Automobile tray bearing nut locking gasket blanking-molding-punching composite die and process thereof

A bearing nut and lock washer technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of long production time, low production efficiency, large number of molds, etc., to increase production capacity, stable strength performance, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

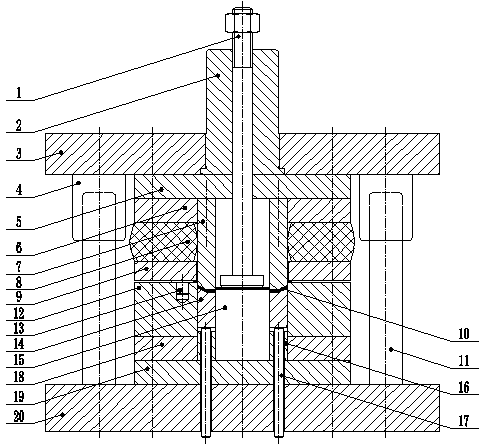

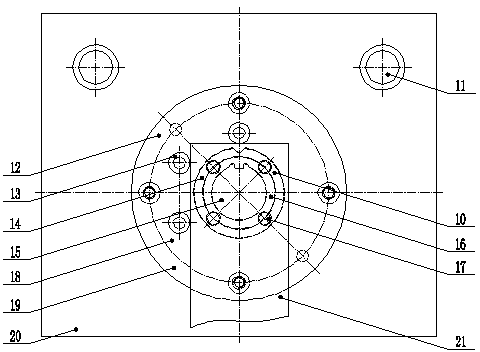

[0026] Example: see figure 1 — Figure 4 .

[0027] A kind of blanking forming and punching composite mold for bearing nut lock washer of automobile pallet type, comprising an upper mold and a lower mold, and the upper mold includes an upper discharge rod 1, a mold handle 2, an upper Template 3, upper backing plate 5, upper fixing plate 6, upper unloading rubber 8 and upper unloading plate 9, the upper fixing plate 6 is provided with a convex and concave die seat hole and is fixedly connected with the blanking forming punching punch and concave die 7, and the upper The unloading rubber 8 and the upper unloading plate 9 are provided with the guide holes of the punching and concave dies and are slidingly connected with the blanking forming punching punching and concave dies 7, and the blanking forming punching punching and concave dies 7 are cylindrical structures; the upper unloading rod 1 and the mold handle 2 1. The middle guide hole of the upper backing plate 5 is slidingl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com