Pipeline tap welding installation device

A technology for source extraction components and installation devices, which is applied in the field of pipeline source extraction components welding and installation devices, can solve the problems that chemical cutting cannot be used, and cannot realize automatic installation of source extraction components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

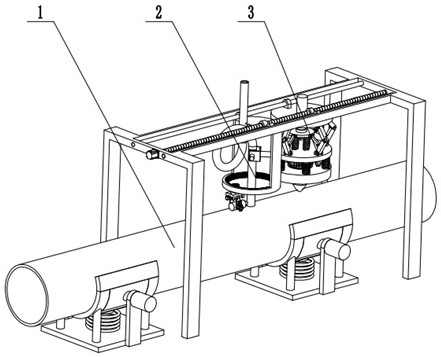

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown is a welding installation device for pipe source components. Main frame system 1 is base, also is the installation platform of welding system 2, drilling system 3 simultaneously.

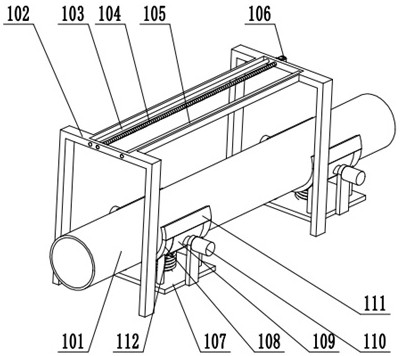

[0022] The specific structure of the main frame system 1 is as follows: figure 2 As shown, wherein the main frame 102 is placed on the ground, the translation motor 106 is fixedly installed on the main frame 102, the two ends of the left guide rail 103 and the right guide rail 105 are fixedly installed on the main frame 102, and one end of the translation screw rod 104 is rotatably installed on the main frame 102, the other end is fixedly installed on the motor shaft of the translation motor 106, the bottom plate 107 is placed on the ground, the tube support 108 is fixedly installed on the bottom plate 107, the upper card 111 is detachably fixed on the tube support 108, and the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com