Reversed punching structure aiming at inclined plane shapes and punching process

A technology of reverse punching and hole structure, which is applied in the field of stamping processing molds, can solve the problems of damage to the die, poor precision, and increase the repair rate of the mold, so as to avoid movement, improve processing accuracy and processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

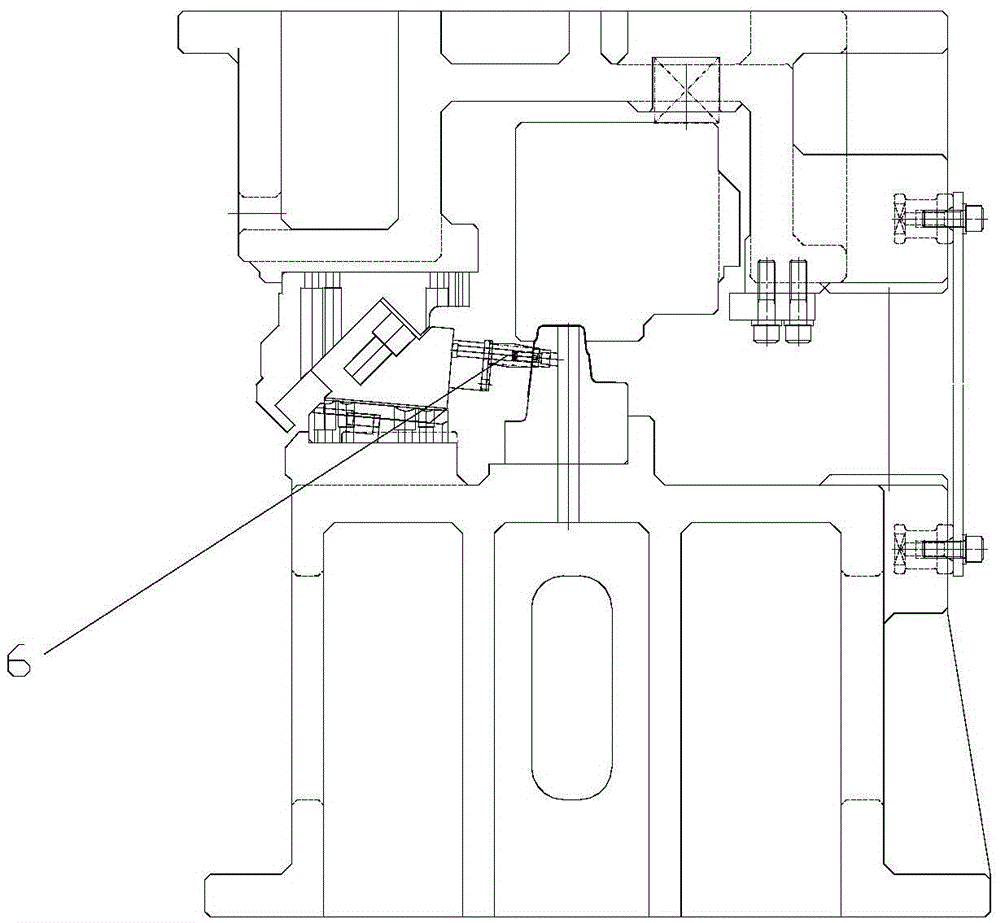

[0030] refer to figure 1 , figure 1 It is a schematic diagram of the punch setting structure of the stamping die in the prior art. The punch 6 punches the workpiece from left to right, and the driving block driving the punch 6 is likely to interfere with the workpiece to be processed; in addition, the punch of this type of structure When the workpiece is directly punched, the reaction force caused by the force applied to the workpiece during processing is applied to the punch 6, which easily causes the punch to move and travel unstable, and reduces the processing accuracy.

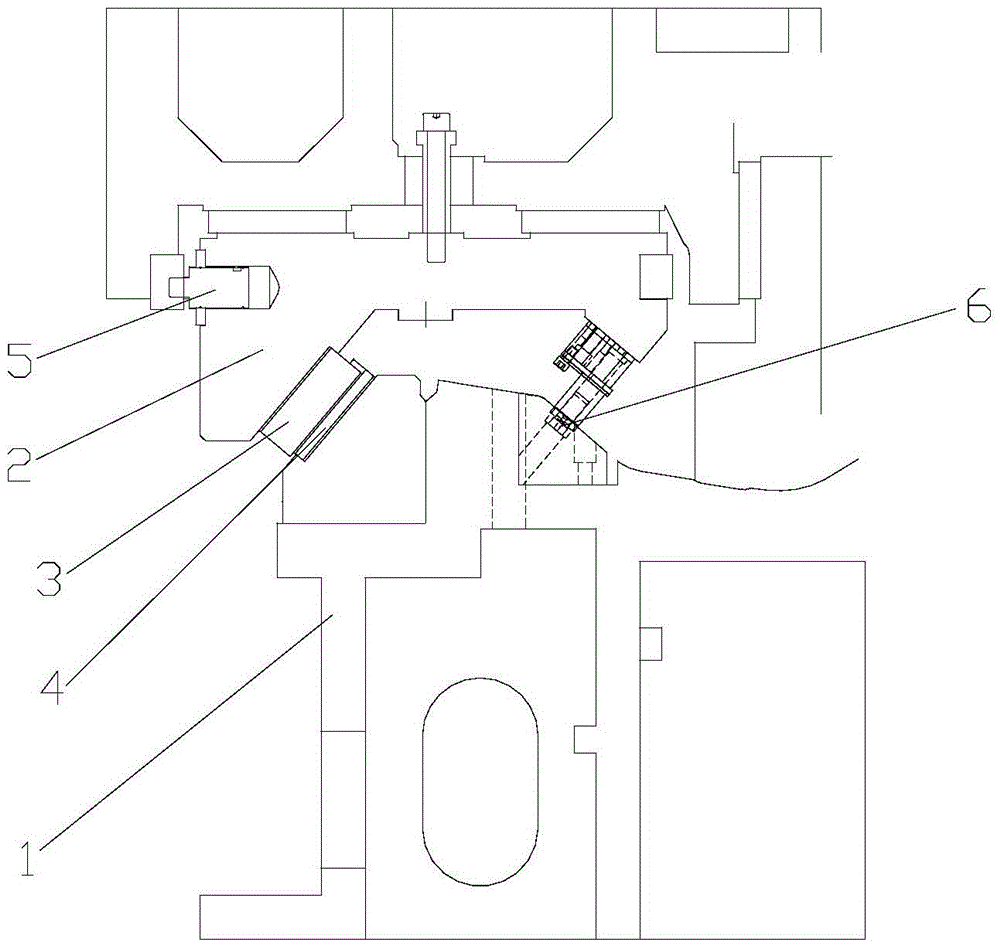

[0031] refer to figure 2 , the present invention provides a reverse punching structure aimed at the shape of the inclined plane, which includes a base 1 and a sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com