Clamp special for machining valve block of pneumatic roof bolter

A technology of rock bolt rig and valve block, which is applied in the direction of drilling templates for workpieces, metal processing machinery parts, manufacturing tools, etc., and can solve the problems of unguaranteed hole spacing, unstable product quality, and low working accuracy. Achieve the effect of simple structure, reduce process error and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

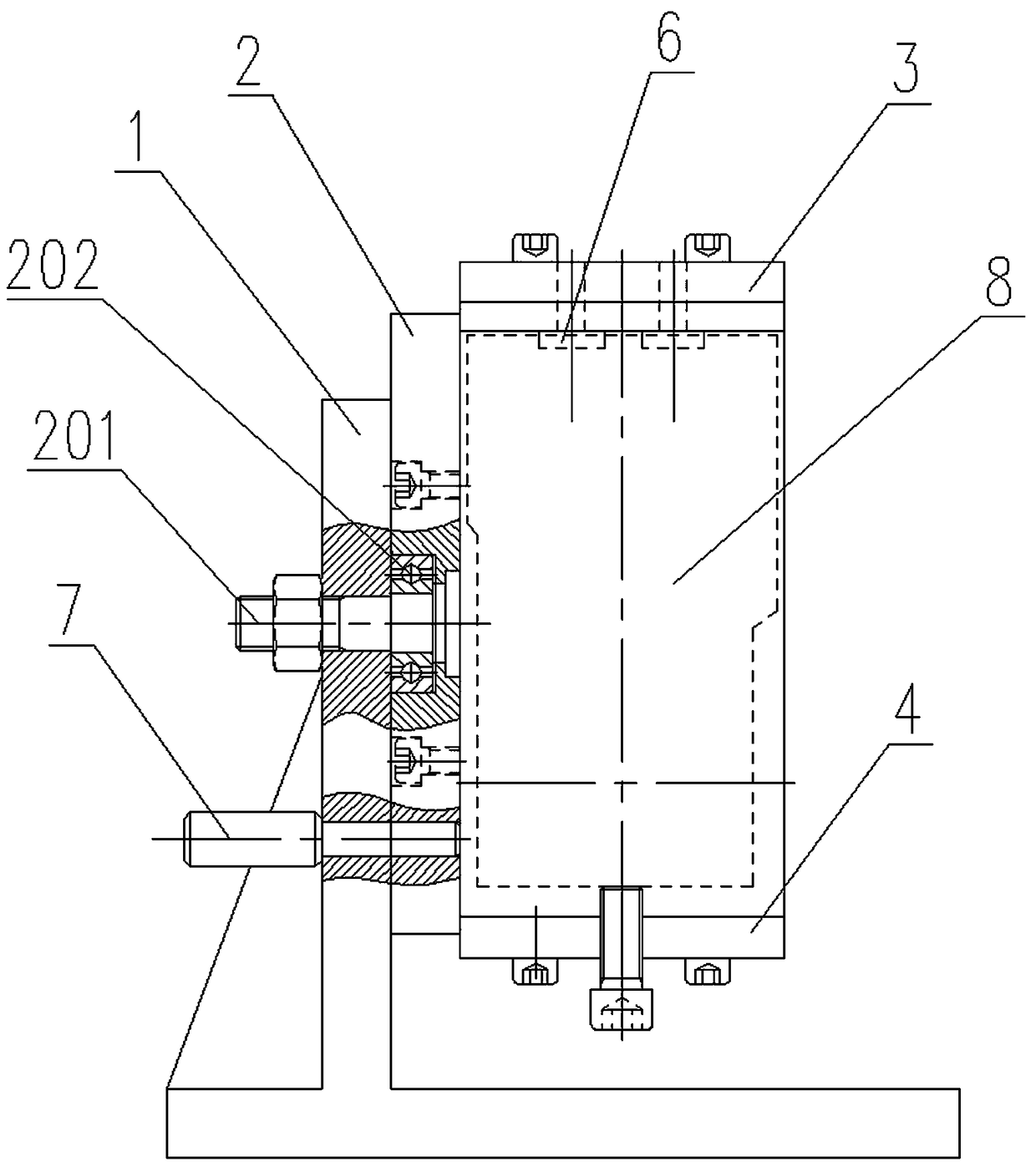

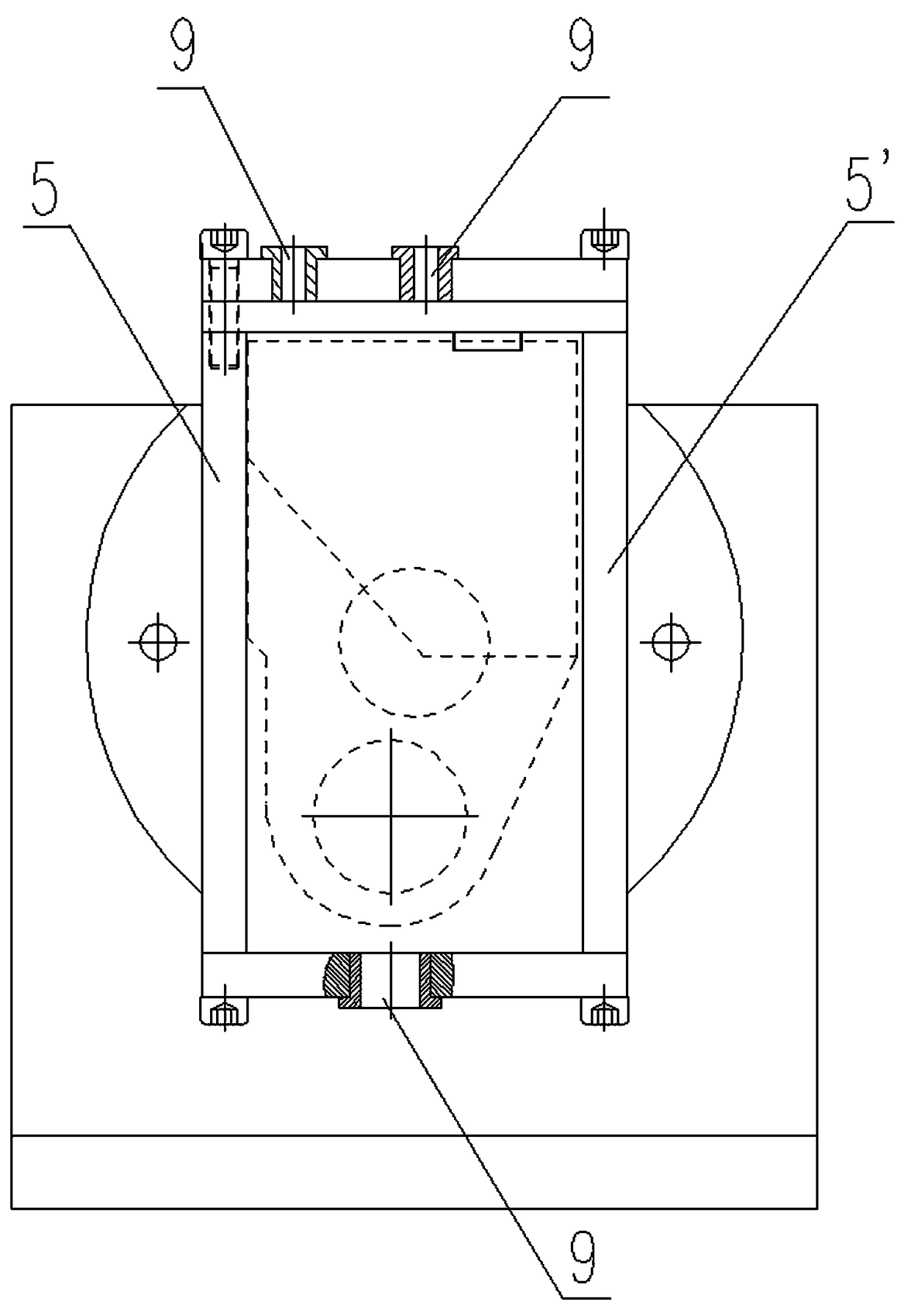

[0009] The fixture specially used for processing the valve block of the pneumatic rock drill according to the present invention will be further described in detail below in conjunction with the accompanying drawings. The accompanying drawings constituting this application are used to provide a further understanding of the present invention, and the schematic embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute improper limitations to the present invention.

[0010] Depend on figure 1 , figure 2 It can be seen that the fixture of this embodiment, which is specially used for processing the valve block of a pneumatic rock bolt, is characterized in that it includes a fixed support 1, and a disc 2 is arranged on one side of the fixed support 1, and the disc 2 2 is connected to the fixed support 1 through the mandrel assembly 201; the mandrel assembly 201 includes a bearing 202 arranged at one end of the disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com