Patents

Literature

97results about How to "Punch stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

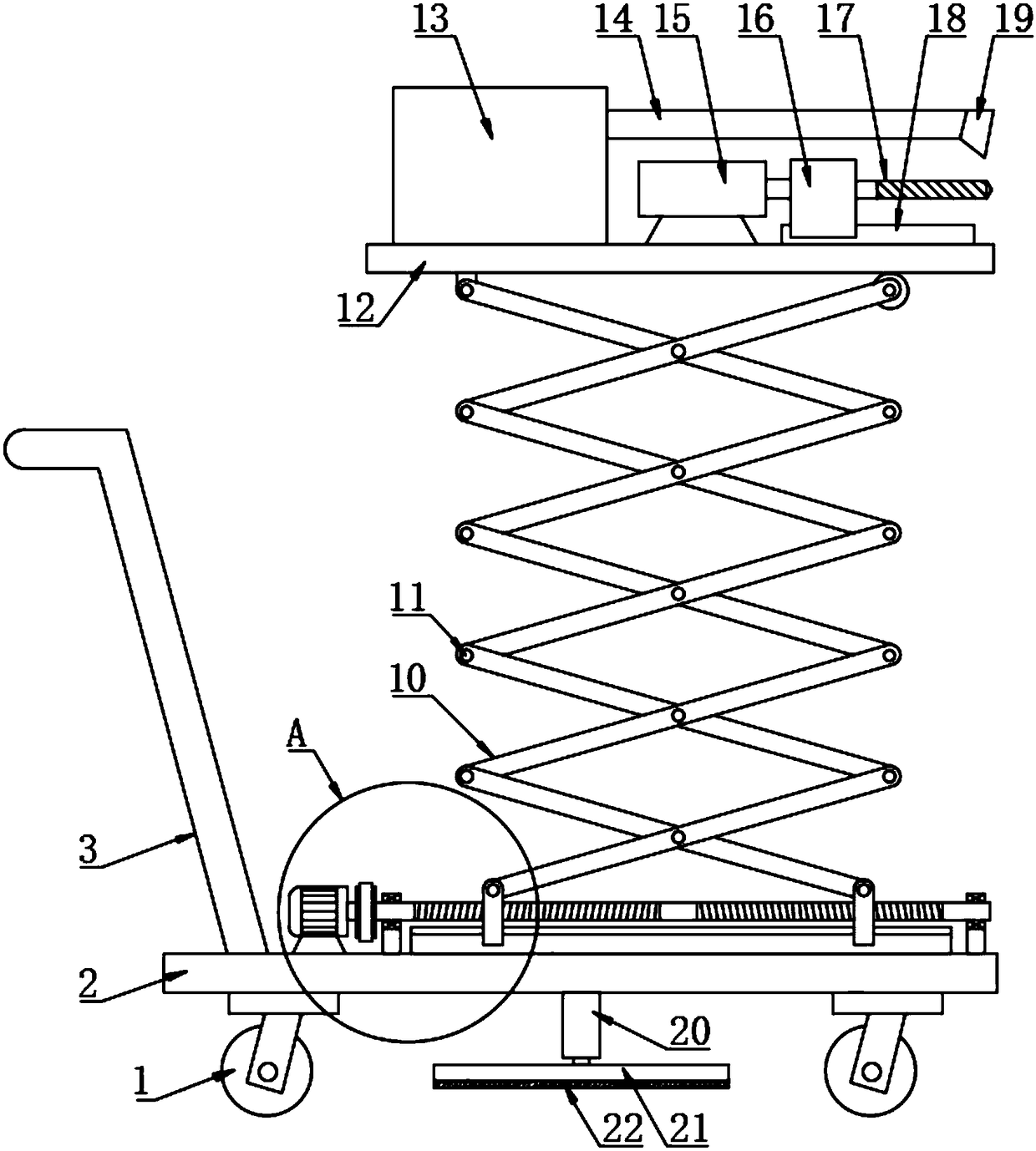

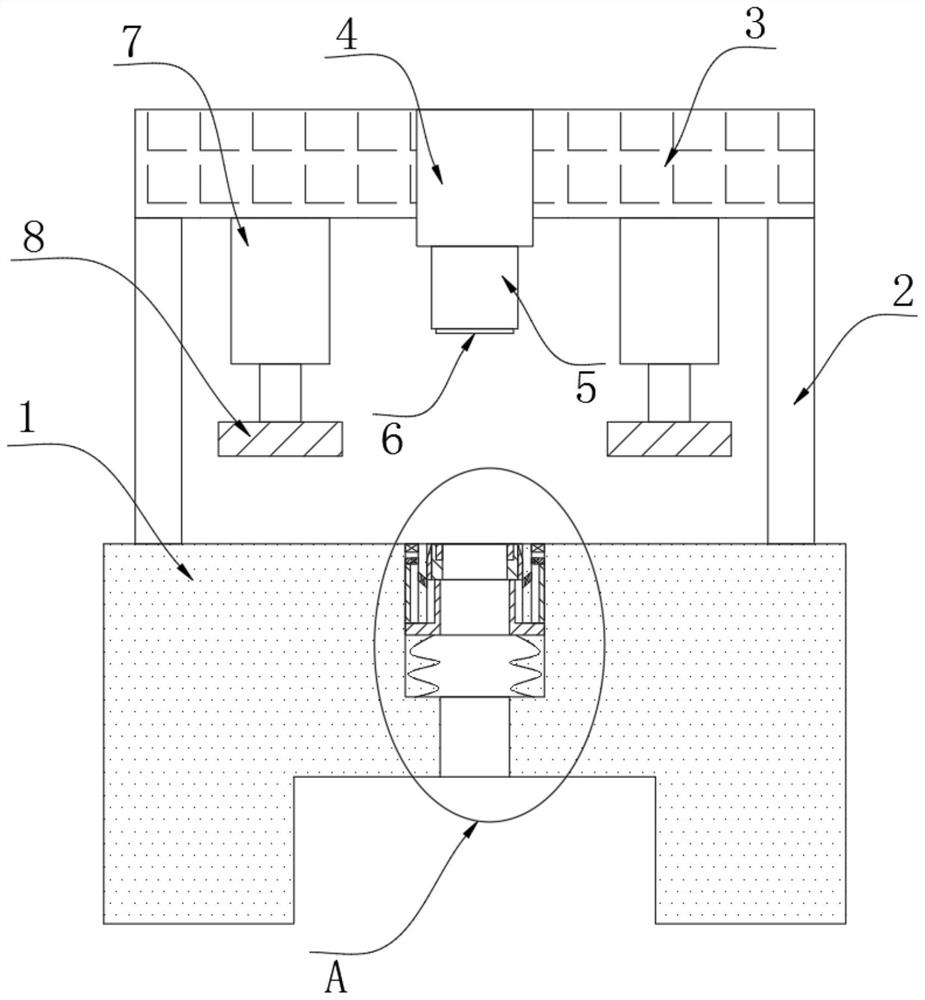

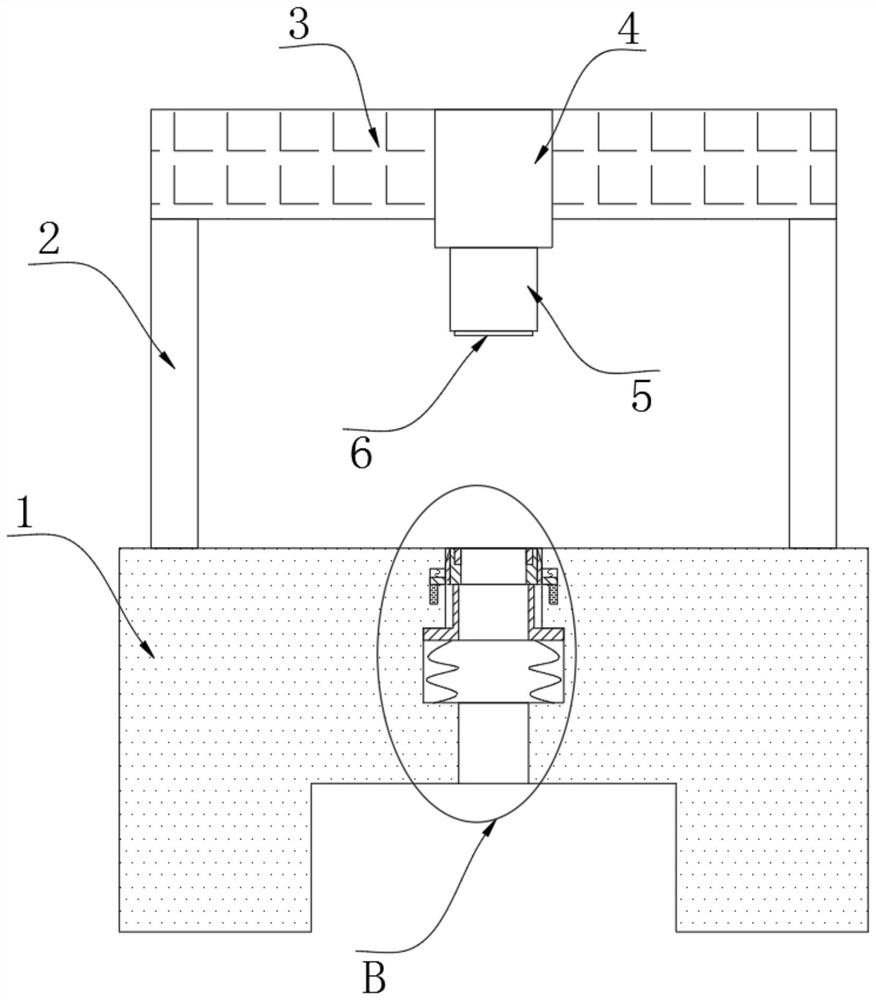

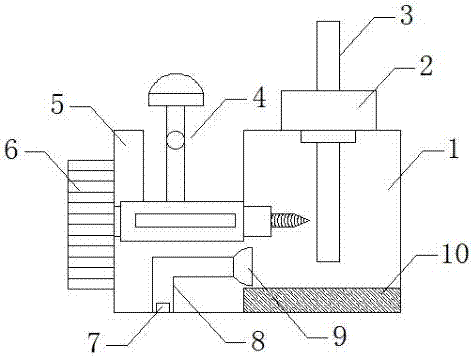

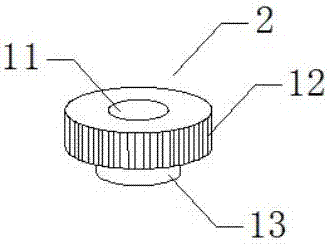

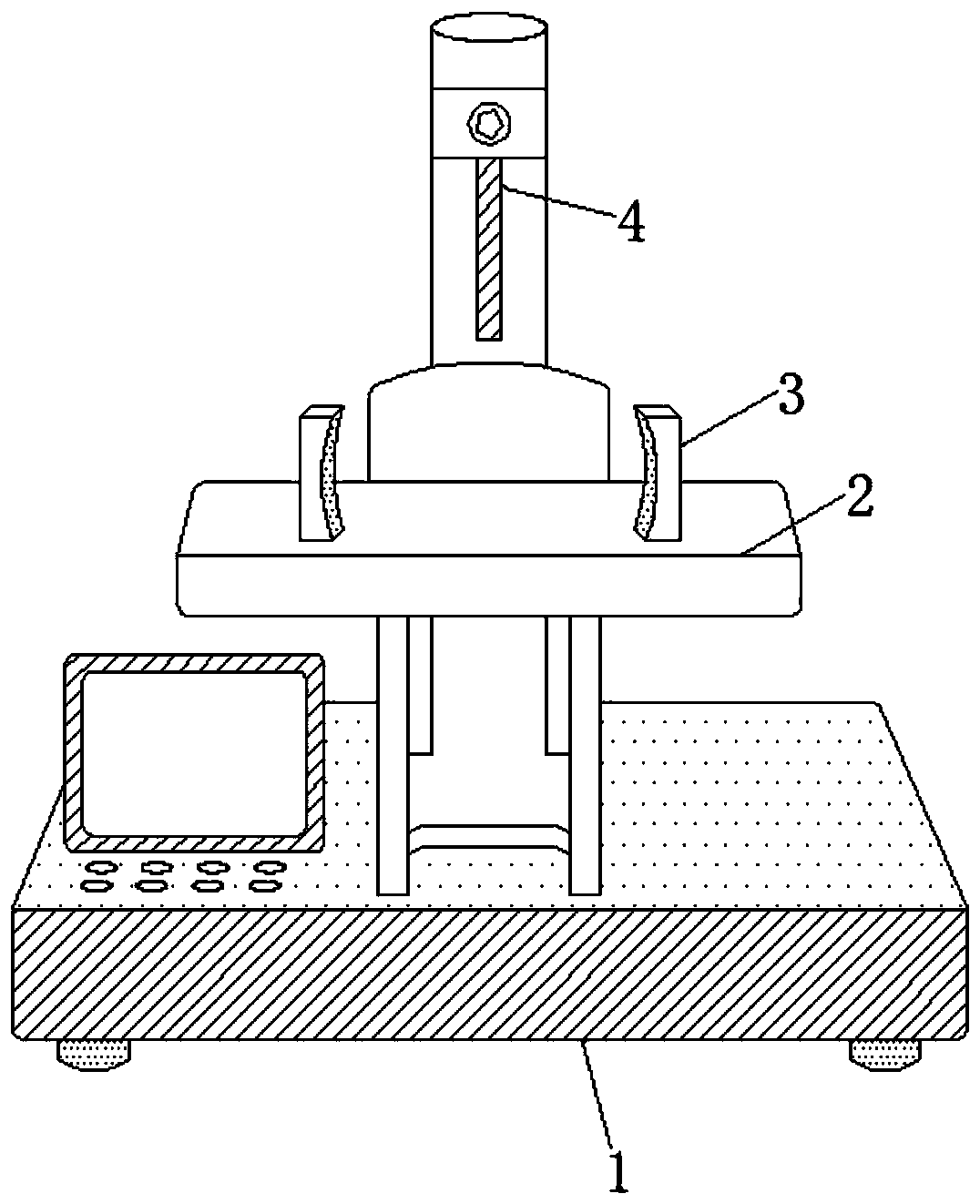

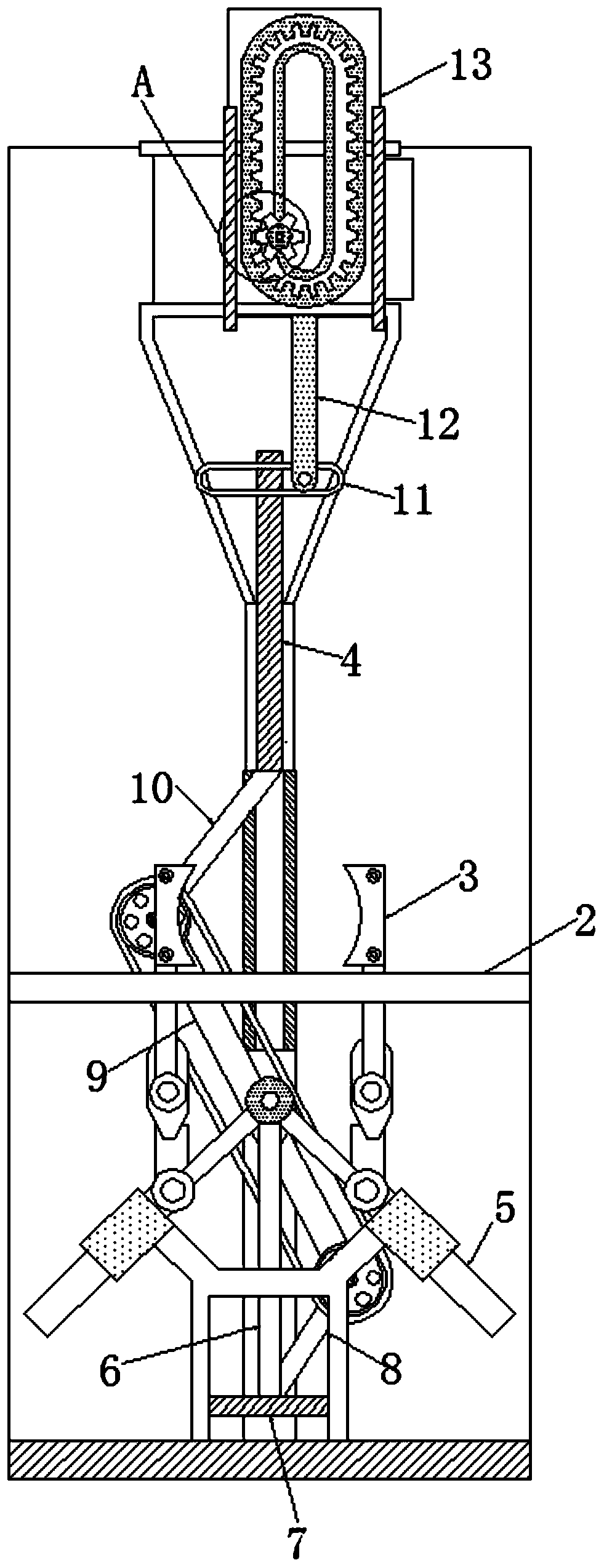

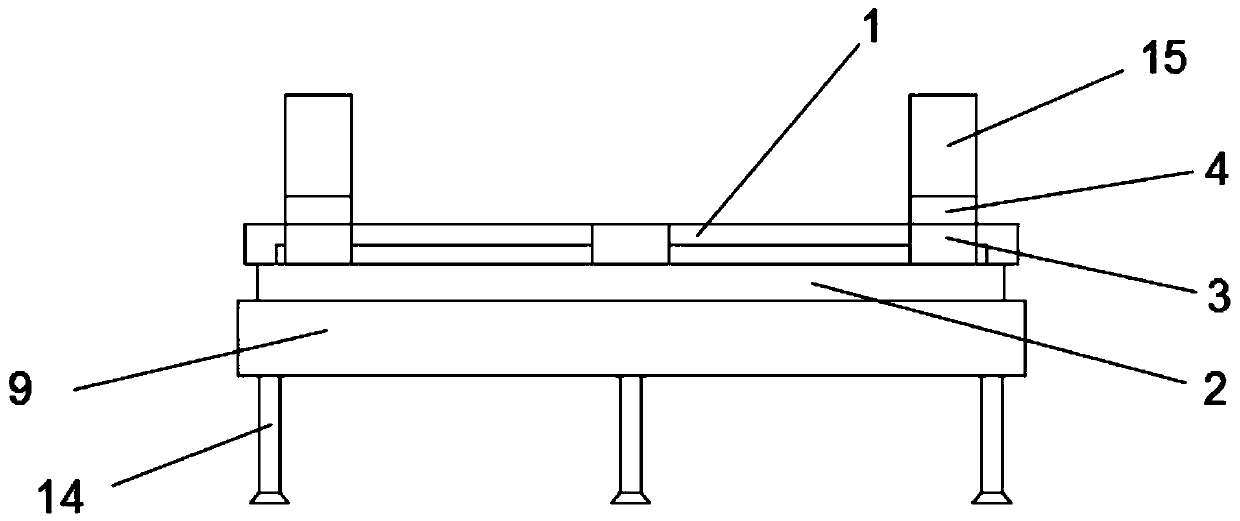

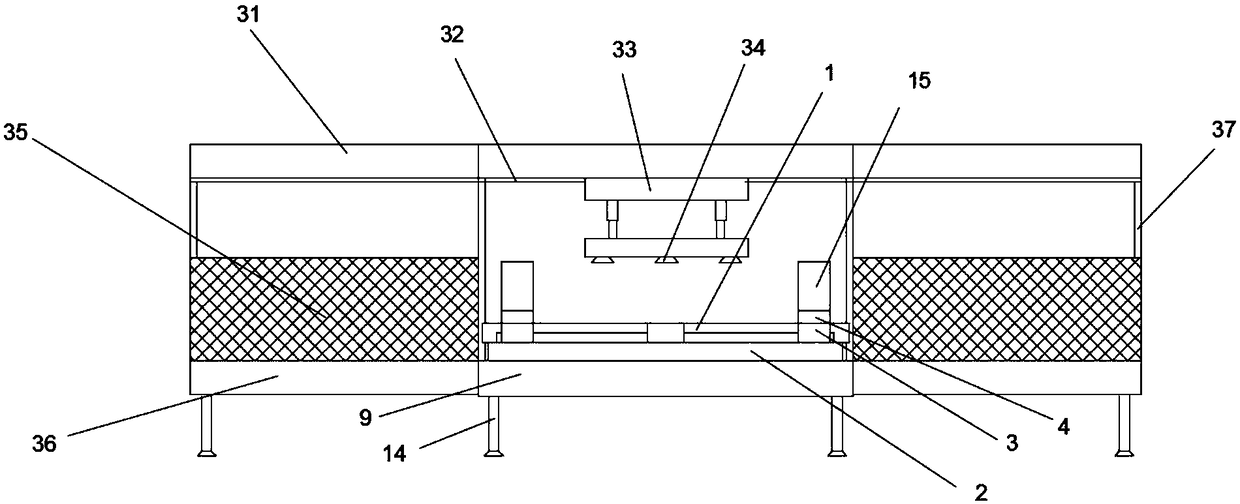

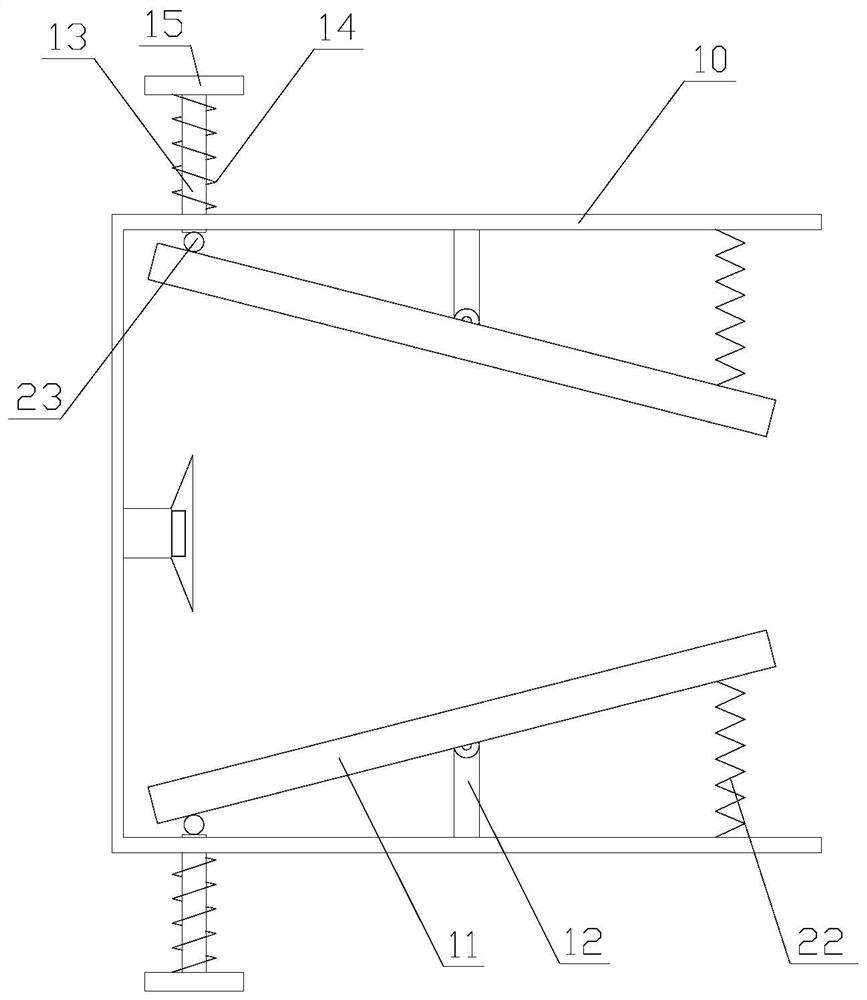

Stable scissor lifting wall surface punching device

InactiveCN108127798AAvoid the hassle of climbingAvoid dangerWorking accessoriesStone-like material working toolsPunchingEngineering

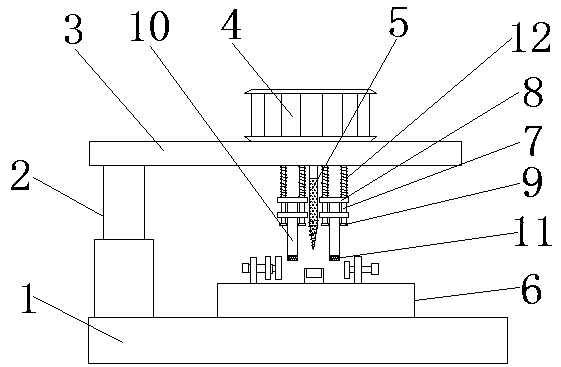

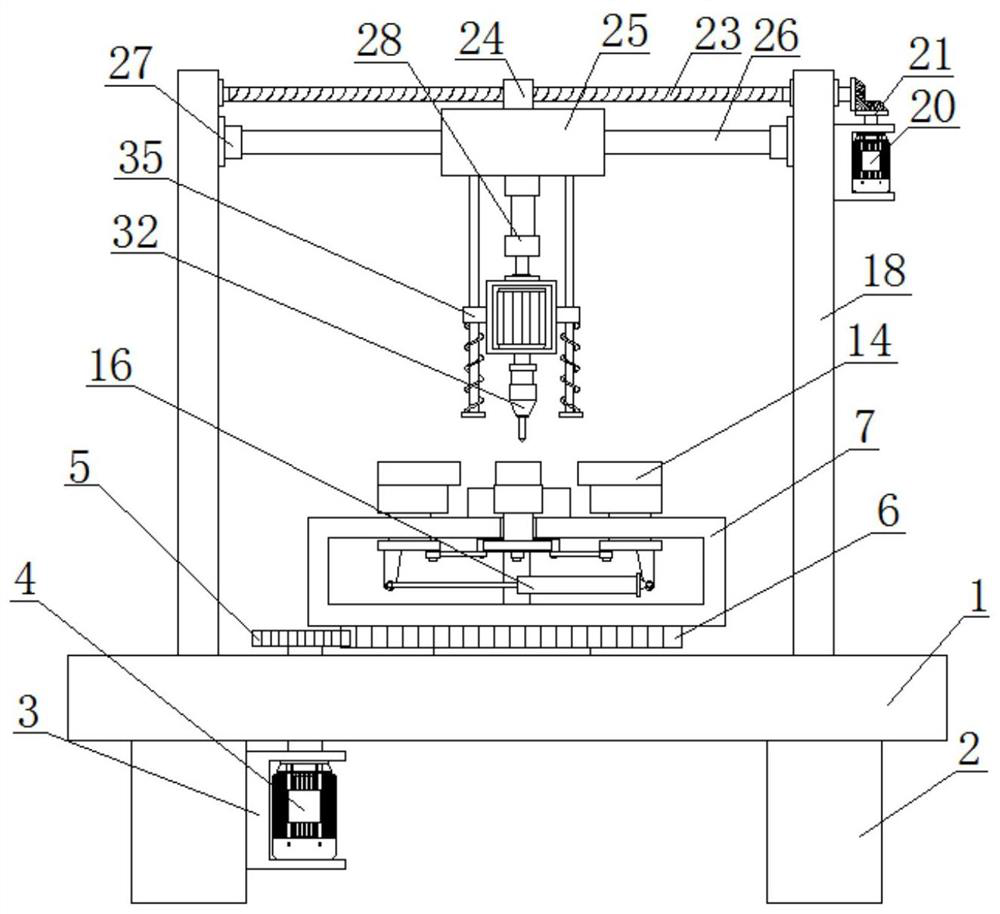

The invention discloses a stable scissor lifting wall surface punching device. The device comprises a base, the top of the base is provided with two front and rear slide rails, each of the slide railsis slidably connected with two left and right movable seats, supporting rods are hinged above the movable seats, the left and right supporting rods are cross-arranged, and the middles of the left andright supporting rods are hinged;a plurality of pairs of supporting rods are provided, the bottom ends of the upper supporting rodsare hinged to the top ends of the lower supporting rodsthrough connecting rods,the front supporting rods and the rear supporting rodsare connected through the connecting rod, andtop platesare arranged above the supporting rods; the top of the base is also fixedly provided with a gear motor, and a motor shaft at the right end of the gear motor is connected with the left end of a front side screw rod; the top of the top plate is fixedly provided with an electric push rod,the right end of the electric push rod is fixedly connected with an electric drill, and a drill bit is connected to the right side of the drill. According to the device, punching heights are adjusted by a scissor lifting mechanism,the punching heights can be achieved by controlling the forward and reverse rotation of the gear motor, the control is simple, andtrouble and danger caused by climbing of a person with the electric drill in hands are avoided.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

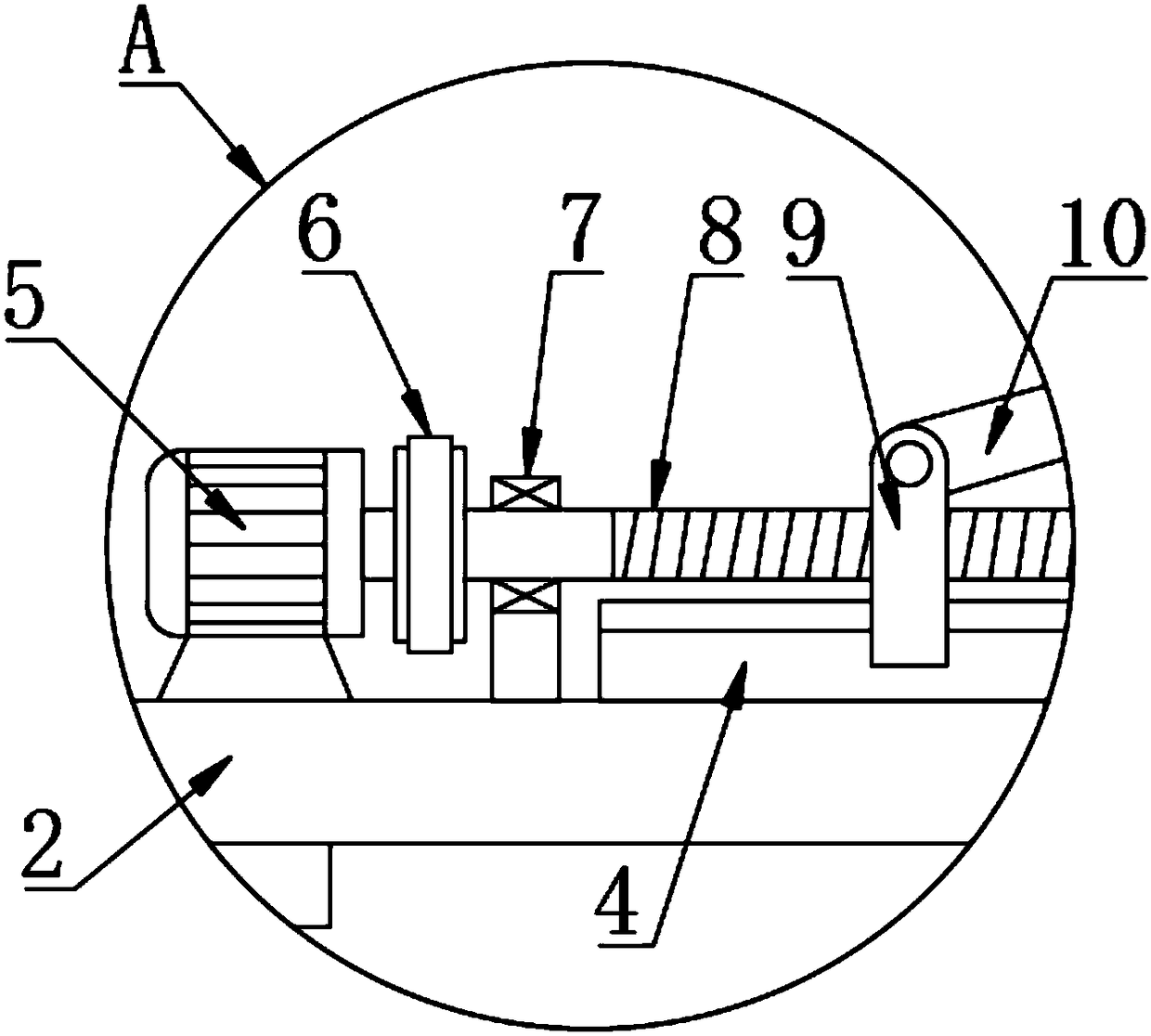

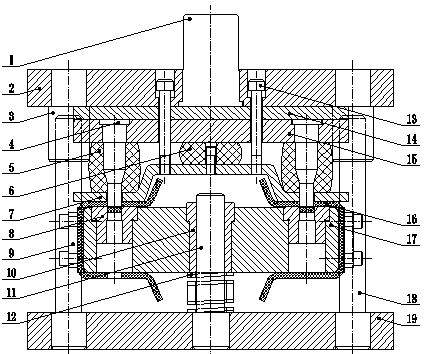

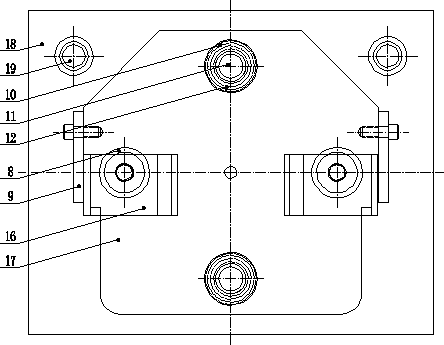

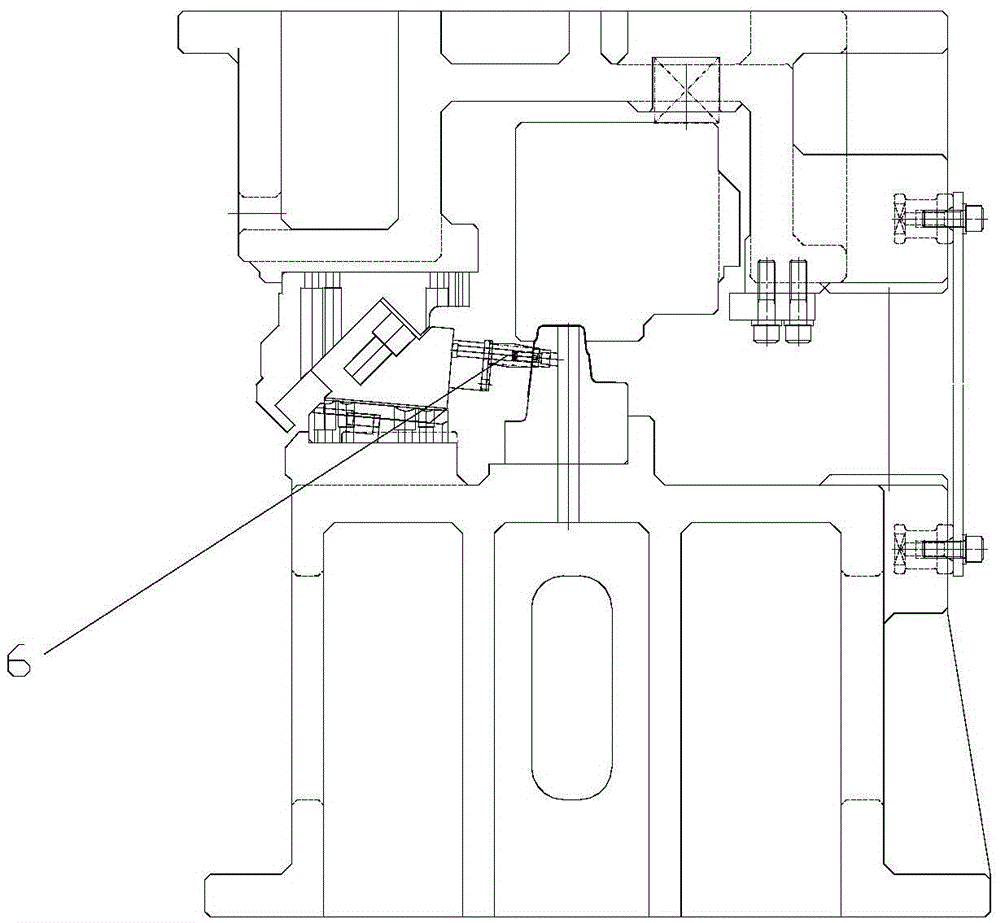

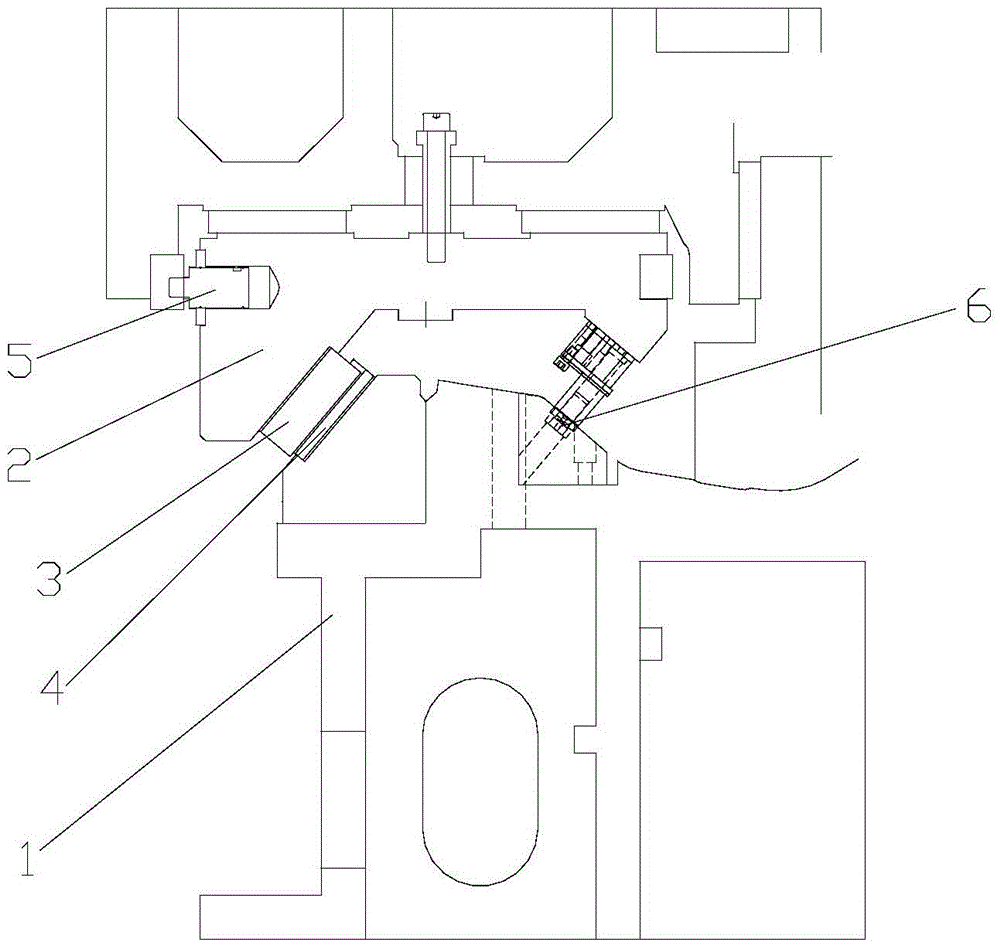

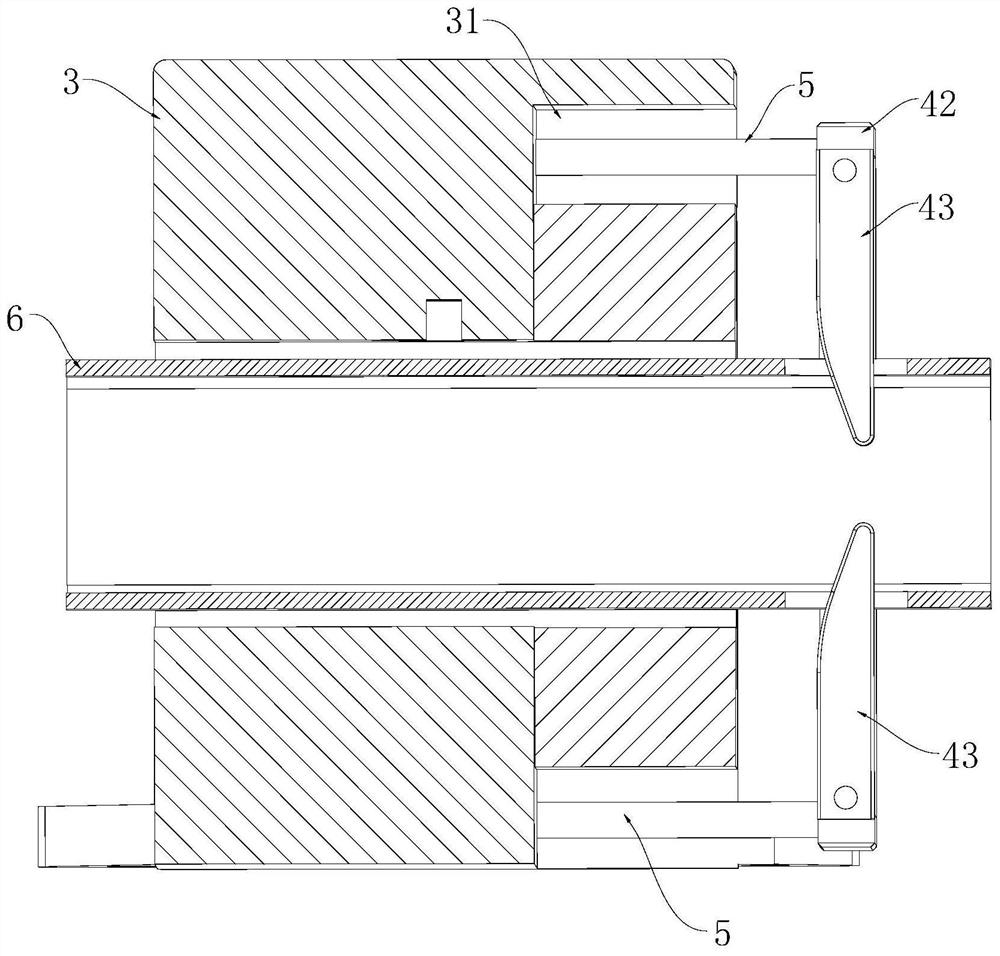

Automobile tray bearing nut locking gasket blanking-molding-punching composite die and process thereof

The invention discloses an automobile tray bearing nut locking gasket blanking-molding-punching composite die. The automobile tray bearing nut locking gasket blanking-molding-punching composite die comprises an upper die and a lower die, wherein the upper die comprises a die handle, an upper template, an upper base plate, an upper fixing plate and an upper discharging plate which are tightly connected in sequence from top to bottom; a blanking-molding-punching punch-die is arranged inside the upper fixing plate; the lower die comprises a blanking female die, a punching male die outer fixing plate, a lower base plate and a lower template which are tightly connected in sequence from top to bottom; a molding female die is arranged in the middle of the blanking female die; a punching male die inner fixing plate is arranged in the middle of the punching male die outer fixing plate; a punching male die is arranged in the middle of the punching male die inner fixing plate; the blanking-molding-punching punch-die, the molding female die and the punching male die form a molding die cavity for workpieces. The molding male die and the punching female die are compounded integrally, so that molding and punching are realized during blanking of blanks, the blank molding and punching processes are stable, and regular appearances and stable strength performance of bearing nut locking gaskets are ensured.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

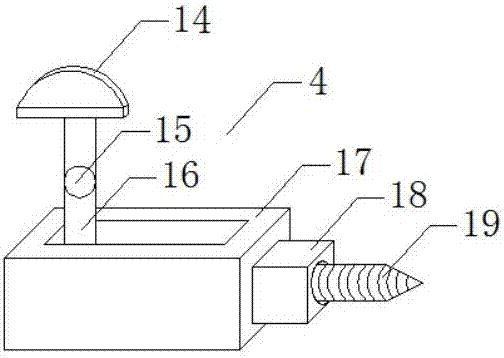

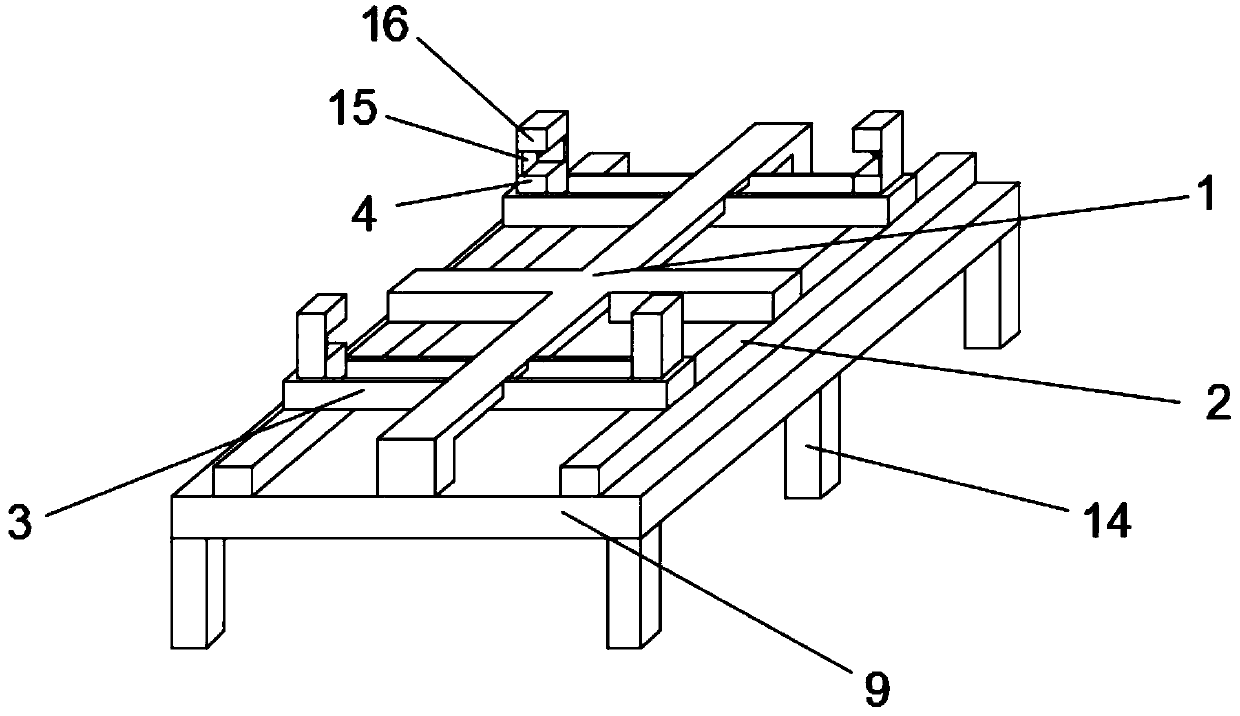

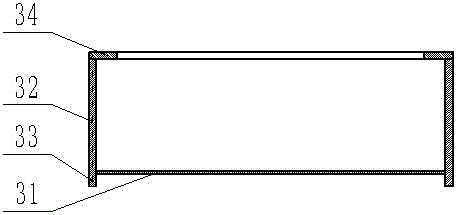

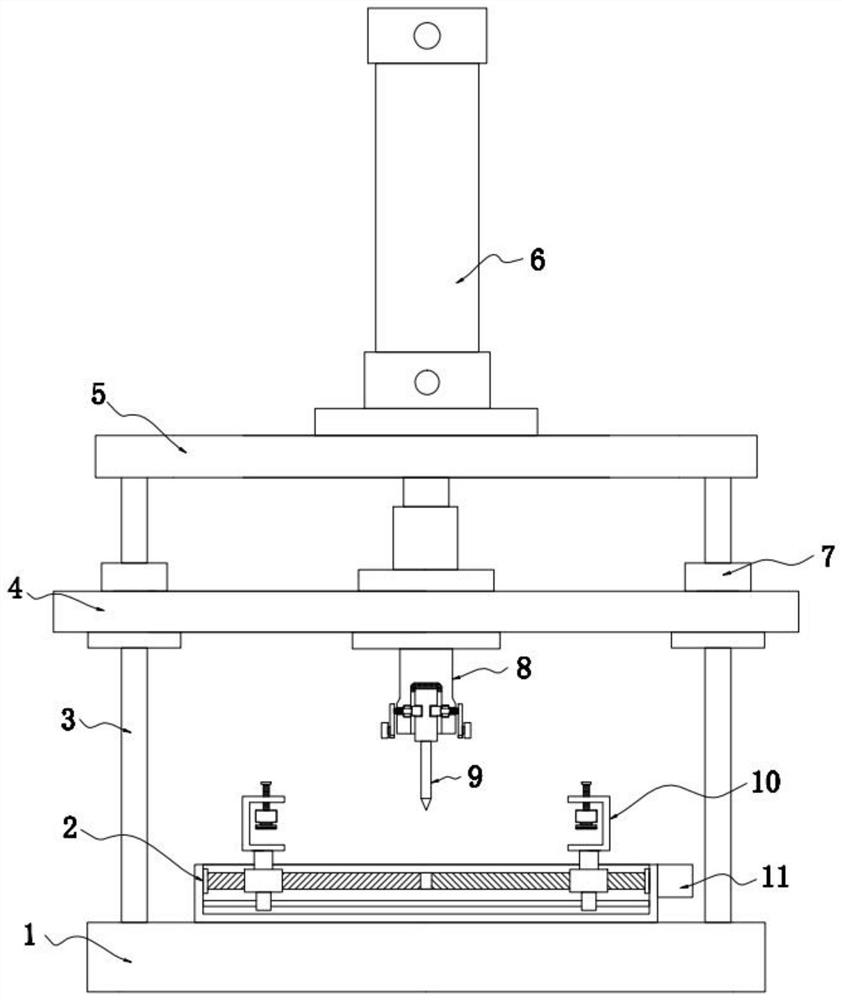

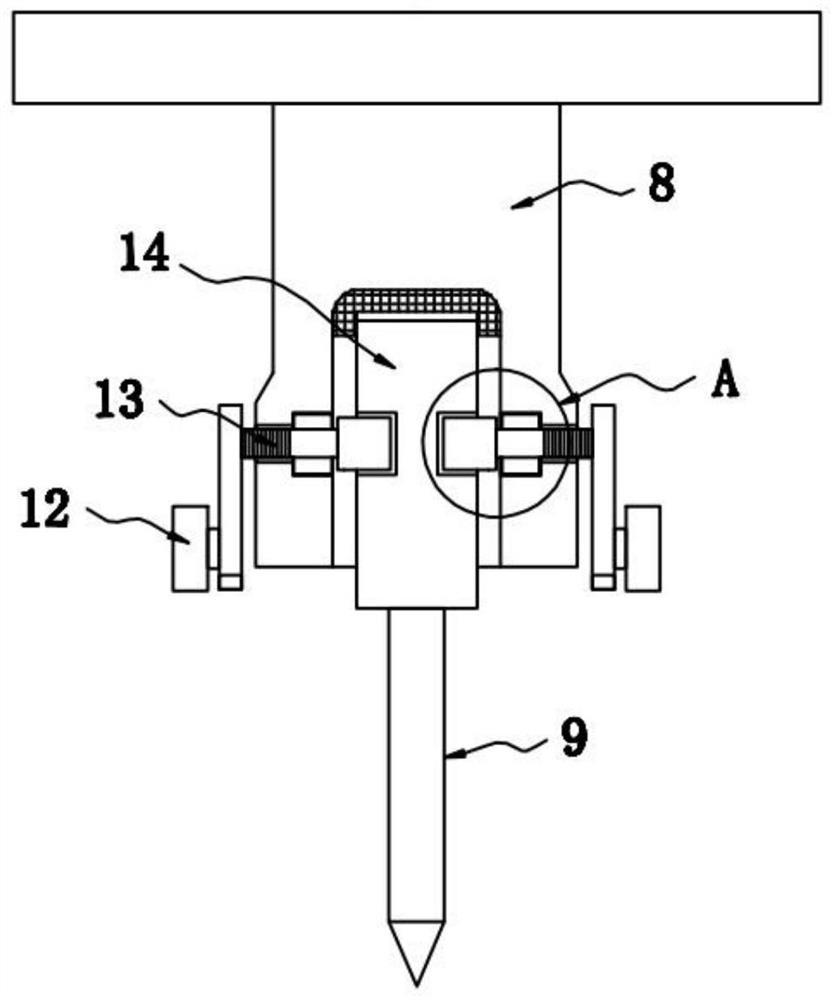

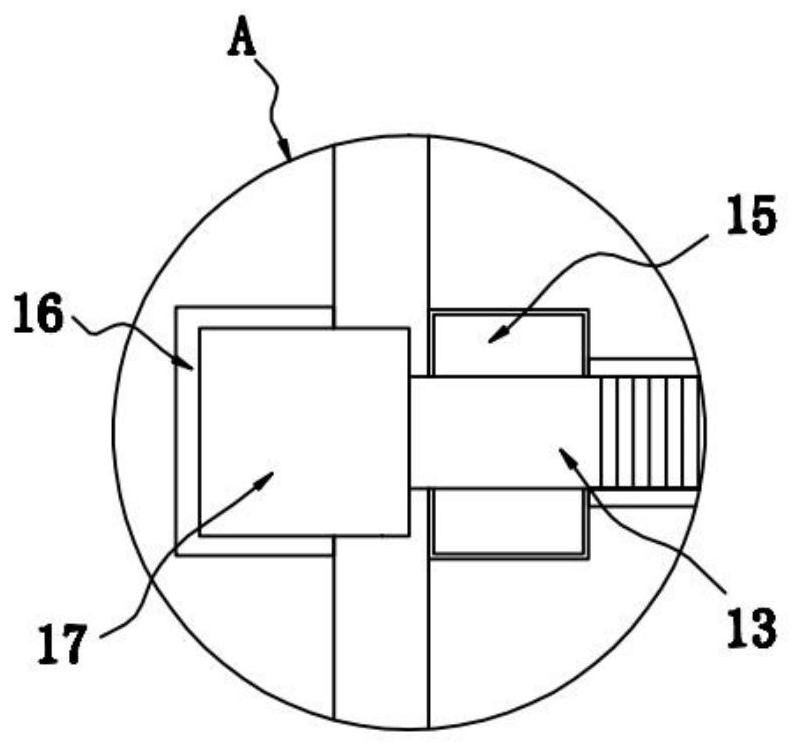

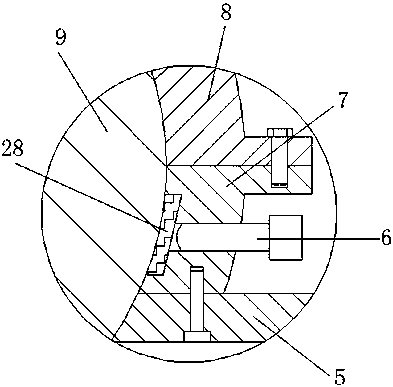

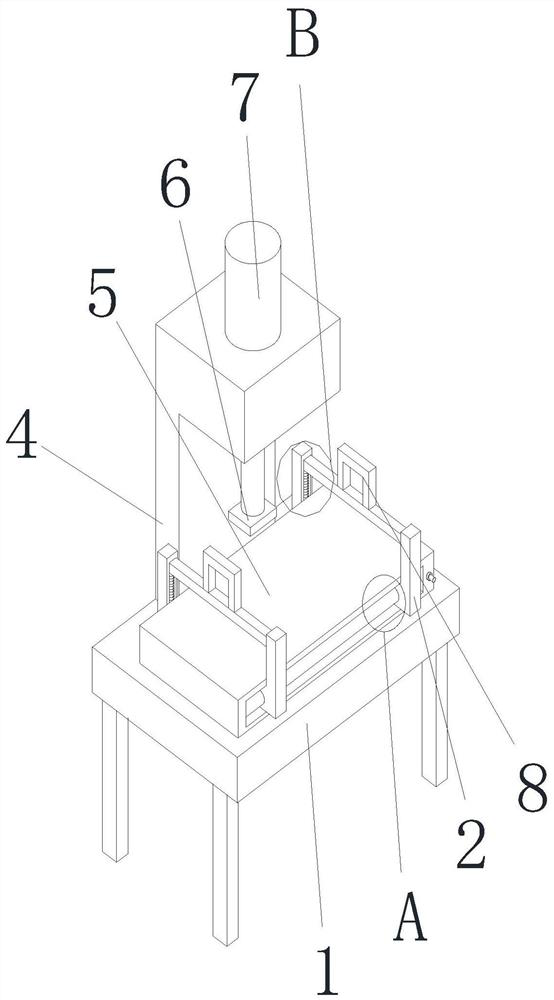

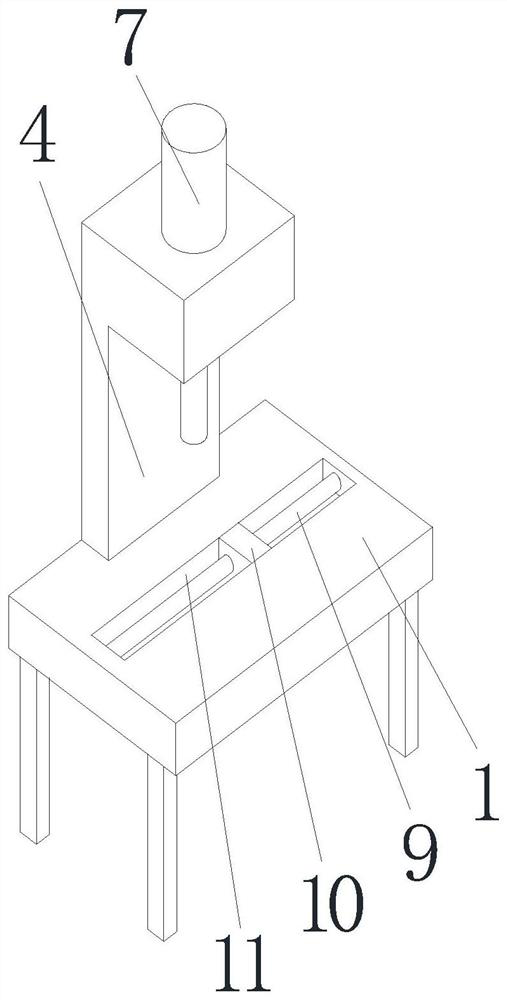

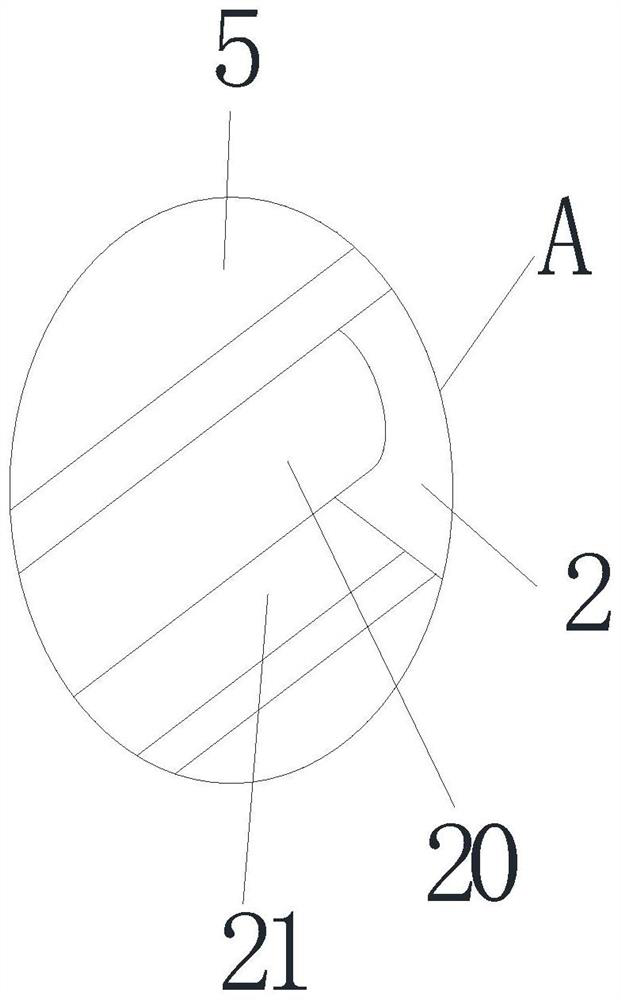

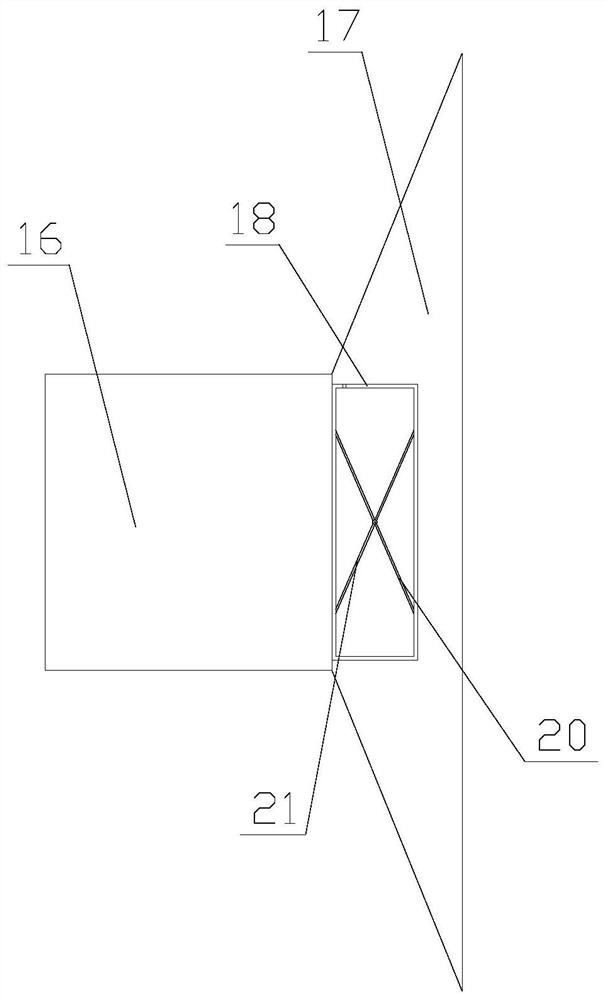

Stable cutting sheet punching device

PendingCN107891294APunch stableEasy to fixGrinding devicesPositioning apparatusEngineeringDrill floor

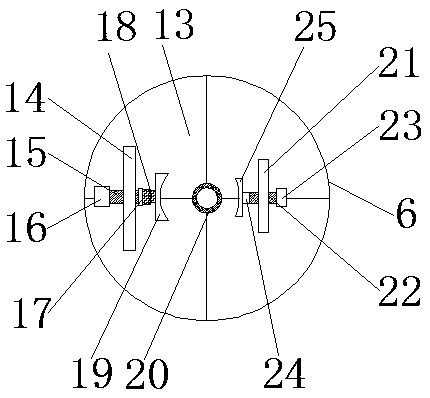

The invention provides a stable cutting sheet punching device, and relates to the technical field of grinding material and grinding tool machining. The stable cutting sheet punching device comprises abase. An electric telescopic rod is fixedly arranged on the top of the base, and the top of the electric telescopic rod and the bottom of a top plate are fixedly connected. A motor is fixedly arranged on the top plate. An output shaft of the motor penetrates the top of the top plate and extends to the bottom of the top plate to be fixedly connected with the top of a drill bit. A fixing device isarranged at the position, located under the drill bit, of the top of the base. According to the stable cutting sheet punching device, a cutting sheet is clamped and fixed through mutual cooperation ofa left clamping block and a right clamping block, the position of the cutting sheet on the device can be adjusted, and the punching direction of the cutting sheet is more convenient to control. A pressing rod is used for tightly pressing the cutting sheet, and cutting sheet punching is more stable; and through the arrangement of a drilling barrel, the situation that the drill bit descends excessively and makes contact with a bottom plate is prevented, and device damage is prevented.

Owner:郑州博尔德磨料磨具有限公司

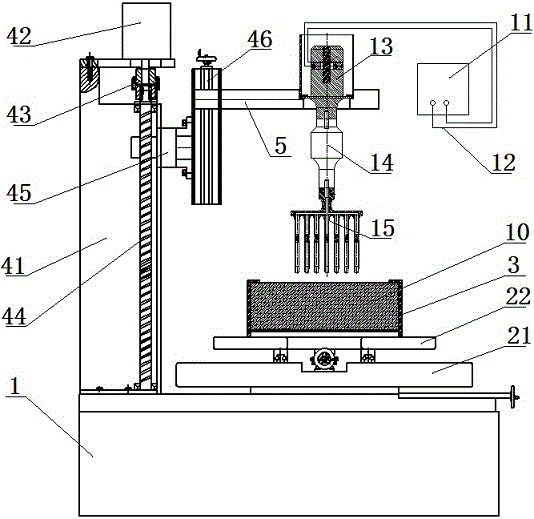

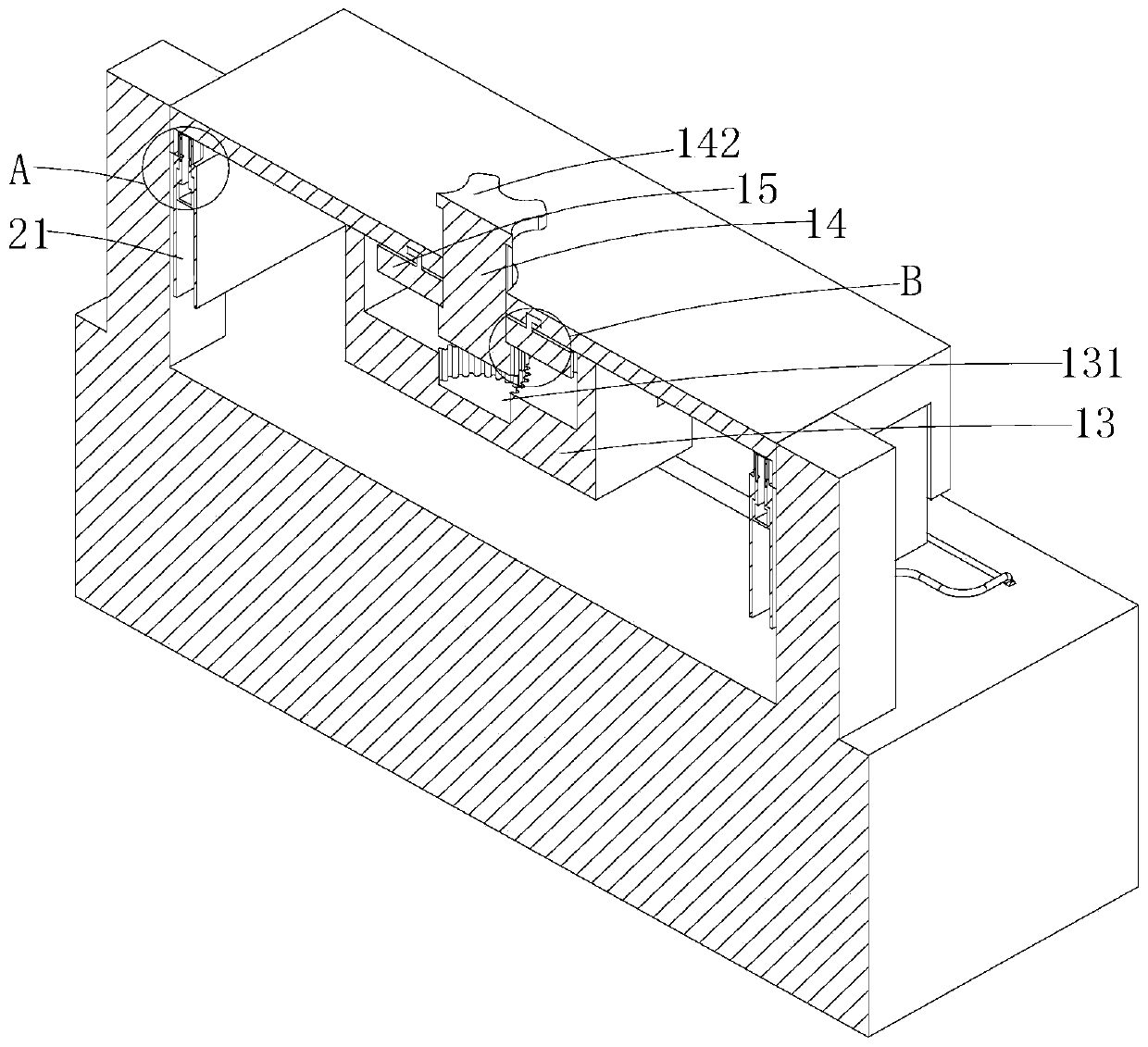

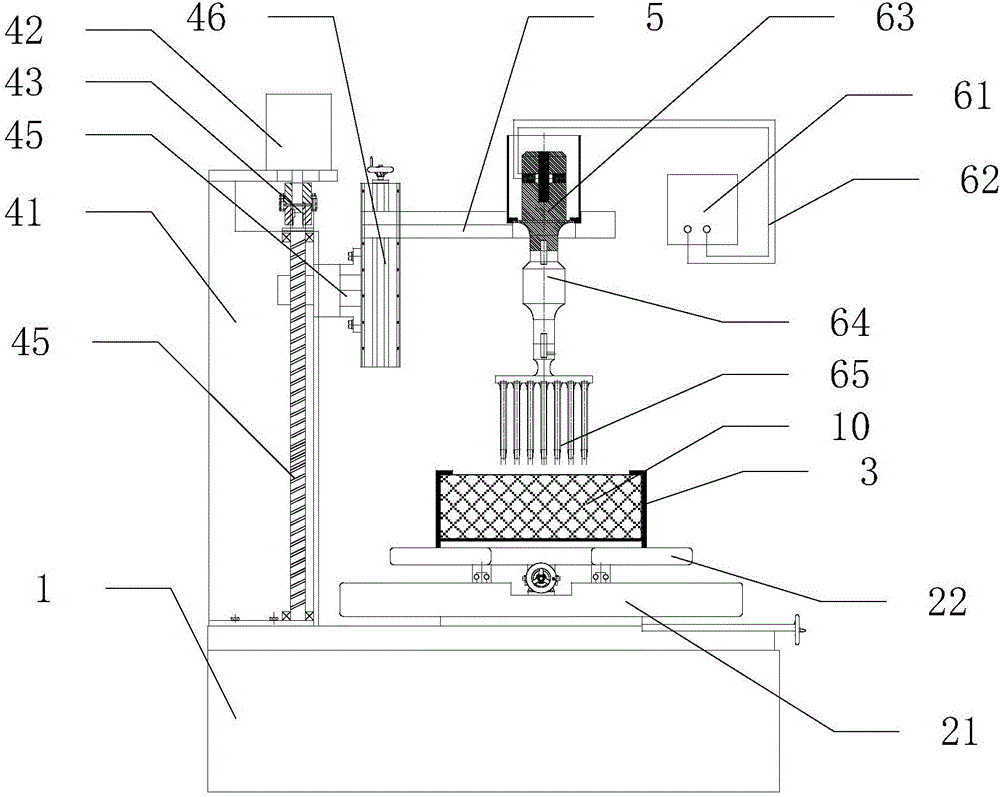

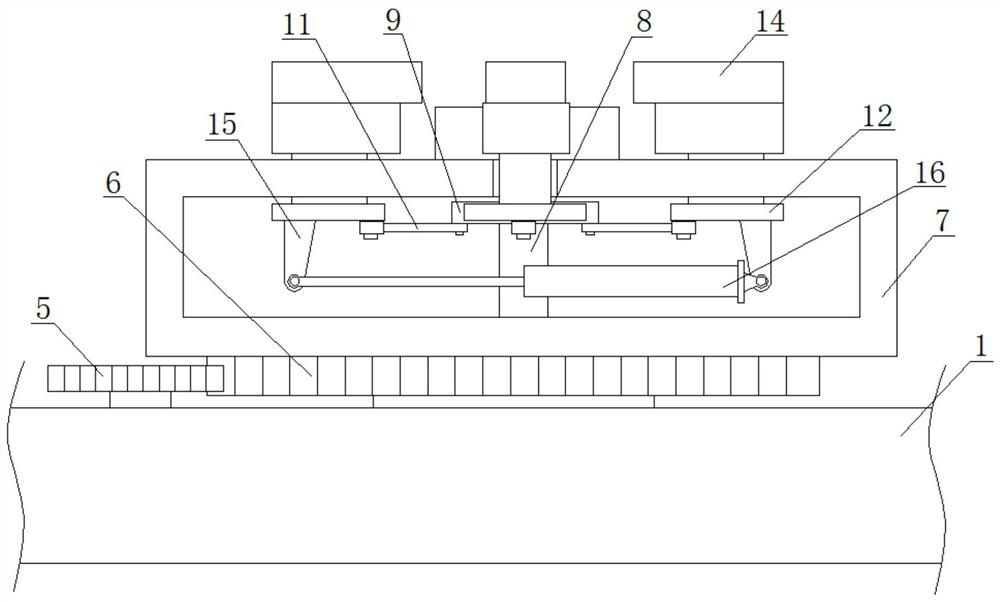

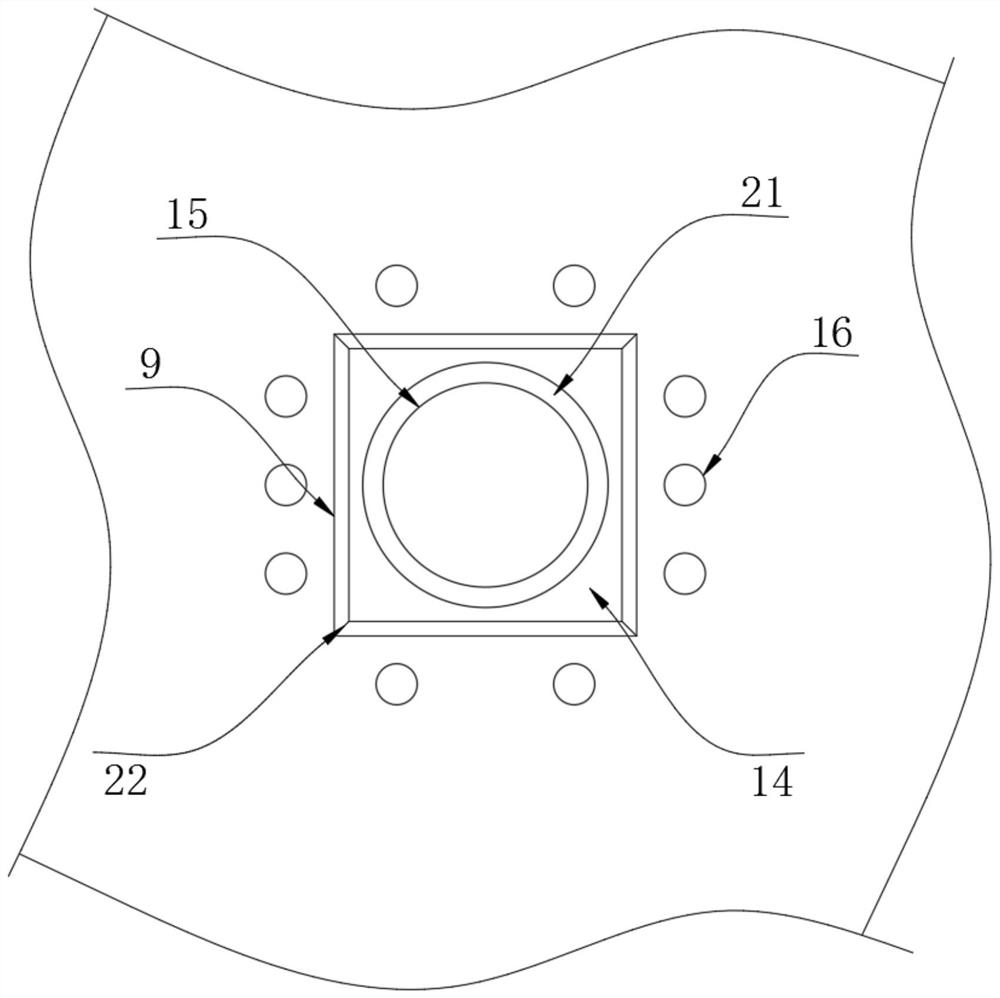

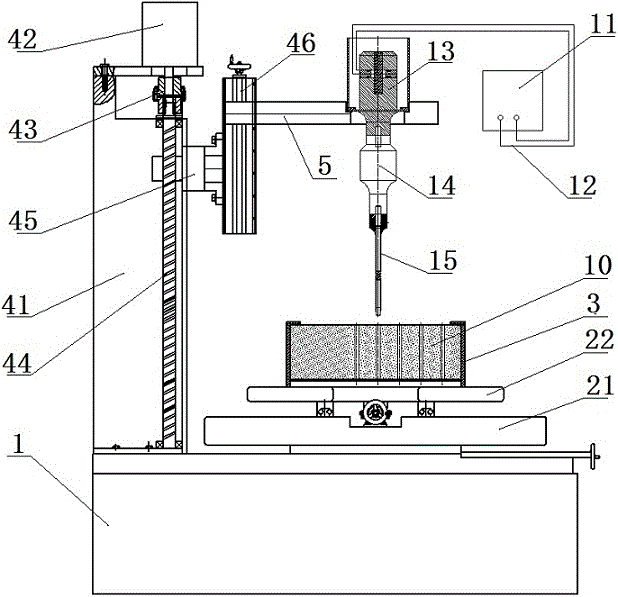

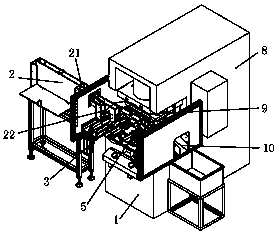

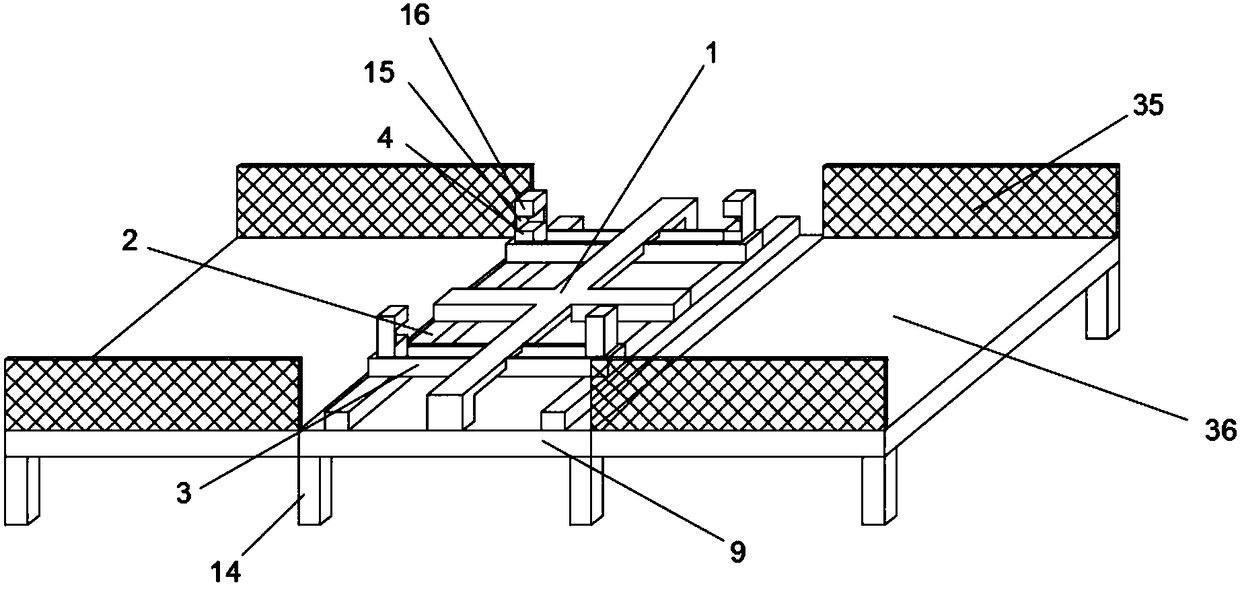

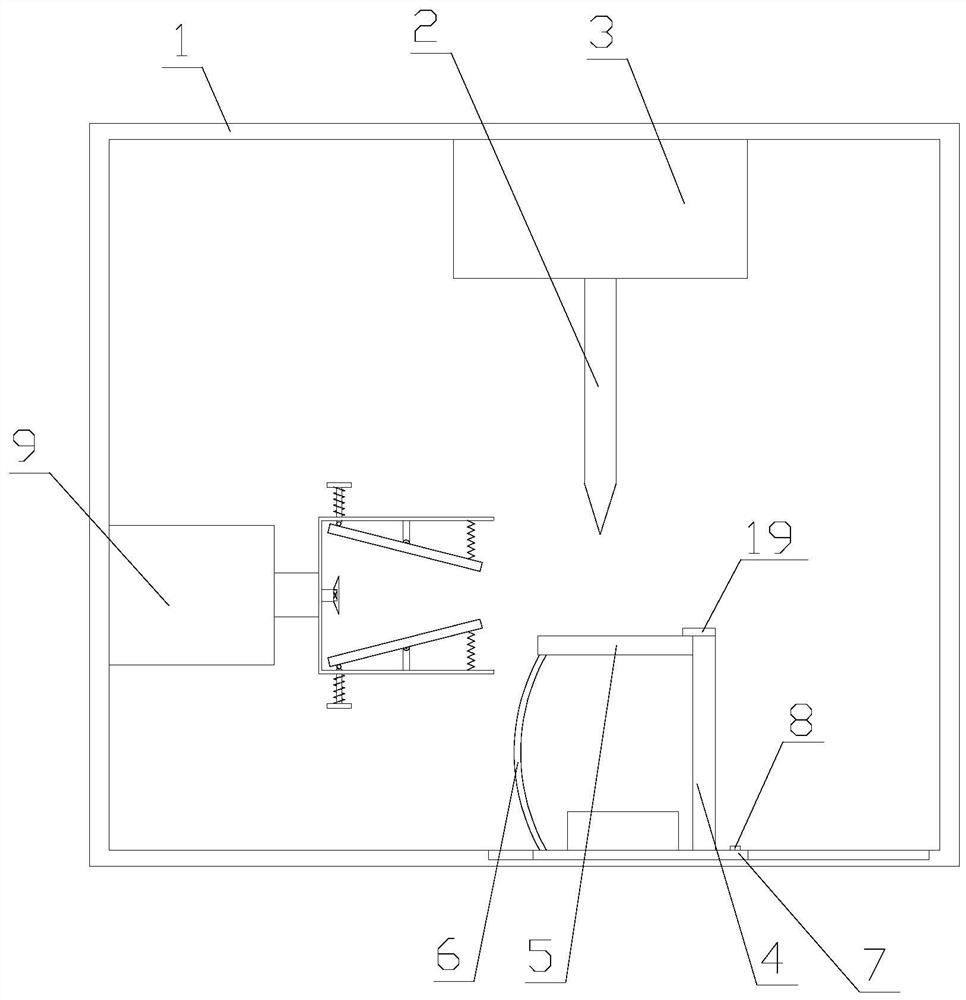

High-frequency longitudinal-torsional composite vibratory sponge gang-drill drilling worktable and application

InactiveCN105666547AAutomated processing is of great significanceHigh precision of aperture sizeMetal working apparatusPunchingHigh frequency vibration

The invention relates to a high-frequency longitudinal-torsional composite vibratory sponge gang-drill drilling worktable and application. The worktable comprises a base, a horizontal moving mechanism, a fixing rack, a vertical moving mechanism, a supporting frame and a high-frequency longitudinal-torsional composite vibratory sponge gang-drill drilling device, wherein the high-frequency composite vibratory sponge gang-drill drilling device comprises an ultrasonic generator, an ultrasonic transducer, an ultrasonic transducer, at least one stage of a variable-amplitude pole and a multi-tube cutter. The multi-tube cutter comprises a connector connected with the variable-amplitude pole, a tube body arrangement plate, multiple tube bodies with cavities and cutting edges, one end of each tube body is detachably connected with the tube body arrangement plate, the other end of each tube body extends out of the corresponding cutting edge, and longitudinal-torsional composite vibratory transformational structures are arranged on the tube bodies. The worktable easily performs punching in sponge in a high-frequency vibratory mode, any trajectory movement of a workpiece within a two-dimensional plane is achieved through the horizontal moving mechanism, the gang-drill drilling device can achieve vertical and accurate movement, and one-time multi-hole automatic forming can be conducted on the workpiece to be machined through the fixing rack as required.

Owner:SUZHOU UNIV OF SCI & TECH

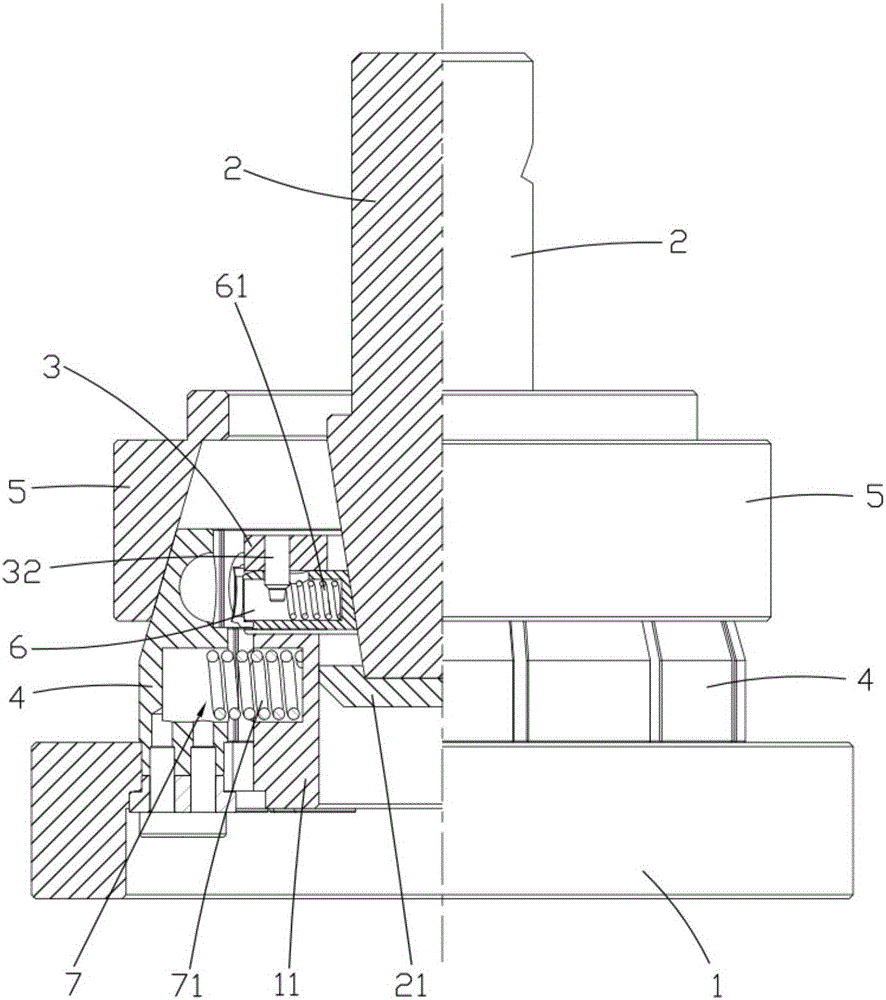

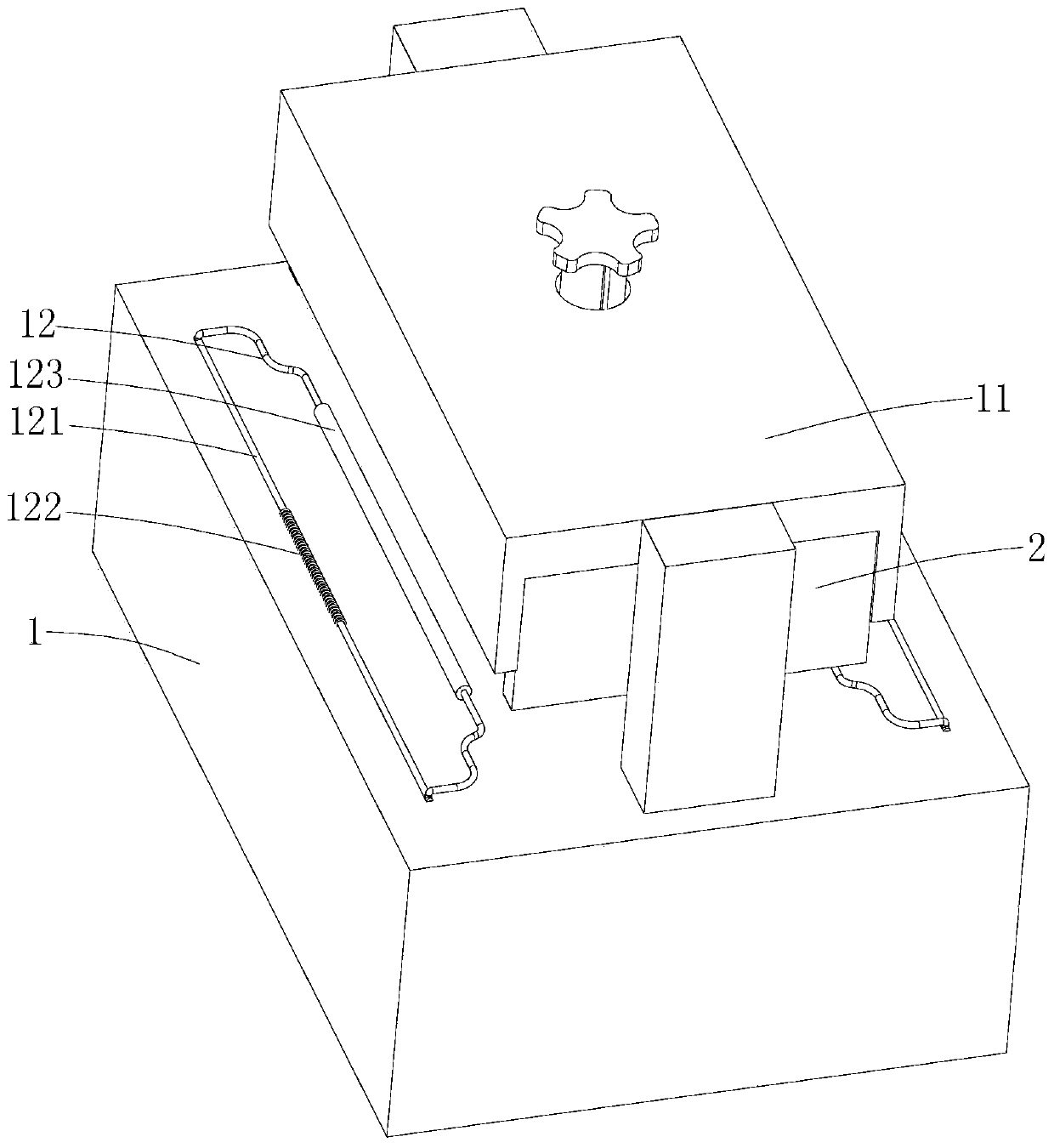

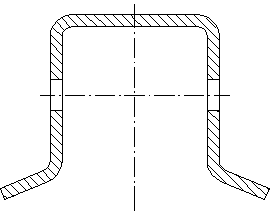

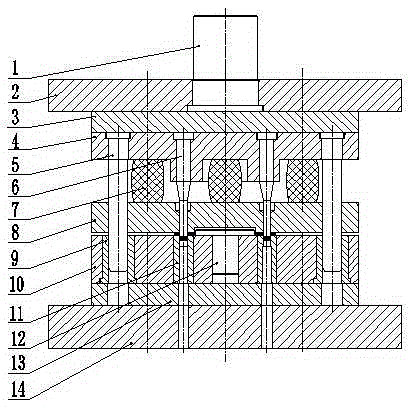

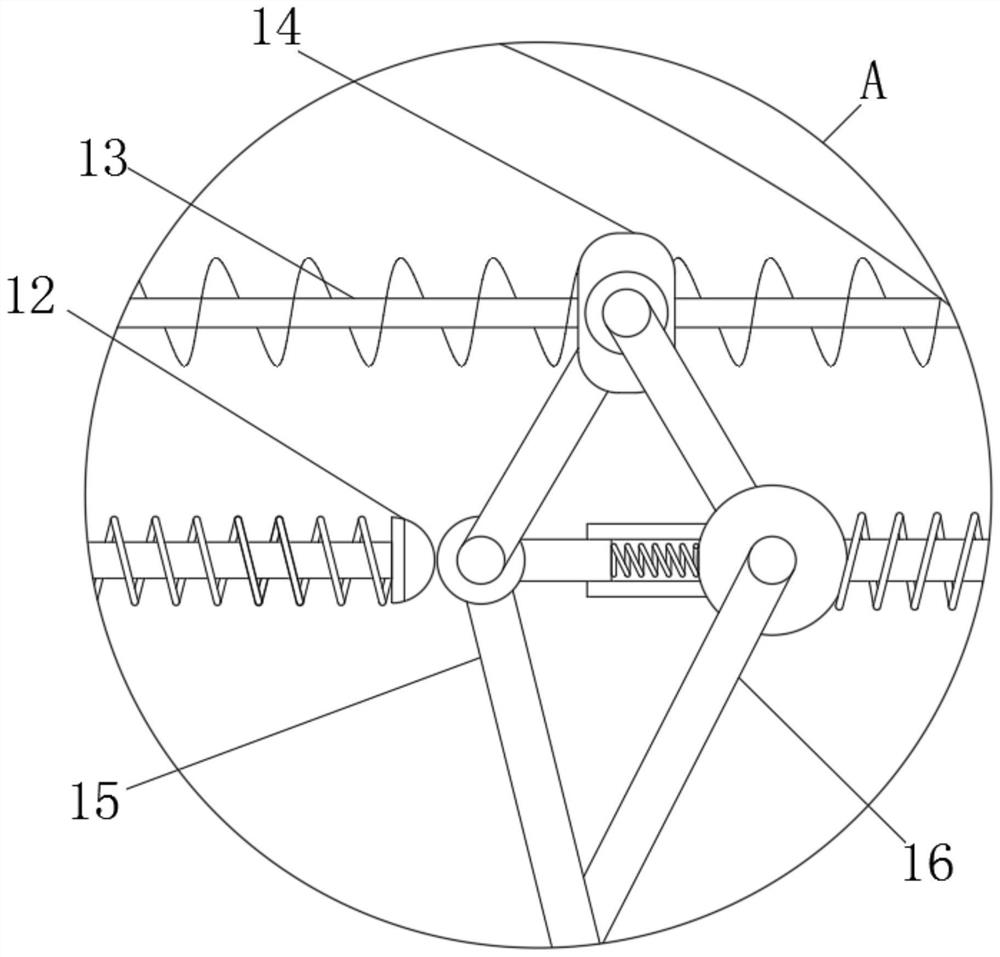

One-time stamping forming mold for ball pocket of holder

ActiveCN105689591AEven by forceNot easy to damagePerforating toolsBearing componentsPunchingEngineering

The invention relates to a one-time stamping forming mold for a ball pocket of a holder. The one-time stamping forming mold comprises a base, a main sliding body, an inner mold, outer molds and a shrink sleeve. The main sliding body is arranged inside the base vertically; the main sliding body is sleeved with the inner mold, and a plurality of outer molds are evenly arranged on the base in the circumferential direction; the outer molds are all arranged outside the inner mold; the shrink sleeve is arranged on the upper portions of the outer molds in a sleeving mode; a plurality of punches are evenly arranged on the side wall of the inner mold in the circumferential direction; and limiting grooves are formed in the inner walls of the outer molds. A first spring is placed horizontally inside each punch; a kidney-shaped hole is formed in the upper portion of each punch; a plurality of pin holes are evenly formed in the upper end face of the inner mold; and a plug pin is arranged inside each pin hole. According to the one-time stamping forming mold for the ball pocket of the holder, the diameter variation of the main sliding body is utilized to push the punches to move radially in a divergent way along the main sliding body, so that multiple holes are punched in the ball pocket of the holder at a time; through the elastic effect of the first springs arranged inside the punches, automatic resetting of the punches after the completion of the punching is achieved. The mold is simple, punching is stable and highly precise, and automation and flow line operation can be easily achieved.

Owner:ZHEJIANG GUNAI RUBBER & PLASTIC SCI & TECH

Sticky label paper processing technology

ActiveCN110126017AImprove drilling efficiencyDifficult to cleanPaper/cardboard articlesPattern printingPulp and paper industryPaper sheet

The invention discloses a sticky label paper processing technology. The sticky label paper processing technology comprises the steps of 1, unrolling, wherein sticky label raw paper which is in a rollis unfolded through unrolling equipment and stably conveyed to the next procedure; 2, printing, wherein patterns or characters are printed onto the sticky label raw paper through a printing machine; 3, lustering, wherein the sticky label raw paper is coated with lustering oil; 4, gold stamping, wherein the patterns or characters can be clear, attractive in appearance, dazzlingly beautiful in colorand resistant to abrasion and weather; 5, drilling, wherein needed holes are drilled in the sticky label raw paper through drilling equipment; 6, die cutting, wherein the continuous sticky label rawpaper is cut into semi-finished products of predetermined length through a cutting machine; 7, waste discharge, wherein the unqualified semi-finished products are removed; and 8, piece cutting, wherein label paper is cut into labels of the predetermined size through a piece cutting machine.

Owner:中山市榕源印刷有限公司

Side hole punching die of U-shaped guide rod base of automobile driving axle

ActiveCN103894475AStable concentricityImprove production taktPerforating toolsCar drivingEngineering

The invention discloses a side hole punching die of a U-shaped guide rod base of an automobile driving axle. The side hole punching die comprises an upper die body and a lower die body, and is characterized in that the upper die body comprises a die handle, an upper die plate, a male die base plate, a male die fixing plate, a punching male die, side edge unloading rubber, middle unloading rubber and an unloading plate, the die handle, the upper die plate, the male die base plate, the male die fixing plate, the punching male die, the side edge unloading rubber, the middle unloading rubber and the unloading plate are sequentially fastened and connected from top to bottom, the lower die body comprises a punching female die, a female die fixing plate, a female die fixing plate inner guide sleeve, a female die fixing plate inner guiding column, a female die fixing plate supporting spring and a lower die plate, the punching female die, the female die fixing plate, the female die fixing plate inner guide sleeve, the female die fixing plate inner guiding column, the female die fixing plate supporting spring and the lower die plate are sequentially fastened and connected from top to bottom, the middles of the left side edge and the right side edge of the female die fixing plate are respectively provided with a side edge locating block, and the female die fixing plate is connected with the lower die plate through the female die fixing plate supporting spring. The punching process is stable, deformation is avoided, and it is accordingly guaranteed that the concentricity of side holes in the two edges is stable.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

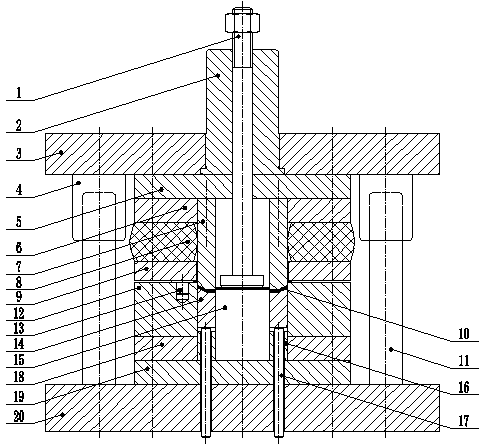

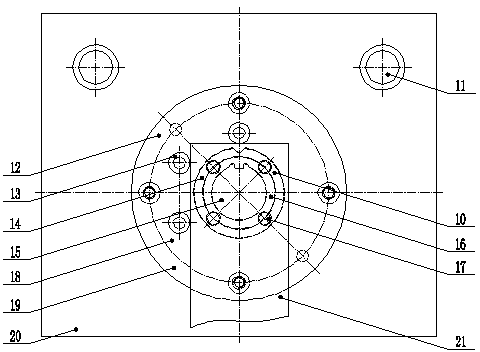

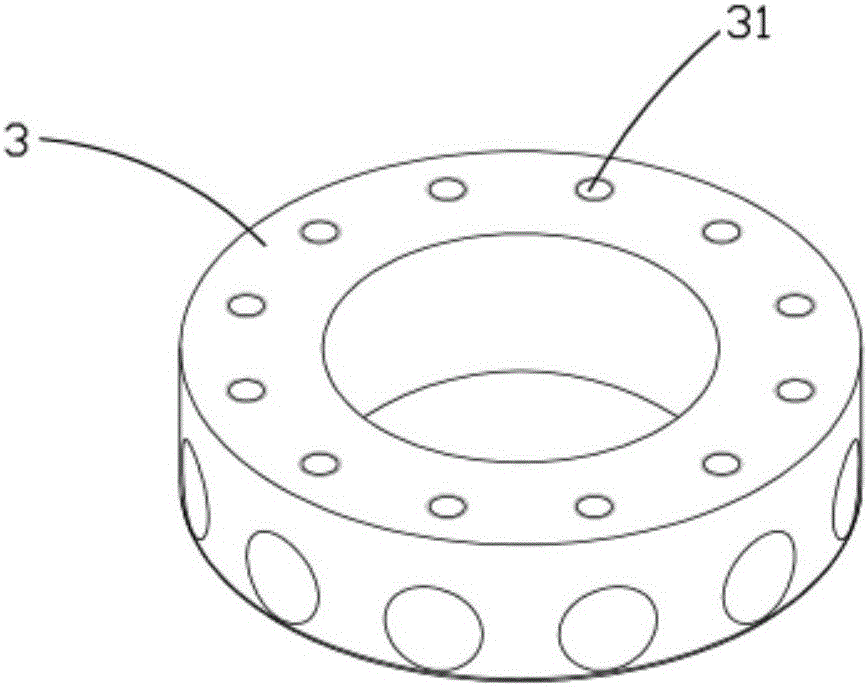

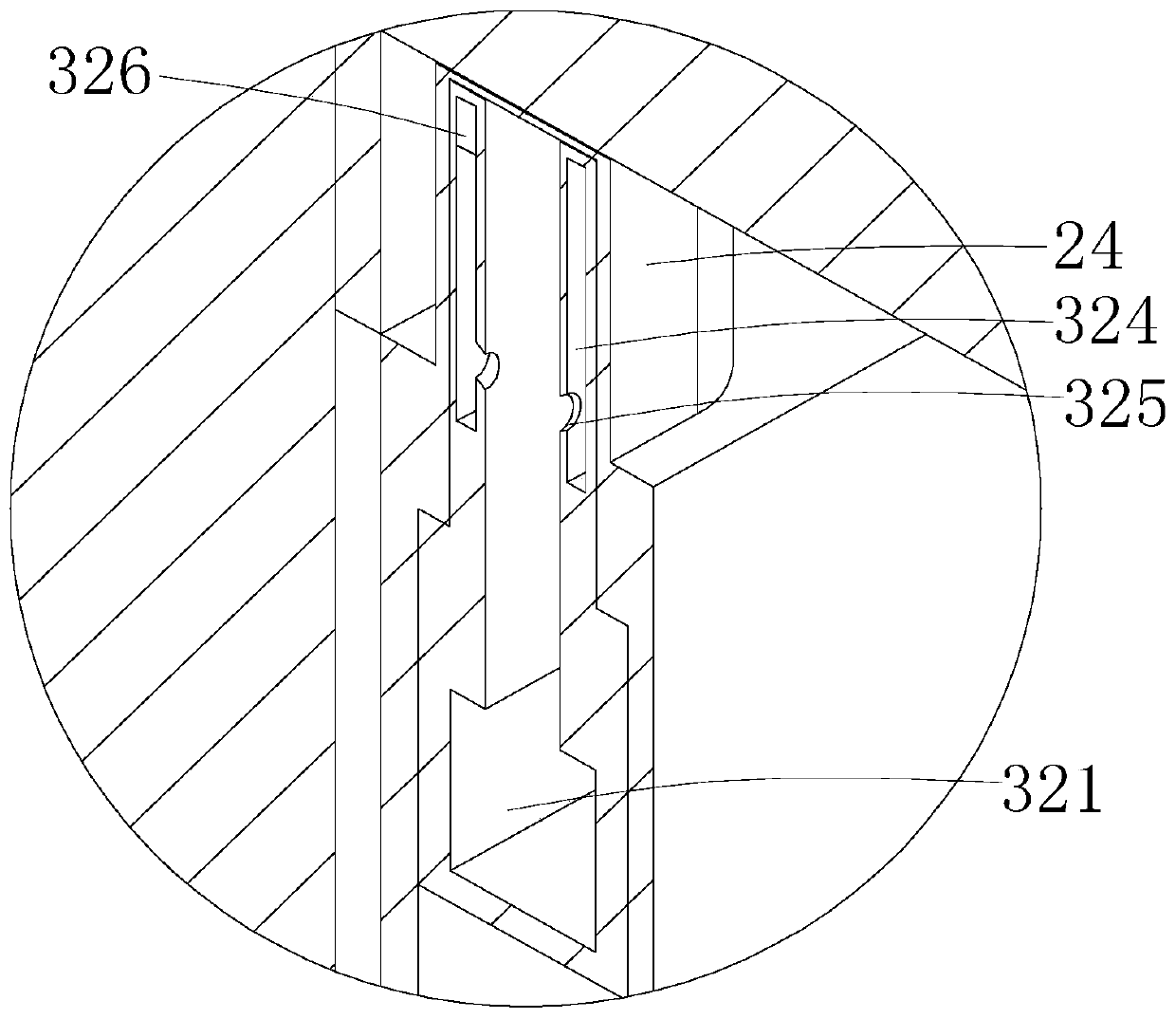

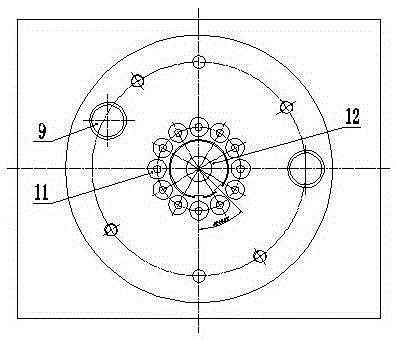

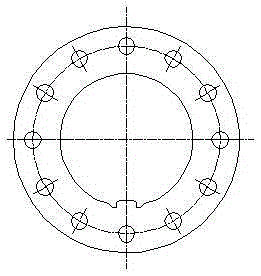

Rear axle locking gasket die capable of punching 24 holes in two steps and machining process of die

InactiveCN105251867APunch stableGuaranteed neatnessPerforating toolsStripping-off devicesPunchingTwo step

The invention discloses a rear axle locking gasket die capable of punching 24 holes in two steps. The die comprises an upper die body and a lower die body. The upper die body comprises a die shank, an upper die plate, an upper base plate and a male die fixing plate. The male die fixing plate is of a step structure with the upper portion being large and the lower portion being small. The step of the lower portion of the male die fixing plate is cylindrical. 12 punching male die bodies are uniformly arranged on the male die fixing plate in the circumferential direction of the cylindrical step. The lower die body comprises a female die fixing plate, a lower die base plate and a lower die plate. 12 female die positioning holes are uniformly formed in the female die fixing plate in the circumferential direction of the center. A punching female die body is arranged in each female die positioning hole. An automatic correction guiding mechanism and a discharging mechanism are arranged between the male die fixing plate and the female die fixing plate. Punching stations are arranged between a punching male die body and punching holes of a punching female die body. According to the rear axle locking gasket die, the service life is long, the punching process is stable, secondary punching is adopted so that a set of dies is omitted, positioning for the secondary punching is convenient, and the appearance of a product is regular.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

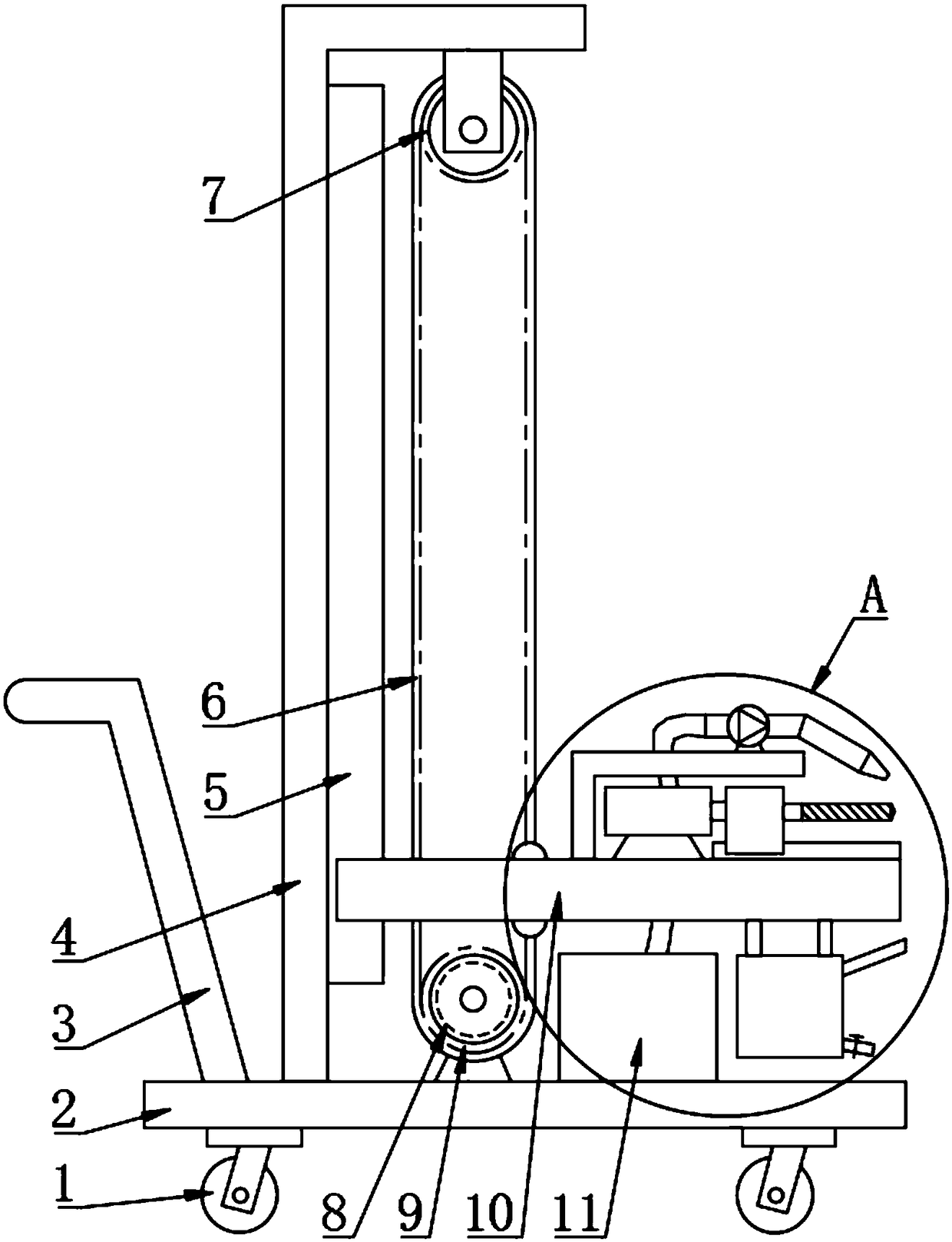

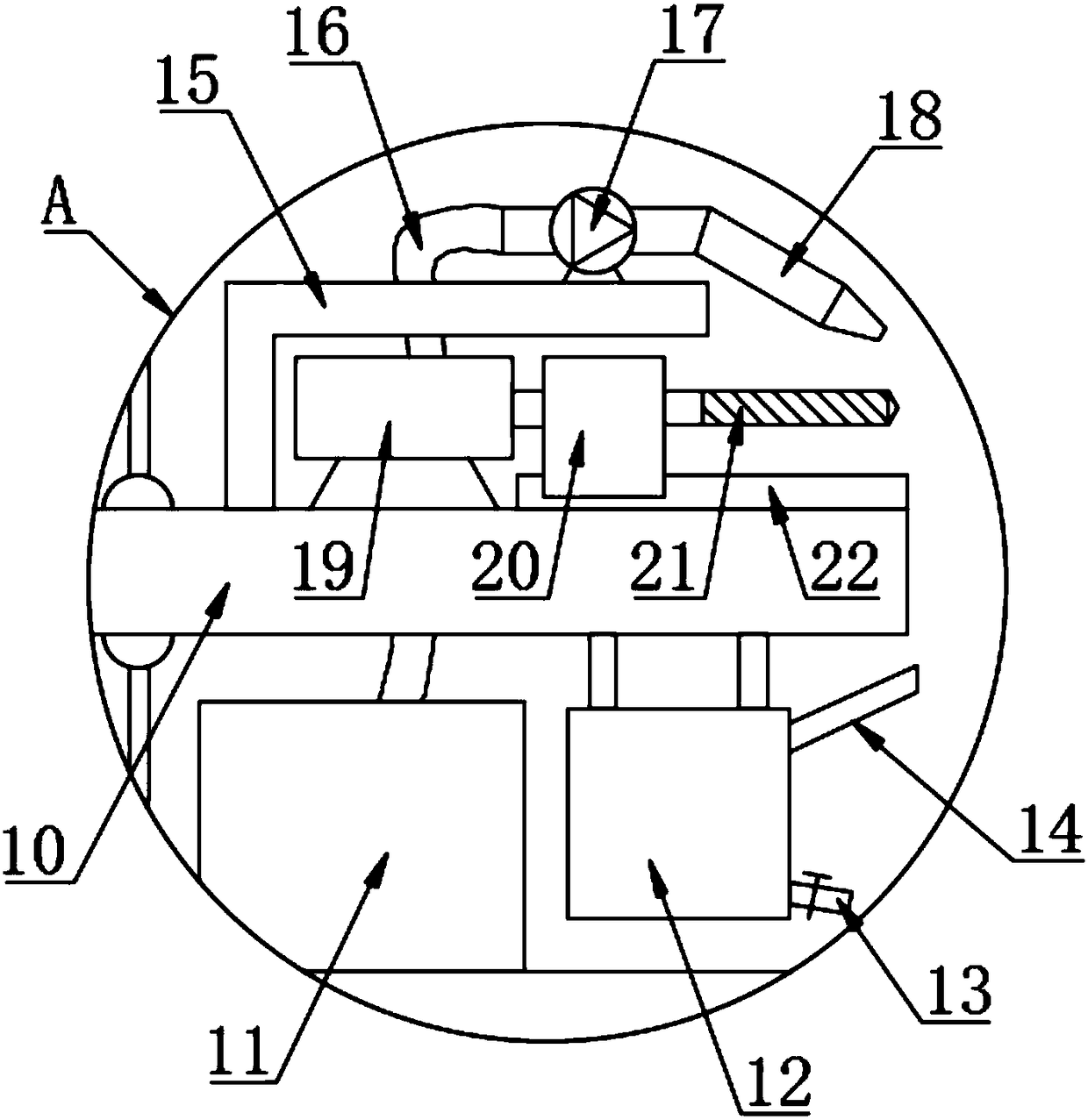

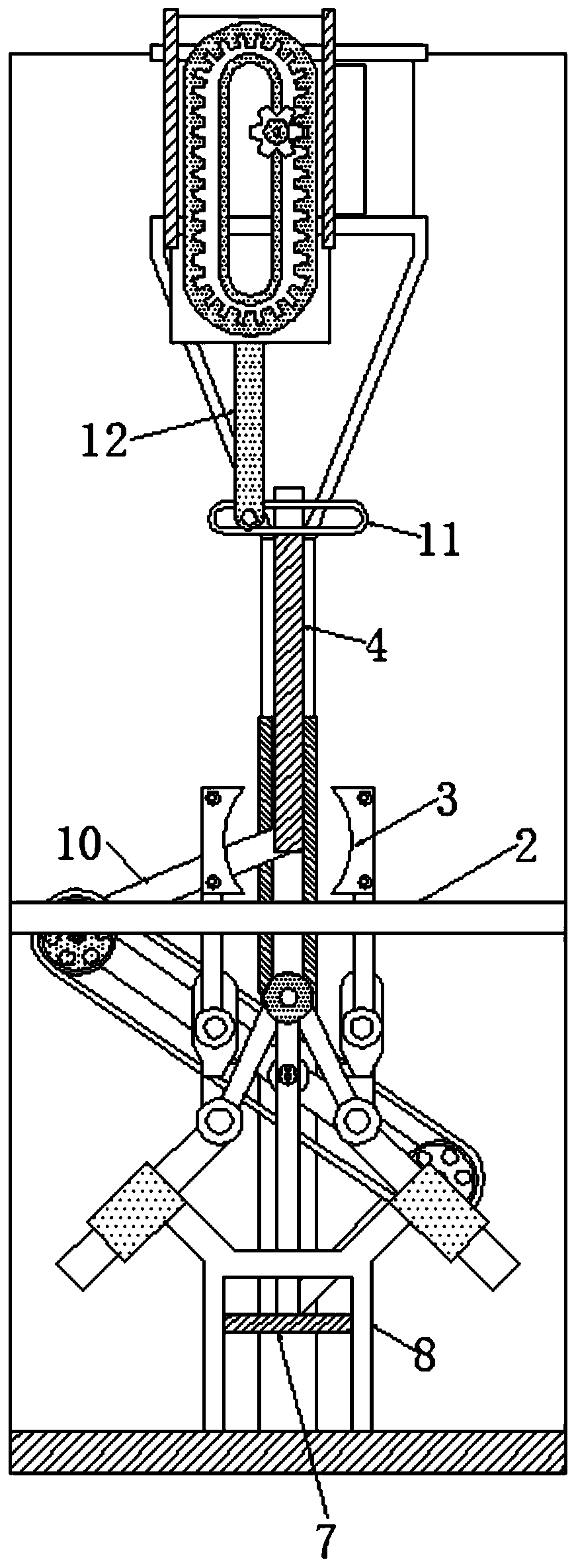

Wall punching device with water spraying function

InactiveCN108162203AEasy to punchPunching, easy to controlWorking accessoriesStone-like material working toolsPunchingEngineering

The invention discloses a wall punching device with a water spraying function. The device comprises a base; a first support plate is fixedly arranged at the top of the base; a first slide rail is fixedly arranged on the right side wall of the first support plate; the right side of the first slide rail is slidingly connected with a lifting plate; a speed reducing motor is fixedly arranged at the top of the base; a motor shaft at the front end of the speed reducing motor is connected with a first chain wheel; the bottom surface of the top of the first support plate is rotationally connected witha second chain wheel through a bracket; a chain is connected between the first chain wheel and the second chain wheel; the two ends of the chain are fixedly connected with the top and the bottom of alifting plate; a slide rail is fixedly arranged at the top of the lifting plate, and is slidingly connected with an electric drill; the right end of the electric drill is connected with a drill bit;an electric push rod is fixedly arranged at the top of the lifting plate; and the right end of a push rod of the electric push rod is fixedly connected with the electric drill. Through rotation of thechain wheels, the wall punching height can be controlled, so that walls with different heights are conveniently punched, and the trouble and the danger of climbing at the time of holding the electricdrill by a human hand are prevented.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

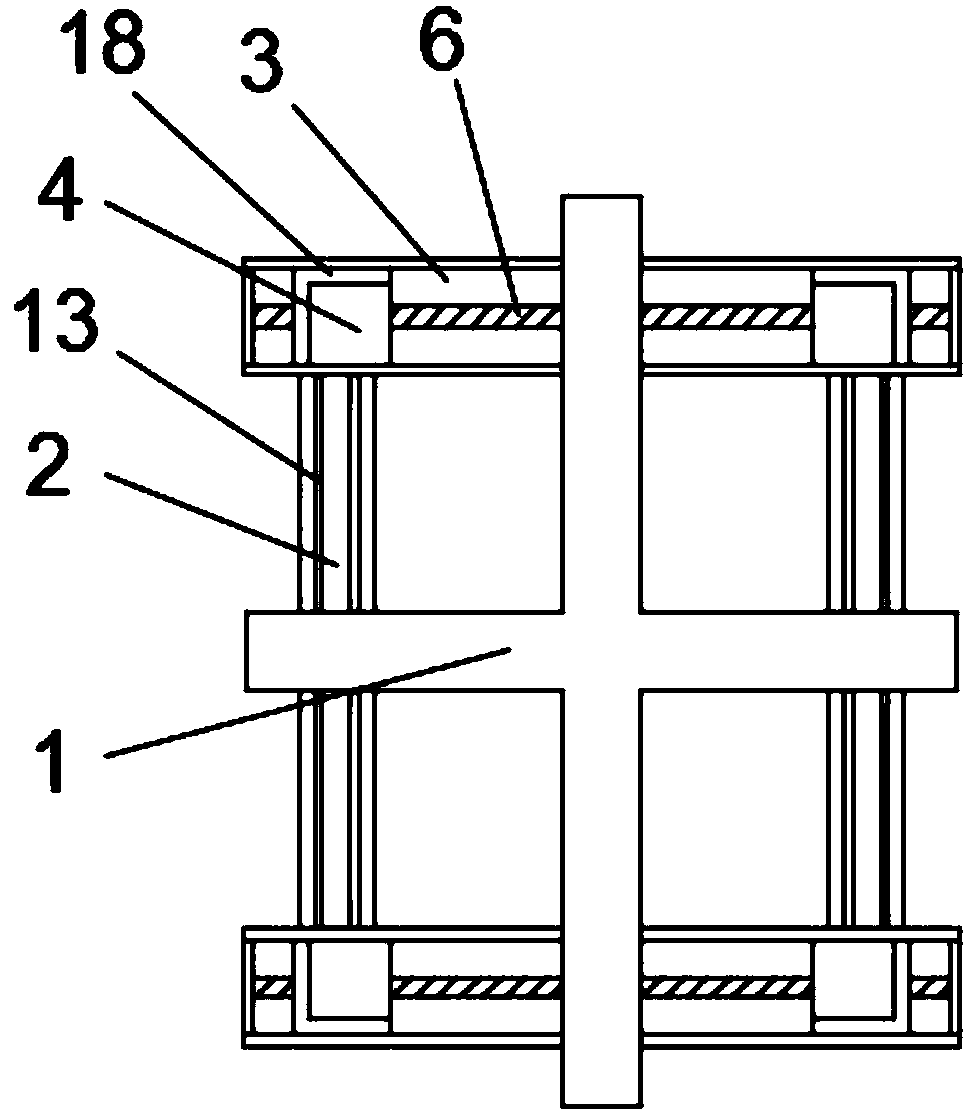

High-frequency vibration worktable for forming holes on sponge by gang drill

InactiveCN105773713AAutomated processing is of great significanceHigh precision of aperture sizeMetal working apparatusFixed frameEngineering

The invention relates to a high-frequency vibration worktable for forming holes on sponge by gang drill. The high-frequency vibration worktable comprises a base, a horizontal moving mechanism, a fixed frame, a vertical moving mechanism, a supporting frame and a high-frequency vibration device for forming holes on the sponge by gang drill, wherein the horizontal moving mechanism is arranged on the base; the fixed frame is arranged on the horizontal moving mechanism; the vertical moving mechanism is arranged on the base; the supporting frame is arranged on the vertical moving mechanism; the high-frequency vibration device for forming the holes on the sponge by gang drill is arranged on the supporting frame, is positioned above the fixed frame and comprises an ultrasonic generator, an ultrasonic transducer, at least one stage of amplitude-change pole and a multi-tube cutter; the ultrasonic transducer is connected with the ultrasonic generator through a wire; the at least one stage of amplitude-change pole is connected with the ultrasonic transducer; and the multi-tube cutter is connected with the amplitude-change pole. According to the high-frequency vibration worktable disclosed by the invention, holes are easily formed in the sponge by adopting a high-frequency vibration mode; workpieces can be moved in a two-dimensional plane at any trace through the horizontal moving mechanism; accurate up-down motion can be realized by a gang drill drilling device; and one-time multi-hole automatic forming of the workpieces to be processed can be realized through the fixed frame according to requirements.

Owner:SUZHOU INOAC ZHONGDING OFFICE MACHINE PRODS

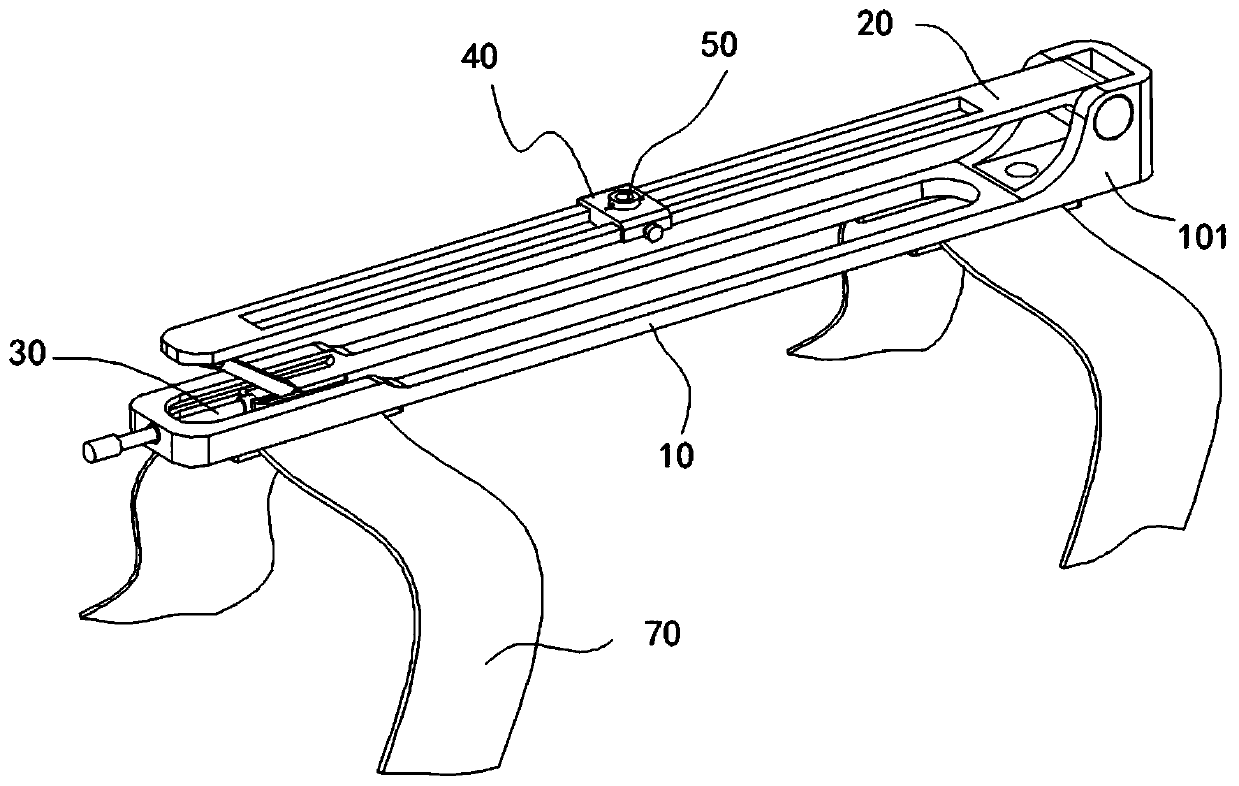

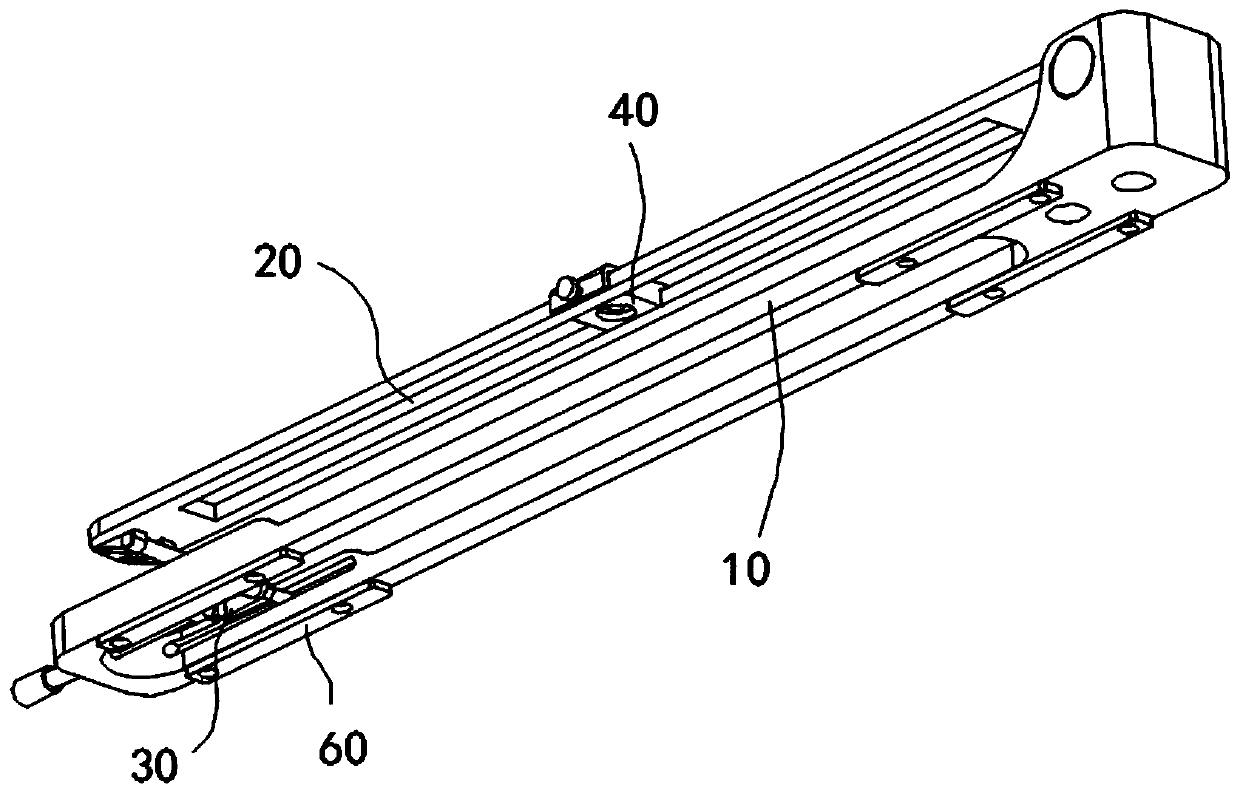

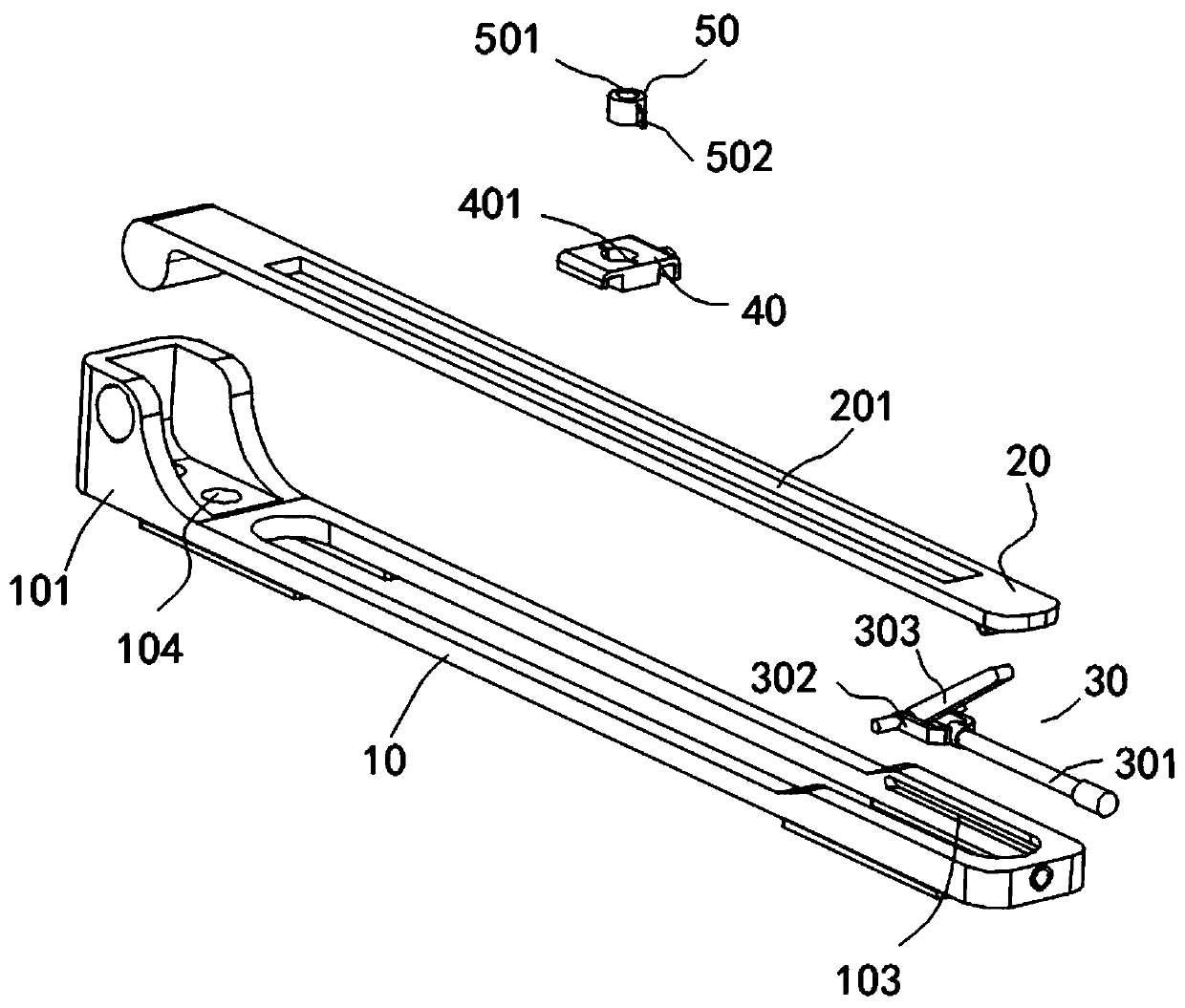

Orthopedic positioner

Owner:刘超

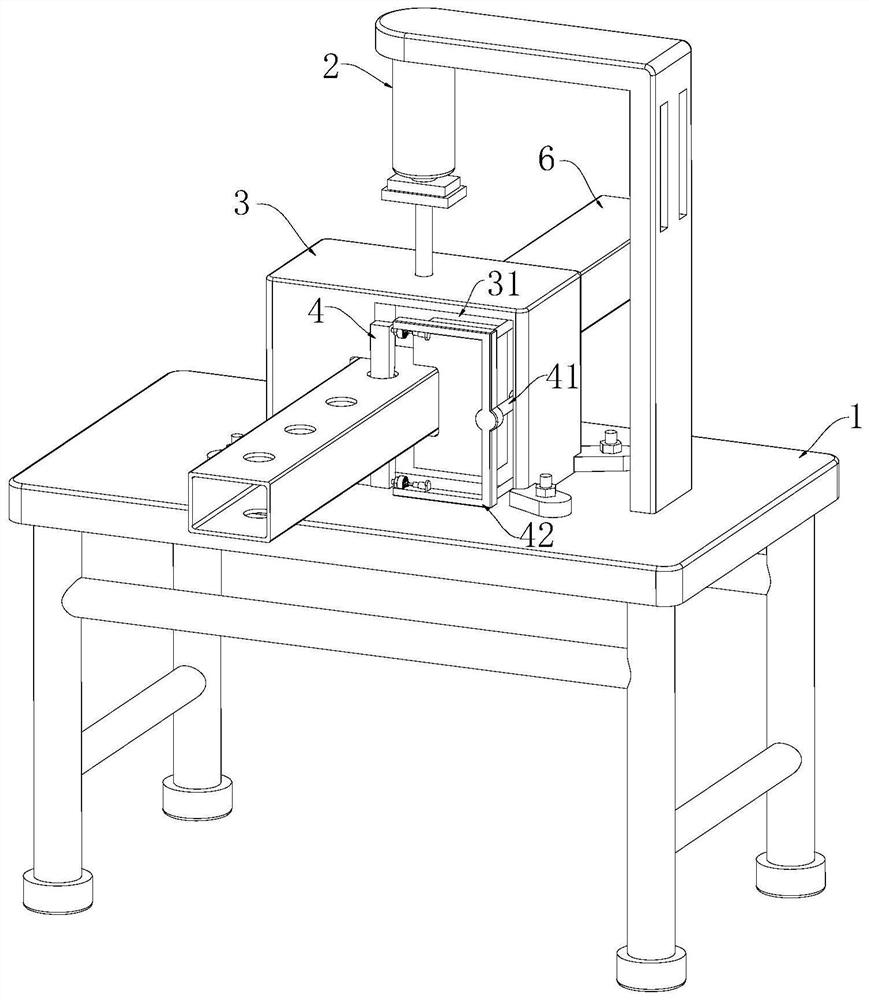

Drilling device for automobile brake pad

PendingCN112809044AFix stability issuesPunch stableLarge fixed membersPositioning apparatusGear wheelControl theory

The invention discloses a drilling device for an automobile brake pad. The drilling device comprises a transverse plate, wherein supports are fixed to the two sides of the lower end of the transverse plate, a first fixing piece is fixed to the inner side of the support located on the left side, a rotating mechanism is arranged in the first fixing piece, a second gear is arranged on the rotating mechanism, the second gear is rotationally connected to the middle of the upper end of the transverse plate, a clamping and fixing box is fixed to the upper end of the second gear, a clamping and fixing mechanism is arranged in the clamping and fixing box, four sliding parts are arranged on the clamping and fixing mechanism, openings are formed in the periphery of the upper end of the clamping and fixing box, and the four sliding parts are slidably connected into the four openings in a sleeved mode respectively. According to the drilling device, a brake pad can be effectively clamped and fixed, so that the brake pad is more stable during machining, the machining effect of the brake pad can be effectively improved, meanwhile, the punching position of the brake pad can be automatically and accurately positioned, the production quality of the brake pad is effectively guaranteed, and meanwhile the production efficiency of the brake pad can be improved.

Owner:WEIFANG AIRUI BRAKING SYST CO LTD

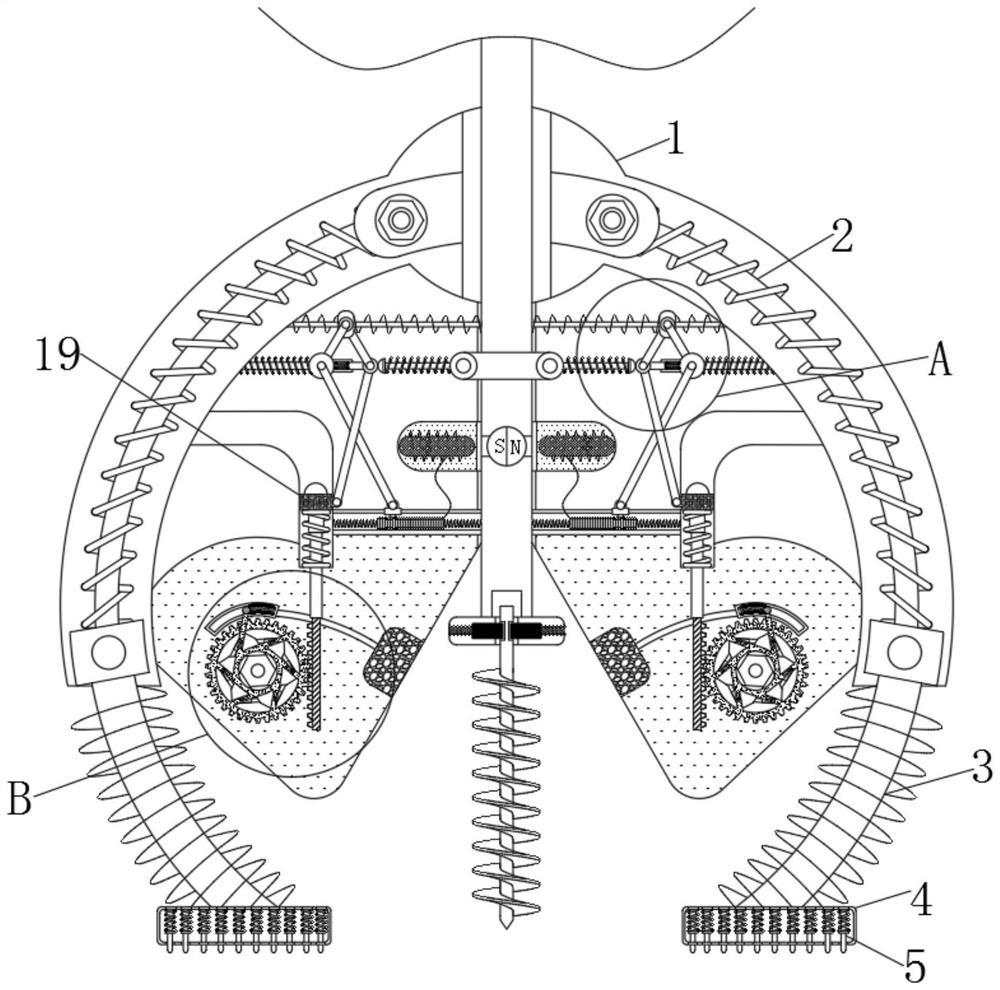

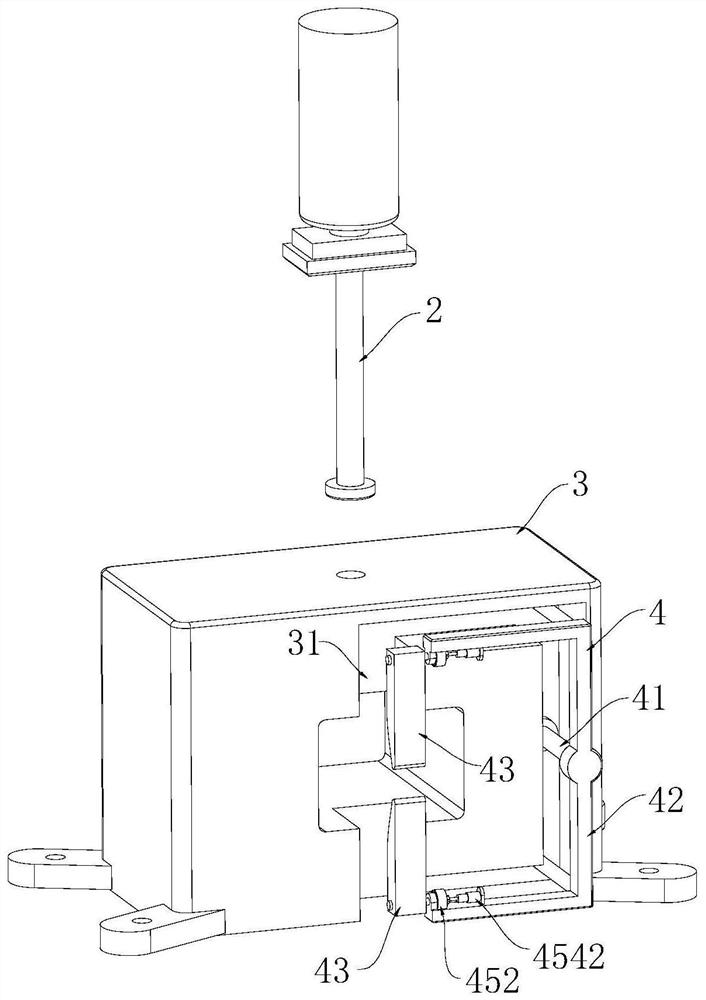

Punching equipment stable in punching, accurate in punching position and capable of avoiding accidental injury

InactiveCN113000897APunching stable and accurate positionAvoid accidental injuryBoring/drilling componentsBoring/drilling machinesPunchingEngineering

The invention relates to the technical field of hardware, and discloses punching equipment stable in punching, accurate in punching position and capable of avoiding accidental injury. The punching equipment comprises a frame body, arc-shaped sliding rods are fixedly connected to the left side and the right side of the frame body, sleeving rods are elastically connected to the bottom ends of the arc-shaped sliding rods, auxiliary foot pads are fixedly connected to the bottom ends of the sleeving rods, and spring needles are elastically connected in the auxiliary foot pads. A rotating shaft is rotationally connected to the center of the frame body, a limiting block is elastically connected to the position, close to the bottom end, in the rotating shaft, and a drill bit is clamped to the bottom end of a main shaft. The resistance value of a slide rheostat is changed to hinder rotation of the rotating shaft, so that the drill bit quickly stops rotating, and the situation that the drill bit continues rotating due to inertia, cannot stop after a long time and is prone to accidentally injury people is avoided. More labor is saved when the drill bit moves up and down in the drilling process through cooperation of the sleeving rods and the spring needles, the drill bit is well assisted to be more stable in the drilling process, the punching position is more accurate, and punched holes are more standard.

Owner:通星(广州)网络科技有限公司

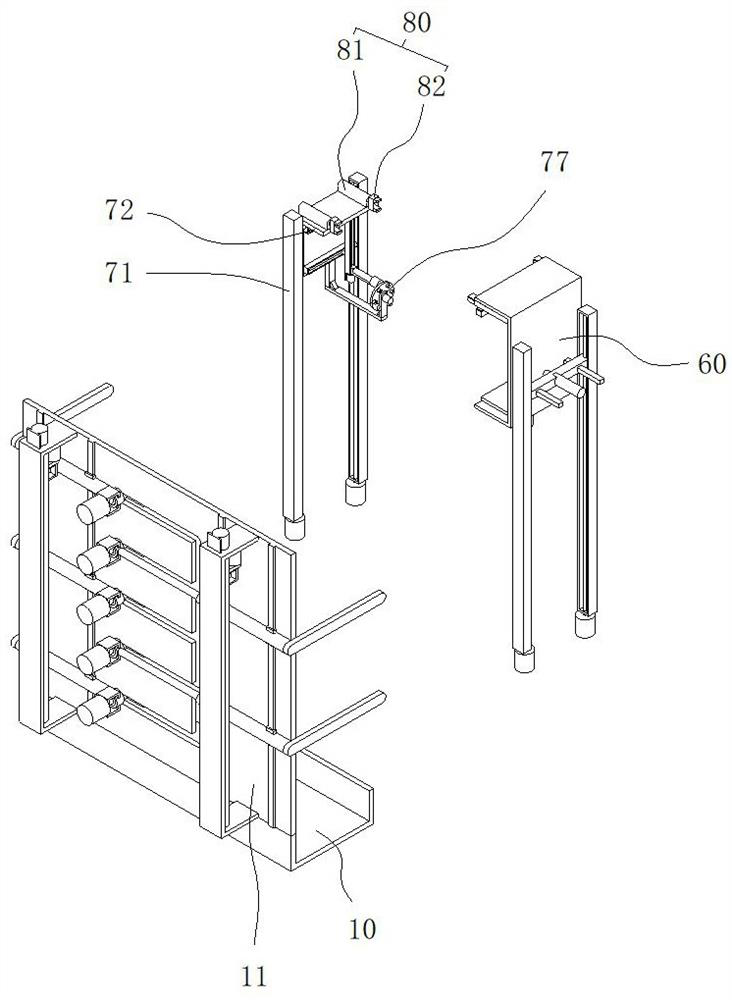

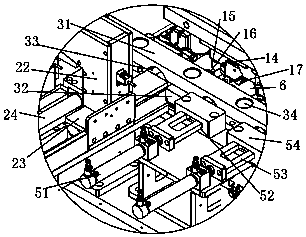

Collaborative processing device for multiple layers of PCBs (printed circuit boards)

PendingCN114828414AEasy to combine processingEasy to cleanConductive pattern polishing/cleaningStructural engineeringMechanical engineering

The invention discloses a multi-layer PCB collaborative processing device which comprises a base plate and two vertical plates, the outer walls of the two vertical plates are sequentially provided with a plurality of first PCB positioning devices and second PCB positioning devices from top to bottom, the first PCB positioning devices and the second PCB positioning devices are distributed in a staggered mode, and the side walls of the vertical plates are provided with first lifting driving devices and second lifting driving devices correspondingly. A drilling device and a plate body cleaning device are arranged between the two vertical plates; the first driving cylinder and the second driving cylinder are arranged at the two ends of the cross rod and slidably connected with the outer walls of the two vertical plates respectively, the rotating component is arranged at the executing end of the first driving cylinder, the telescopic component is arranged at the executing end of the second driving cylinder, and the executing end of the rotating component penetrates through the horizontal long hole to be connected with the first PCB positioning clamping plate. The execution end of the telescopic component penetrates through the horizontal long hole and is connected with the second PCB positioning clamping plate. According to the processing device, combined processing or split board processing of the multi-layer PCB is facilitated, stable punching is facilitated, and the board body is convenient to clean.

Owner:江西奔特科技有限公司

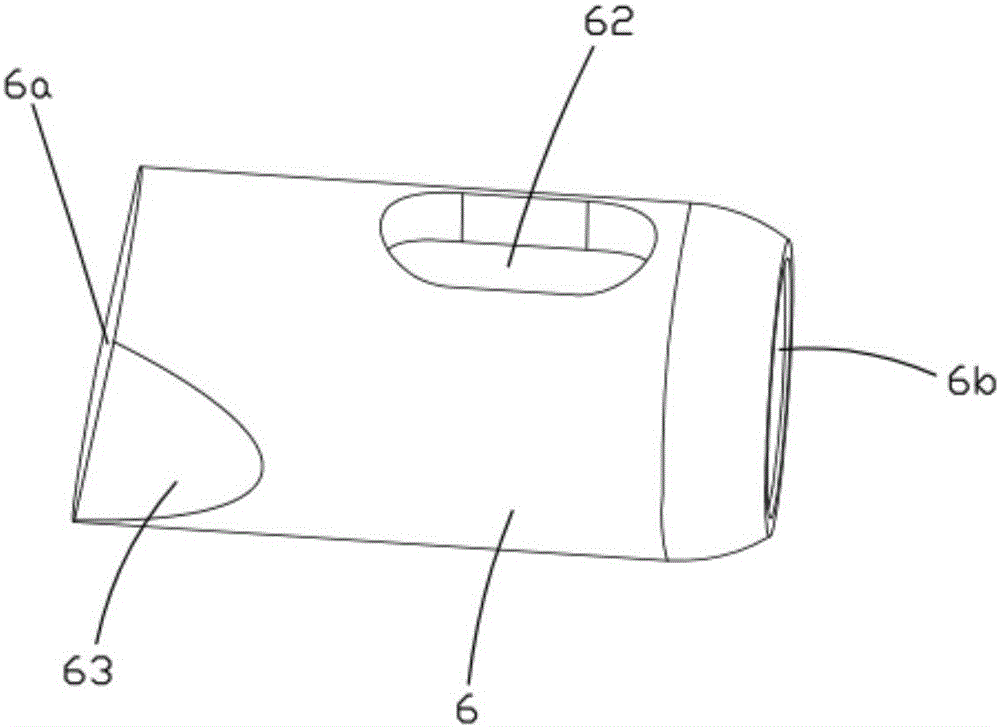

Printed bag punching die

ActiveCN112192659AAvoid moving injuriesImprove accuracy and qualityMetal working apparatusStructural engineeringPunching

The invention discloses a printed bag punching die which comprises a lower die. The upper end of the lower die is connected with a supporting plate through a plurality of supports, an air cylinder isfixed to the bottom of the supporting plate, a punch is fixed to the bottom of the air cylinder, a preset plate is fixed to the bottom of the punch, and two push rods which are symmetrically arrangedare fixed to the bottom of the supporting plate. Press plates are fixed to the bottoms of the two push rods correspondingly, a punching hole is formed in the upper end of the lower die, an expanding groove is formed in the side wall of the punching hole, and a discharging groove is formed in the bottom of the expanding groove in a penetrating mode. The printed bag punching die has the advantages that push plates are pushed through the push rods, a printed bag can be tightly pressed by the push plates to be in a tightened stable state, and therefore the stability and the effectiveness of the punching process are guaranteed; and the preset plate is arranged and can make contact with piezoelectric ceramic firstly in the downward movement process of the punch, and therefore electrorheologicalfluid can be solidified and expanded to push cutting edges to move upwards, the printed bag at the punching position can be jacked up, and the punch can cooperate with the cutting edges to better accomplish the punching motion.

Owner:宁波甜宝生物信息技术有限公司

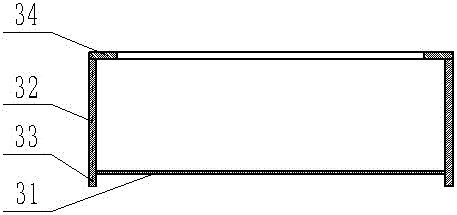

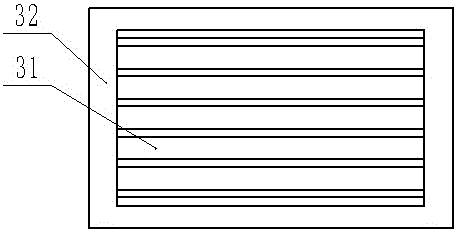

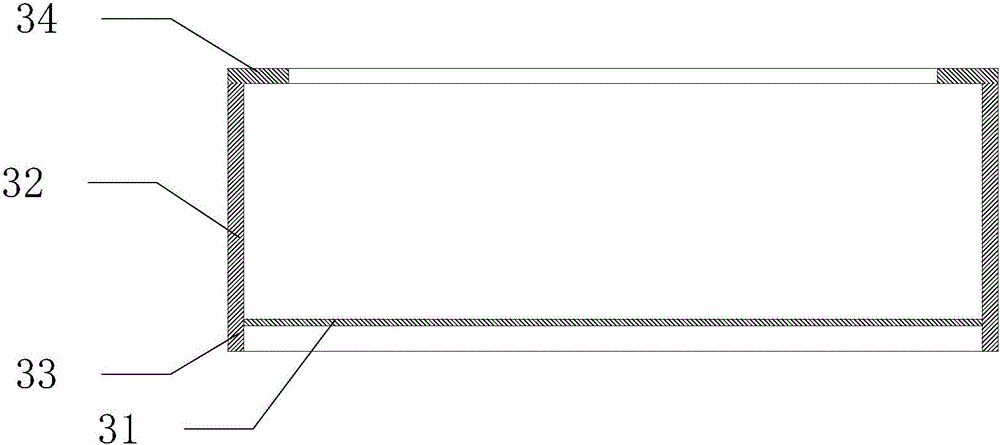

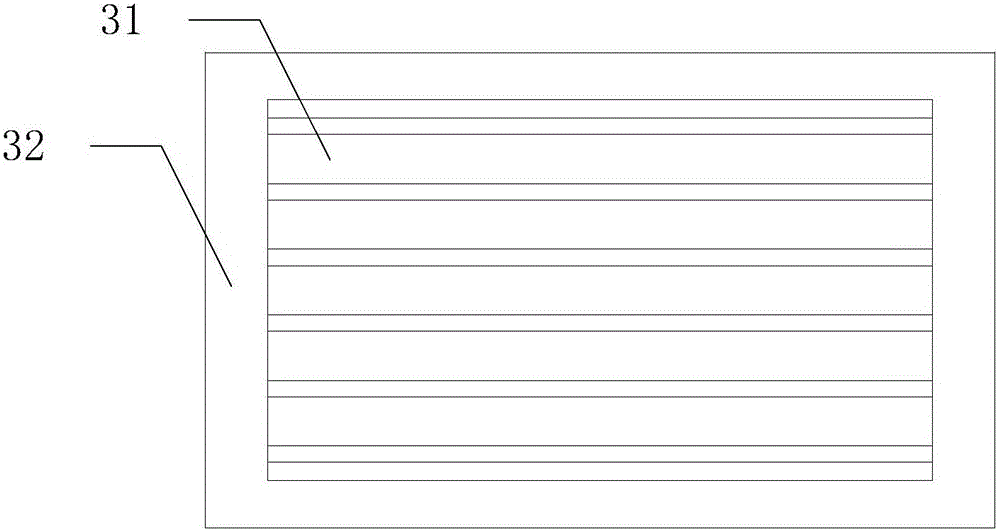

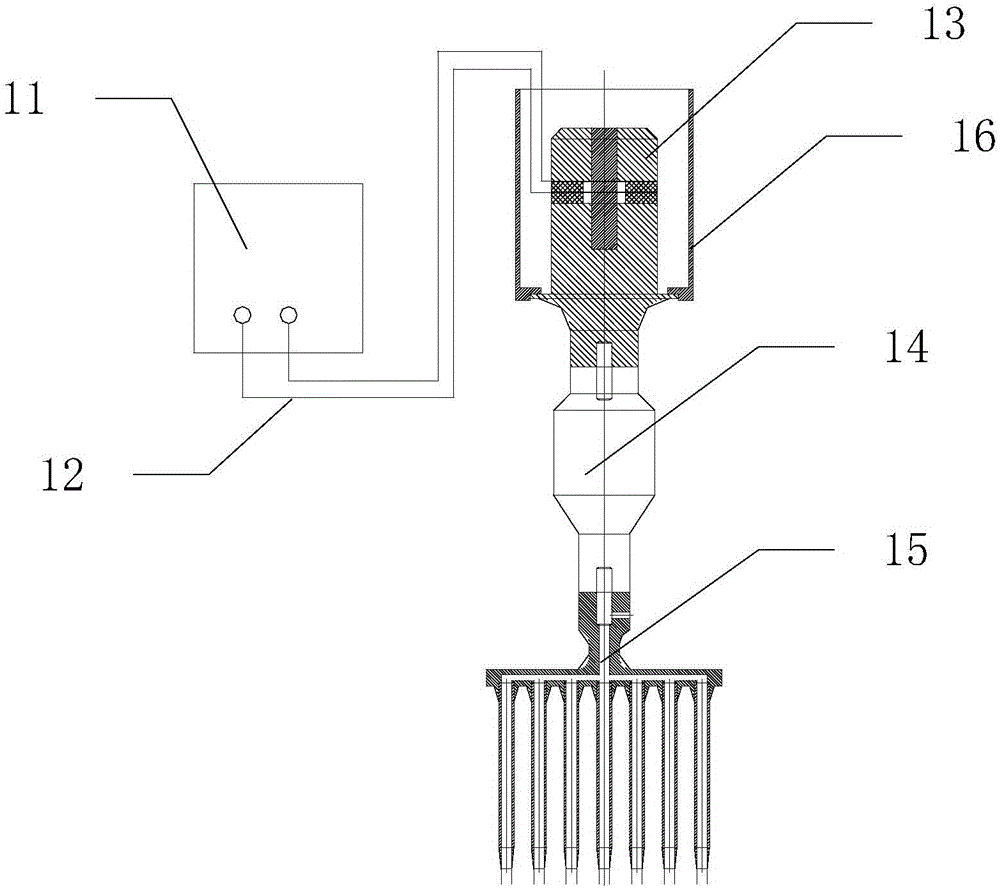

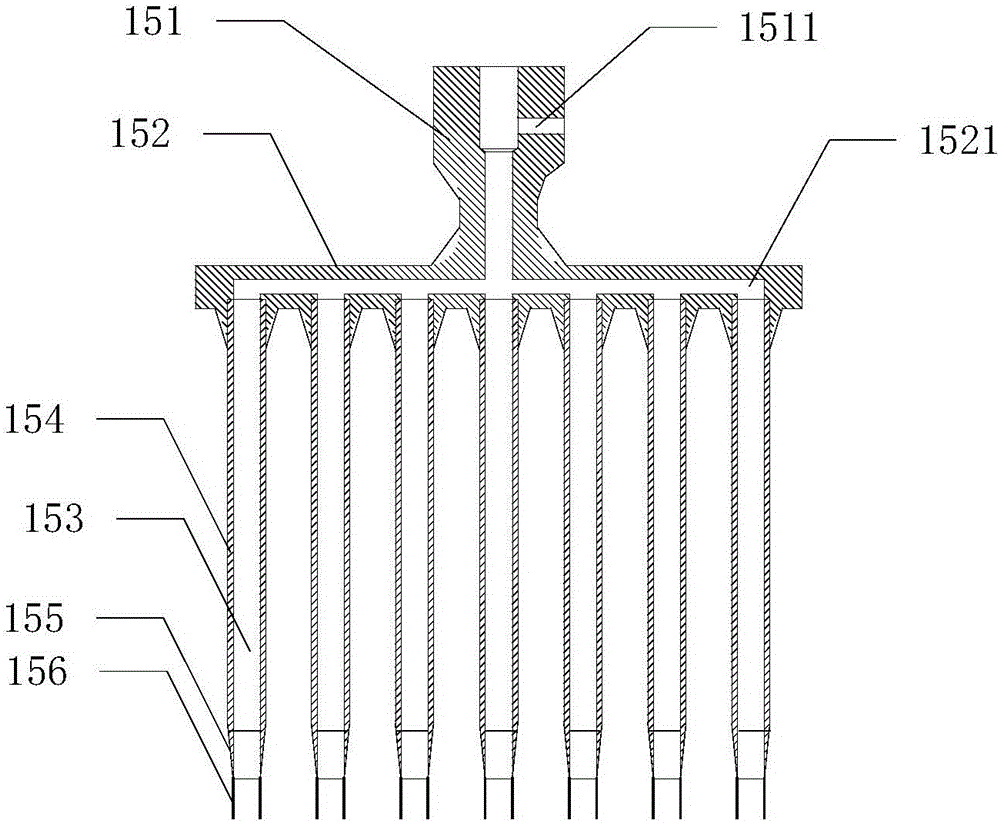

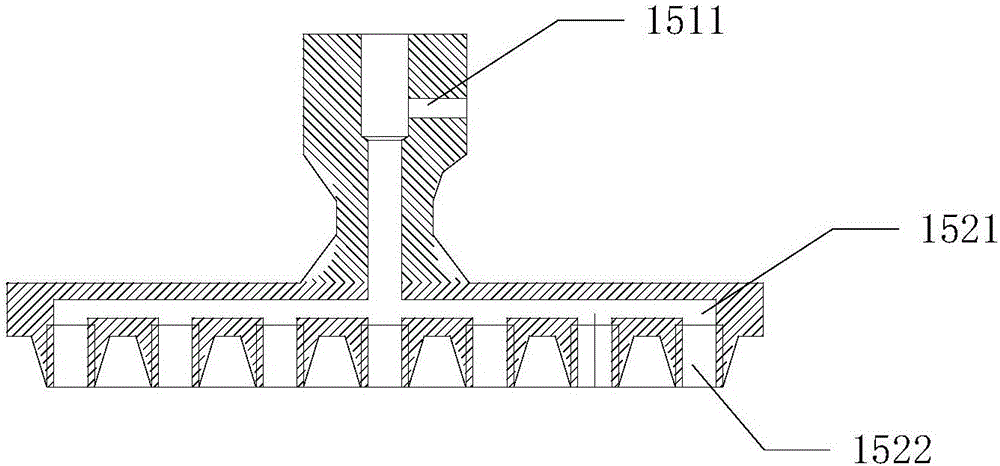

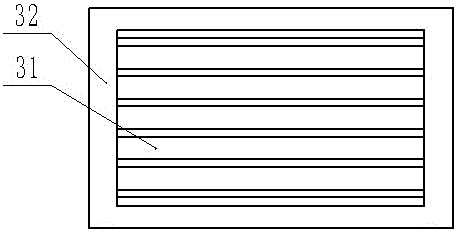

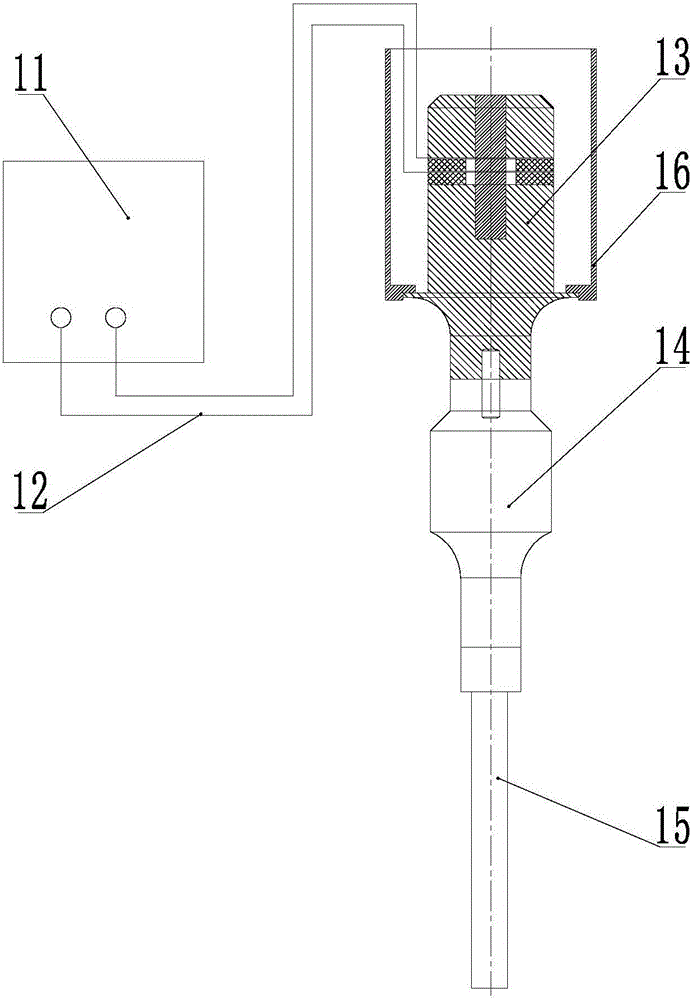

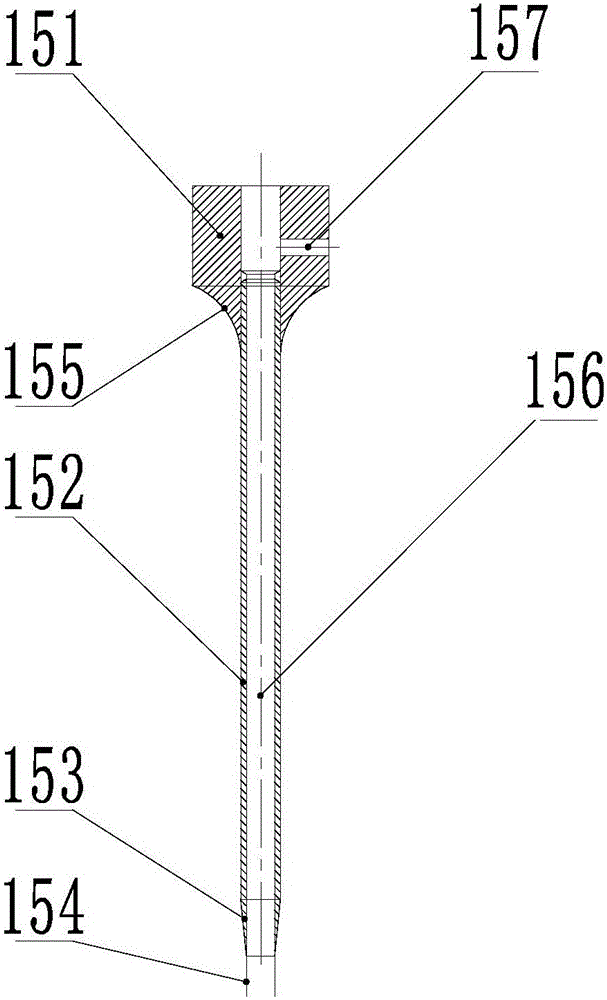

High-frequency vibration device for forming holes on sponge by gang drill

InactiveCN105773714AThe punching process is stableHigh precision of aperture sizeMetal working apparatusUltrasonic generatorEngineering

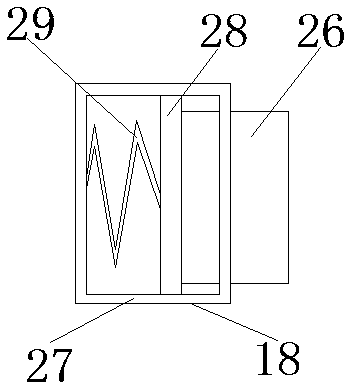

The invention particularly relates to a high-frequency vibration device for forming holes on sponge by gang drill. The high-frequency vibration device comprises an ultrasonic generator, an ultrasonic transducer, at least one stage of amplitude-change pole and a multi-tube cutter, wherein the ultrasonic transducer is connected with the ultrasonic generator through a wire; the at least one stage of amplitude-change pole is connected with the ultrasonic transducer; the multi-tube cutter is connected with the connected amplitude-change pole through threads; the multi-tube cutter comprises a connector connected with the amplitude-change pole and a tube body placing board; a plurality of tube bodies containing cavities and cutting edges are arranged on the tube body placing board; one end of each tube body is detachably connected with the tube body placing board; and other end of each tube body extends out of the corresponding cutting edge. According to the technical scheme provided by the invention, holes are easily formed in the sponge by adopting a high-frequency vibration mode; in addition, by adopting the design of the tube body placing board, forming operation of multiple holes is simultaneously realized; by means of a detachable connecting mode, the tube bodies are changed so as to greatly widen the service range and remarkably improve the production efficiency; and the device is simple in structure.

Owner:SUZHOU UNIV OF SCI & TECH +1

Drilling device used for plastic water pipe

InactiveCN107571330AEasy and flexible slidingImprove cleanlinessMetal working apparatusWater storageInjection port

The invention discloses a drilling device used for a plastic water pipe. The drilling device comprises a drilling cabinet, a fixing device, the plastic water pipe, a puncher, a side plate, a motor, awater injection port, a water storage pipe, a spray nozzle, a waste residue collecting box, a fixing port, a fixing support, a rubber pad, a handle, a rotary ball, a slide bar, a slide groove, a rotary shaft and a drill bit. The drilling device provided by the invention has the beneficial effects that by forming the slide groove and arranging the slide bar in the puncher, the drilling depth of thedrill bit can be adjusted as the slide bar slides horizontally; by mounting the rotary ball in the middle of the slide bar, the slide bar can be bent and folded when not being used; by mounting the handle on the upper portion of the slide bar, a user can slide the slide bar more easily and more flexibly; and by mounting the spray nozzle below the puncher and mounting the waste residue collectingbox below the spray nozzle, waste debris and waste residues generated during drilling of the plastic water pipe can directly fall into the waste residue collecting box after being subjected to water spraying treatment of the spray nozzle, and cleanliness of the device can be guaranteed.

Owner:林海涛

Clamped piston perforating device capable of guaranteeing drilling stability based on reciprocating movement

InactiveCN111496286APunch stableEasy to punchBoring/drilling componentsBoring/drilling machinesReciprocating motionEngineering

The invention relates to the technical field of pistons, and discloses a clamped piston perforating device capable of guaranteeing drilling stability based on reciprocating movement. The clamped piston perforating device comprises a base, wherein a support plate is fixedly connected to the top of the base to support raw materials, clamping plates are movably connected to the top of the support plate, and are curved, so that clamping is stable; a driller is movably connected to the tops of the clamping plates; through cooperation of a limiting frame, a vertical rod, a movable plate and the driller for use, drilling is automatically completed, and an artificial operation is not needed, so that the drilling is convenient, and the working efficiency is high; through cooperation of the clampingplates, a connecting rod, a push rod and the movable plate for use, in the drilling process, clamping can be automatically completed, artificial supporting by hands is not needed, the drilling is stable, and the hole integrity is guaranteed; and through cooperation of a first support rod, a swinging rod and a second support rod for use, movement of a linkage structure can improve the linkage of the entire device, and the operation is simple.

Owner:沈晶俊

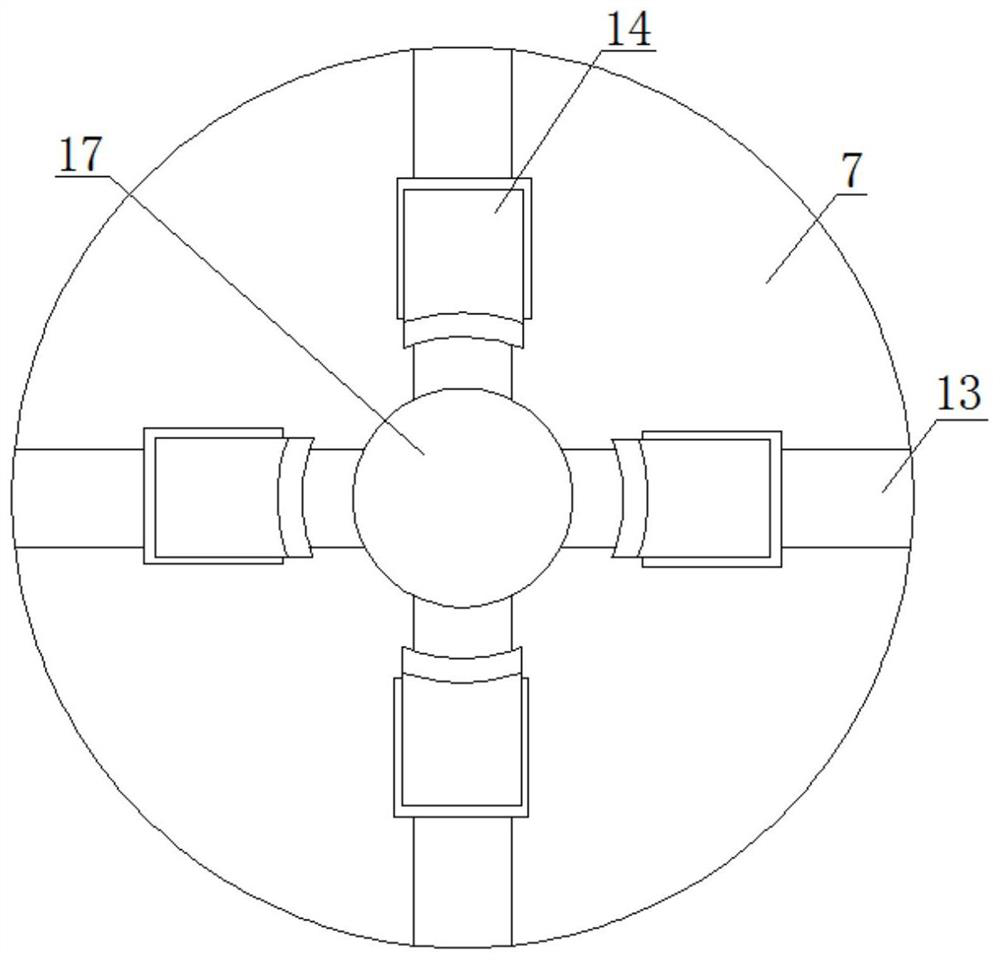

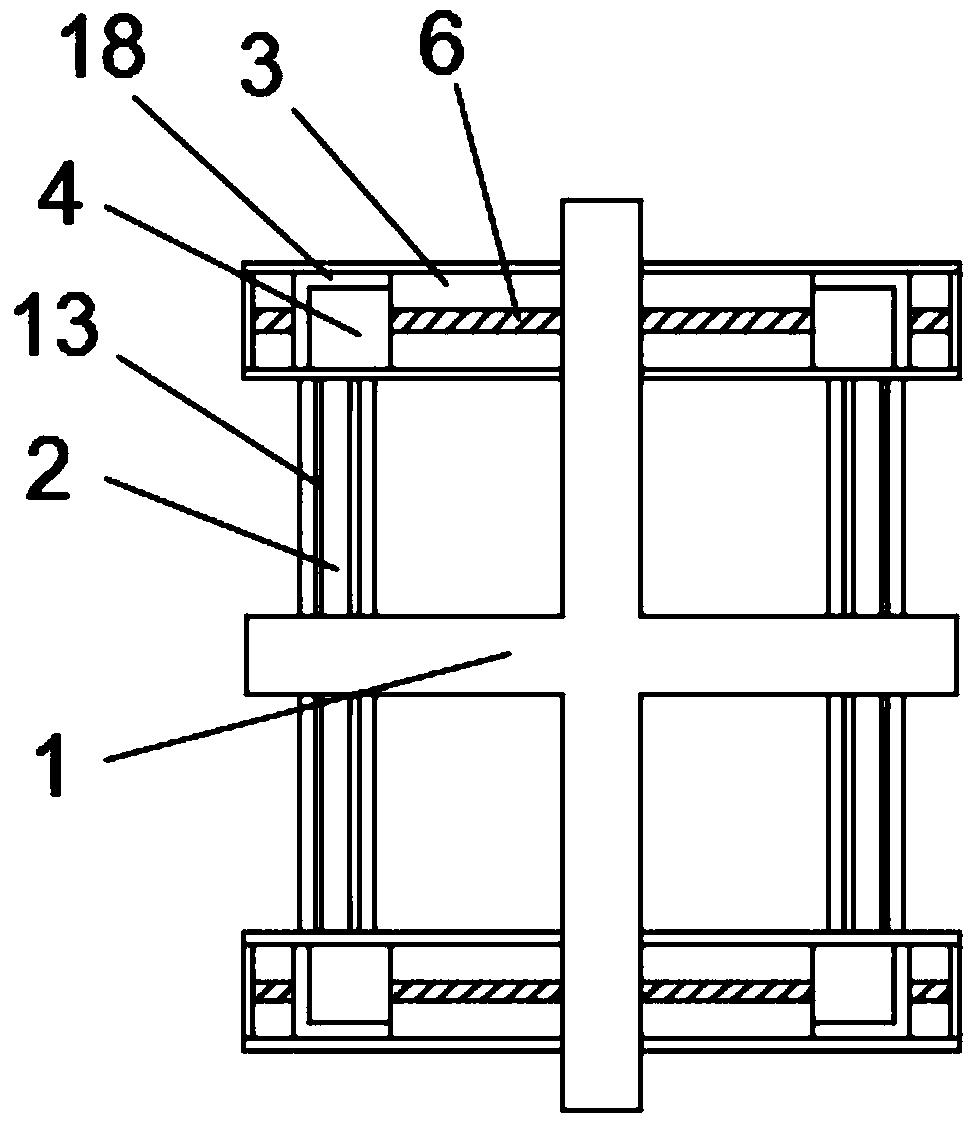

Glass plate four-angle drilling device capable of being adjusted for clamping

InactiveCN108673772APlay a drainage roleSimple structureWorking accessoriesStone-like material working toolsEngineeringGlass sheet

The invention discloses a glass plate four-angle drilling device capable of being adjusted for clamping. The glass plate four-angle drilling device includes a platform; the top of the platform is fixedly connected with two sets of mounting frames, and the platform and the tops of the mounting frames are fixedly connected with a cross loading table; the tops of the mounting frames are movably connected with two sets of sliding frames, and the tops of the sliding frames are movably connected with the bottom of the cross loading table; a moving table is movably in clamed connection with the sliding frames, and the top of the moving table is fixedly connected with a supporting frame; the top of the supporting frame is fixedly connected with a lifting device, and a drill bit is fixedly mountedat the bottom of the lifting device; the top of the moving table is movably connected with a collecting box in a sleeved mode, and two sets of guiding plates are fixedly connected with the top of theinner cavity of the collecting box; and a blanking groove is formed between the guiding plates, and the top of each guiding plate is fixedly connected with a plurality of supporting rods. The glass plate four-angle drilling device is simple in structure, convenient and practical, can be adjusted and positioned according to the size of different glass plates, collect the waste generated by drillingand is easy to apply and popularize.

Owner:ANHUI FENGYANG HUAIHE GLASS

High-frequency longitudinal torsion composite vibration sponge punching workbench and application thereof

InactiveCN105690444ANo damageAutomated processing is of great significanceMetal working apparatusAutomatic controlPunching

The invention relates to a high-frequency longitudinal torsion composite vibration sponge punching workbench and an application thereof. The workbench comprises a base, a horizontal movement mechanism, a fixing frame, a vertical movement mechanism, a supporting frame and a high-frequency longitudinal torsion composite vibration sponge punching device. The high-frequency longitudinal torsion composite vibration sponge punching device comprises an ultrasonic generator, an ultrasonic transducer, at least one stage of amplitude-change pole and a tubular tool. The tubular tool comprises a connector connected with the amplitude-change poles, a tube body with a cavity inside and a cutting edge, wherein one end of the tube body is in threaded connection with the connector; the cutting edge is arranged at the other end of the tube body; and the tube body is provided with a longitudinal torsion composite vibration conversion structure. According to the technical scheme, sponges are punched easily in a high-frequency longitudinal torsion composite vibration mode; horizontal movement of workpieces to be machined is achieved through a horizontal movement mechanism; the punching device can move up and down accurately through the vertical movement mechanism; and by means of the fixing frame, accurate automatic-control punching can be conducted in the specific positions of the workpieces to be machined as needed.

Owner:SUZHOU UNIV OF SCI & TECH

Automatic pipe fitting punching equipment

PendingCN108687222AIncrease productivityImprove yield rateShaping toolsPerforating toolsPunchingPipe fitting

The invention belongs to the technical field of automatic pipe fitting punching equipment appliances, and particularly relates to automatic pipe fitting punching equipment. The automatic pipe fittingpunching equipment comprises a machine frame, wherein a sliding rail is arranged on the machine frame; a punching die frame is arranged on the sliding rail, and the punching die frame can slide on thesliding rail through an air cylinder; an upper punch is arranged on a punching machine, and the upper punch is correspondingly matched with a punching hole of the upper die frame; a discharge chute is formed in one end of the punching die frame, and a material jacking air cylinder is arranged at the side of the discharge chute; and a material jacking plate is connected to the output end of the material jacking air cylinder, and when the punching die frame with pipe fittings slides to the vicinity of the discharge chute, the material jacking air cylinder outputs to enable the material jackingplate to pushe the pipe fittings out of the punching die frame into the discharge chute. The automatic pipe fitting punching equipment has the beneficial effects that feeding, blanking, positioning and one-time punching can be completed through mechanical operation, so that the production efficiency is improved, and the yield and accuracy of products are improved at the same time.

Owner:HUZHOU IRON FORCE METAL PROD

Punching mechanism for circuit board datum hole punching machine

InactiveCN114102743AEasy to clamp and positionGood for getting close to each otherMetal working apparatusPunchingElectric machinery

The invention discloses a punching mechanism for a circuit board datum hole punching machine, which comprises a punching mechanism main body, a fixed seat, a punching head and a clamping piece, guide columns are arranged at four corners of the top of the punching mechanism main body, a top plate is arranged at the top ends of the guide columns, and an air cylinder is arranged at the top end of the top plate; a lifting plate is arranged above the punching mechanism body, the output end of the air cylinder is connected with the lifting plate through a telescopic column, a clamping sleeve is arranged at the bottom end of the lifting plate, a punching head is arranged in the clamping sleeve, and a fixing base is arranged on the portion, below the punching head, of the punching mechanism body. And clamping pieces are arranged at the top ends of the movable sleeves. By installing the punching mechanism body, the fixing base, the groove, the motor, the rotating rod, the movable sleeve and the clamping piece, a circuit board needing to be punched can be automatically clamped and positioned, operation is easy, and time and labor are saved.

Owner:绍兴华创光电科技有限公司

Reversed punching structure aiming at inclined plane shapes and punching process

The invention discloses a reversed punching structure aiming at inclined plane shapes. The reversed punching structure comprises a base, a sliding block, and a puncher pin, wherein a first driving block is arranged at one end of the lower part of the sliding block, a second driving block is arranged at the upper part of the base, the first driving block is connected in a sliding manner with the second driving block, the puncher pin is used for punching a workpiece to be processed, and the puncher pin is arranged at one end of the lower part of the sliding block. Due to the adoption of the reversed punching structure provided by the invention, the problem of not high processing accuracy caused by displacement of the puncher pin in the prior art can be effectively solved, in addition, the problem that the driving block of a die driving puncher pin in the prior art can probably cause interference with workpieces of products can be solved.

Owner:FOSHAN CHENGYANG ZHENGDA MOLD HARDWARE PLASTIC CO LTD

Punching device convenient for punching angle adjustment

ActiveCN110153470ASimple and fast operationPrevent the hole position from being skewedPortable power-driven toolsPortable drilling machinesPunchingRotary switch

The invention discloses a punching device convenient for punching angle adjustment. The punching device comprises a shell and a handle, wherein the handle is arranged on one side of the upper part ofthe shell; a rotary switch and a movable switch are respectively arranged on the lower side of the handle; a holding handle is arranged on the other side, opposite to the handle, of the upper part ofthe shell; a rear end cover is arranged on the upper end of the shell; the interior of the rear end cover is connected with an electric cylinder through a fixing sleeve; the lower end of the electriccylinder is connected with a motor; a motor shaft is arranged in the motor; the other end of the motor shaft is connected with a drill; and sliding blocks are symmetrically arranged on two sides of the motor. The punching device has the advantages of being simple and convenient to operate; inclined holes can be conveniently drilled on a plane and a spherical surface, hole position deviation due tothe deviation of a pressure direction applied to an electric drill from a machine body is avoided, so that the drilling process is more stable, and the drilling efficiency and the drilling quality are improved; and meanwhile, the punching device is applicable to drilling on various working surfaces, the use range is wide, and the use requirements are well met.

Owner:浙江甬岭数控刀具有限公司

Battery grid production equipment

InactiveCN112059010AAchieve clampingEasy to process punchingPerforating toolsMetal-working feeding devicesIndustrial engineeringElectrical and Electronics engineering

The invention relates to the technical field of battery processing, and discloses battery grid production equipment. The battery grid production equipment comprises a workbench, wherein a supporting frame is fixedly connected to the top of the workbench; the supporting frame is in an inverted-L shape; a hydraulic press is fixedly connected to the top of the supporting frame; the telescopic end ofthe hydraulic machine penetrates through the top of the supporting frame and extends out of the supporting frame; and the telescopic end of the hydraulic press is fixedly connected to a stamping die.According to the battery grid production equipment, a handle is moved upwards, so that a clamping rod slides on the surface of a fixed shaft and in a sliding groove, a tension spring stretches, and alead belt is placed at the bottom of the clamping rod, so that workers can machine and punch the lead belt more conveniently; and meanwhile, the device can clamp and fix the lead belt more conveniently, and the situation that the lead belt slides in the punching process, so that the punching position is moved, and the lead belt is scrapped is reduced.

Owner:刘俊汝

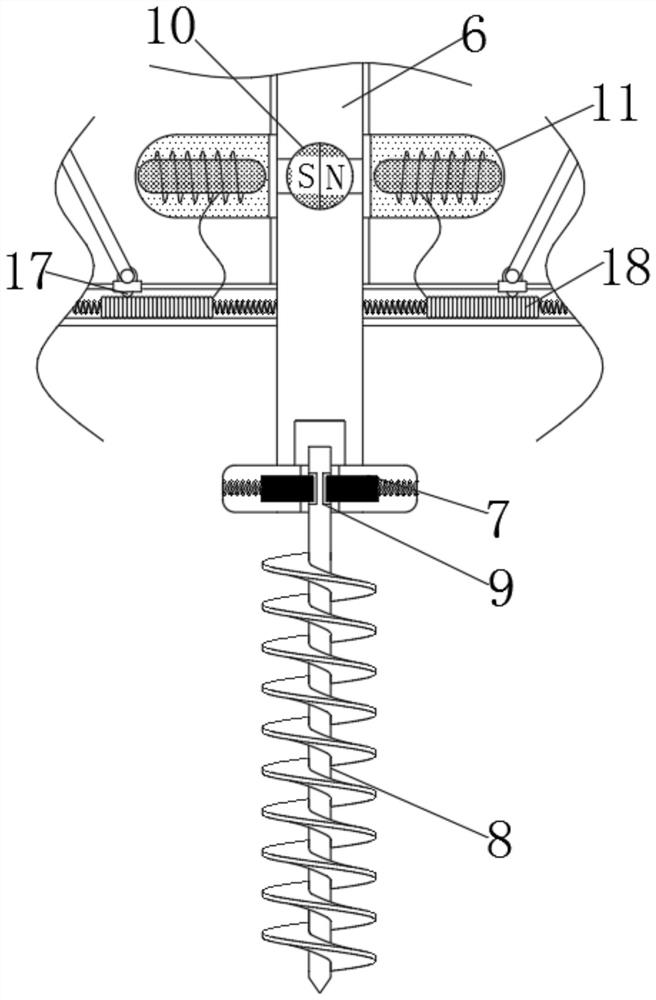

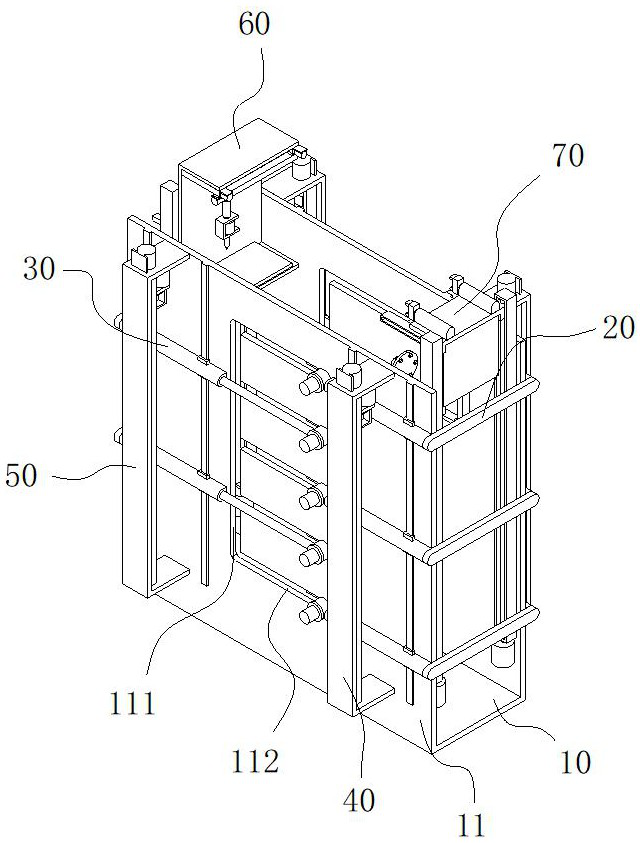

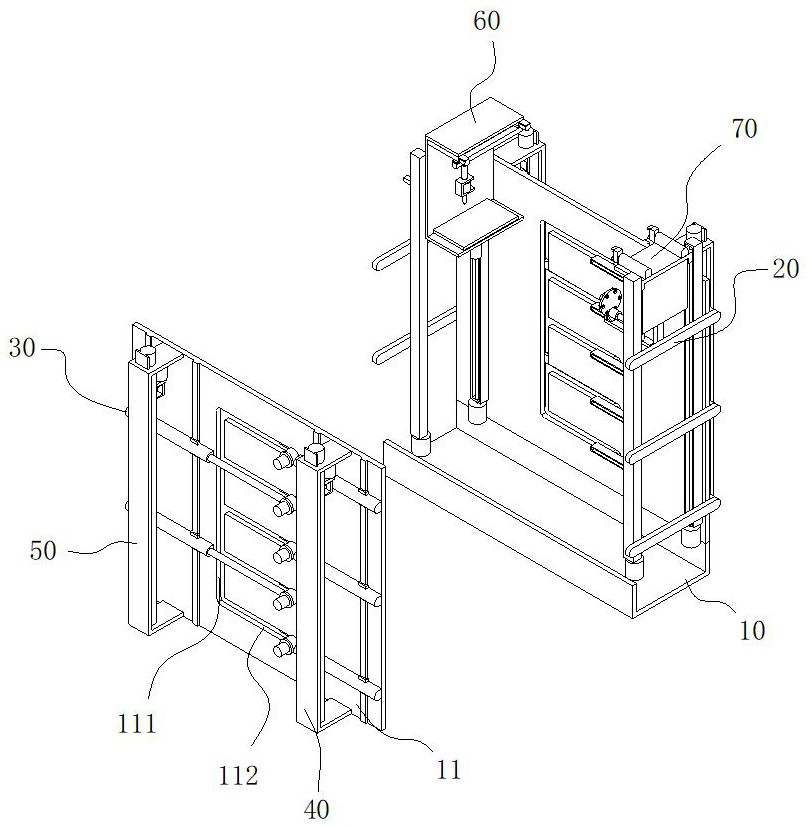

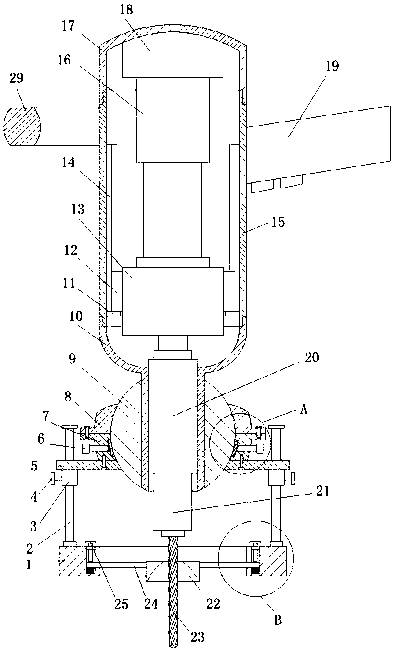

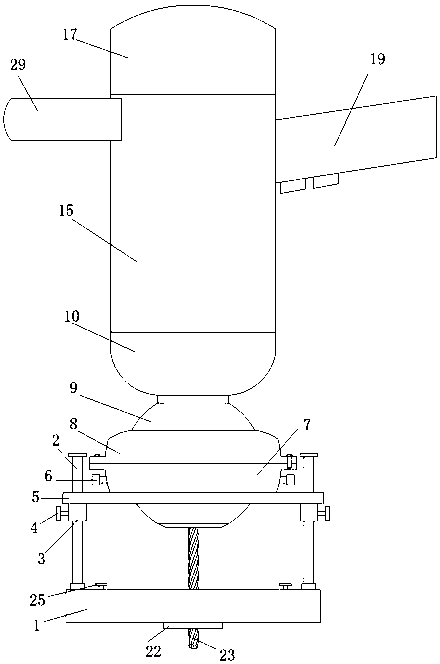

Pipeline tap welding installation device

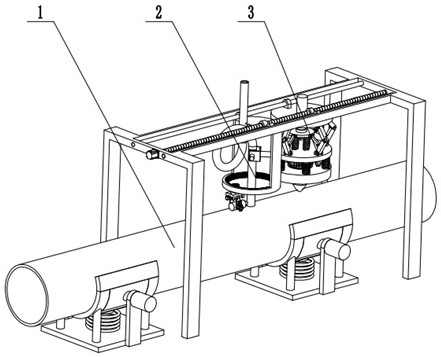

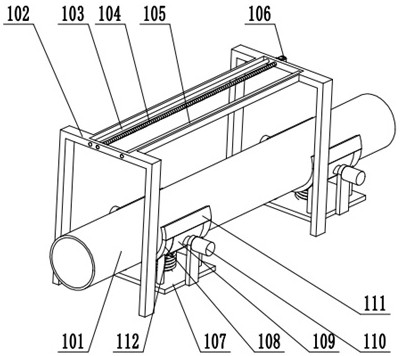

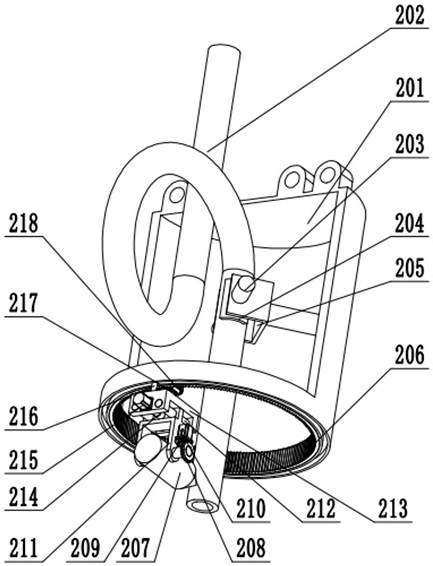

ActiveCN112192222APunch stableAvoid slackWork clamping meansWelding/cutting auxillary devicesDrilling systemDrill hole

The invention discloses a pipeline tap welding installation device. The device comprises a main frame system, a welding system and a drilling system, wherein the main frame system is a base and is also an installation platform of the welding system and the drilling system, the welding system and the drilling system can move left and right along a guide rail on the main frame system, firstly, a pipeline needing to be provided with a tap is placed on the main frame system, the drilling system conducts mechanical drilling on the pipeline, after drilling is completed, the welding system welds thetap to a drilled hole, transmission belts are used in the drilling system, tensioning devices are arranged on the transmission belts, a tensioning spring in the drilling system provides outward tensioning force to control a side tensioning wheel to tension the left transmission belt, a tensioning wheel tensions the right transmission belt, and a buffer spring is arranged at the bottom, with the pipeline placed, of the main frame system, so that when the pipeline is drilled, impact can be relieved, and deformation is reduced.

Owner:江苏源清管业有限公司

Glass plate four corner dust-free drilling automatic transfer device

ActiveCN108582513APlay a drainage roleSimple structureWorking accessoriesStone-like material working toolsEngineeringGlass sheet

The invention discloses a glass plate four corner dust-free drilling automatic transfer device. The glass plate four corner dust-free drilling automatic transfer device comprises a platform; two mounting racks are fixedly connected to the top of the platform; a cross-shaped objective table is fixedly connected to the top of the platform and the mounting racks; two sliding racks are movably connected to the tops of the mounting racks; the tops of the sliding racks are movably connected with the bottoms of the cross-shaped objective table; moving tables are movably connected with the sliding racks in a clamped mode; supports are fixedly connected to the tops of the moving tables; lifting apparatuses are fixedly connected to the tops of the supports; drill bits are fixedly mounted at the bottoms of the lifting apparatuses; collecting boxes are movably connected to the tops of the moving tables in a sleeved mode; every two material guiding plates are fixedly connected to the top of an inner cavity of one collecting box; each material discharging groove is formed between the corresponding material guiding plates; and a plurality of supporting rods are fixedly connected to the tops of the corresponding material guiding plates. The glass plate four corner dust-free drilling automatic transfer device is simple in structure, convenient, practical and capable of achieving automatic transfer, adjustment and positioning are performed according to the sizes of different glass plates, waste materials generated by perforation are collected and treated, and the glass plate four corner dust-free drilling automatic transfer device is easy to apply and popularize.

Owner:ANHUI FENGYANG HUAIHE GLASS

Pipe fixing device for multi-type punching

The invention discloses a pipe fixing device for multi-type punching. The device comprises a supporting table, and a punching device and a fixing die arranged on the supporting table, wherein a groove is formed in the fixing die, and a fixing module capable of limiting a pipe is connected into the groove. According to the pipe fixing device for multi-type punching, through the arranged fixing module, hole pieces, falling off due to punching, at the top of the interior of the pipe can be treated during use, so that the hole pieces punched at the top of the pipe are prevented from falling to the punching position at the bottom of the pipe, the punching precision of the punching device on the pipe is more accurate, and through the arranged fixing module, the position of the pipe can be further positioned during use, so that the pipe is more stable during punching, and the pipe punching precision is improved.

Owner:柳州广升汽车零部件有限公司

High-frequency vibrating sponge perforating device and application thereof

InactiveCN105773679AProcessing is of great significanceHigh precision of aperture sizeMetal working apparatusTransformerEngineering

The invention particularly relates to a high-frequency vibrating sponge perforating device and application thereof. The high-frequency vibrating sponge perforating device is mainly used for processing an elastic layer on a transfer roller in a printer or copier and comprises an ultrasonic generator, an ultrasonic transducer connected with the ultrasonic generator through wires, at least one amplitude transformer connected with the ultrasonic transducer and a tubular tool connected with the amplitude transformer, wherein the tubular tool is in threaded connection with the amplitude transformer and comprises a connector connected with the amplitude transformer, a tube body with an inner cavity and a cutting edge; one end of the tube body is in threaded connection with the connector; the cutting edge is arranged at the other end of the tube body; and a circular arc transition structure is arranged at the joint of the tube body and the connector. Through the technical scheme provided by the invention, the high-frequency vibrating sponge perforating device perforates sponge easily, a perforating process is stable, the dimensional accuracy of holes is high, the surfaces of hole walls are smooth and free of damage, the product percent of pass is greatly increased, and the production efficiency is remarkably improved.

Owner:SUZHOU UNIV OF SCI & TECH +1

Punching equipment with multidirectional rotating function

InactiveCN112025334ARealize the collectionAvoid pinchingLarge fixed membersPositioning apparatusPunchingClassical mechanics

The invention relates to punching equipment with a multidirectional rotating function. The punching equipment comprises a fixing box, a drill bit, a driving box, a rotating mechanism, a supporting mechanism and a clamping mechanism, the supporting mechanism comprises a moving plate, a transverse plate, an elastic piece, a sliding block and a bolt, the rotating mechanism comprises a motor and a rotating block, and the clamping mechanism comprises a clamping plate, a supporting rod, an abutting rod, a first spring and a pushing block. According to the punching equipment with the multidirectionalrotating function, a metal material is rotated through the rotating mechanism, the metal material is clamped through the clamping mechanism, the metal material is elastically clamped through restoring force of a torsional spring and a second spring, and the surface of a workpiece is prevented from being damaged by clamping; the bottom end of the metal material is fixed through the fixing mechanism, secondary fixing of the metal material is achieved through the air pressure difference, and the end, away from the rotating block, of the metal material is supported through the supporting mechanism, so that punching is more stable; and meanwhile, scrap iron is collected through a collecting box below, so that the use practicability is improved.

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com