A method and device for in-situ preparation and molding of aluminum/magnesium alloy semi-solid slurry

A technology of semi-solid slurry and forming device, which is applied in the field of in-situ heating preparation and extrusion casting of aluminum/magnesium alloy semi-solid slurry, which can solve the problem of temperature inhomogeneity, heating temperature of long ingot, heating to reduce electromagnetic induction Heating rate and other problems, to achieve the effect of short transfer time, small heat loss and solving large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

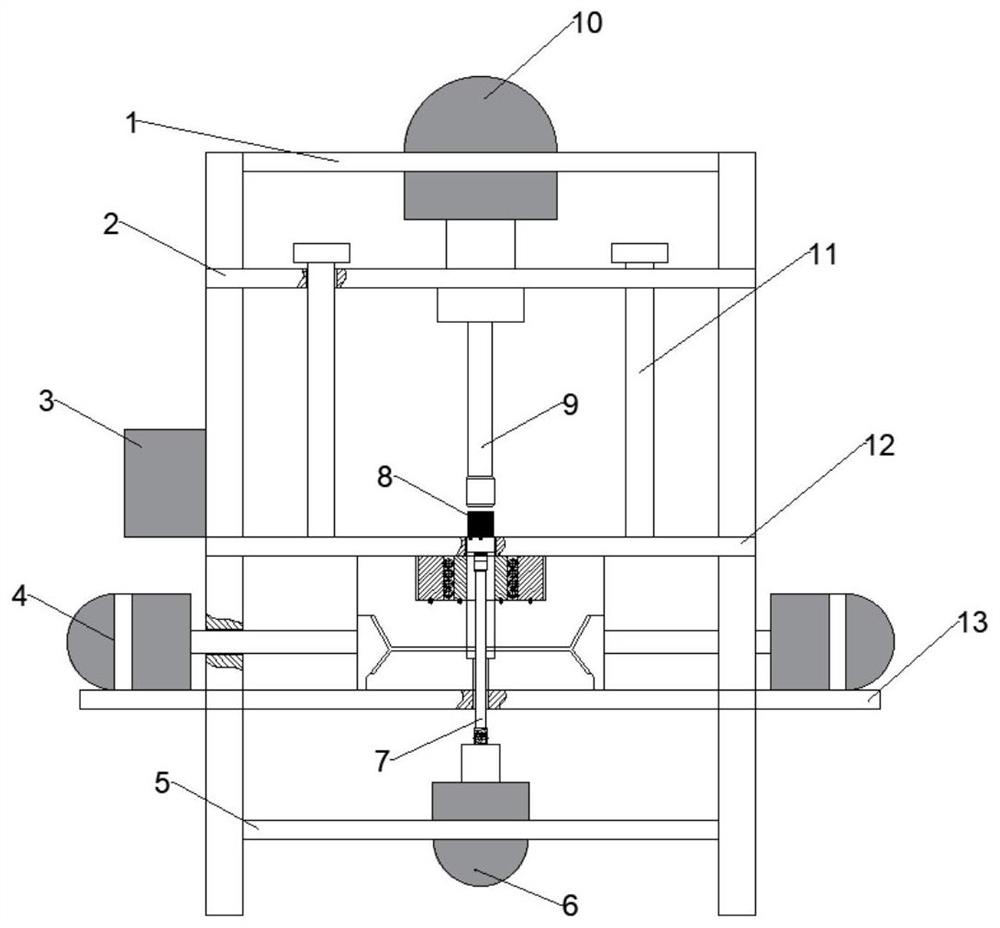

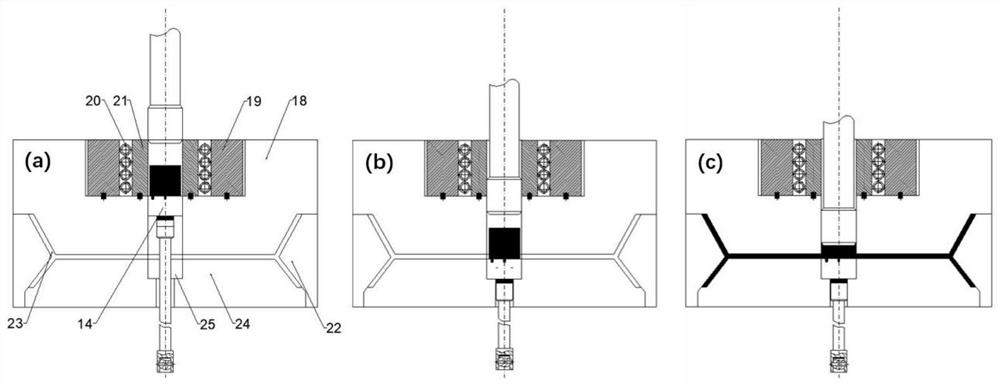

[0061] This example is the preparation of A356.2 aluminum alloy automobile wheel hub by in-situ heating preparation of aluminum / magnesium alloy semi-solid slurry and extrusion casting molding method. The schematic diagram of the device used is as figure 1 and image 3 As shown, the schematic diagram of the process principle is shown in figure 2 shown.

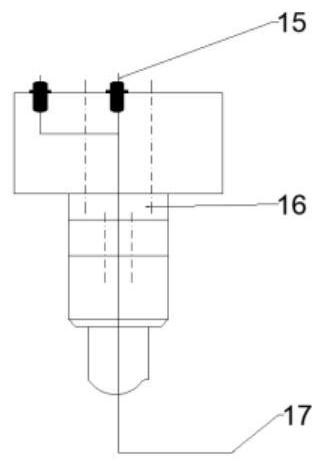

[0062] The aluminum / magnesium alloy semi-solid slurry in-situ heating and squeeze casting molding device includes a squeeze casting machine and a mold with a semi-solid slurry in-situ heating system arranged in the squeeze casting machine. A mold with a semi-solid slurry in-situ heating system includes an upper mold 18, a lower mold 24, a side mold 22 and a mold cavity 23 formed therefrom, and the center of the upper mold 18 is provided with a semi-solid blank connected to the mold cavity an in-situ heating chamber, an in-situ heating system is arranged outside the in-situ heating chamber for the semi-solid billet / slurry; ...

Embodiment 2

[0085] This example is the preparation of AZ91D magnesium alloy automobile wheel hub by in-situ heating preparation of aluminum / magnesium alloy semi-solid slurry and extrusion casting molding method.

[0086] The equipment that adopts is identical with embodiment 1. The AZ91D semi-solid billet has a diameter of 200mm and a height of 150mm, which is prepared by electromagnetic stirring semi-continuous casting.

[0087] Concrete preparation steps are as follows:

[0088] Step 1: Loading of semi-solid billet: 16-inch magnesium alloy automobile wheel mold is closed under the action of a 350-ton squeeze casting machine oil cylinder. The wheel mold is composed of upper, lower, left and right parts. The initial temperature of the mold is 300-350 °C . After the mold is closed, the supporting plate is moved up until its upper surface is flush with the upper surface of the upper mold seat plate, and the preheated magnesium alloy semi-solid blank (solid) is put in by the manipulator. T...

Embodiment 3

[0100] Using the equipment and method shown in Example 1, the A365.2 ingot with a diameter of 200 mm and a height of 150 mm is used to heat the semi-solid slurry in situ to prepare the semi-solid slurry, and the liquid phase ratio can be obtained in 6 minutes. 55% semi-solid slurry. And the disclosed semi-solid slurry of existing device (the semi-solid metal blank automatic continuous secondary heating device disclosed in CN201310521522.1) The preparation time is 10 minutes, and it can be seen that the semi-solid slurry pulping time shortened by more than 40% by adopting the equipment of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com