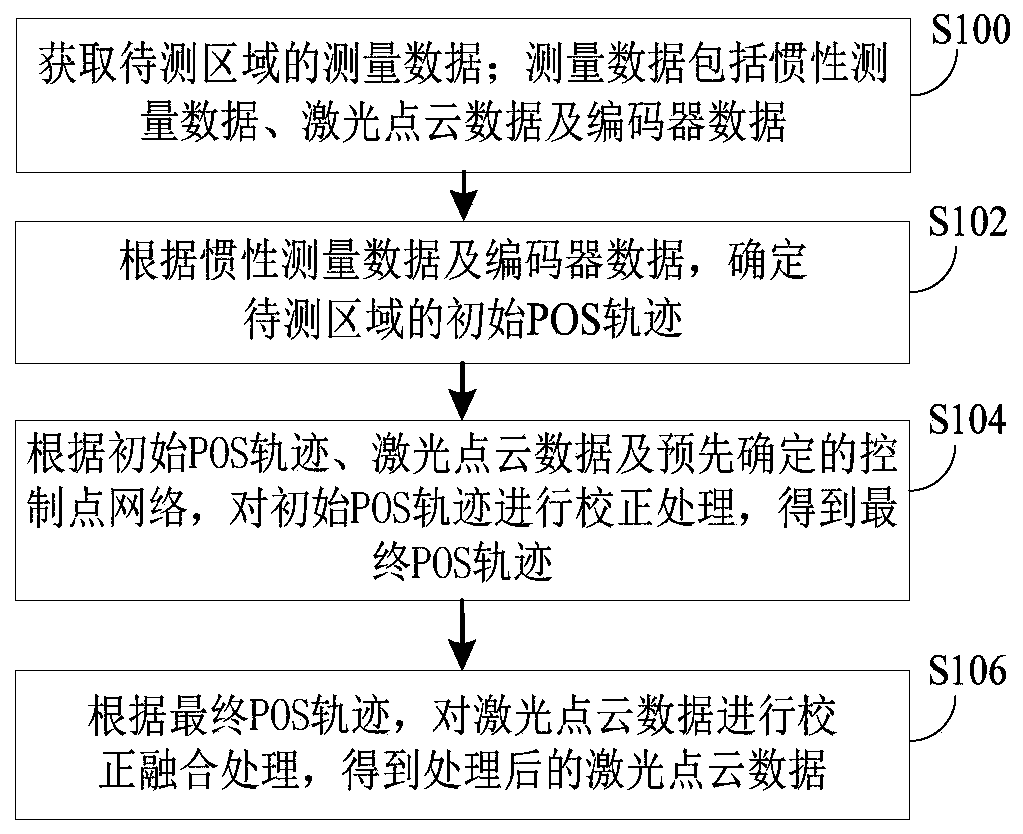

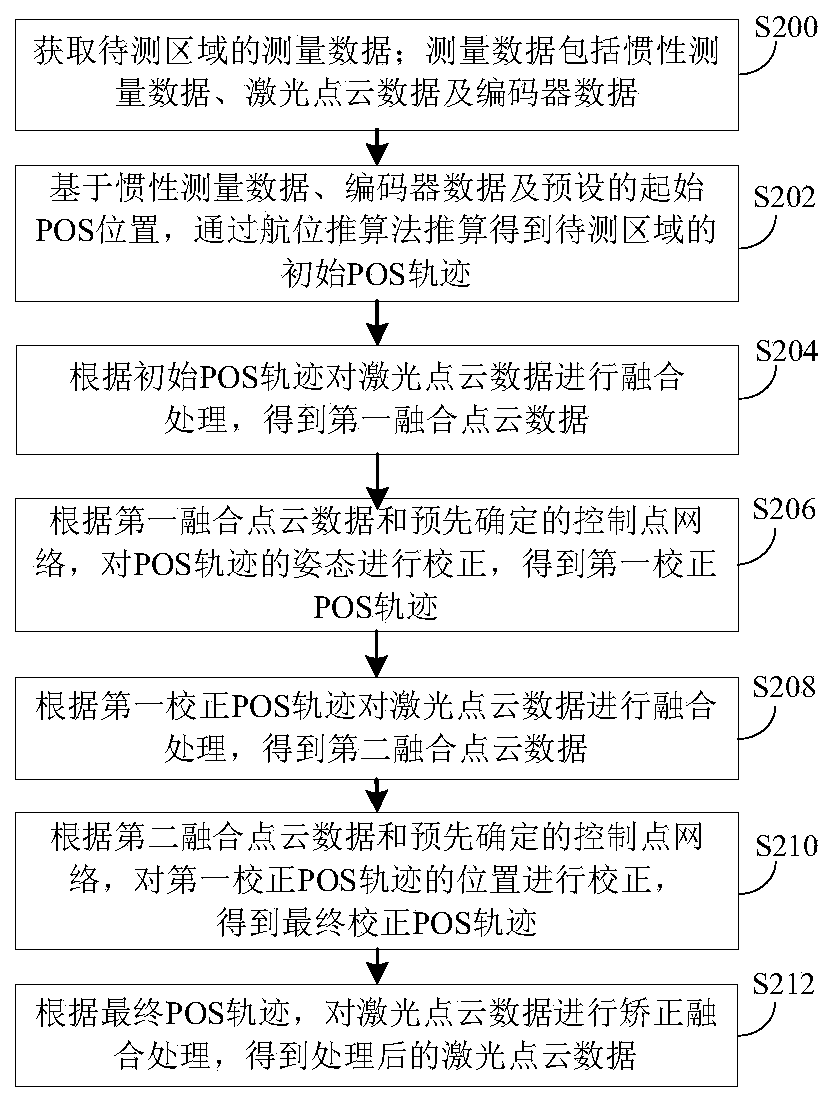

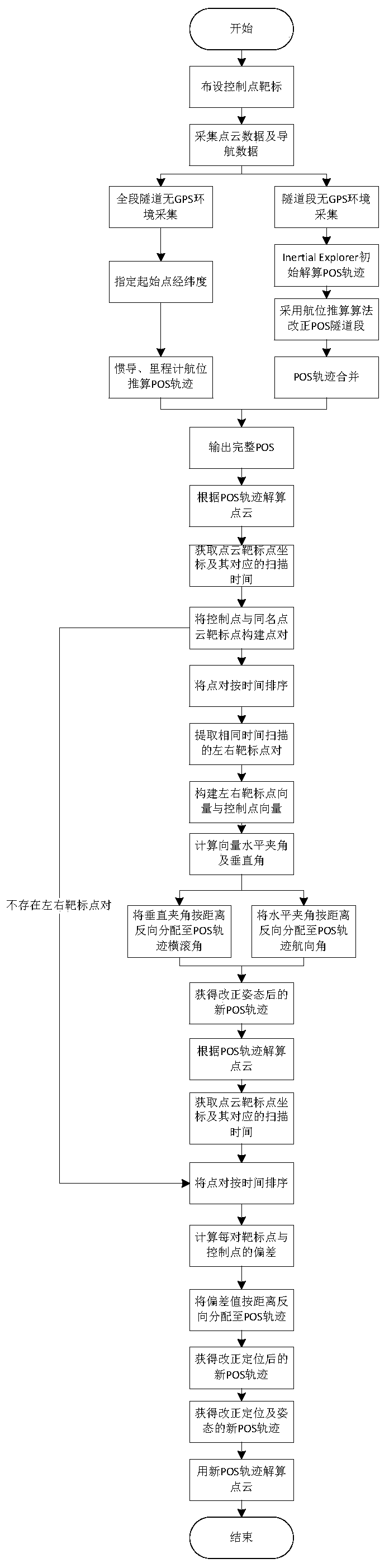

Laser point cloud data processing method, device and system

ActiveCN111007530AReduce process errorHigh measurement accuracyNavigation by speed/acceleration measurementsElectromagnetic wave reradiationPoint cloudEngineering

The invention provides a laser point cloud data processing method, device and system, and the method comprises the steps: determining an initial POS track of a to-be-measured region according to inertia measurement data and encoder data after the measurement data of the to-be-measured region is obtained; correcting the attitude and position of the initial POS track through the initial POS track, laser point cloud data and a predetermined control point network to obtain a final corrected POS track; and according to the final POS track, carrying out correction fusion on the laser point cloud data to obtain processed laser point cloud data. According to the invention, the POS track is corrected in a tunnel and other GNSS-free measurement environments, the laser point cloud data processing error is reduced, and the measurement precision of the to-be-measured region is improved.

Owner:WUHAN HANNING TECH +1

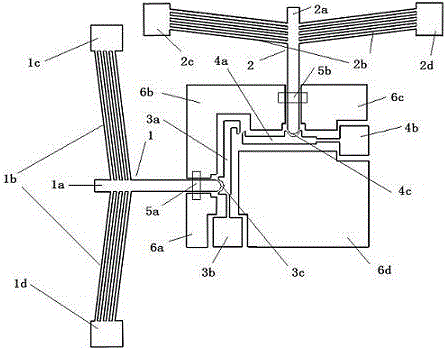

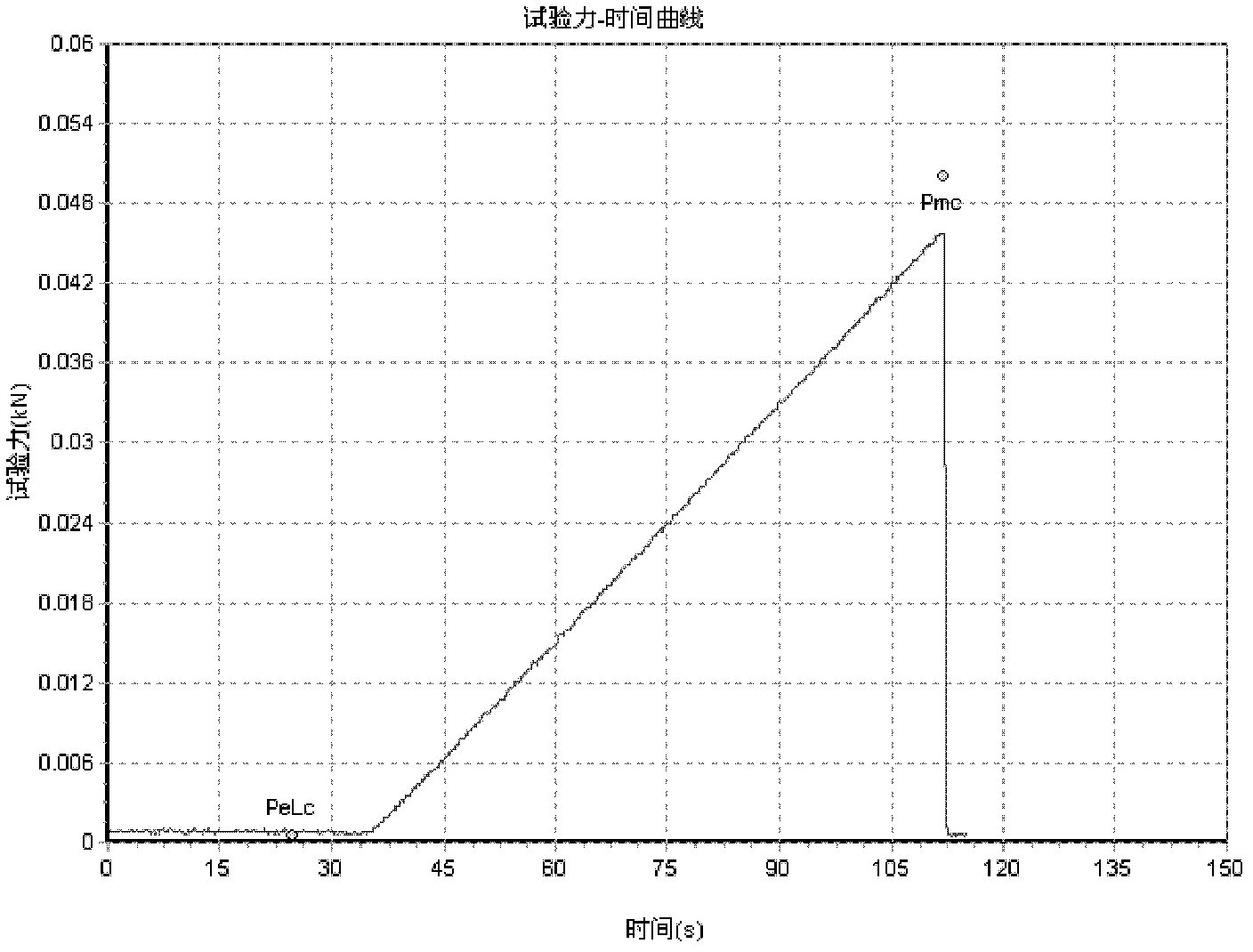

Thermally-driven RF MEMS switch

InactiveCN104993192AConformal propertiesSmall dielectric lossPiezoelectric/electrostrictive devicesWaveguide type devicesCantilevered beamShaped beam

The invention provides a thermally-driven RF MEMS switch which comprises a substrate. A buckling switch structure is arranged on the substrate. The buckling switch structure comprises cantilever beams (3a, 4a). The tail ends of the cantilever beams (3a, 4a) are provided with mutually cooperating locking hooks. The side surface of the cantilever beam (3a) is provided with a V-shaped beam buckling thermal driver (1) used for driving the cantilever beam (3a). The side surface of the cantilever beam (4a) is provided with a V-shaped beam unlocking thermal driver (2) used for driving the cantilever beam (4a). A horizontal thermally-driven switch is adopted in the invention. The technical errors of an LCP substrate are reduced. The switch reliability, consistency and performance stability when the substrate is bent are improved.

Owner:SOUTHEAST UNIV

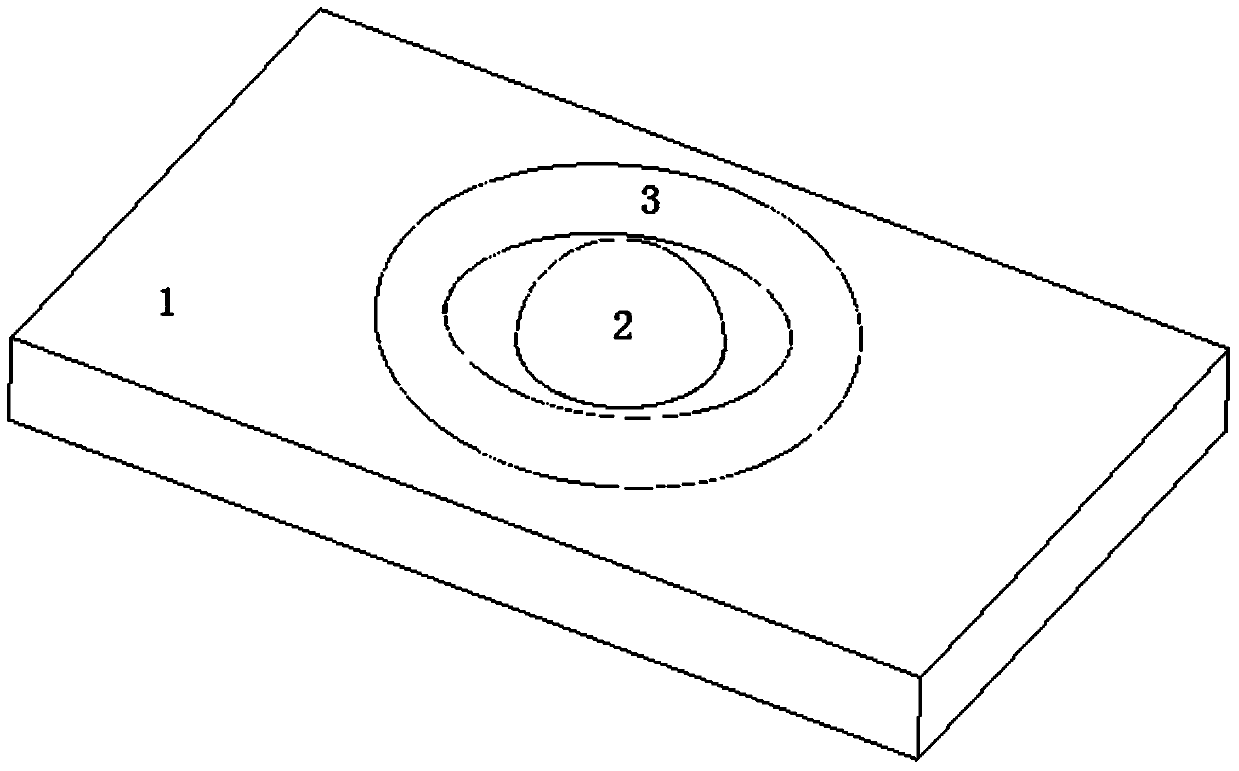

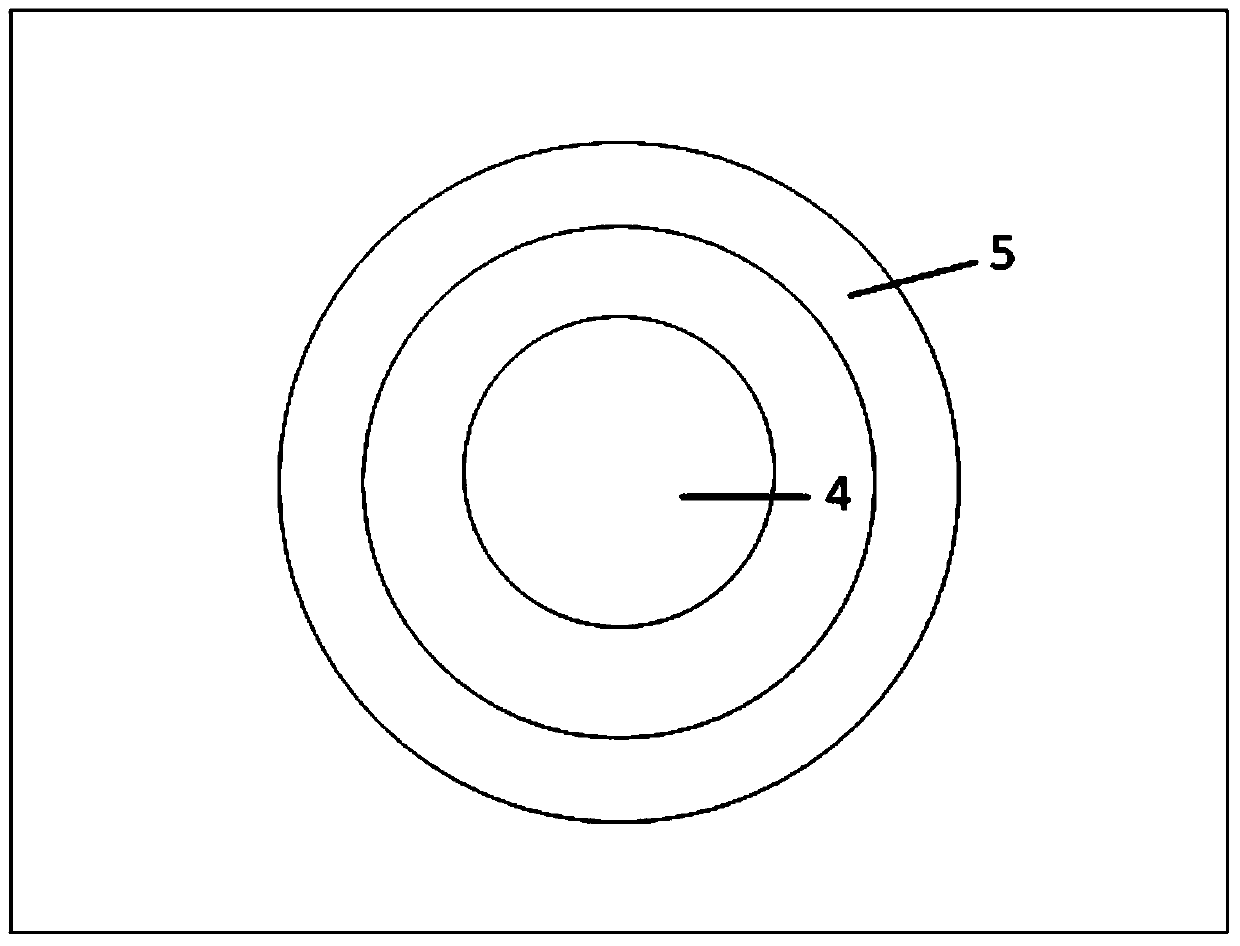

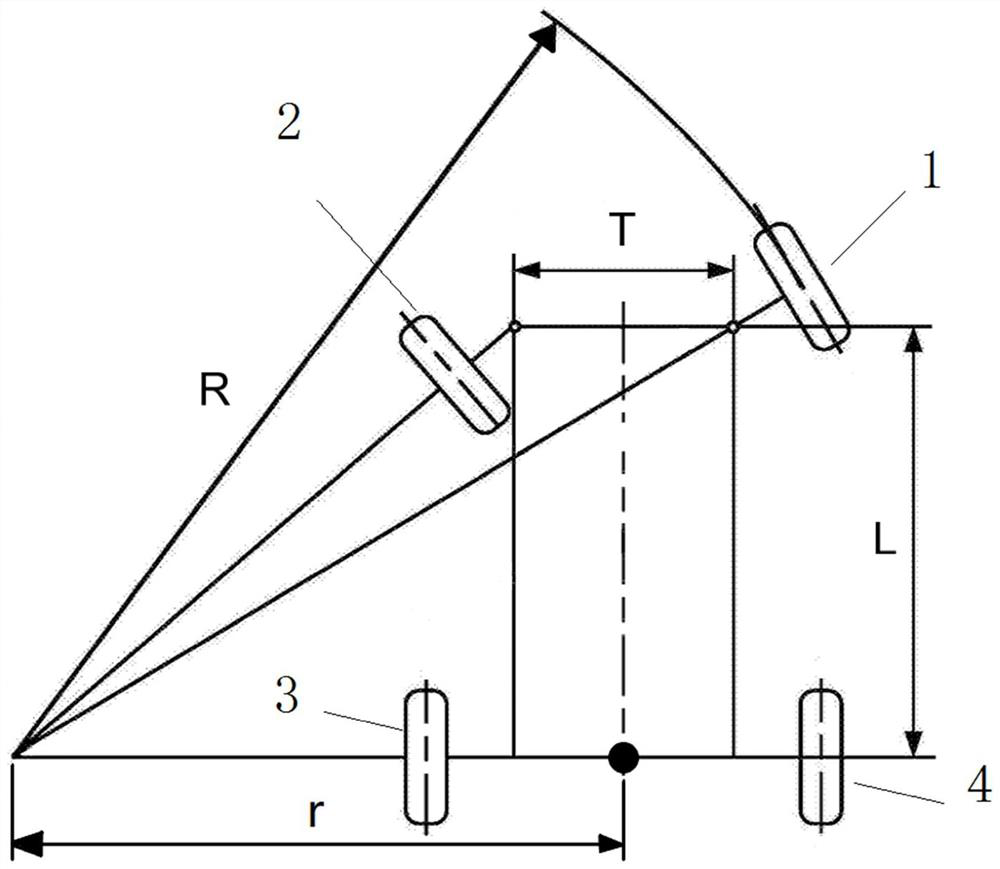

Annular glass surrounded glass-blown miniature hemispherical resonant gyroscope and manufacturing method thereof

ActiveCN104197911ASimple processLow costTurn-sensitive devicesHemispherical resonator gyroscopeMetal electrodes

The invention provides an annular glass surrounded glass-blown miniature hemispherical resonant gyroscope and a manufacturing method thereof. The gyroscope comprises a cuboidal silicon base, a hemispherical shell type central resonator, an annular glass shell and eight metal electrodes formed on annular glass, wherein the eight electrodes are uniformly distributed around the central resonator, consist of four drive electrodes and four detection electrodes and are connected to pins through leads; the drive electrodes and the detection electrodes can achieve electrostatic drive and detection through applying positive and negative voltage to corresponding pins; the hemispherical shell type central resonator and peripheral annular glass are manufactured by adopting a glass blowing process. The gyroscope adopts an MEMS (Micro-Electromechanical Systems) process for processing, is simple in structure, small in volume and relatively high in accuracy, and has great development prospects.

Owner:SHANGHAI JIAO TONG UNIV

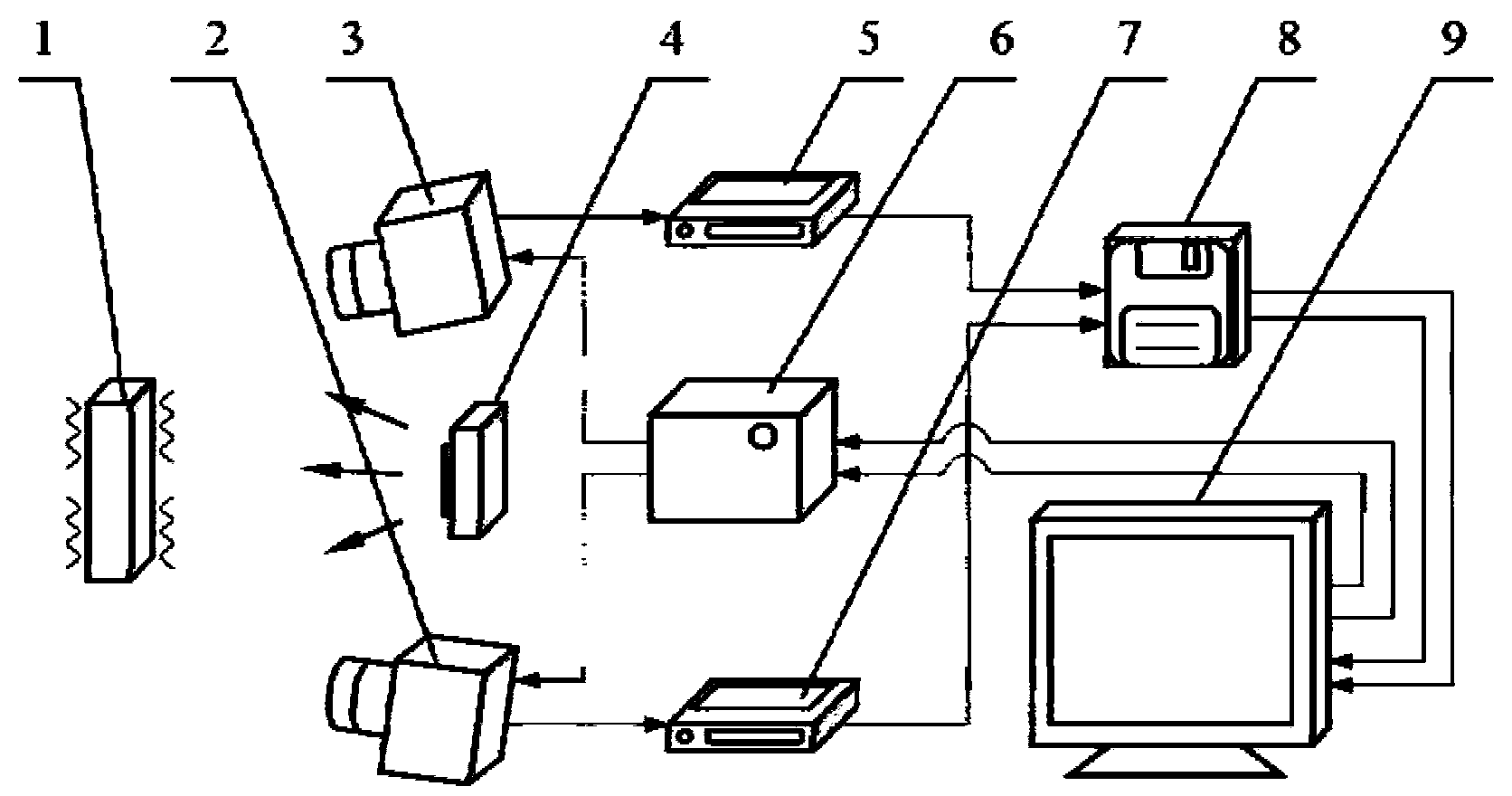

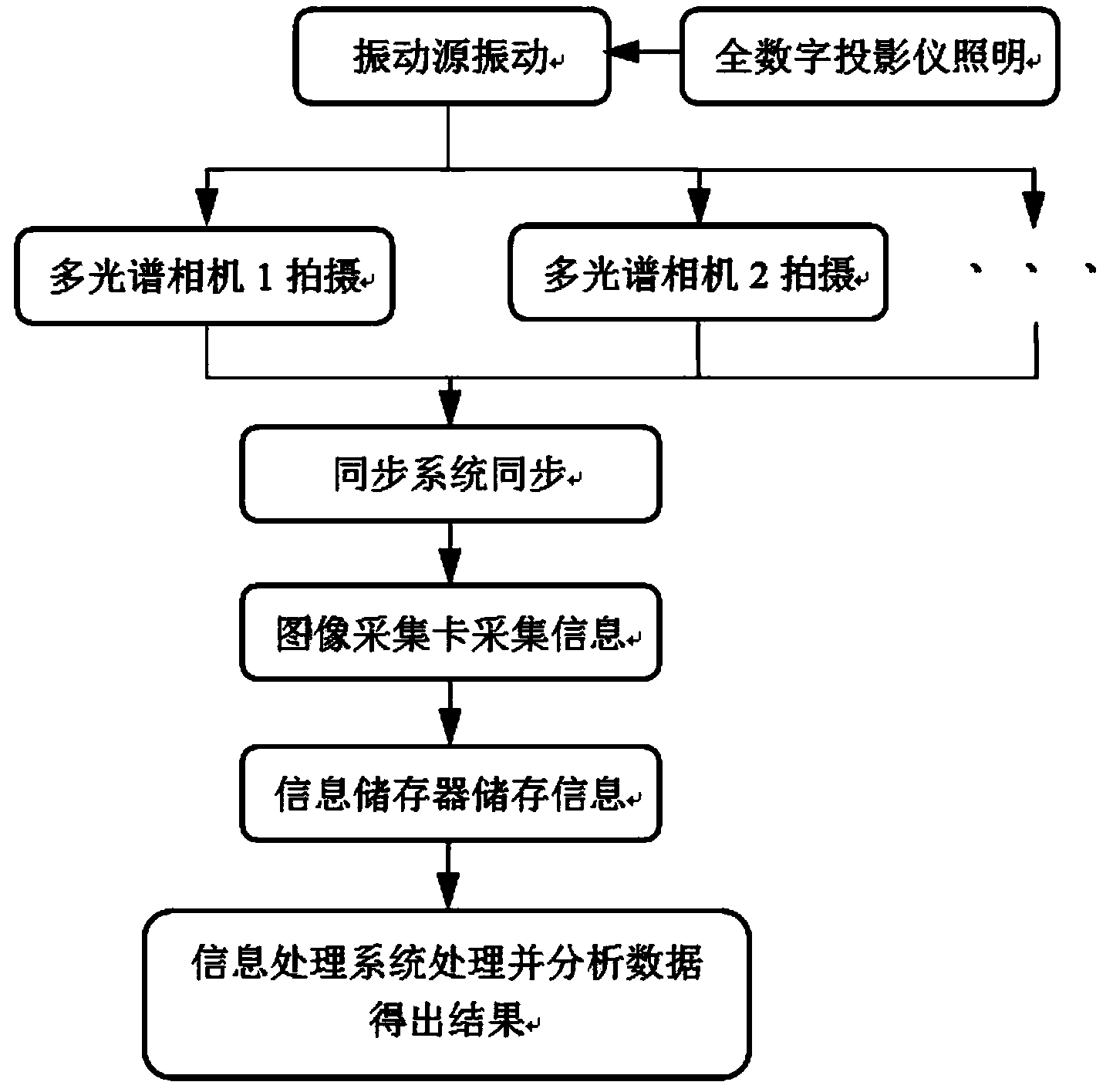

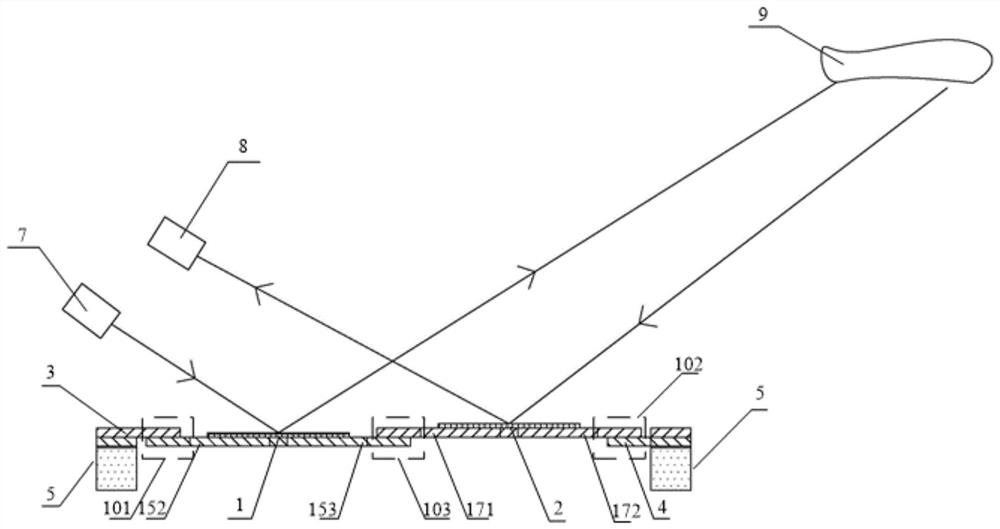

Dynamic system multi-physics field imaging detection system

InactiveCN104236695AImproving Simultaneous Sampling AccuracyReduce Image Processing ErrorsSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansAmbulatory systemImage capture

The invention discloses a dynamic system multi-physics field imaging detection system which comprises a digital projection illuminating device. The digital projection illuminating device is arranged right in front of a measured vibration object, multi-spectral cameras are symmetrically arranged on the two sides of the digital projection illuminating device, and the surface of the measured vibration object radiates under the irradiation of the digital projection illuminating device. A synchronous sampling device controls the multi-spectral cameras to capture a radiance image of the measured vibration object at the same time, an image capture card is connected with the multi-spectral cameras to be used for collecting data and outputting the image data to an information storing device and an information processing system, the synchronous sampling device is connected to the information processing system, and the information processing system is a PC. According to the dynamic system multi-physics field imaging detection system, a digital projector is used for lighting, the synchronous sampling system is additionally arranged, so that measuring errors are reduced, and the measuring accuracy is improved; the wavelength measuring range is wide, a plurality of wavebands can be measured, the multiple physical quantities such as the vibration source temperature and the materials can be detected, and therefore the measuring reliability and the measuring precision are improved.

Owner:HEFEI UNIV OF TECH

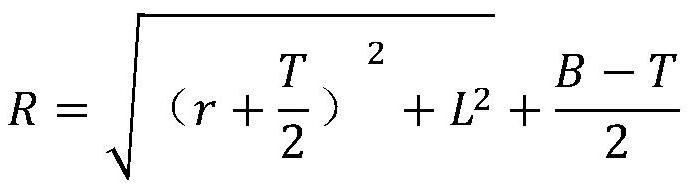

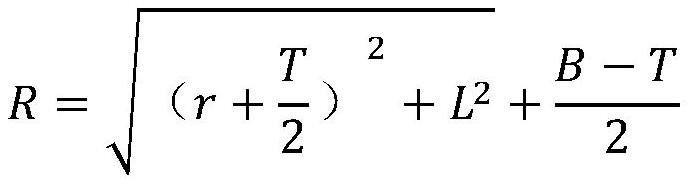

Automobile minimum turning radius measuring system and measuring method

PendingCN112284773AEasy to operateHigh measurement accuracyVehicle steering/rolling behaviourSatellite radio beaconingAutomotive engineeringReal time data transmission

The invention discloses an automobile minimum turning radius measuring system which comprises a GPS signal receiving module, a real-time data transmission module, a GPS real-time data processing module and a reference station. The real-time data transmission module and the GPS real-time data processing module are installed on a tested vehicle, the GPS signal receiving module is installed in the middle of a connecting line of two rear wheels of the tested vehicle, and the reference station is arranged at a position outside the tested vehicle; data transmission is carried out among the GPS signal receiving module, the real-time data transmission module and the GPS real-time data processing module through cables, and data transmission is carried out between the GPS signal receiving module andthe reference station in a wireless mode. The invention further provides a measuring method based on the automobile minimum turning radius measuring system. The method can measure the minimum turningradius of the automobile more conveniently and accurately.

Owner:的卢技术有限公司

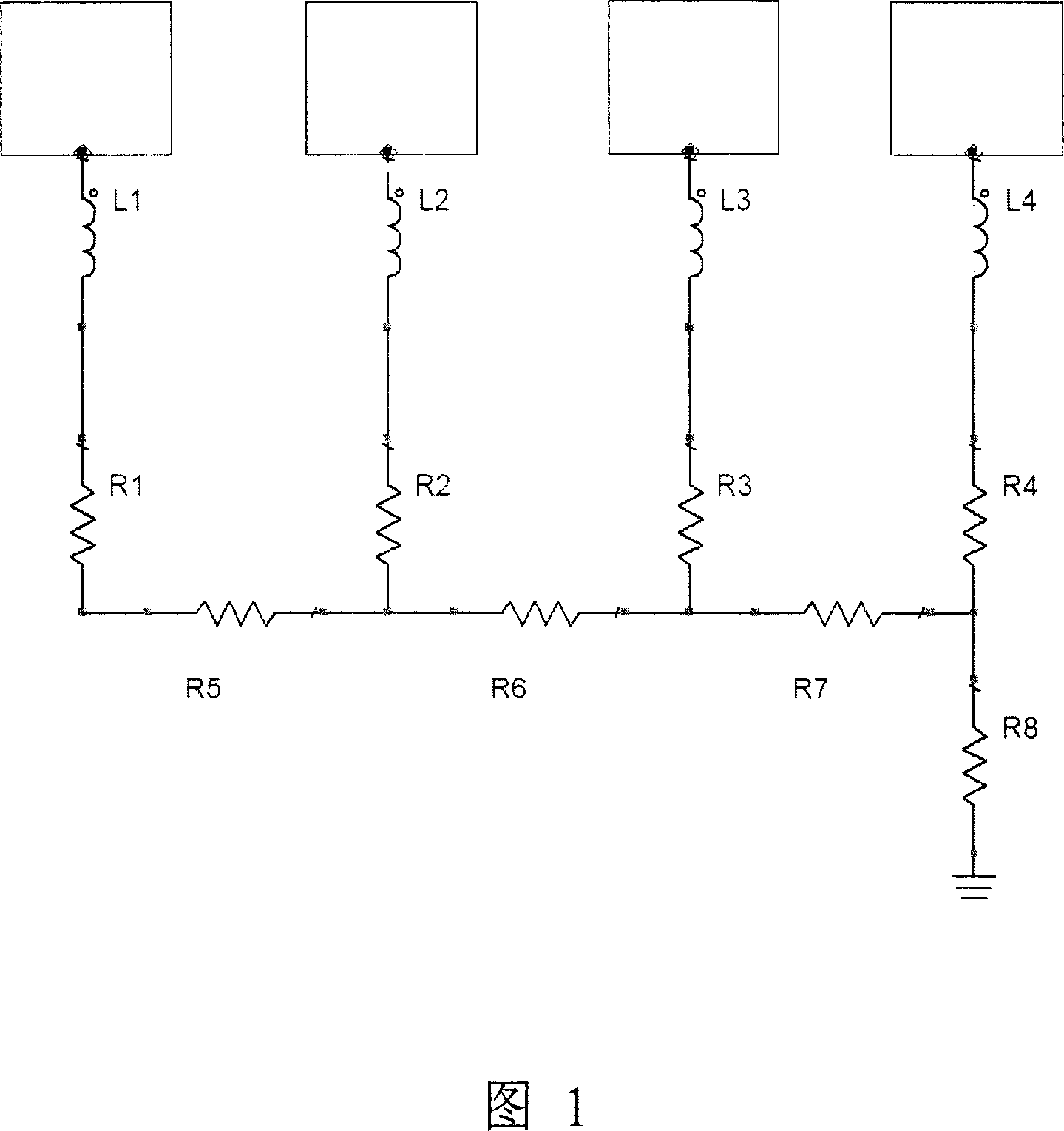

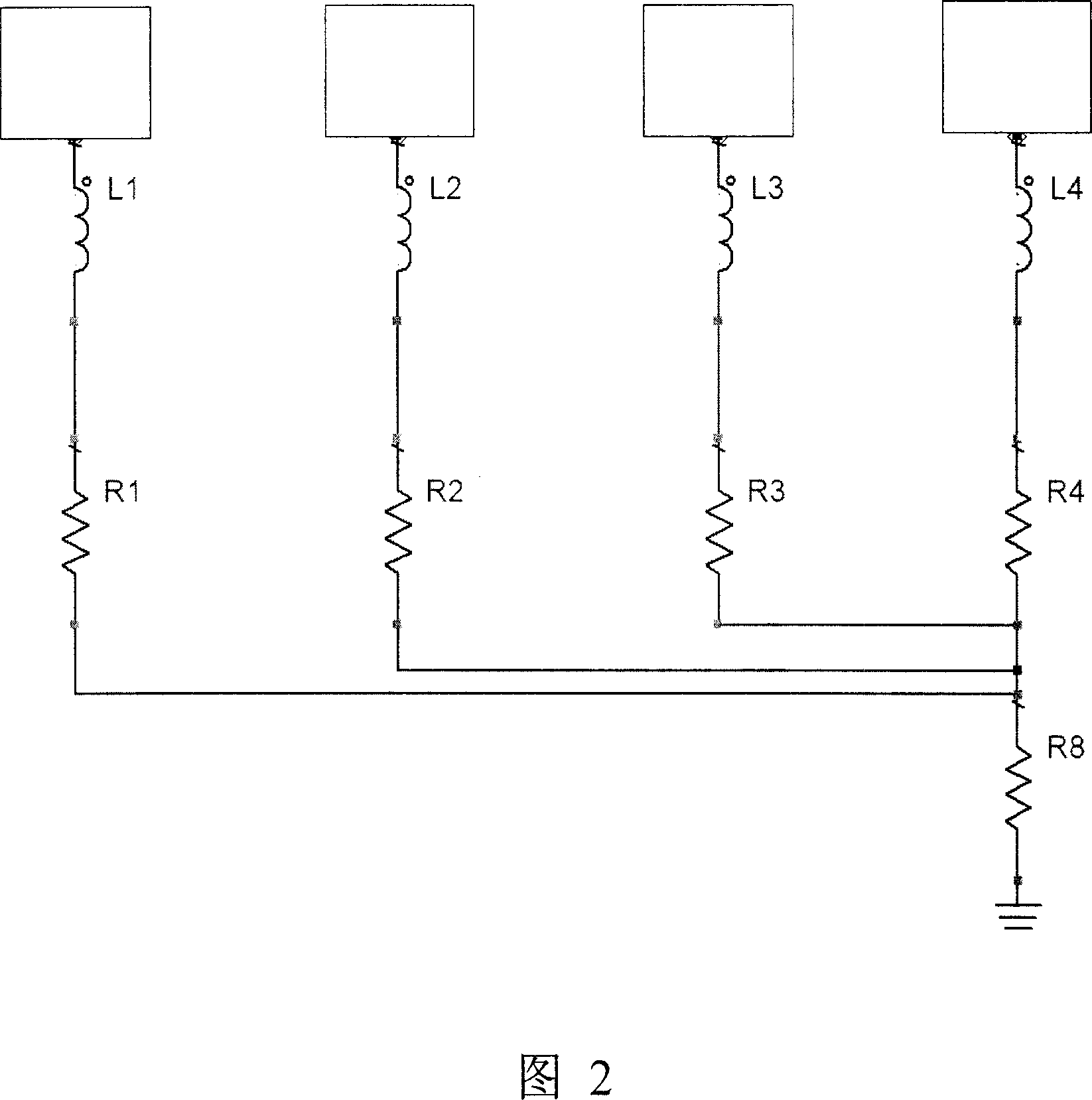

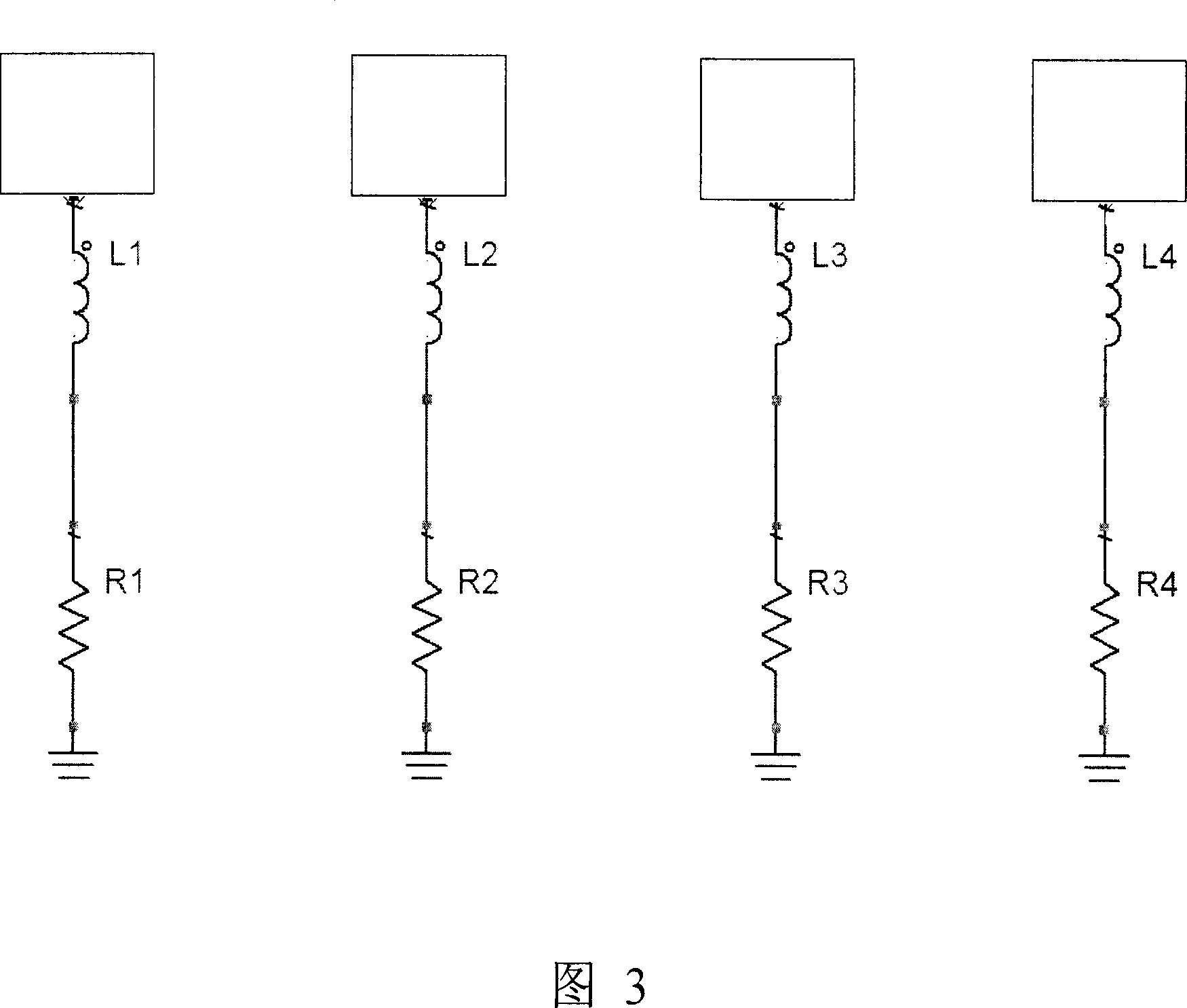

Ground wire layout graph for reducing microwave single-sheet integrated circuit standing wave ratio

InactiveCN101145547AReduce process errorEasy to install and adjustSemiconductor/solid-state device detailsSolid-state devicesStanding waveCapacitance

The invention discloses a ground wiring pattern for reducing the standing-wave ratio of a microwave monolithic integrated circuit (MMIC), which is characterized in that the ground wiring pattern at least comprises a pattern unit, wherein the pattern unit is composed of a signal microstrip line which is printed on a printed circuit board and a domain plane and which has a Z-shaped projecting pattern, and earth wire grounded through holes distributed along the signal microstrip line. The invention can reduce the increase in standing-wave ratio caused by the inductance of metal jumper wire and the processing error of capacitance blocking capacitor, and facilitate the installation of the elements required for the regulation of standing-wave ratio, without inducing large parasitic inductance. Therefore, the invention can reduce the mismatched sensitivity of input / output terminals to the change of imaginary impedance, improve the standing-wave ratio, and increase the success rate of MMIC test.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

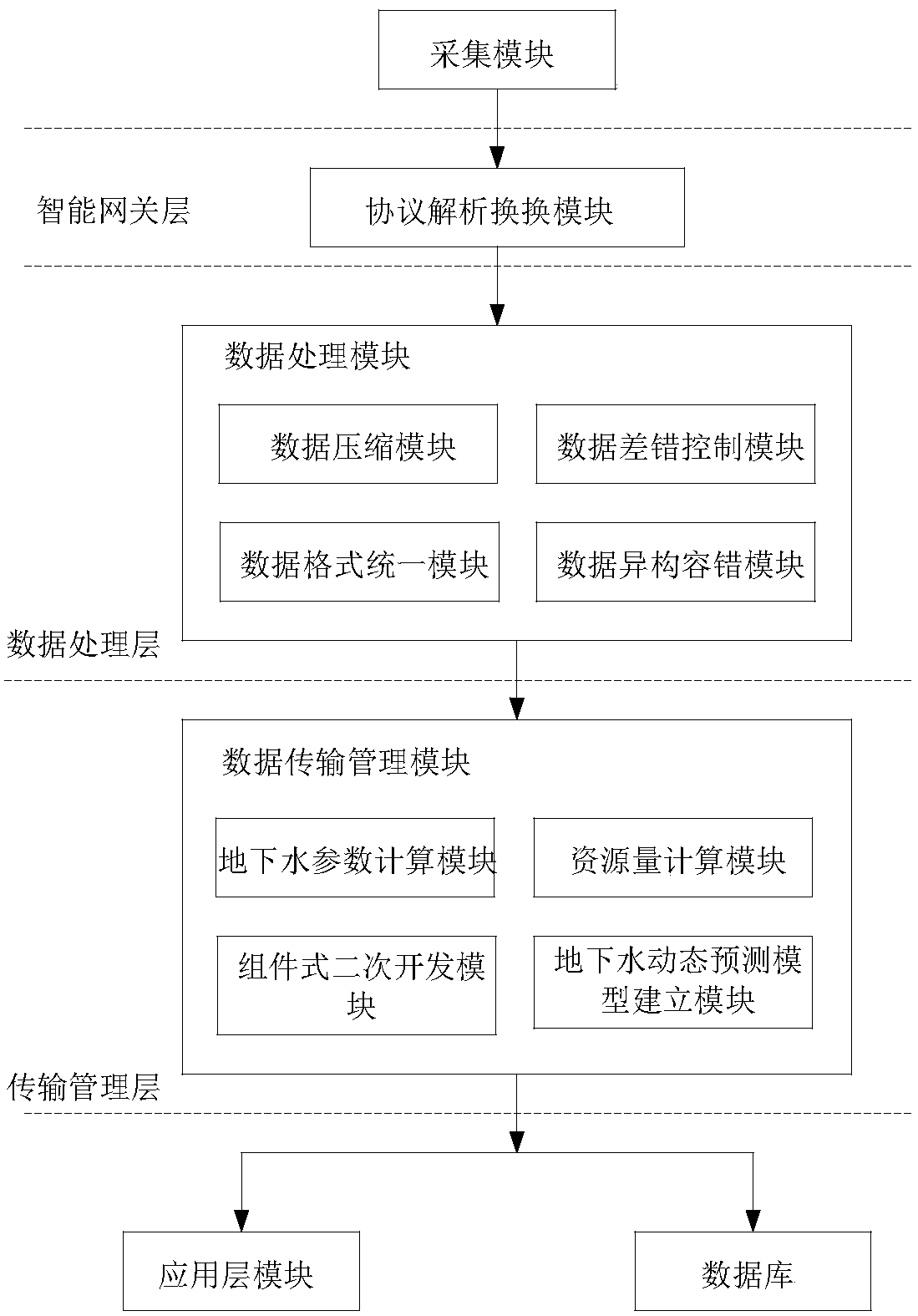

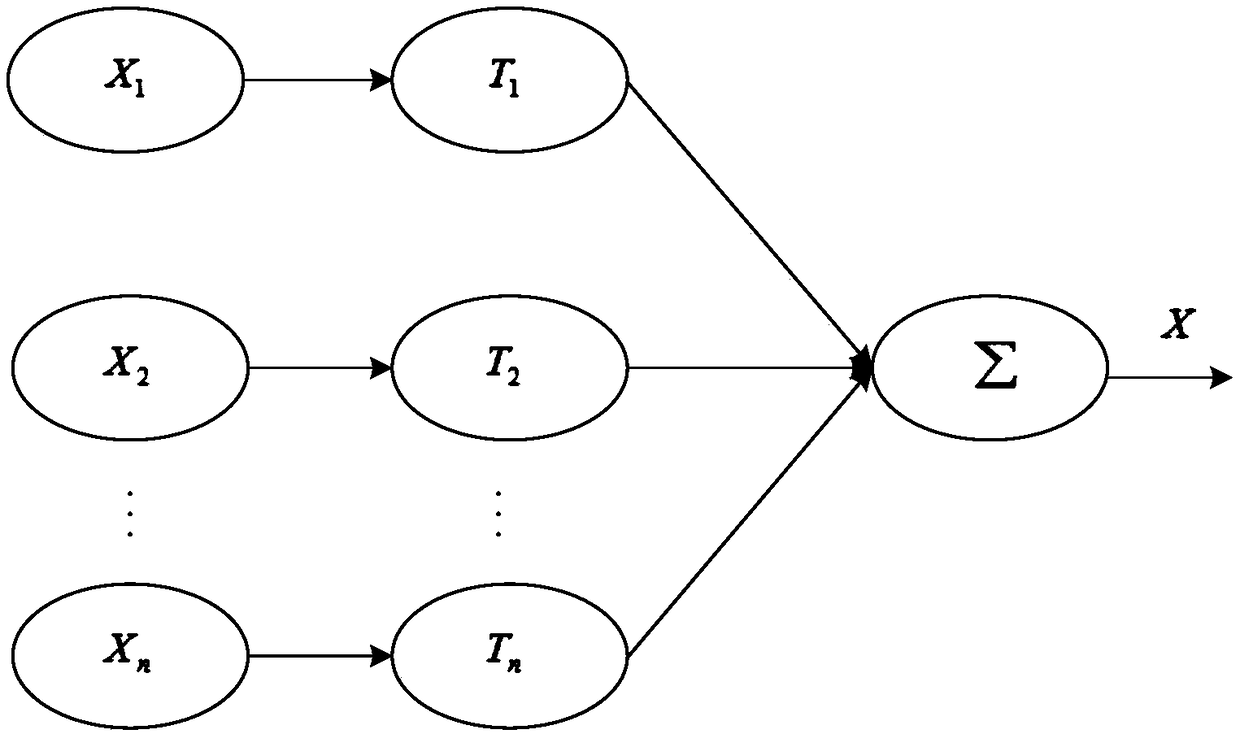

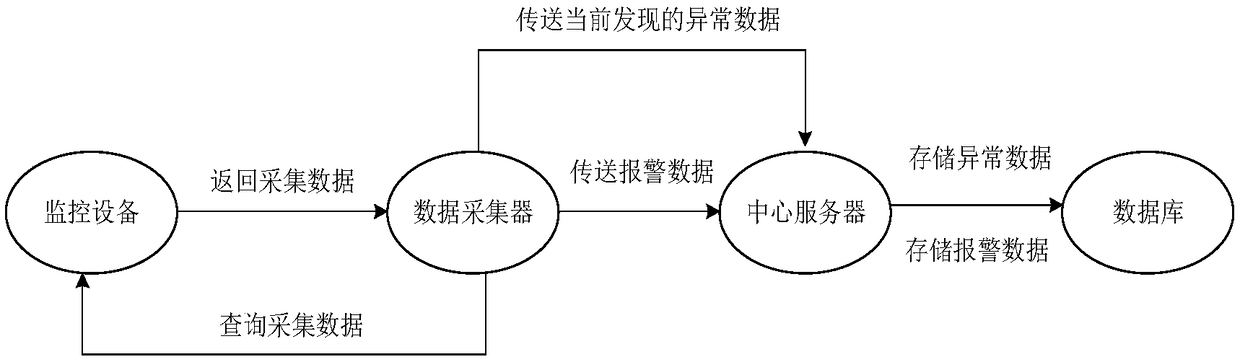

Water environment data transmission system and method based on Internet of Things

InactiveCN109413003AImprove accuracyAvoid errorsMeasurement devicesData switching networksReal-time dataMonitoring system

The invention provides a water environment data transmission system and method based on Internet of Things, belonging to the technical field of Internet of Things. The water environment data transmission system comprises a collection module, a protocol analysis and conversion module, a data processing module, a data transmission management module, a database and an application layer module. The method comprises a collecting step, a protocol analyzing and converting step, a data processing step, a data transmission management step, and a database and application layer step. The water environment data transmission system and method can be applied to various water environment monitoring systems, and have the advantages of real-time data monitoring, high accuracy and the like.

Owner:THE INST OF AUTOMATION HEILONGJIANG ACADEMY OF SCI +1

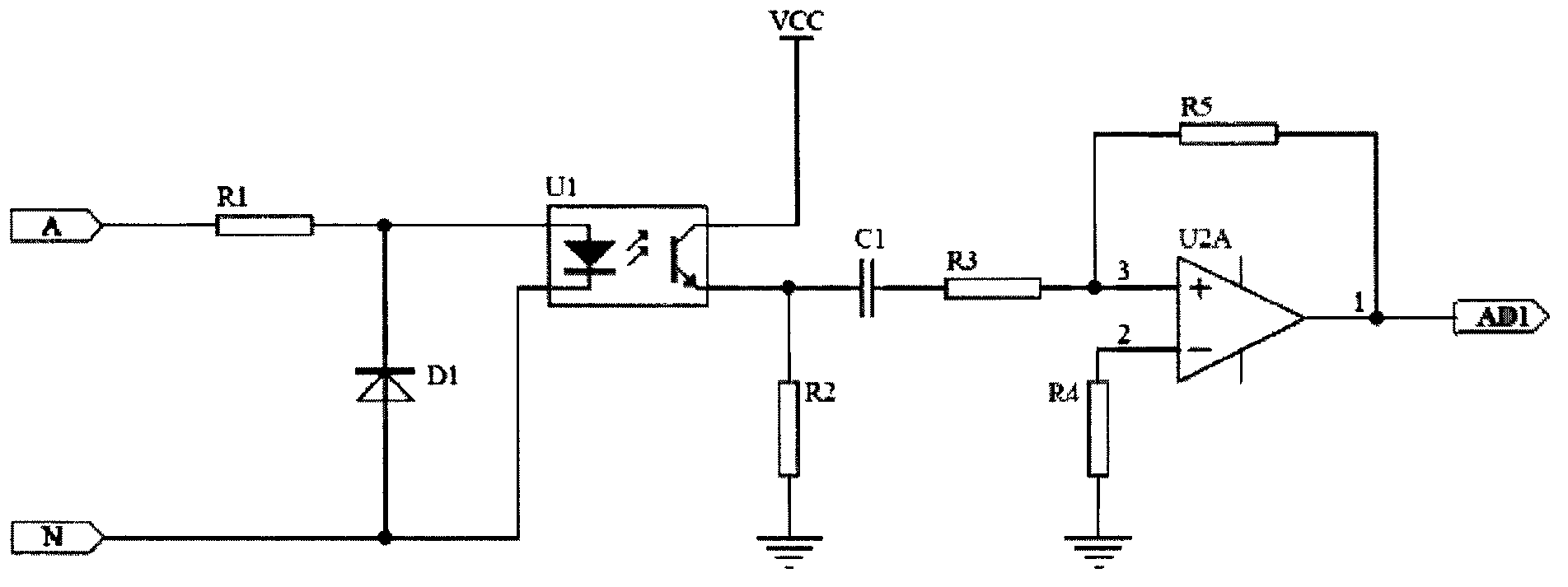

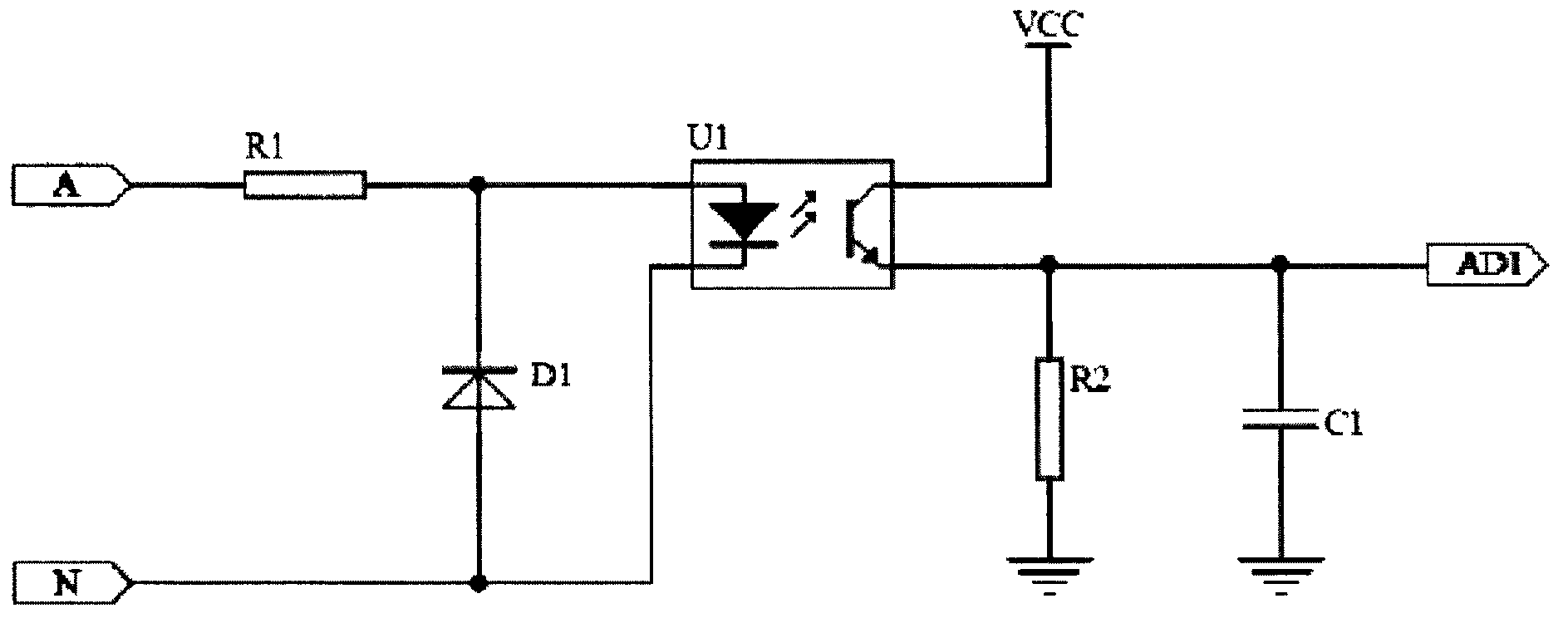

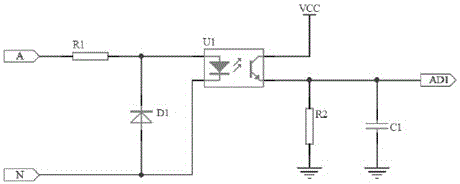

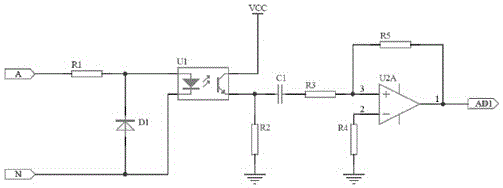

Voltage signal conditioning circuit of automatic reclosing lock breaker in time of electric leakage

InactiveCN103364613AMeet the requirements of precise measurementAchieve universalCurrent/voltage measurementEngineeringFeedback circuits

The invention relates to a voltage signal conditioning circuit of an automatic reclosing lock breaker in the time of electric leakage. A phase line of power supply phase voltage or line voltage goes through the anode of a diode D1 and the cathode of the phase line is connected with one end of a resistor R1. The voltage signal conditioning circuit further comprises a phase voltage and line voltage selecting circuit, a voltage feedback circuit, a diode D2, a direct-current power supply VCC, an analog-digital converter AD1, a resistor R4 and a filter capacitor C1. A null line of the phase voltage and line voltage selecting circuit or the other phase line of the line voltage is connected with the input end of the phase voltage and line voltage selecting circuit. One end of the voltage feedback circuit is connected with the R1 and the other end of the voltage feedback circuit is connected with the phase voltage and line voltage selecting circuit. The diode D2 is connected with the voltage feedback circuit. The direct-current power supply VCC is connected with a photoelectric coupler U1a. The analog-digital converter AD1 is connected with a photoelectric coupler U1b. One end of the resistor R4 is connected with five pins of the photoelectric coupler U1b and the other end of the resistor R4 is connected to the ground. One end of the filter capacitor C1 is connected with the analog-digital converter AD1 and the other end of the filter capacitor C1 is connected to the ground. The voltage signal conditioning circuit of the automatic reclosing lock breaker in the time of electric leakage can solve the problem of temperature excursion, improve linearity and achieve common use of a three-phase three-wire system and a three-phase four-wire system.

Owner:CNC ELECTRIC GRP

Method for automatically determining layout area of safety sign at construction site

InactiveCN107180310AArrange the area reasonablyImprove scienceCharacter and pattern recognitionEye diagnosticsVisit timeFixation time

The invention discloses a method for automatically determining a layout area of a safety sign at a construction site. In the method, the eye movement indicators such as the visit time, fixation times, pupil diameter, regression times and the like of operating staff to each area at a construction site are captured in real time by an eye tracker, main concerns of the operating staff are automatically found out, and the layout area of the safety sign is determined. According to the invention, the rationality of the layout area of the safety sign at the construction site can be improved, the precaution ability of the operating staff is thus improved, and the occurrence of accidents is reduced or avoided.

Owner:CHINA THREE GORGES UNIV

Preparation method of poly(p-phenylene benzobisoxazole) fibers

ActiveCN112760737AReduce accumulationReduce decreaseMonocomponent synthetic polymer artificial filamentFiberSpinning

The invention belongs to the field of high-performance fibers, and particularly relates to a preparation method of poly(p-phenylene benzobisoxazole) fibers. The preparation method comprises the following steps of taking frozen polyphosphoric acid powder, phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid as raw materials, putting the phosphorus pentoxide into a reaction system step by step in a reasonable proportion in a proper time period, and detecting and regulating the apparent viscosity of the materials in real time in a prepolymerization process to ensure that a prepolymer with uniform apparent viscosity is obtained; performing post-polymerization to obtain PBO spinning slurry; and performing dry-jet wet spinning and post-spinning to obtain the finished PBO fibers. The method overcomes the defects that traditional solid raw materials are poor in solvent mixing and dispersing effect, easy to agglomerate and incapable of uniformly reacting, ensures the consistency of a prepolymerization reaction end point, and reduces the process errors. The intrinsic viscosity of the polymer in the same batch in different time periods is small in change and high, the mechanical property of the fibers can be obviously improved, and the quality stability is also improved.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

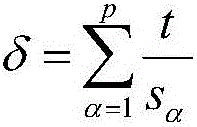

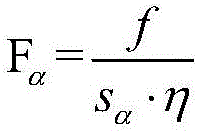

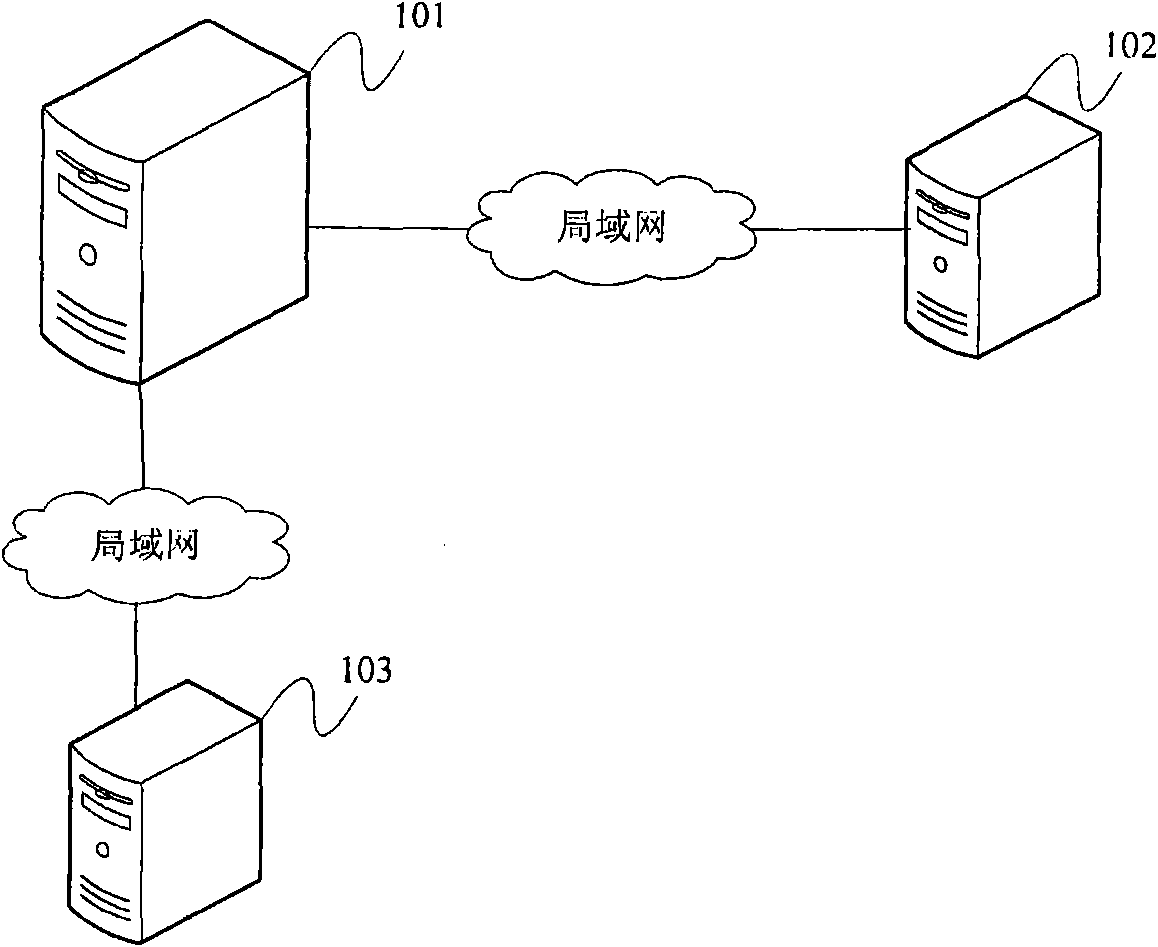

Data processing method for realizing bond discount and premium distribution, server and system

The invention provides a data processing method for realizing bond discount and premium distribution, a server and a system. The data processing method comprises the following steps of: firstly, acquiring data processing request information including bond information from a trade processing server; secondly, generating an actual day rate approximate value of the bond according to the bond information, and making the bond discount and premium distribution be zero at the expiration date of the bond; thirdly, detecting whether the actual day rate approximate value is less than the precise threshold value; fourthly, generating the actual day rate when the discount and premium distribution is zero according to the actual day rate approximate value less than the precise threshold value finally, sending the data processing information including the actual day rate to an account checking server. By processing the data of the bond discount and premium, the embodiment of the invention reduces the data processing error and improves the data processing speed.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Medical instrument for interventional therapy

The invention relates to a medical instrument for interventional therapy. The medical instrument comprises at least one fabric body and a fixing and connecting device, wherein each fabric body is composed of a plurality of knitting yarns, and a part of the knitting yarns is provided with knitting yarn fixing ends; and the fixing and connecting device comprises an inner sleeve and an outer sleeve, the inner sleeve is fixed in the outer sleeve, the knitting yarn fixing ends are fixed between the inner sleeve and the outer sleeve, the inner sleeve is completely hollow and two ends of the inner sleeve are open. The medical instrument solves the problems that an existing fixing and connecting device for the fabric body planted into the medical instrument protrudes outwards or protrudes much and the like, so that the outer surface near the fixing and connecting device is flatter, and safe, convenient and controllable threaded connection manner is reserved.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

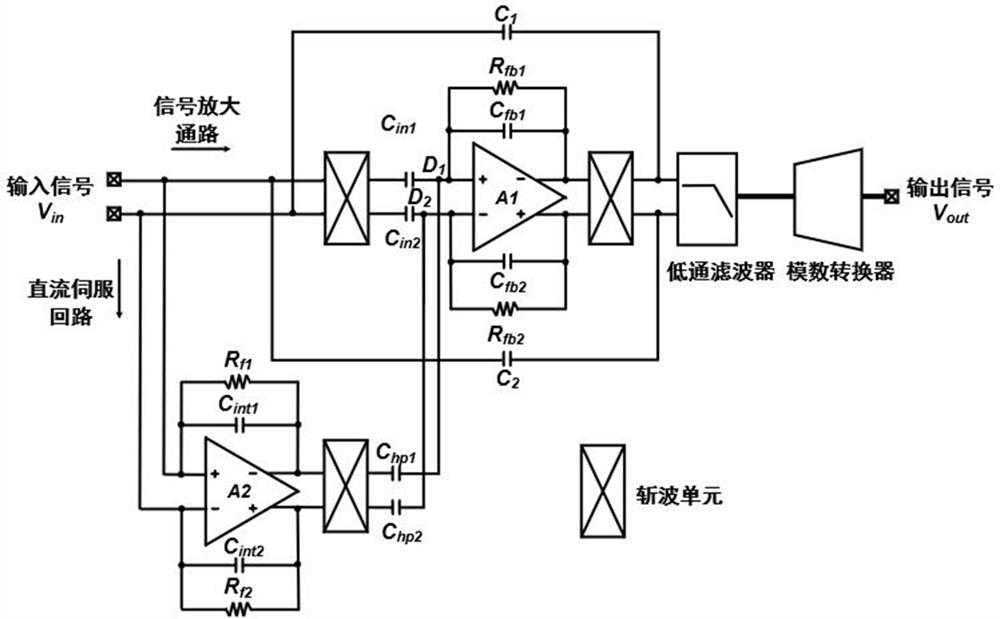

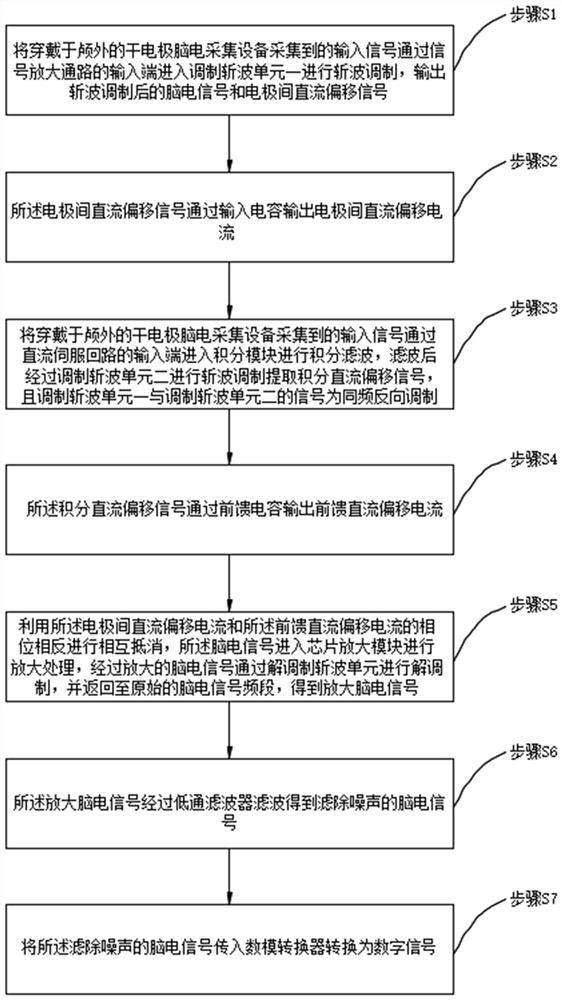

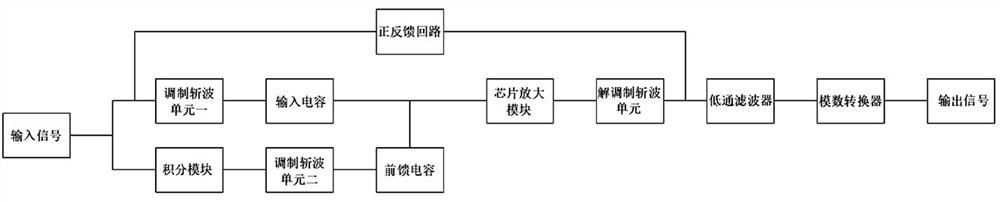

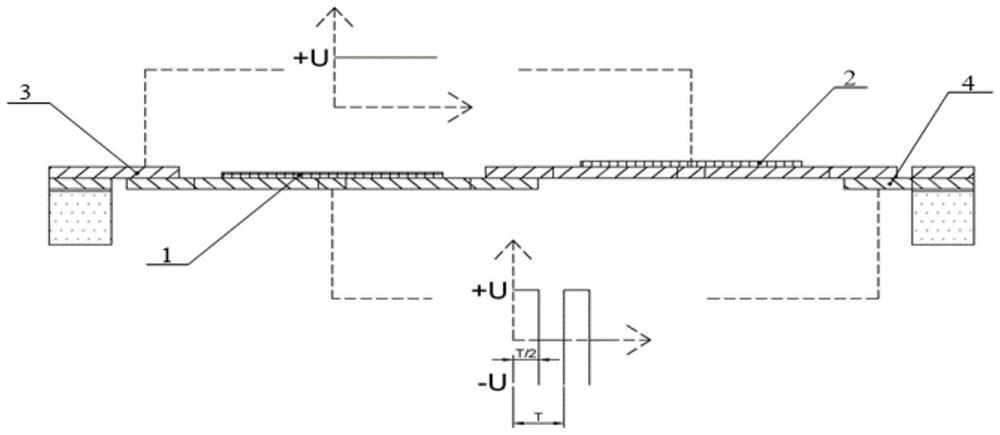

Method and system for eliminating direct current offset between electrodes based on chopping technology

ActiveCN114533087AEliminate DC OffsetDC Offset AccurateDiagnostic recording/measuringSensorsCapacitanceLow-pass filter

The invention discloses a method and a system for eliminating direct current offset between electrodes based on a chopping technology. The method comprises the following steps: step S1, outputting an electroencephalogram signal after chopping modulation and a direct current offset signal between the electrodes; s2, outputting direct current offset current between the electrodes; s3, extracting an integral direct current offset signal; s5, the electroencephalogram signals enter a chip amplification module to be amplified and demodulated, the electroencephalogram signals are returned to an original electroencephalogram signal frequency band, and original electroencephalogram signals are obtained; s6, filtering the original electroencephalogram signals through a low-pass filter to obtain noise-filtered electroencephalogram signals; and S7, transmitting the noise-filtered electroencephalogram signal into a digital-to-analog converter, and converting the noise-filtered electroencephalogram signal into a digital signal. The direct-current servo circuit effectively suppresses direct-current offset between the electrodes, compared with a traditional direct-current servo circuit, the process delay is reduced, meanwhile, the capacitance value of the input capacitor in the circuit is the same as that of the feed-forward capacitor, an ABBA type layout arrangement mode can be adopted, and process errors in the chip manufacturing process are effectively avoided.

Owner:ZHEJIANG LAB

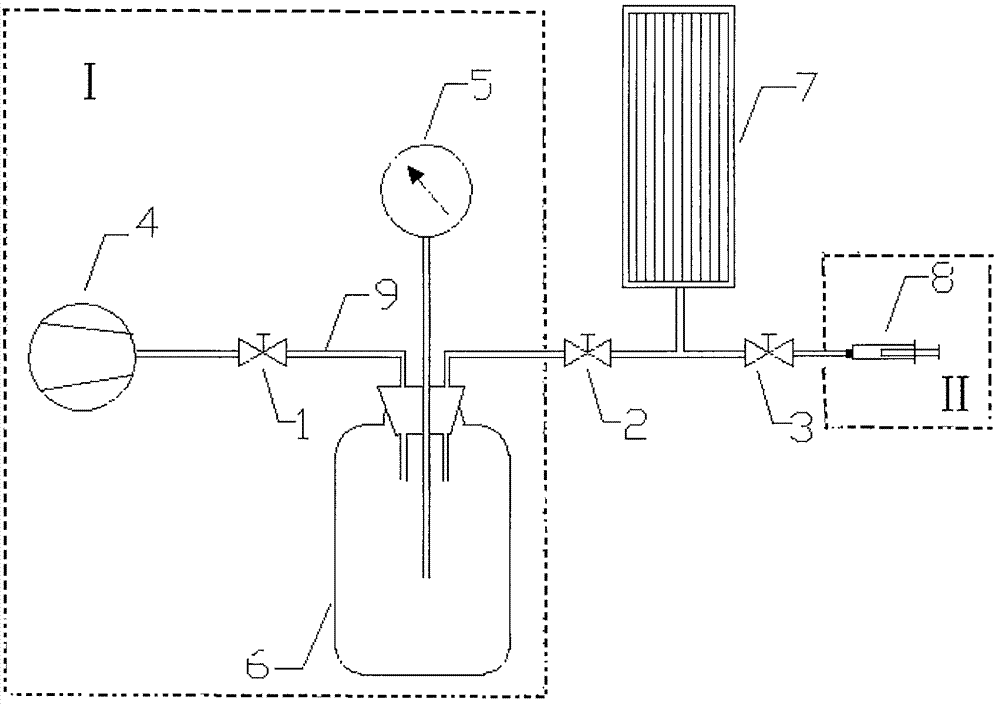

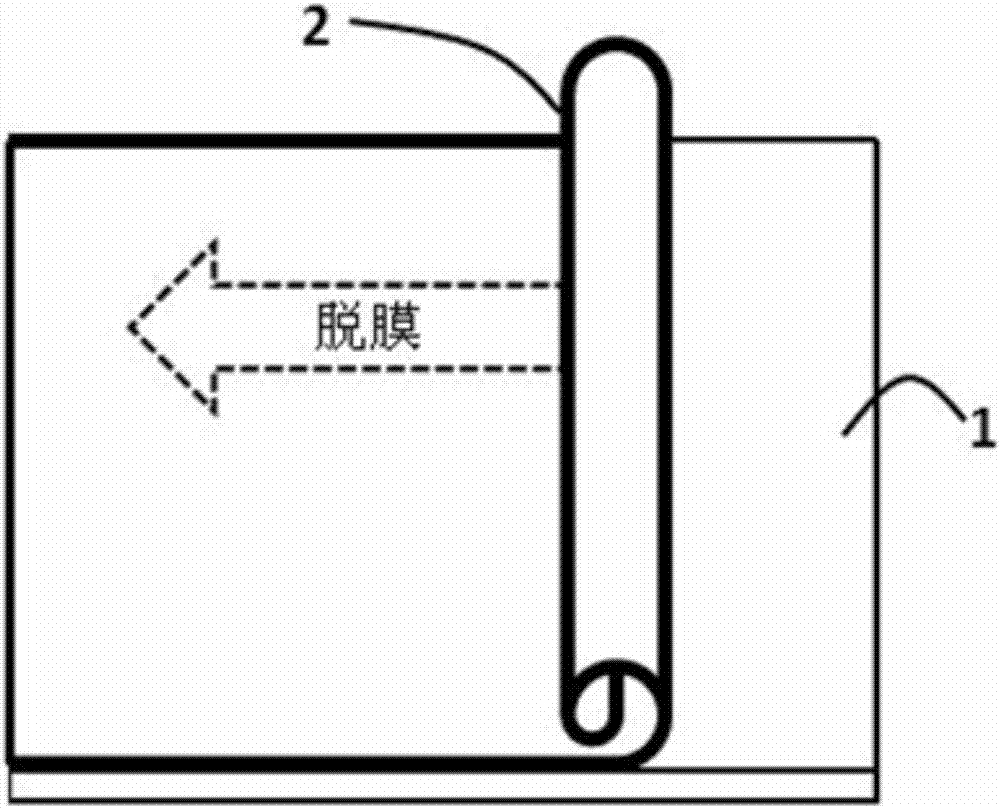

Flat plate micro heat pipe vacuumizing and liquid injection device and method thereof

PendingCN106931814AAvoid errorsRealize automatic and precise injectionIndirect heat exchangersGas cylinderCapillary Tubing

The invention provides a flat plate micro heat pipe vacuumizing and liquid injection device and a use method thereof. The flat plate micro heat pipe vacuumizing and liquid injection device is composed of a vacuumizing part and a liquid injection part. The vacuumizing part is composed of a vacuum pump, a vacuum meter, an air collection bottle and a capillary tube. The vacuum pump is used for vacuumizing a flat plate micro heat pipe and the air collection bottle. The vacuum meter is used for observation of the vacuum degree. The liquid injection part is composed of an injector and a capillary tube. Liquid is injected into the flat plate micro heat pipe through the injector. In the vacuumizing and liquid injection processes, connection of the flat plate micro heat pipe and all parts is controlled by a manual valve. The flat plate micro heat pipe vacuumizing and liquid injection device is simple in structure, low in cost, high in precision of the vacuum degree and liquid injection volume, easy to operate and reliable in operation.

Owner:GUANGDONG UNIV OF TECH

Floating rate bond pricing and risk interest arbitrage method

InactiveCN104182895AReduce process errorHelp in decision makingFinanceSimulationErrors and residuals

The invention discloses a floating rate bond pricing and risk interest arbitrage method, which relates to the technical field of financial market activities. The floating rate bond pricing and risk interest arbitrage method comprises the following steps: analyzing according to an existing national debt on-demand yield curve, calculating an implicit long-term base rate through a no arbitrage principle, judging implicit interest rate raising anticipation in the on-demand yield curve through a long-term base rate level, and combining with practicality to judge corresponding investment value; obtaining a data processing request message containing bond information from a transaction processing server; according to the bond information, generating the actual daily rate approximate value of bond, and causing that the discount or premium distribution on the same day of a bond due date is zero; detecting whether the actual daily rate approximate value is smaller than a precision threshold; and according to the actual daily rate approximate value which is smaller than the precision threshold, generating the actual daily rate when the bond due date is zero. The implicit future base rate anticipation of the floating rate bond is directly obtained by virtue of a rate exchange market, data processing errors are reduced, and the method is visual and simple and is favorable for investors to make a decision.

Owner:CHONGQING UNIV OF EDUCATION

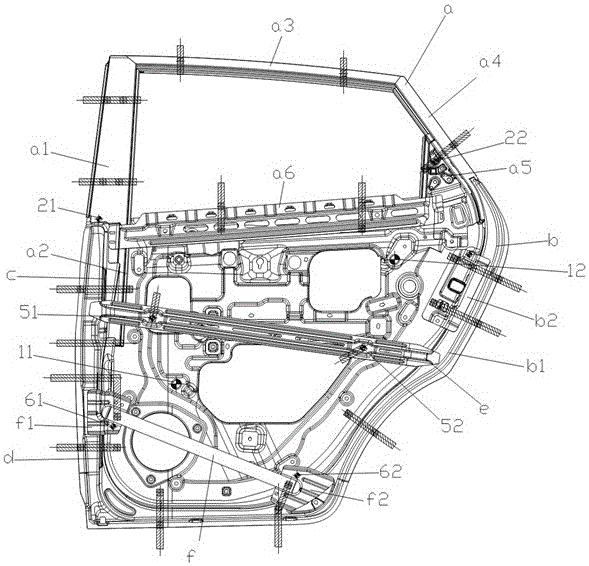

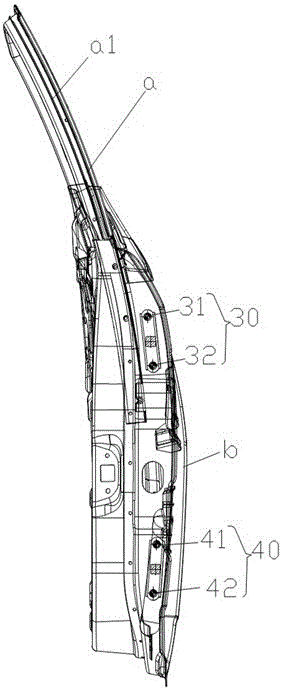

Production process for left-rear side inner car door panel assembly

ActiveCN106001960AReduce process errorAvoid large fit gapsWelding/cutting auxillary devicesAuxillary welding devicesProcess errorCar door

The invention relates to a production process for a left-rear side inner car door panel assembly. The production process comprises the following steps: welding an upper frame assembly; welding an anti-collision rod assembly; welding the inner car door panel assembly; locating the inner car door panel assembly; installing the upper frame assembly; locating an upper nut plate and a lower nut plate; clamping the upper frame assembly, the inner car door panel assembly, the upper nut plate and the lower nut plate through a clamp, and welding contact points of the upper frame assembly, the inner car door panel assembly, the upper nut plate and the lower nut plate; installing an outer panel support plate; clamping the outer panel support plate through a clamp, and welding contact points of the outer panel support plate and a fixture in an eighth step; installing the anti-collision rod assembly; and clamping the anti-collision rod assembly through a clamp, and welding contact points of the anti-collision rod assembly and a fixture in a tenth step. According to the production process, a process error of the left-rear side inner car door panel assembly is reduced, a large fit clearance or fit extrusion of the left-rear side inner car door panel assembly is avoided, assembly and machining for left-rear side outer car door panels relative to the left-rear side inner car door panel assembly is benefited, and the rejection rate of left-rear side car doors is reduced.

Owner:安徽大洋机械制造有限公司

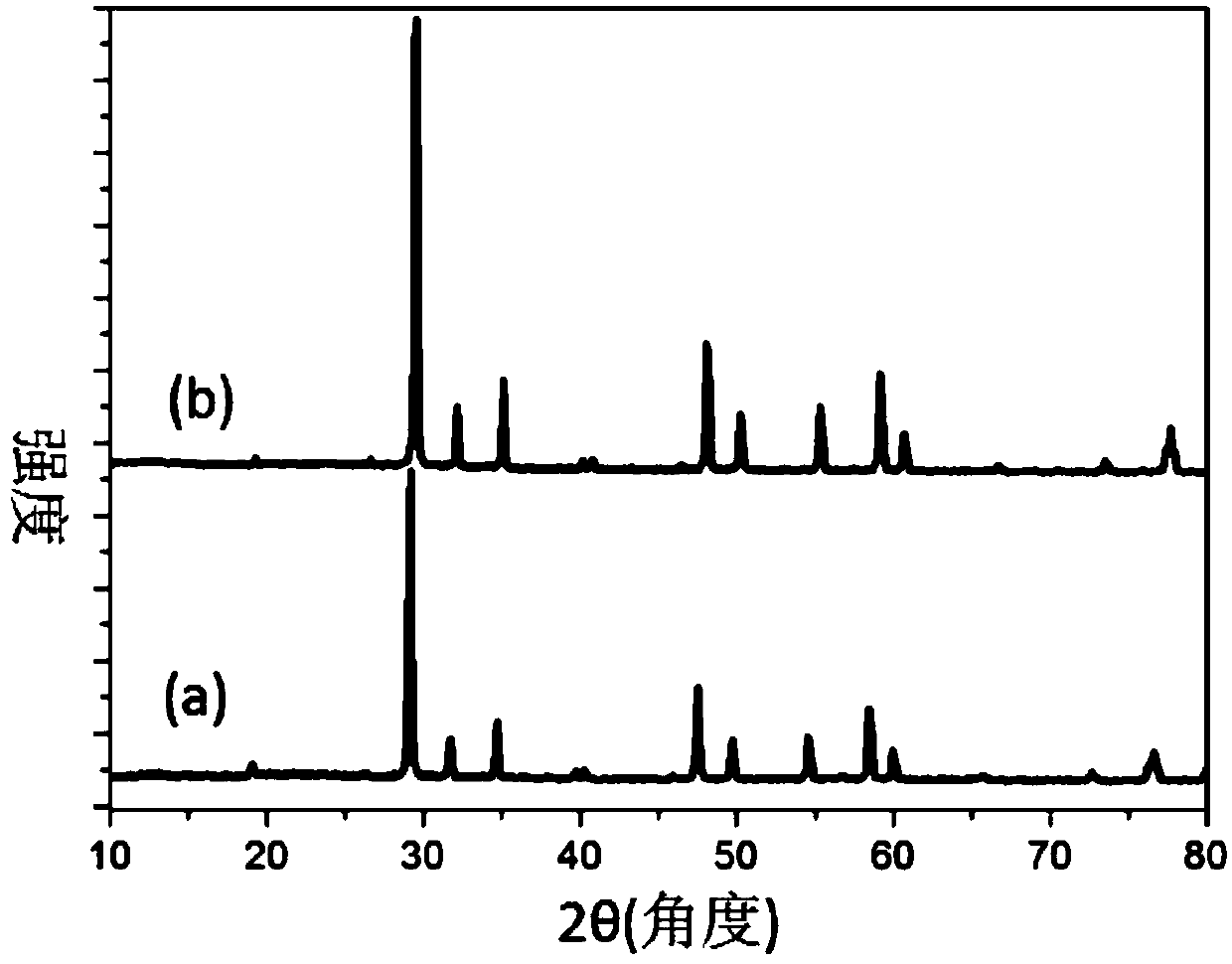

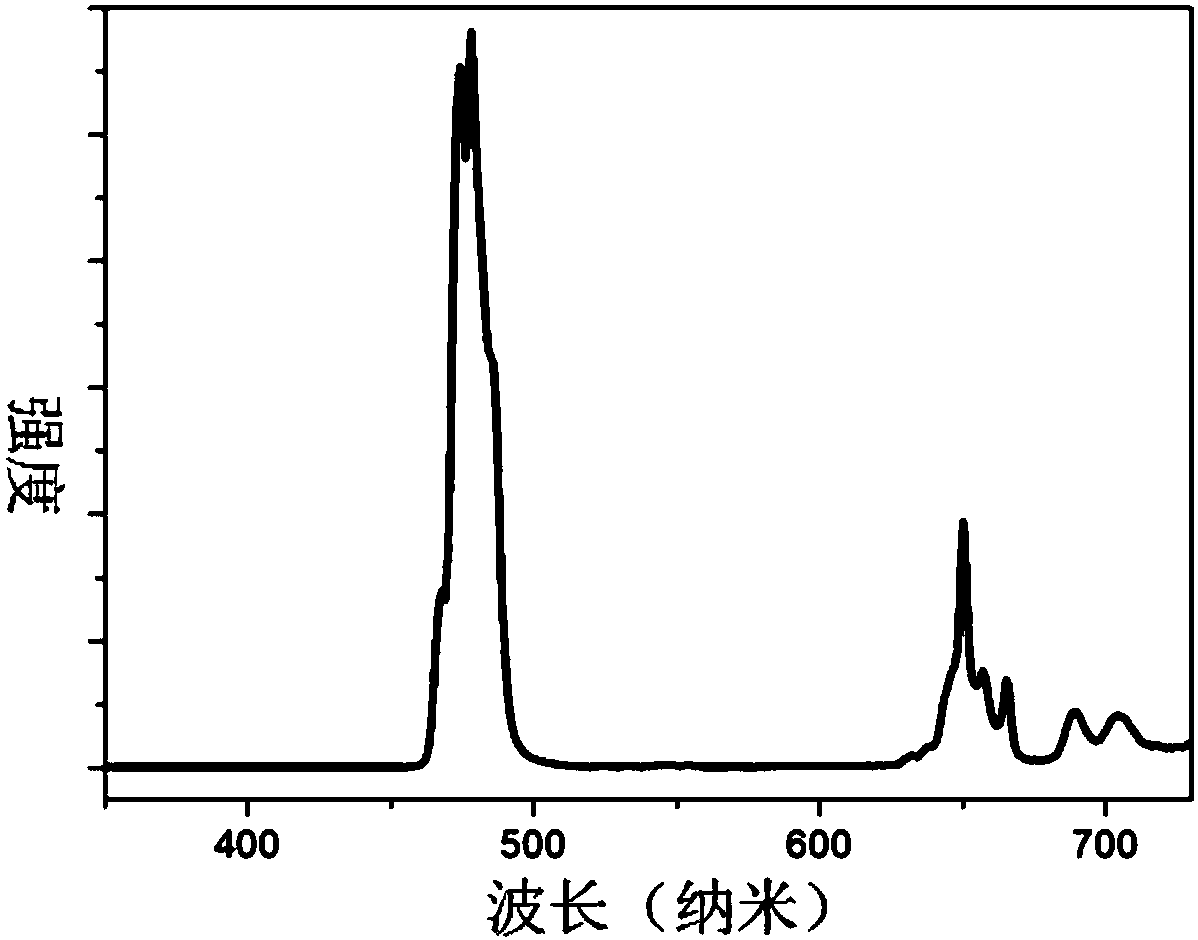

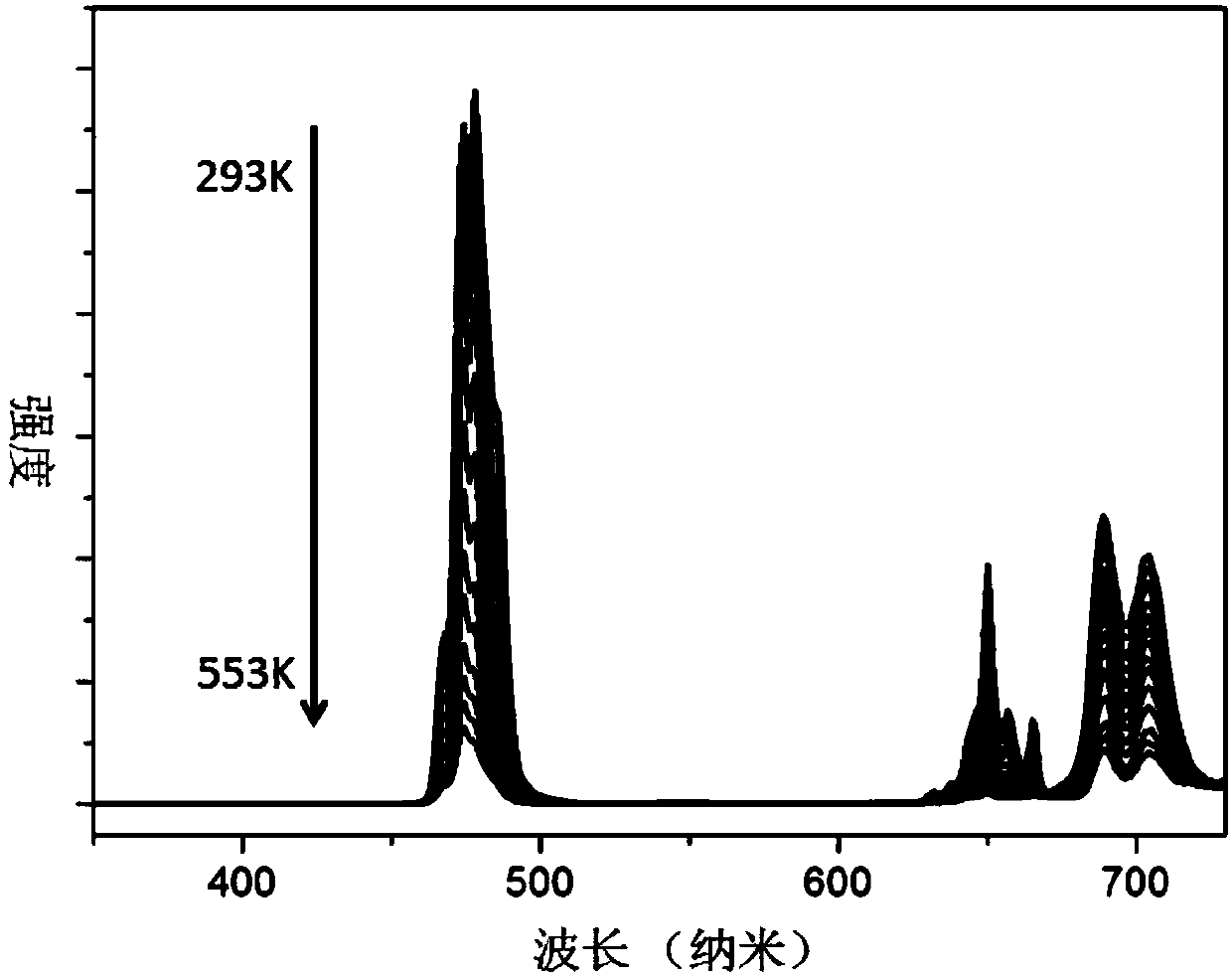

High-sensitivity upconversion fluorescence temperature probe material and preparation method thereof

ActiveCN107779193AHigh strengthIncrease spacingFluorescence/phosphorescenceLuminescent compositionsRare earth ionsUltimate tensile strength

The invention belongs to the field of inorganic luminescent materials, and discloses a high-sensitivity upconversion fluorescence temperature probe material. The molecular formula of the probe material is Yb / Tm / Sr:NaGd (MoO4)2. The high-sensitivity upconversion fluorescence temperature probe material has the advantages that a selected fluorescence emission peak has a long distance and excellent screening performances, data processing errors are greatly reduced, molybdenum serves as a substrate, crystal field environments around rare earth ions are adjusted by the aid of alkaline earth Sr2+, and the variation amplitude of fluorescence intensity ratio is greatly improved, so that the high-temperature detection sensitivity of the upconversion material is achieved.

Owner:CHINA JILIANG UNIV

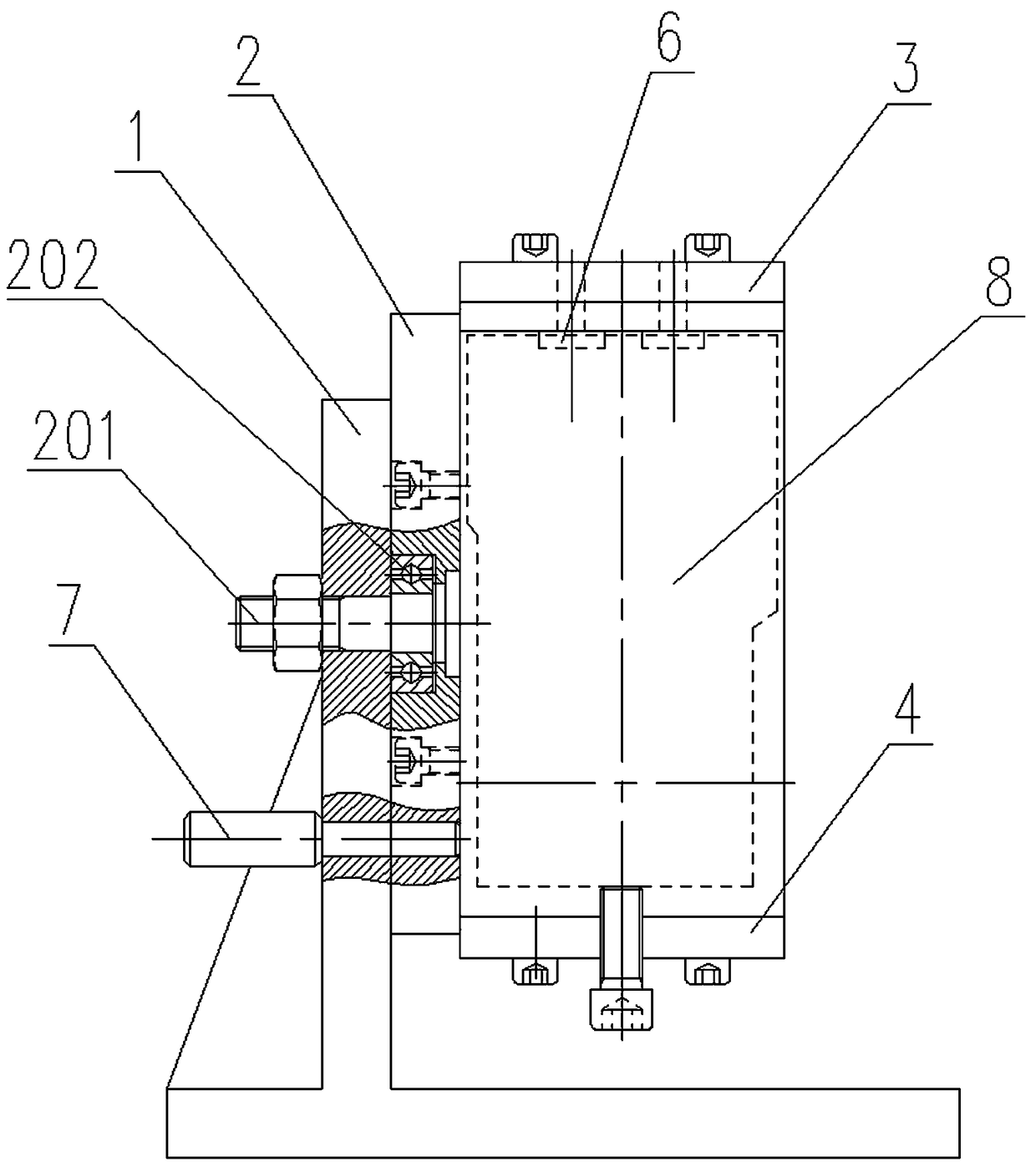

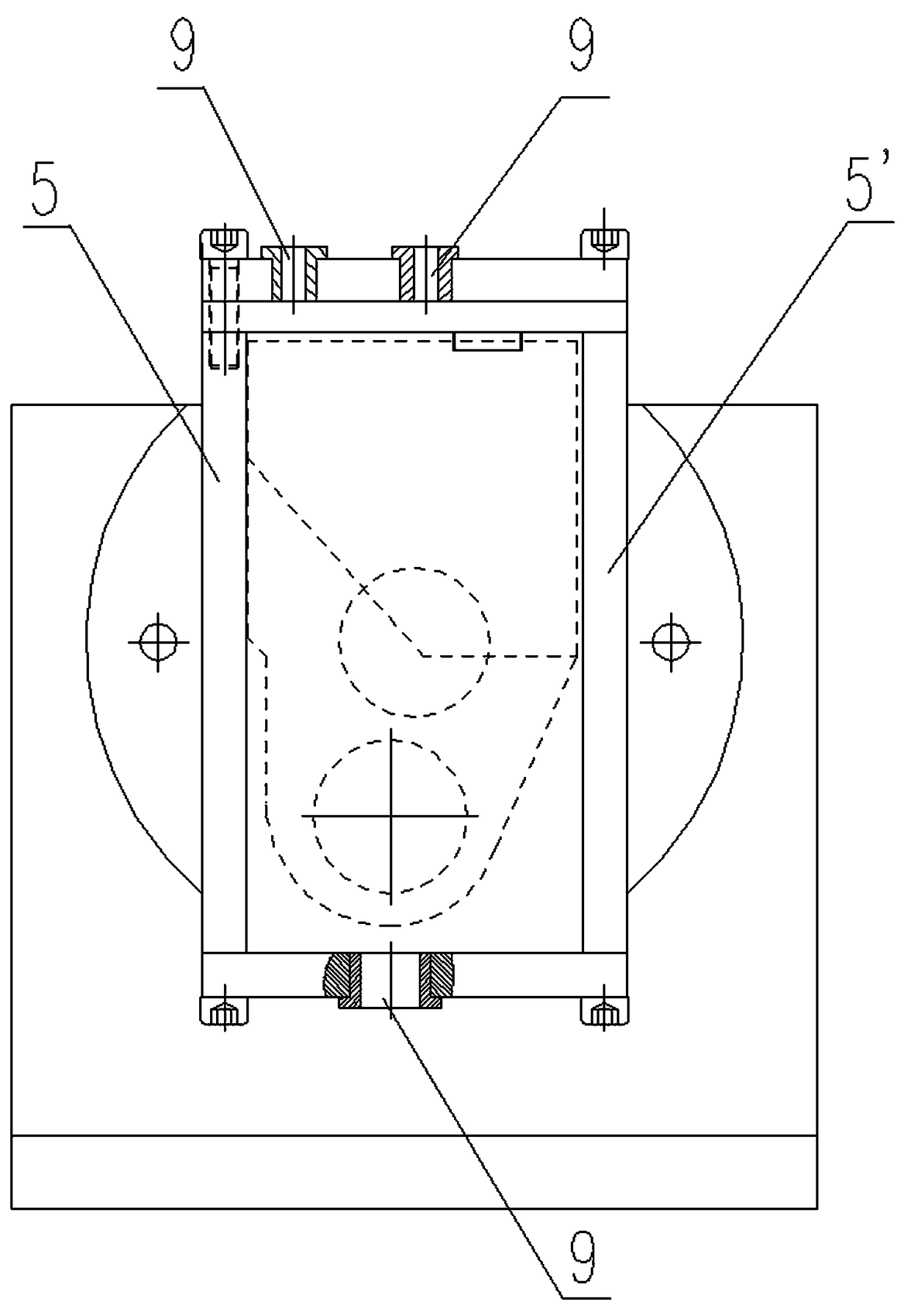

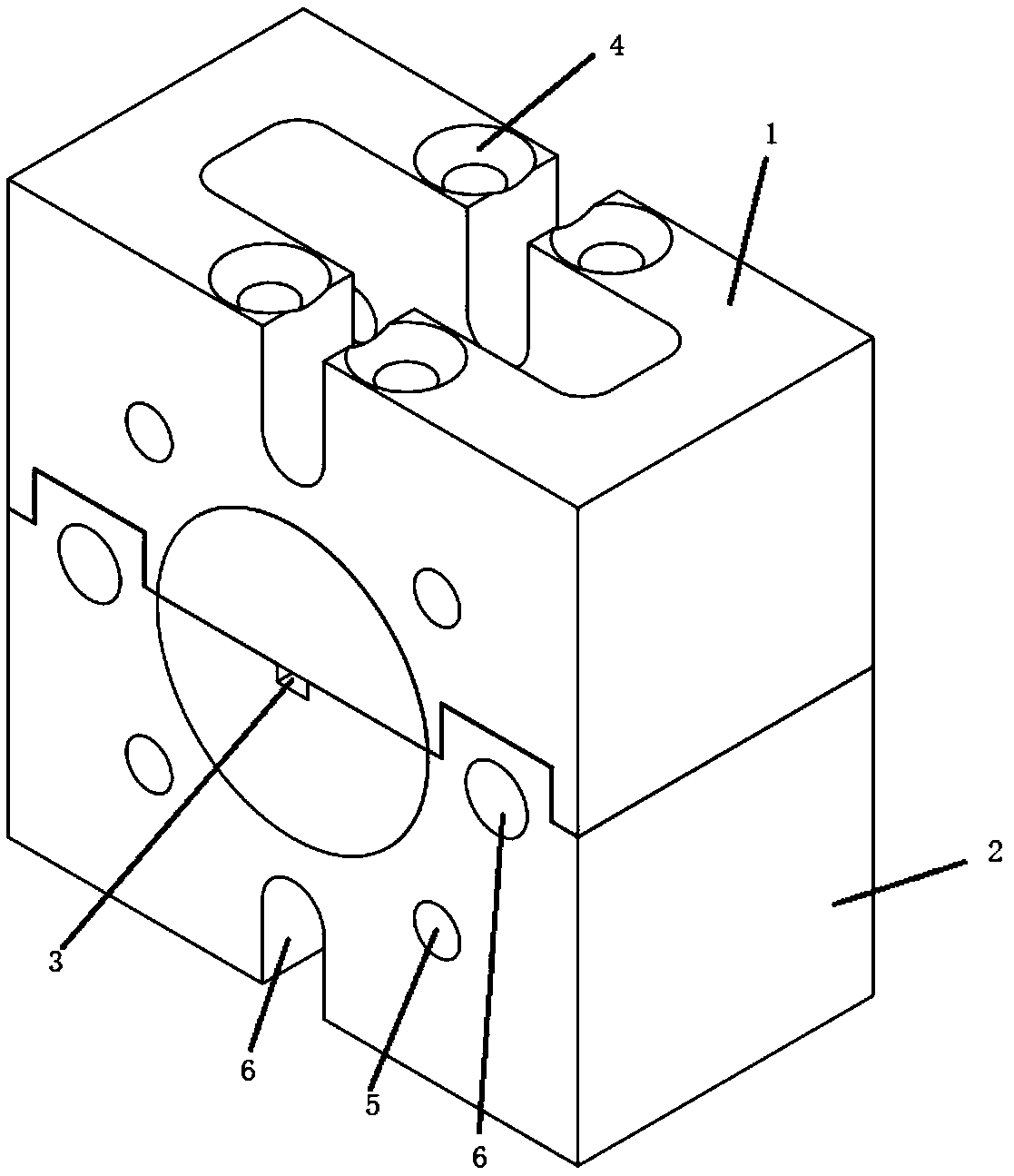

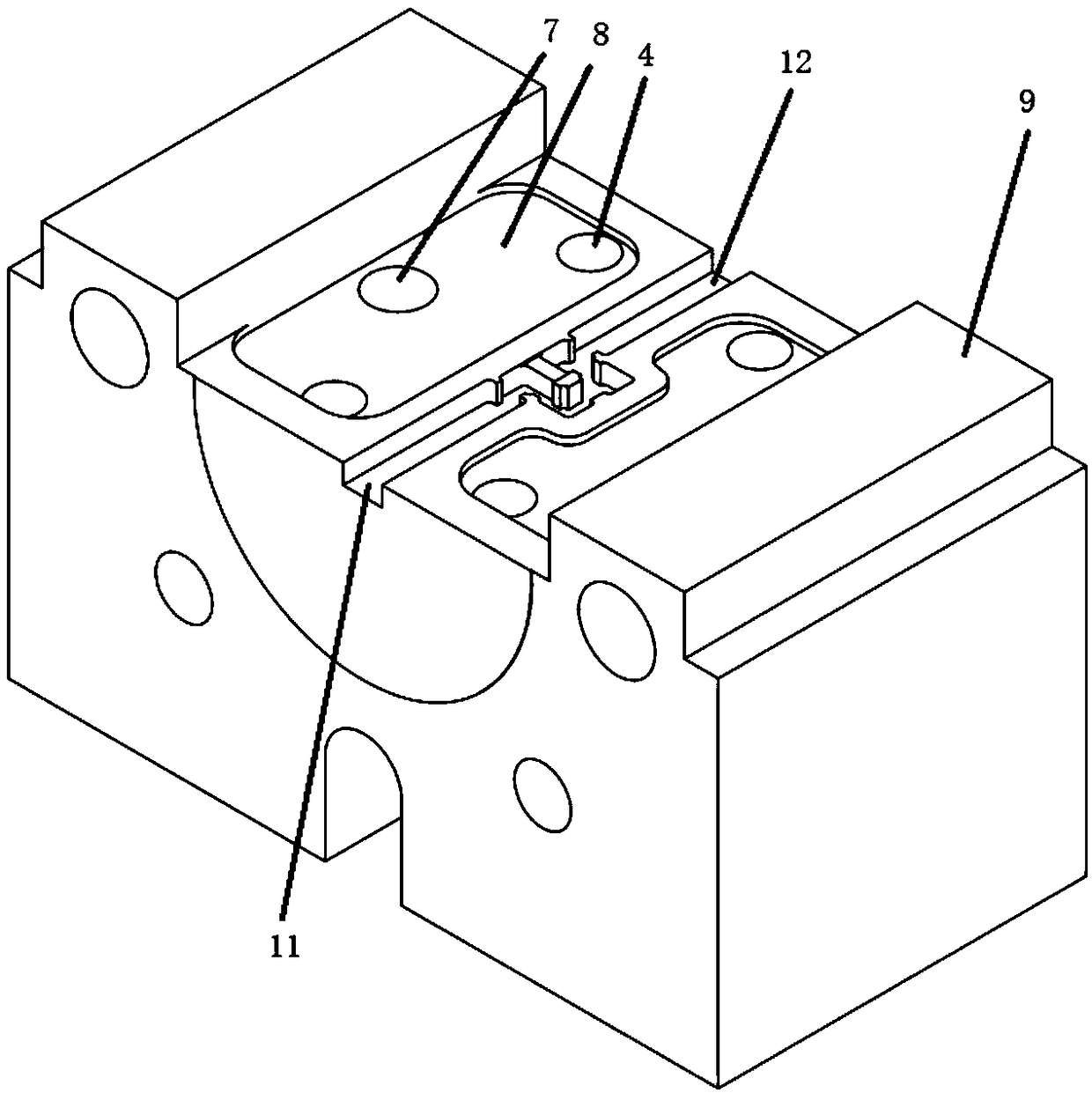

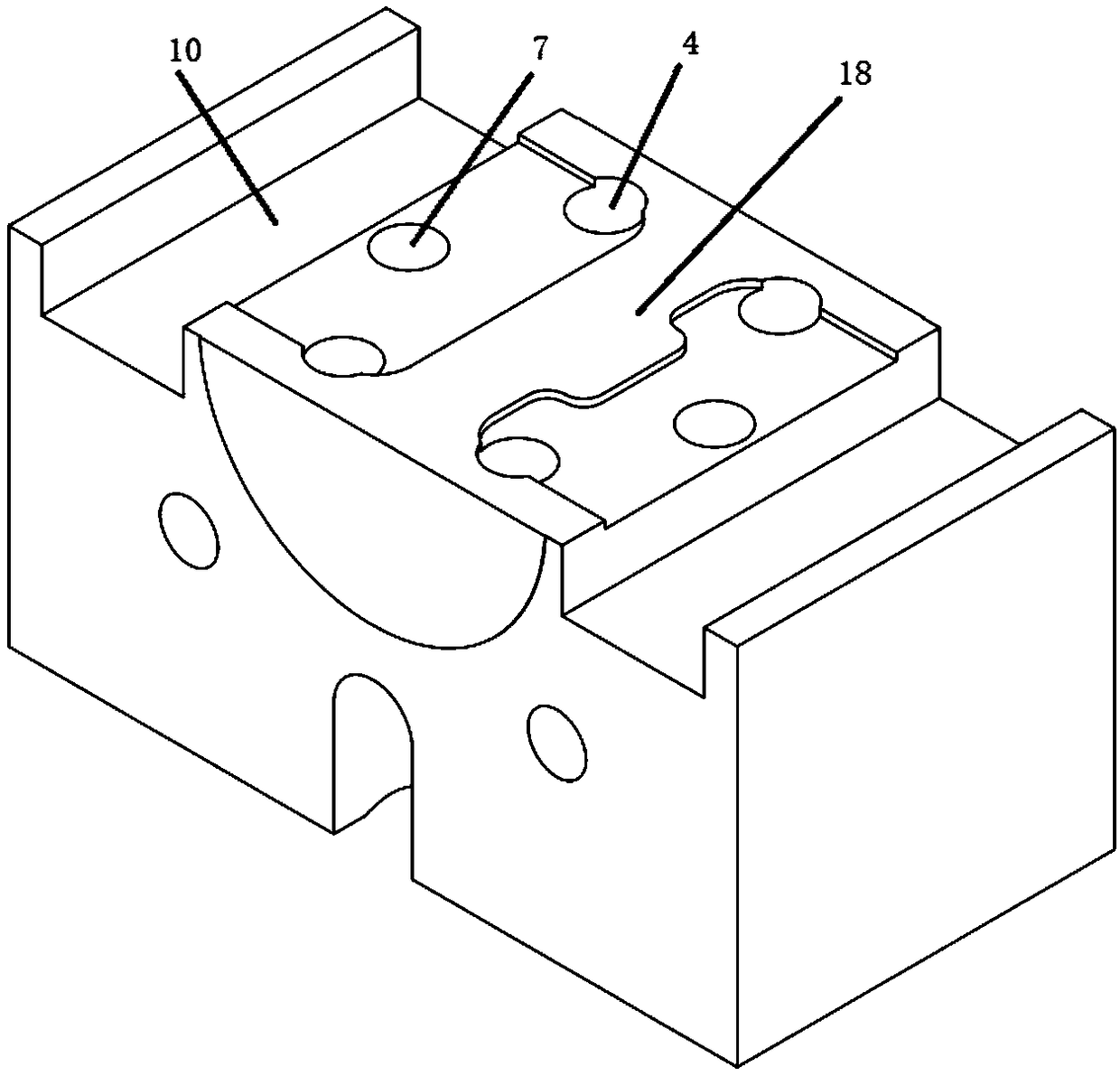

Clamp special for machining valve block of pneumatic roof bolter

InactiveCN109014347AHigh hole pitch accuracySimple structurePositioning apparatusDrill jigsEngineeringRelative motion

The invention discloses a clamp special for machining a valve block of a pneumatic roof bolter. The hole pitch precision of the valve block of the roof bolter can be effectively improved, the technological error is reduced, using is convenient, and the structure is simple. A disc is arranged on one side of a fixed support of the clamp, and the disc is connected with the fixed support through a central spindle assembly; the central spindle assembly comprises a bearing arranged at one end of the disc and is used for supporting the disc and all fixing pieces on the disc to rotate around the axis;the clamp further comprises an upper drill mold plate, a lower drill mold plate, a left vertical plate and a right vertical plate, a positioning pin and a positioning inserting pin; the upper drill mold plate, the lower drill mold plate, the left vertical plate and the right vertical plate are fixed to the disc through bolts; a plurality of hole positions are formed in each of the upper drill mold plate and the lower drill mold plate; the upper drill mold plate, the lower drill mold plate, the left vertical plate and the right vertical plate form a square box whole; the positioning pin is connected with the upper drill mold plate and used for positioning the workpiece precision; and pin holes matched with the positioning inserting pin are formed in the fixed support and the disc and usedfor limiting the relative motion of the fixed support and the disc.

Owner:ANHUI SHENGTAI ELECTRIC

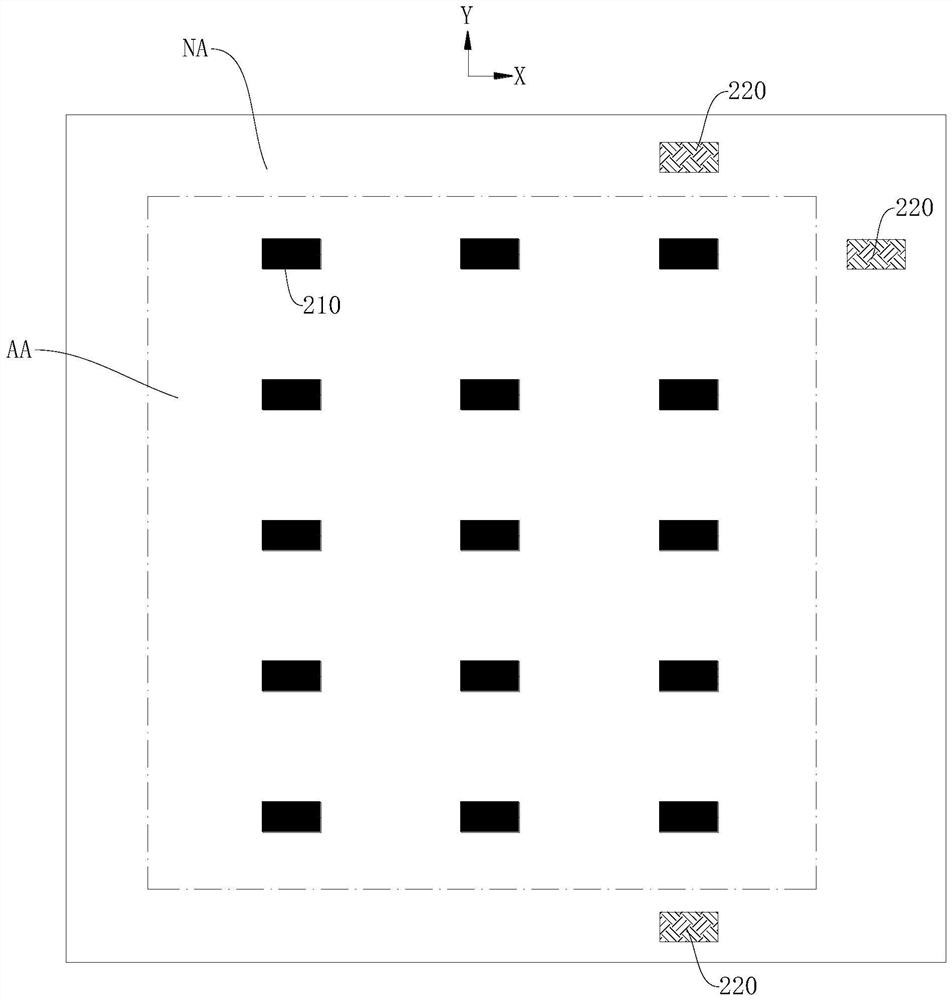

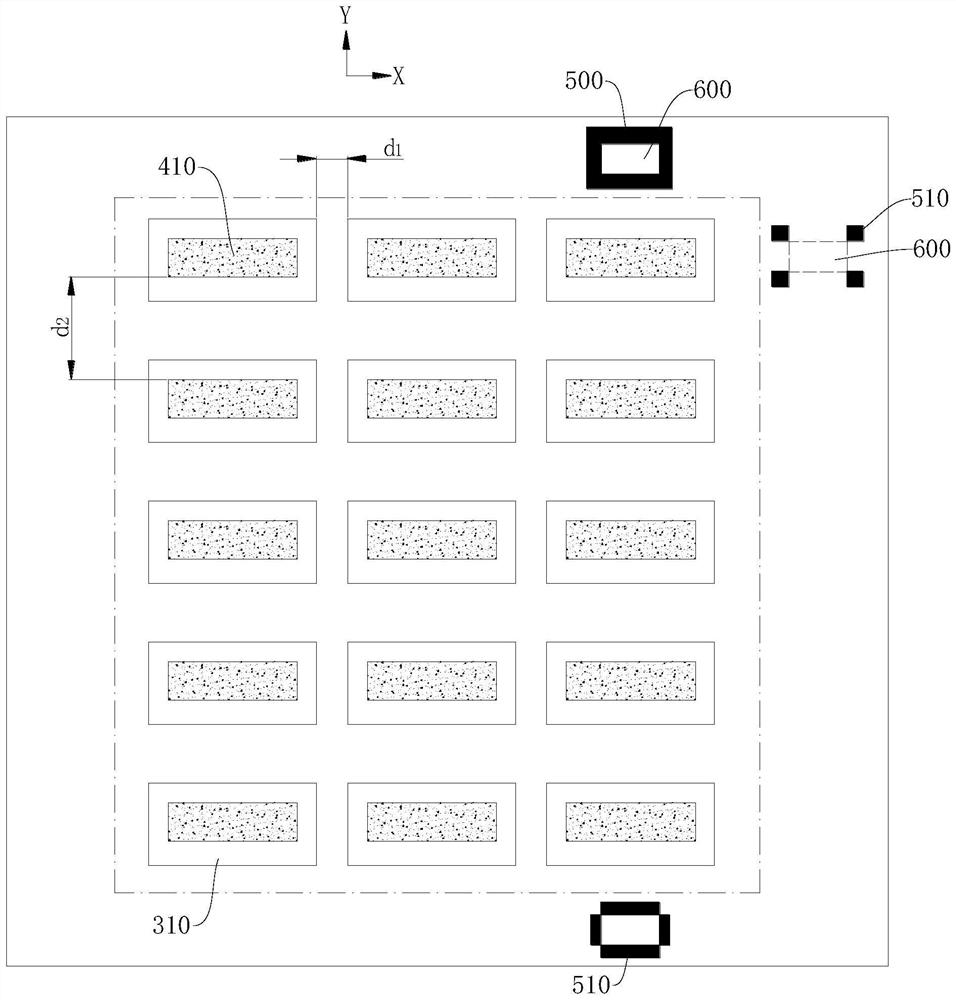

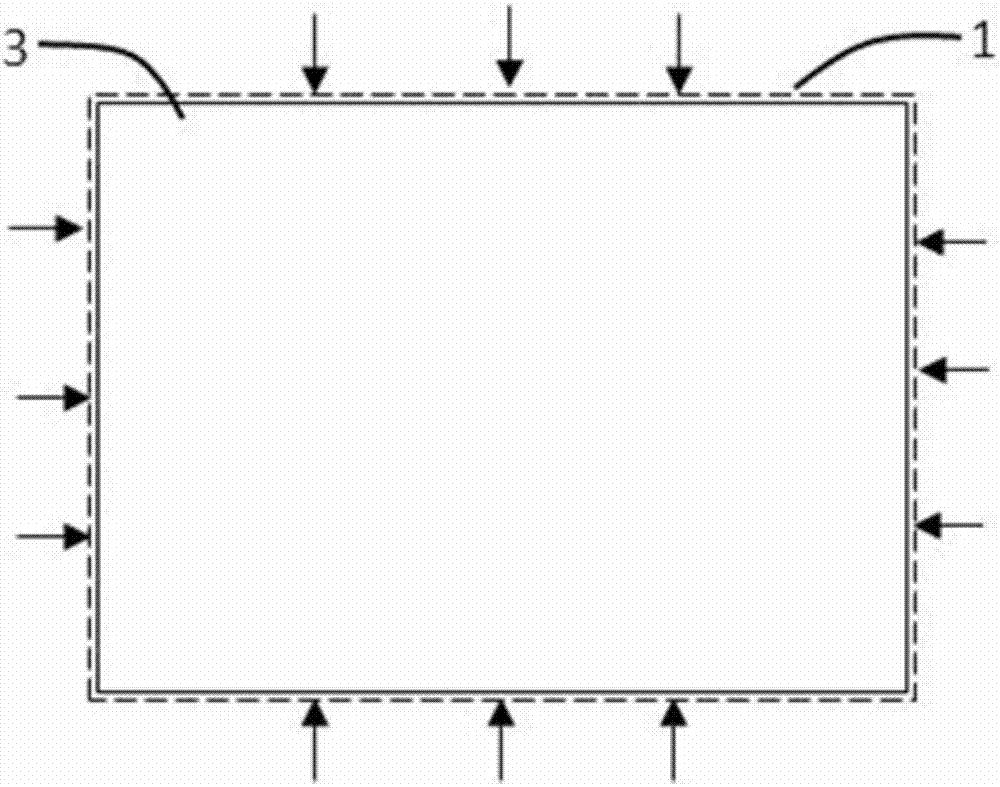

Display panel, display device and preparation method of display panel

ActiveCN112164334AImprove total errorReduce process errorIdentification meansComputer hardwareComputer graphics (images)

The embodiment of the invention provides a display panel, a display device and a preparation method of the display panel, and aims to reduce the production process deviation of the display panel. Thedisplay panel comprises a first substrate and a second substrate which are oppositely arranged, a plurality of light-emitting units which are located on the side, facing the second substrate, of the first substrate and comprise display units and marking units; the second substrate is provided with a positioning mark, and the marking unit and the positioning mark are arranged in an aligned mode. Inthe embodiment of the invention, the process error of the display panel can be reduced by reusing the light-emitting unit as the marking unit.

Owner:HUBEI YANGTZE IND INNOVAION CENT OF ADVANCED DISPLAY CO LTD

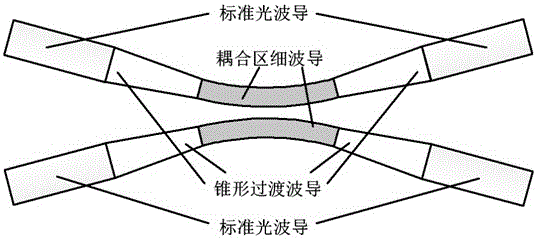

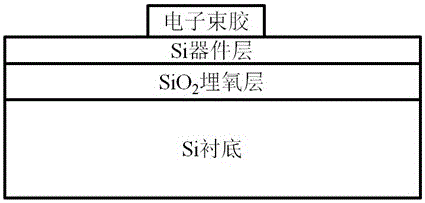

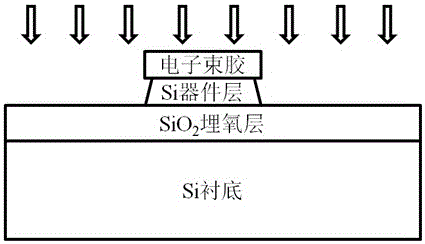

High-efficiency coupling structure among silicon-based optical waveguides and manufacturing method thereof

ActiveCN106680935AImprove coupling efficiencyReduce process errorCoupling light guidesPhotoresistMicrometer

The invention provides a high-efficiency coupling structure among silicon-based optical waveguides and a manufacturing method thereof. The structure comprises: (1) a standard silicon-based optical waveguide, which is 450-500 nanometers in width and serves as a waveguide of an optical device; (2) a tapered transition waveguide, which is 10-20 micrometers in length and serves as a transition waveguide among optical waveguides with different widths; and (3) a coupled zone fine waveguide, which is 380-420 nanometers in width and 10-15 micrometers in length and serves as an evanescent wave coupling waveguide. The manufacturing method includes the following steps: 1) using a photoresist to make a mask on a silicon-on-insulator; 2) making a trapezoid silicon-based optical waveguide through an inductively coupled plasma through etching; and 3) removing the photoresist mask and thus finishing manufacture of the high-efficiency coupling structure among silicon-based optical waveguides. The advantages are as follows: the trapezoid fine waveguide is adopted to serve as a coupling waveguide in a coupled zone, so the coupling efficiency among waveguides in a condition of the same coupling space is increased, a space among waveguides in a condition of the same coupling efficiency is increased, technical errors generated by proximity effects when electron beams etch the coupled zone are reduced, and technical tolerances are increased.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

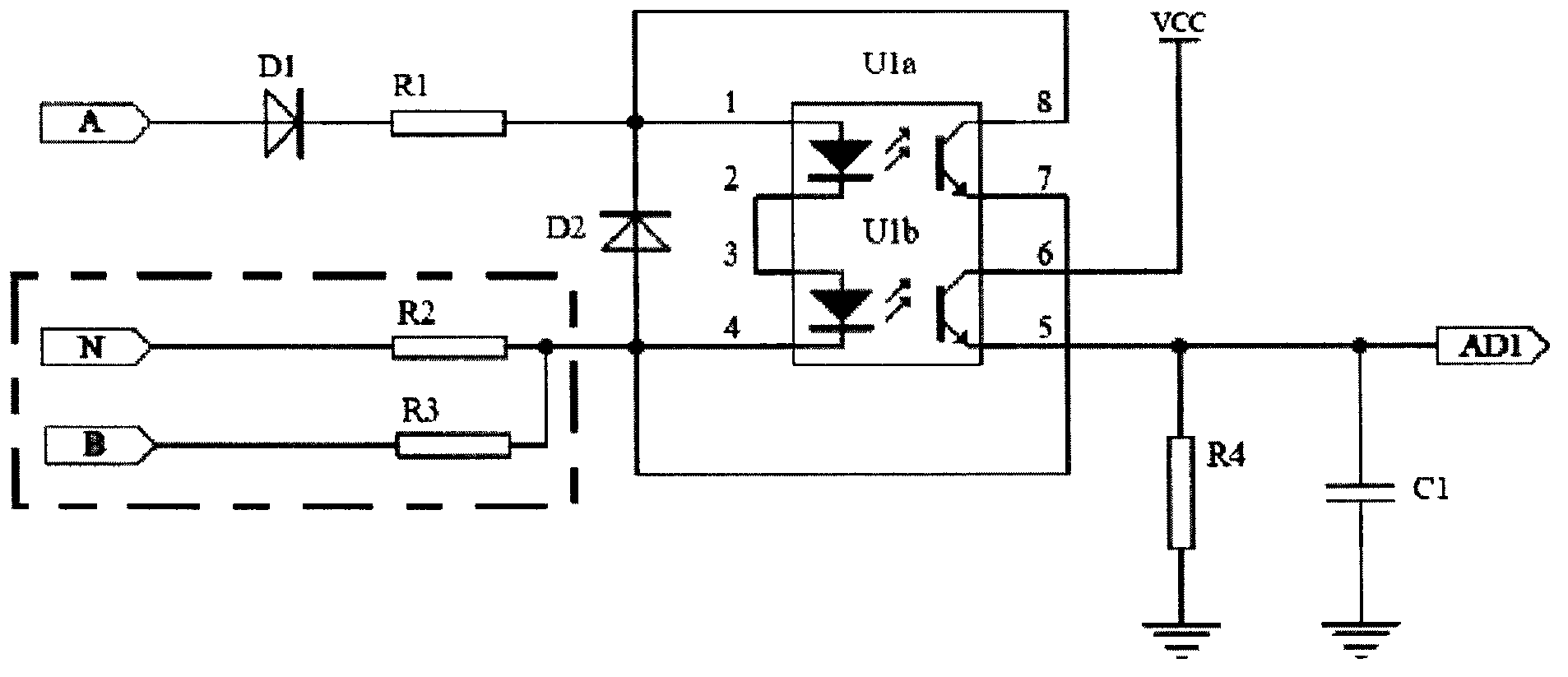

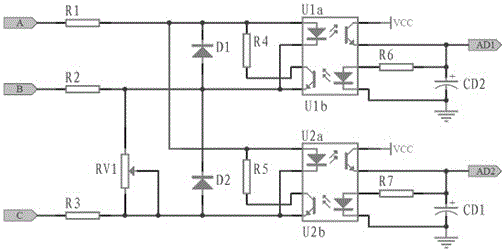

Double-power-supply voltage detection circuit

InactiveCN104569554AAvoid temperature driftResistance to temperature driftCurrent/voltage measurementFeedback circuitsEngineering

The invention relates to a double-power-supply voltage detection circuit. The double-power-supply voltage detection circuit comprises power supply input and further comprises voltage decreasing resistors R1, R2 and R3, an adjustable resistor RV1, amplitude limiting protection diodes D1 and D2, resistors R4, R5, R6 and R7, photoelectric couplers U1a, U1b, U2a and U2b and capacitors CD1 and CD2. The resistors R4 and R6 and the photoelectric coupler U1b form a feedback circuit, and the resistors R5 and R7 and the photoelectric coupler U2b form another feedback circuit. The double-power-supply voltage detection circuit effectively solves the problem that because the photoelectric couplers are affected by environment temperature, temperature excursion occurs, the linearity degree of the photoelectric couplers is greatly increased, and the requirement for accurately measuring a voltage signal of the double-power-supply product is met better; technology errors generated in the production process are reduced for the photoelectric couplers, and assembling and wiring of a user are facilitated.

Owner:CNC ELECTRIC GRP

Terahertz quasi-elliptical waveguide filter that is easy to implement by CNC

The invention provides a terahertz quasi-elliptic waveguide filter that is easy to implement by CNC. The filter comprises an upper structural block and a lower structural block. The upper structural block and the lower structural block are detachably connected, and an H-face single-sided crack waveguide structure is arranged between the upper structural block and the lower structural block. The H-side single-sided crack waveguide structure comprises a source input waveguide, a load output waveguide and four resonant cavities in the same size. The four resonant cavities are arranged in a foldedmanner along an H-face, and adjacent resonant cavities are magnetically coupled, and cross electric coupling is used between non-adjacent resonant cavities. The high-frequency filter can be processedby a CNC process and gold is plated on an outer layer. The filter operates in a 220 GHz band and has a low insertion loss characteristic of -0.6 dB, and two distinct zero points near a passband existout of a band, so that the edge selection characteristic of the filter is very good, that is, the filter has a quasi-elliptical response. The filter is applied to a terahertz detection system to achieve continuous spectrum astronomical observation with 10% bandwidth in the 220 GHz band.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

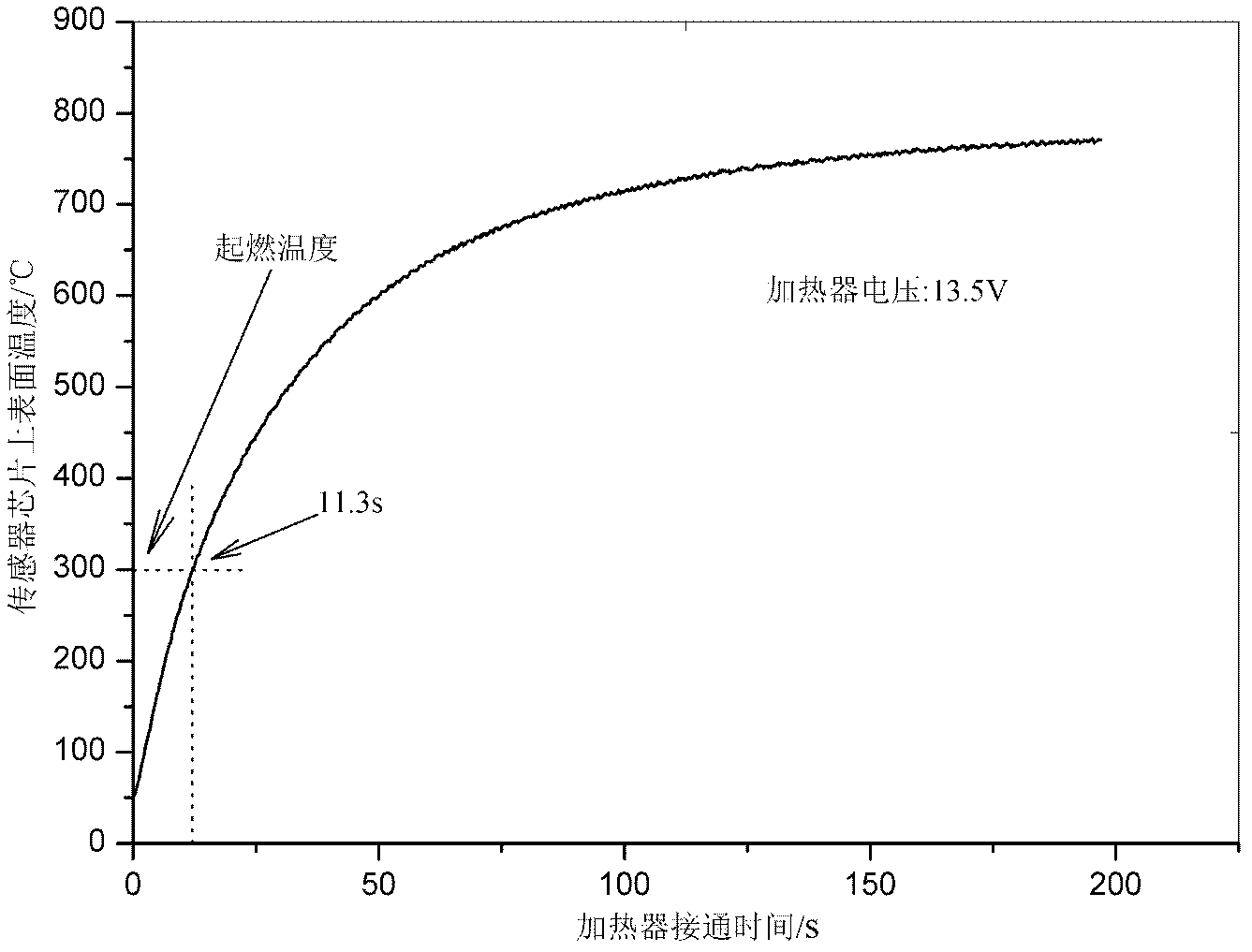

Flat oxygen sensor and preparation method thereof

ActiveCN102608193BDefects in homogenization preparation processHigh strengthMaterial analysis by electric/magnetic meansInsulation layerOxygen sensor

The invention discloses a flat oxygen sensor and a preparation method thereof. The flat oxygen sensor comprises a sensor chip prepared by seven layers of zirconium oxide ceramic raw pieces which are 0.2 to 0.25 mm thick, wherein the chip sequentially comprises a signal functional layer consisting of the first and second layers of ceramic raw pieces, a reference channel functional layer consisting of the third, fourth and fifth layers of ceramic raw pieces and a heating functional layer consisting of the sixth and seventh layers of ceramic raw pieces; an outer electrode and a signal electrode pin are arranged on the upper surface of the first layer of ceramic raw piece; a porous protection layer is arranged on the outer electrode; a lead protection layer is arranged on the signal electrode pin; a reference electrode is arranged between the second and third layers of ceramic raw pieces; a heater is arranged between the fifth and sixth layers of ceramic raw pieces; an upper heater insulation layer and a lower heater insulation layer are arranged on and below heater respectively; and a heating electrode pin is connected to the heater. The preparation method comprises the following steps of preparing, forming, printing and stacking the ceramic raw pieces and sintering the sensor.

Owner:WUXI LONGSHENG TECH

Process method for improving interlayer alignment accuracy in multilayer co-fired ceramic circuit processing

ActiveCN107046779AImprove interlayer stabilityImprove compatibilityPrinted circuits stress/warp reductionCircuit susbtrate materialsCo-fired ceramicCoating

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

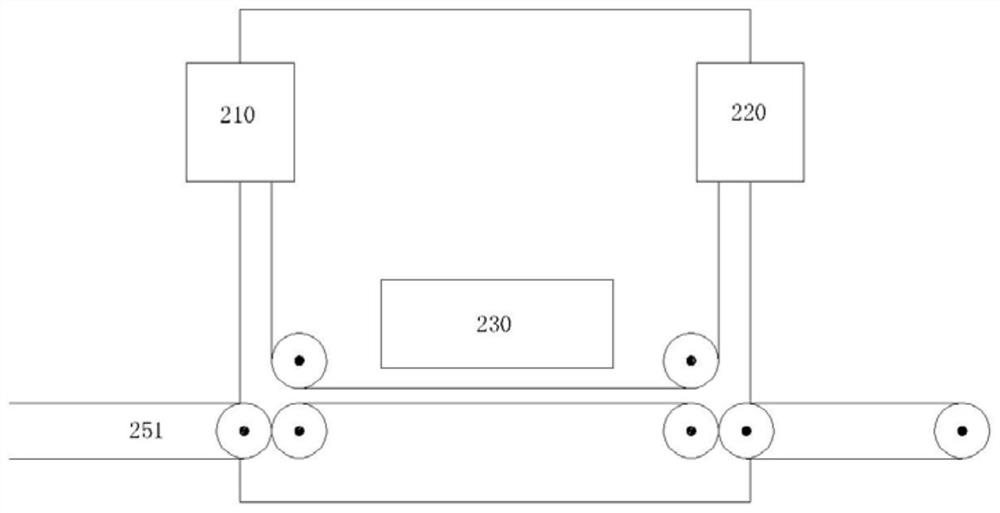

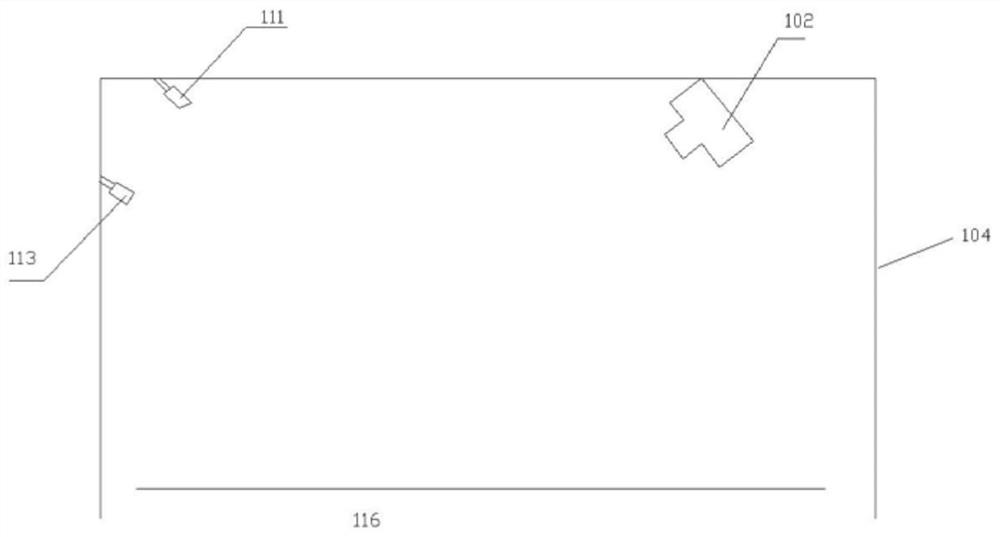

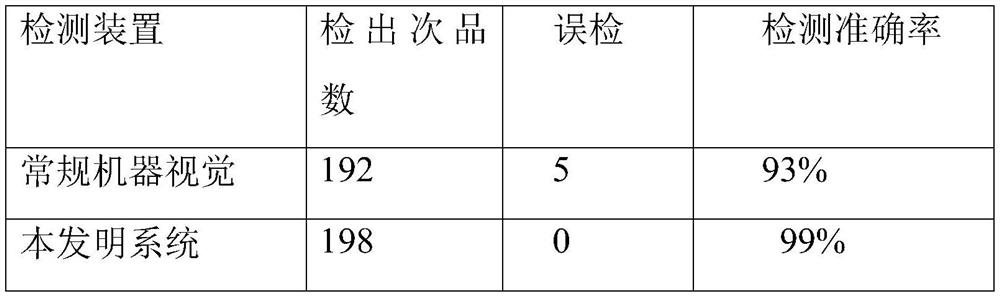

Hot stamping system with automatic hot stamping quality detection device

ActiveCN112078237AAvoid Splitting RequirementsReduce process errorTransfer printingPrinting press partsHot stampingImaging processing

The invention discloses a hot stamping system with an automatic hot stamping quality detection device. The hot stamping system comprises a laser transfer film unwinding device (210), a laser transferfilm winding device (220) and an imprint transfer device (230), wherein the imprint transfer device is installed between the laser transfer film unwinding device and the laser transfer film winding device; the automatic hot stamping system further comprises the automatic hot stamping quality detection device that is arranged in the downstream of the imprint transfer device (230), and comprises a light source (101), an image acquisition device (102) and an image processing device (103).

Owner:北京黎马敦太平洋包装有限公司

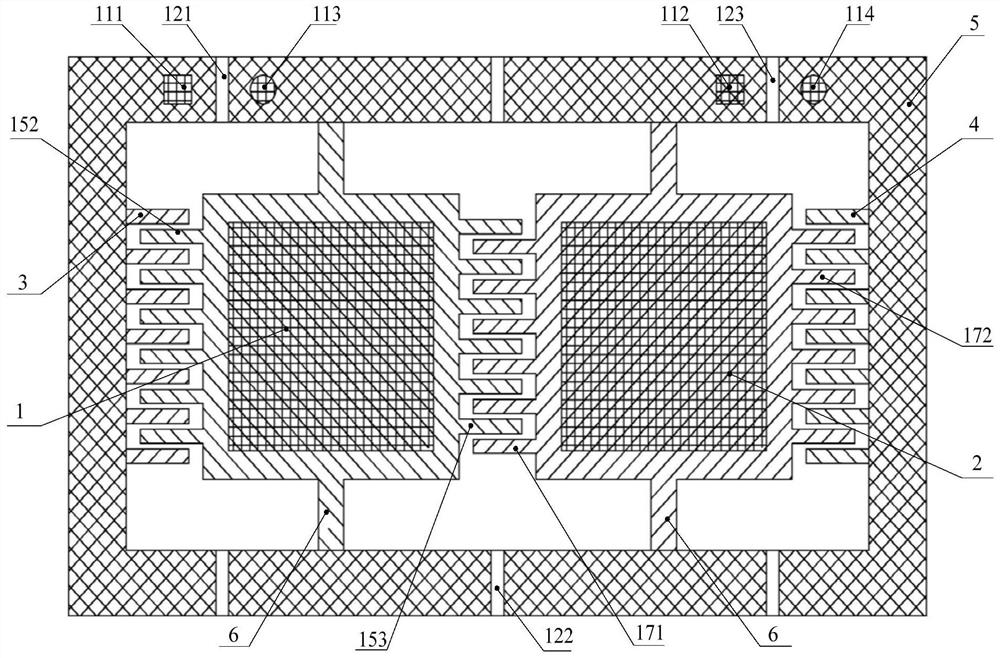

Off-axis MEMS micro-mirror and preparation method thereof

ActiveCN112965240AImprove reliabilityAvoid short circuitTelevision system detailsImpedence networksPotential differenceComb drive

The invention discloses an off-axis MEMS micro-mirror and a preparation method thereof, and relates to the technical field of MEMS. The off-axis MEMS micro-mirror comprises a first micro-mirror, a second micro-mirror, a first fixed comb tooth, a second fixed comb tooth and a driving electrode, the first micro-mirror and the second micro-mirror synchronously rotate by taking a rotating shaft as an axis, the first micro-mirror is used for scanning reflection of incident laser, the second micromirror is used for synchronously receiving reflected laser, and the driving electrode provides driving voltage; a first vertical comb tooth pair, a second vertical comb tooth pair and a third vertical comb tooth pair are formed between the movable comb teeth of the two micro-mirrors and between the movable comb teeth of the two micro-mirrors and the two fixed comb teeth respectively, and the first vertical comb tooth pair and the second vertical comb tooth pair provide clockwise deflection driving force for the first micro-mirror and the second micro-mirror respectively; and a third vertical comb tooth pair provides driving force deflecting in the anticlockwise direction for the first micro-mirror and the second micro-mirror, the two micro-mirrors attract each other in a certain period by manufacturing the potential difference between the vertical comb tooth pair structures, independent control is not needed any more, and the completely same-frequency and same-phase deflection state is achieved.

Owner:无锡微视传感科技有限公司

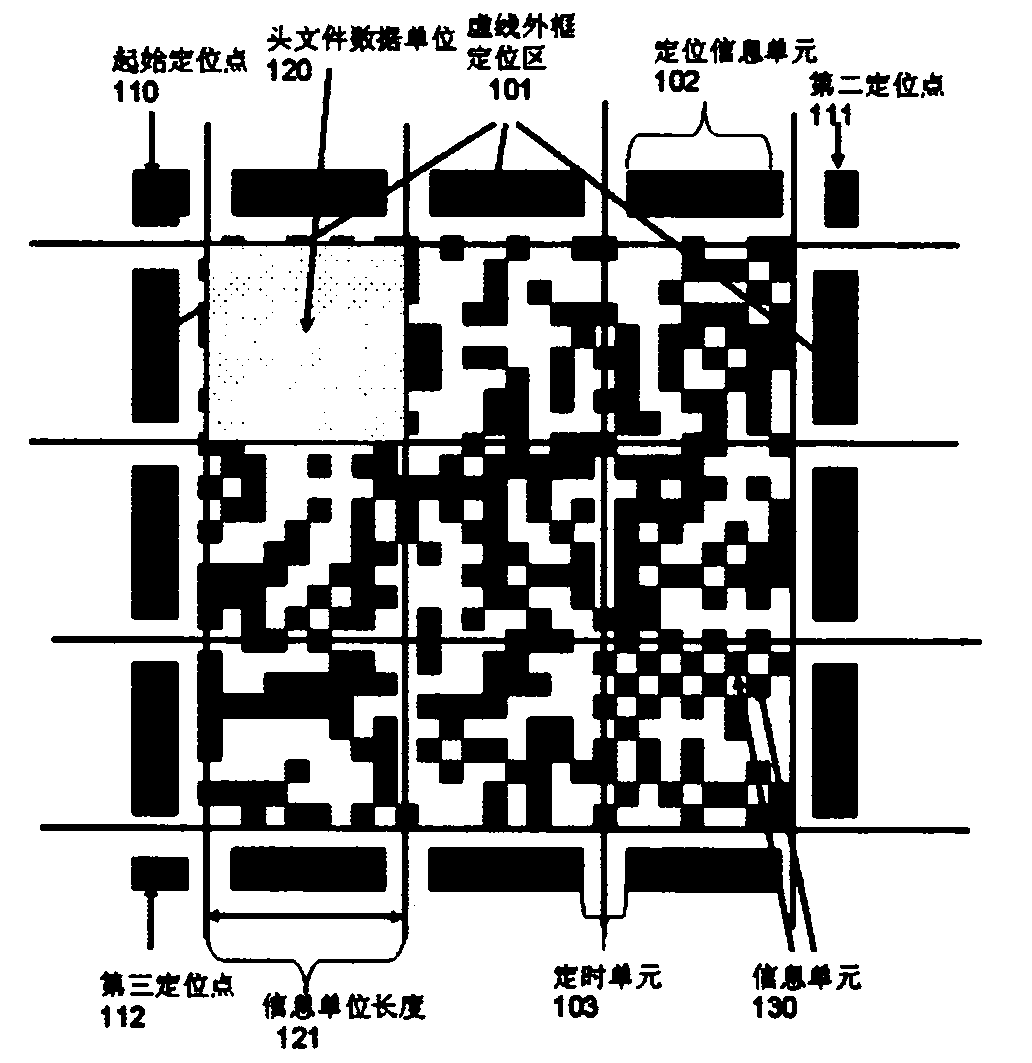

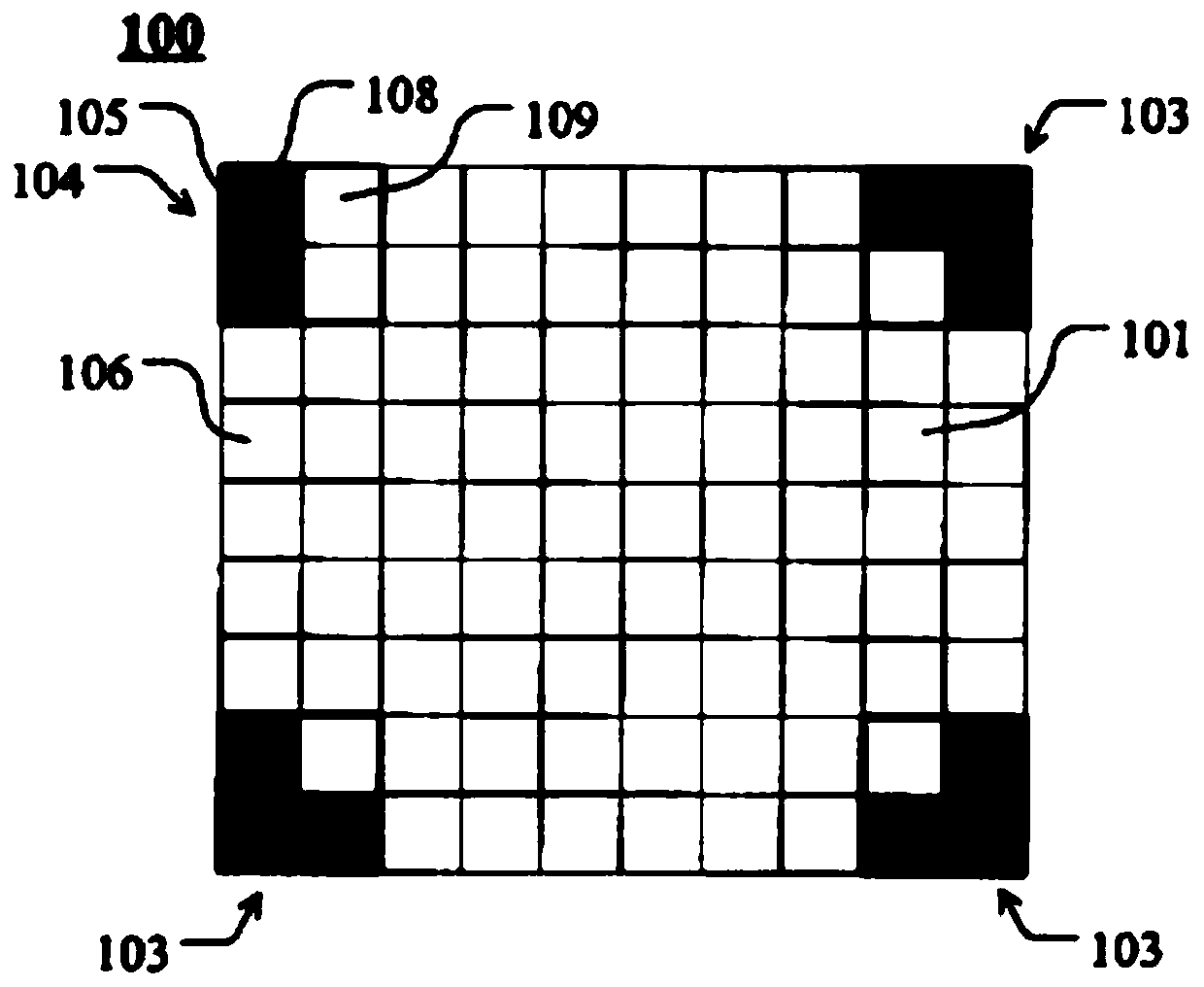

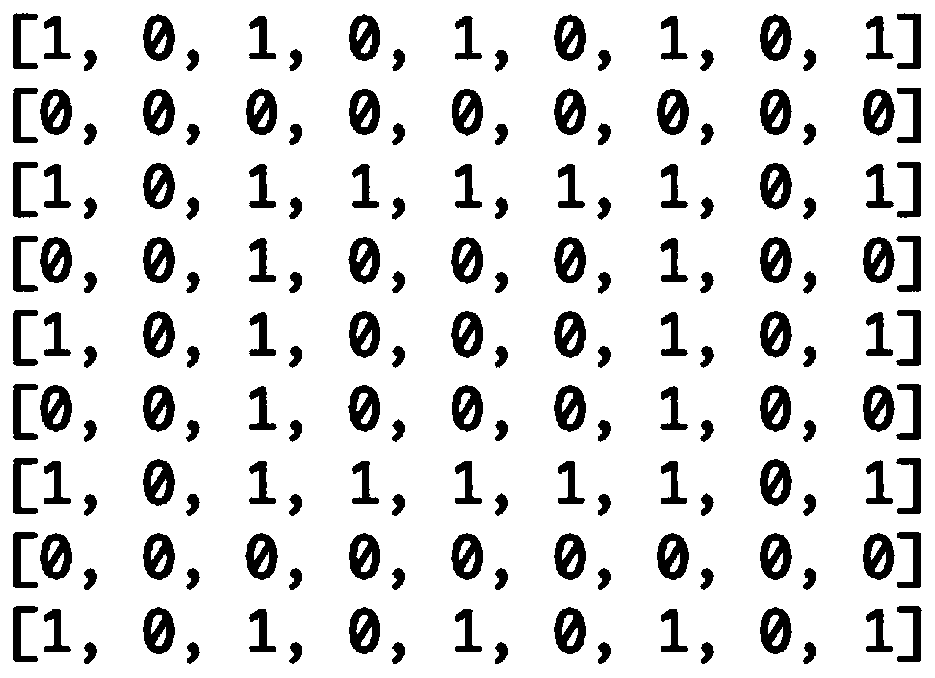

A quick positioning two-dimensional code positioning point lattice forming and capturing method

ActiveCN109740404AImprove reliabilityImprove the resolution and recognition rateSensing by electromagnetic radiationAlgorithmDot matrix

The invention relates to the field of data identification, in particular to a two-dimensional code forming and capturing technology. The invention provides a quick positioning two-dimensional code positioning point dot matrix forming and capturing method. The two-dimensional code positioning point dot matrix forming method comprises the following steps: setting or reading a positioning point datadot matrix; drawing four centrosymmetric main positioning point lattices on a set background; and adding a positioning interval area to the periphery of the main positioning point dot matrix. The technical problems of long positioning time consumption and high positioning error rate during two-dimensional code identification are solved, the reliability of two-dimensional code positioning is enhanced, the identification efficiency is improved, and the pollution of positioning points and data is reduced.

Owner:UNI2K INFORMATION TECH CO LTD

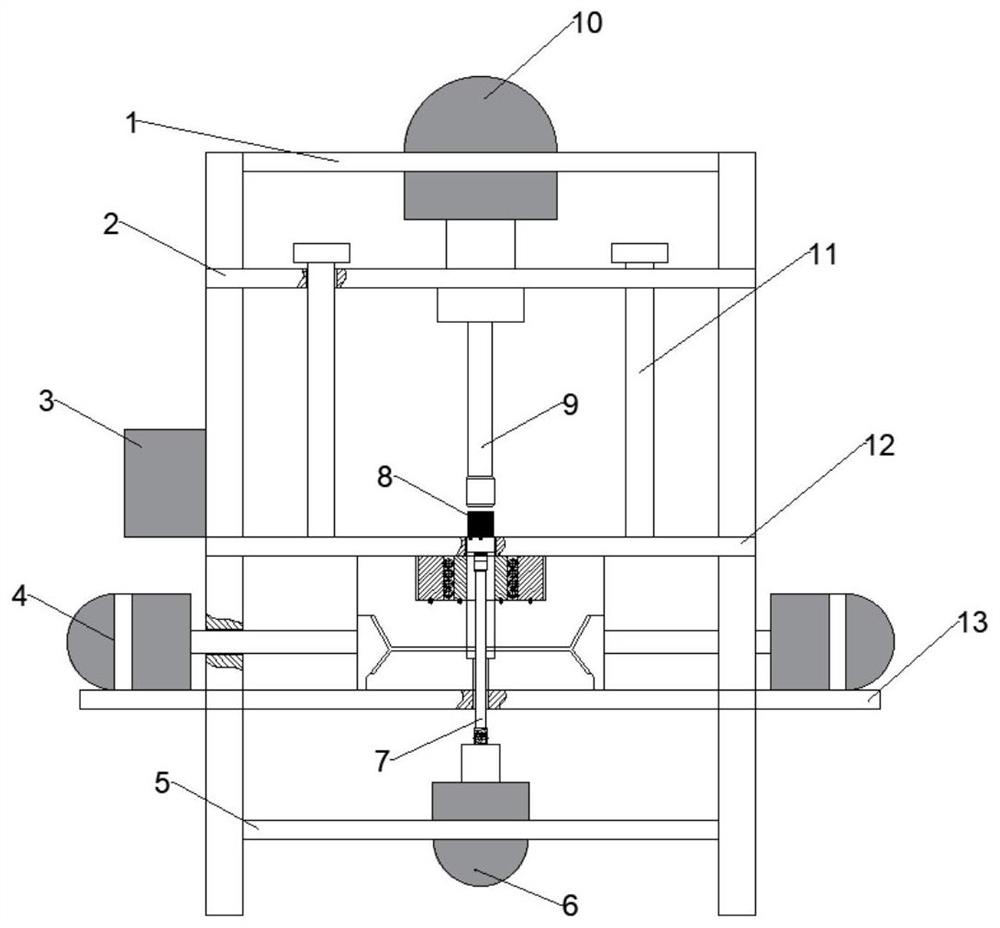

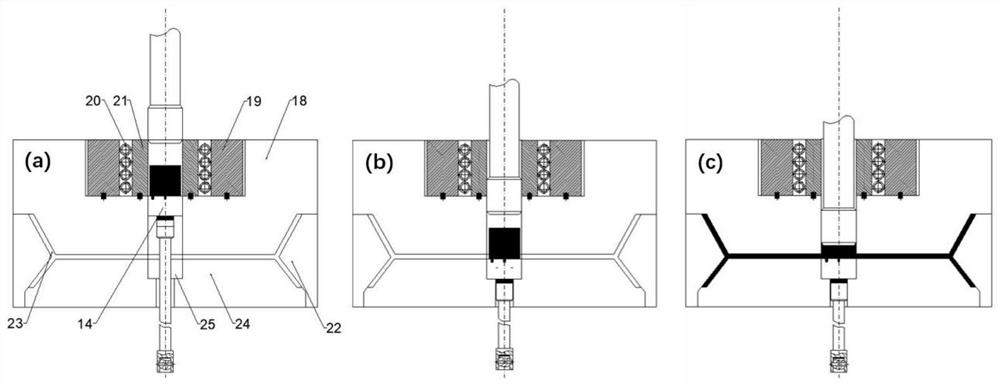

A method and device for in-situ preparation and molding of aluminum/magnesium alloy semi-solid slurry

ActiveCN111069566BReduce lossesSolve industrial technical problems with large lossesSemi solidSlurry

The invention provides a method and device for in-situ preparation and molding of aluminum / magnesium alloy semi-solid slurry. The device includes a squeeze casting machine and an in-situ heating system with semi-solid slurry arranged in the squeeze casting machine The mold includes an upper mold, a lower mold, a side mold and a mold cavity formed by the upper mold, the center of the upper mold is provided with a semi-solid blank in-situ heating cavity connected to the mold cavity, and the semi-solid blank / The outside of the slurry in-situ heating chamber is equipped with an in-situ heating system. The forming method includes: A. loading of semi-solid billet; B. preparation of semi-solid slurry; C. extrusion casting of semi-solid slurry; D. opening mold and taking out casting. The method can effectively reduce the heat loss in the transfer process of the semi-solid slurry, improve the formability and process stability of the semi-solid slurry, shorten the time required for the preparation of the semi-solid slurry by electromagnetic induction heating, and significantly reduce the equipment of the squeeze casting machine. Cost, and at the same time more conducive to the realization of mechanization and safe production.

Owner:SHANGHAI JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com