Off-axis MEMS micro-mirror and preparation method thereof

A technology of the first micro-mirror and micro-mirror, applied in the field of micro-electromechanical, can solve the problems of difficulty in two-way driving signals, difficulty in synchronizing sending and receiving of lidar systems, differences in driving frequency, angle, and phase difference, etc., to prevent short circuits, reduce The effect of tape-out cost and process error reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

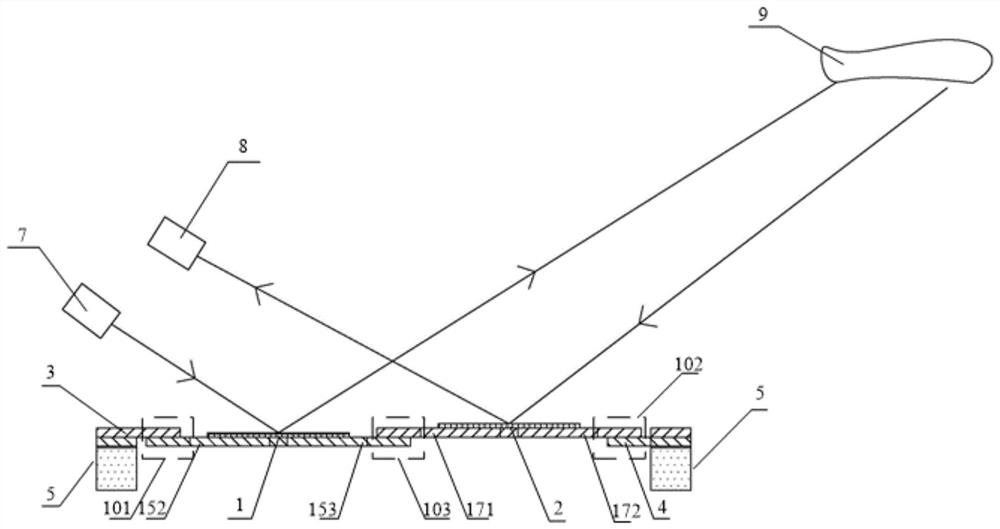

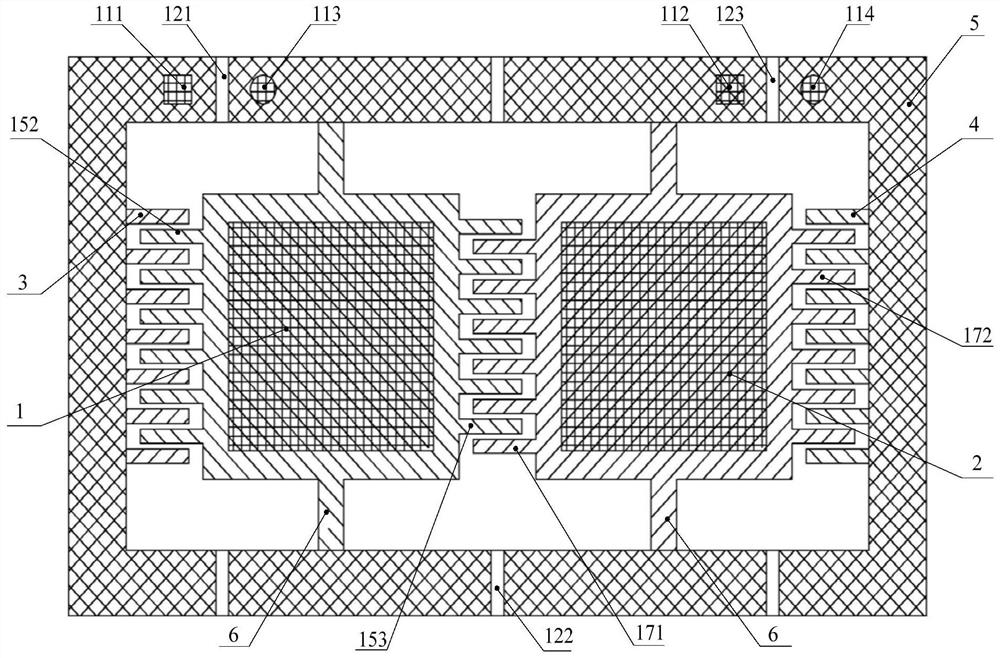

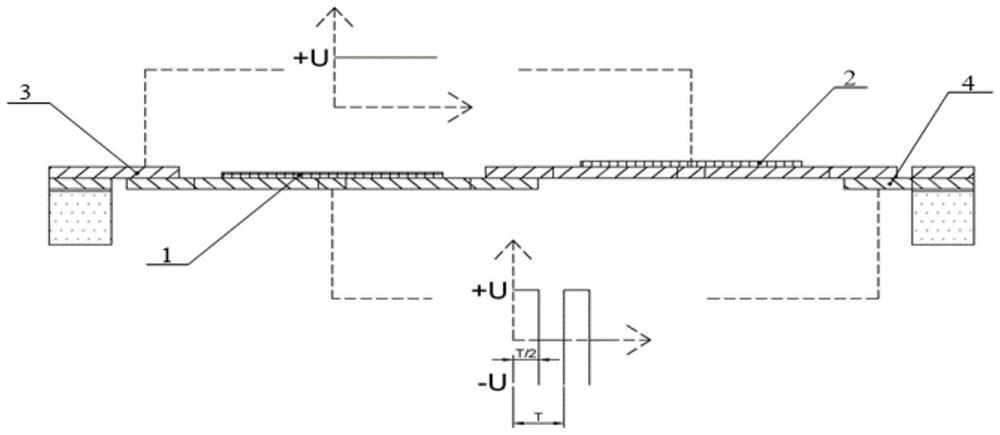

[0035]The application discloses an off-axis MEMS micromirror, combined with figure 1 , figure 2 As shown, it includes a first micromirror 1, a second micromirror 2, a first fixed comb 3, a second fixed comb 4, a driving electrode, a frame 5 and an isolation groove, the first micromirror 1 and the second micromirror 2 The first inner side of the frame 5 is connected by two symmetrical rotating shafts 6, each group of rotating shafts 6 is located on the central axis of the respective micromirror, and the first micromirror 1 and the second micromirror 2 rotate synchronously around the rotating shaft 6. The off-axis MEMS micromirror is used in conjunction with the light source 7 and the detector 8, where the light source 7 provides the incident laser light, the detector 8 receives the reflected laser light, the first micromirror 1 is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com