Rolling device

A technology for rolling punching and punching needles, applied in the field of rolling punching devices, can solve the problems of additional unloading equipment or manual unloading, damage to punching needles or die, and high labor costs, so as to save assembly costs and avoid punching needle damage. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

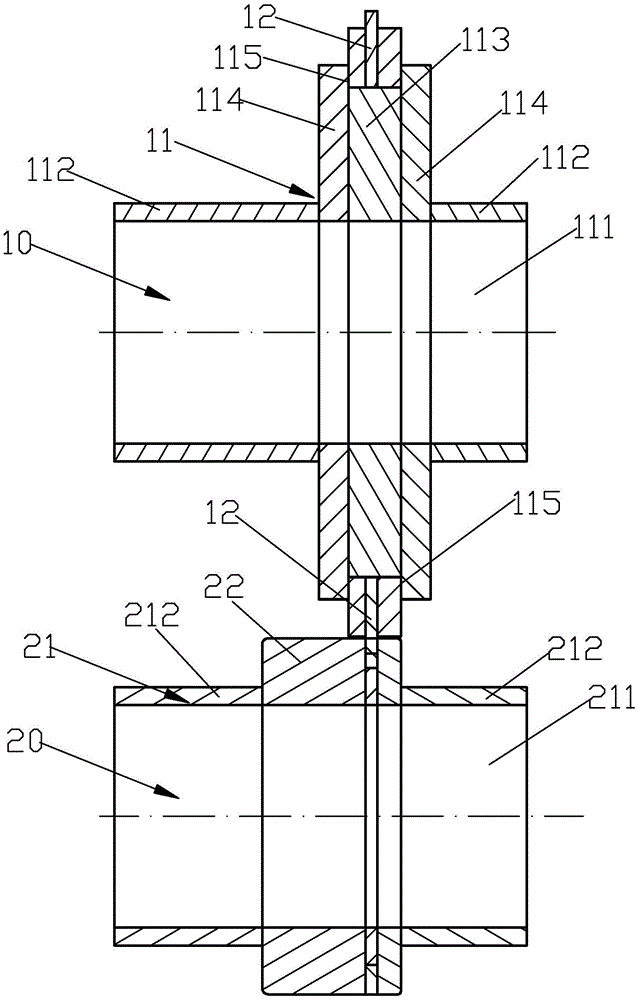

[0016] Please check figure 1 , a rolling device, including a frame, a rotatable first roller unit 10 arranged on the frame and a second roller unit 20 rotatably arranged on the frame. The axis of rotation of the first roller unit 10 is parallel to the axis of rotation of the second roller unit 20 . In this embodiment, the rolling device is more effective for rolling thin metal plates, such as thin plates with a thickness less than 0.5mm, and metals such as steel plates.

[0017] The first roller unit 10 includes a first rigid wheel 11 and at least one punching pin 12 disposed on the first rigid wheel 11 , of course, the tip of the punching pin 12 protrudes from the outer rotating surface of the first rigid wheel 11 . Preferably, the punching pins 12 are detachably fixed on the first rigid wheel 11, the number of the punching pins 12 is multiple, and the multiple punching pins 12 are evenly spaced in a ring. In this embodiment, the first rigid wheel 11 includes a first rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com