Glass plate four corner dust-free drilling automatic transfer device

A transfer device and glass plate technology, applied in the field of machinery, can solve problems such as inability to adjust positioning, low efficiency, and deviation of punching holes, and achieve the effects of easy popularization and application, simple structure, and easy washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

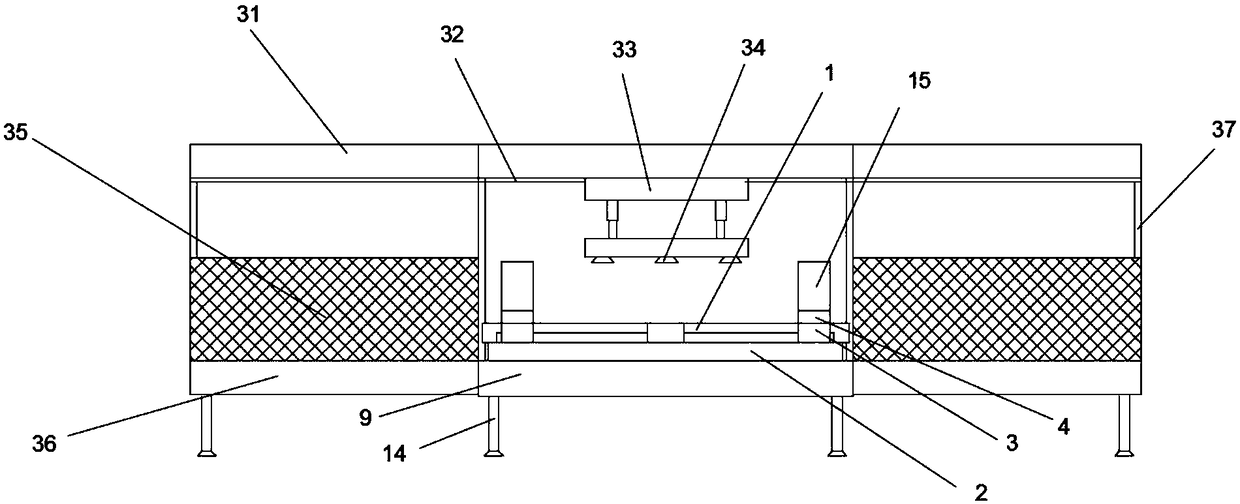

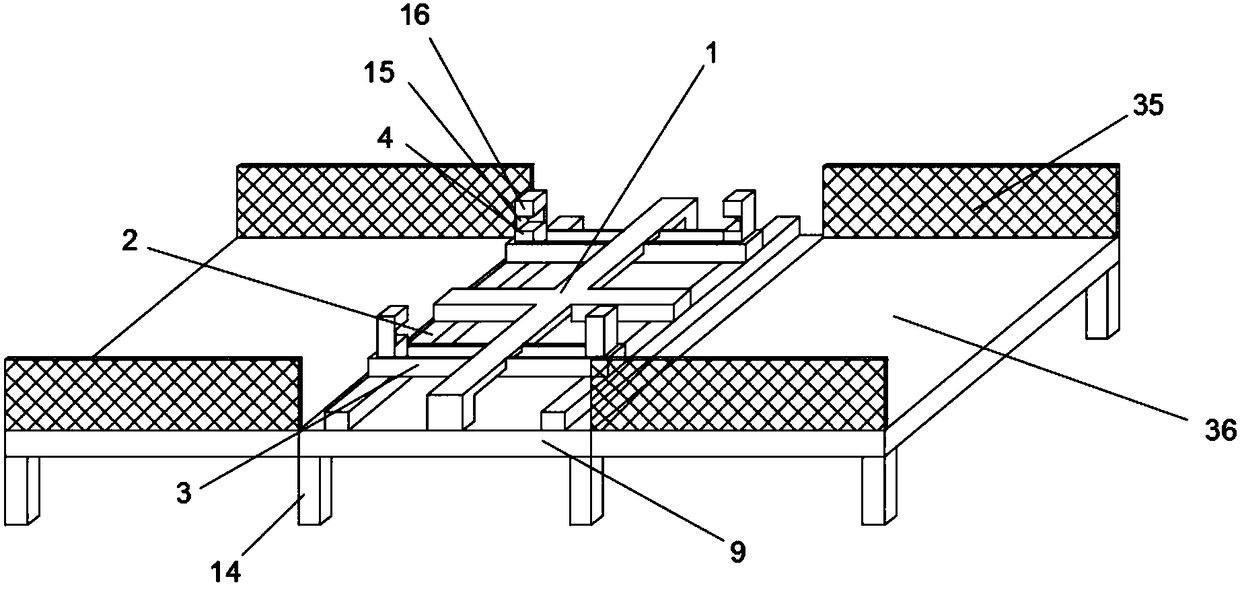

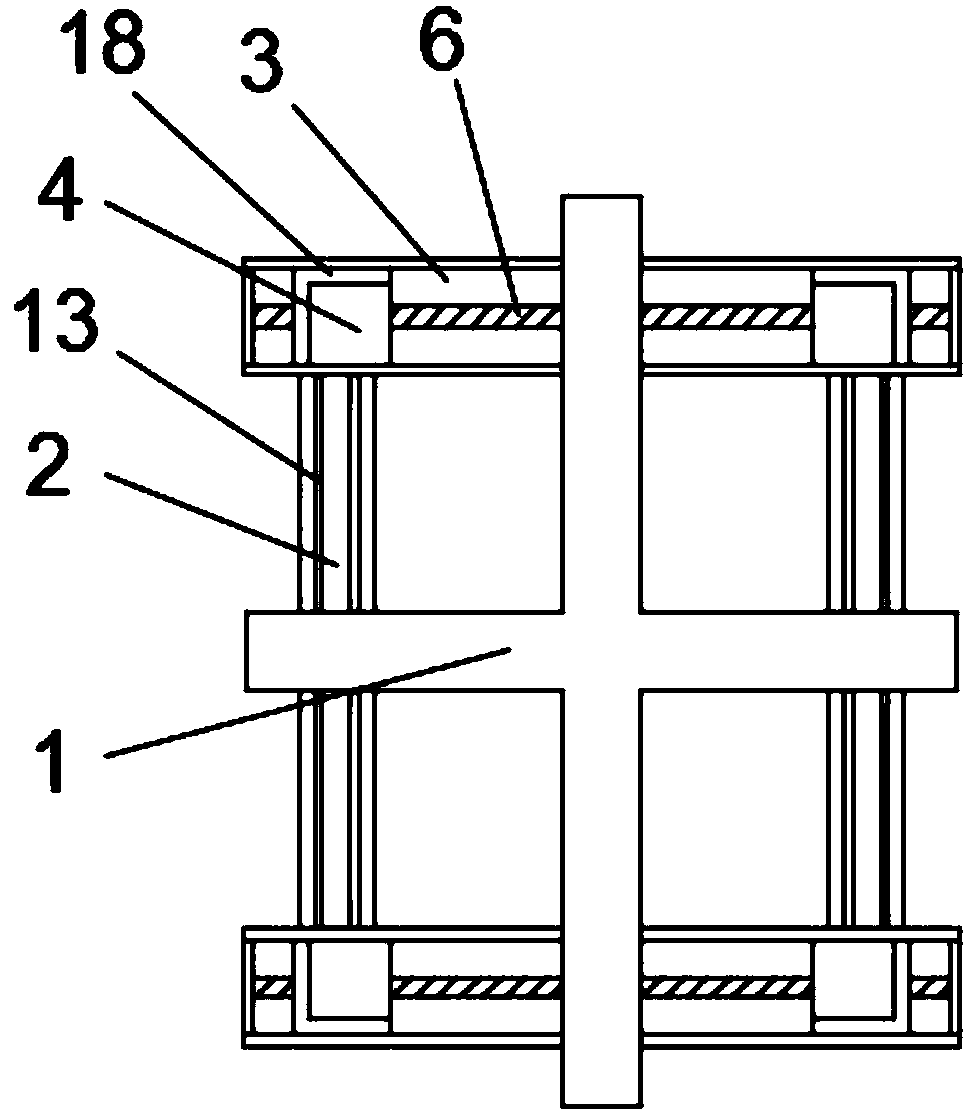

[0027] Embodiment 1: as figure 1 - as shown, a glass plate four corners dust-free drilling automatic transfer device, including a platform 9, the two sides of the platform 9 are fixedly connected with a placement frame 26, and the tops of the platform 9 and the placement frame 26 are fixedly connected with a bracket 37, the top of the support 37 is fixedly connected with a top frame 31, the bottom of the top frame 31 is fixedly installed with a sliding rail 32, and the bottom of the top frame 31 is movably connected with a moving frame 33 through the sliding rail 32, and the moving The bottom of the frame 33 is fixedly equipped with a lifting platform 38, and the bottom of the lifting platform 38 is fixedly equipped with a number of suction cups 34, and the bottom of the platform 9 is fixedly connected with supporting feet 14, and the supporting feet 14 are provided with six groups. Two groups of mounting frames 2 are fixedly connected to the top of the platform 9 and the top ...

Embodiment 2

[0029] Embodiment 2: as figure 1As shown, an automatic transfer device for dust-free drilling at four corners of a glass plate includes a platform 9, the two sides of the platform 9 are fixedly connected with a placement frame 26, and the tops of the platform 9 and the placement frame 26 are fixedly connected with a bracket 37 , the top of the support 37 is fixedly connected with a top frame 31, the bottom of the top frame 31 is fixedly equipped with a slide rail 32, and the bottom of the top frame 31 is movably connected with a mobile frame 33 through the slide rail 32, and the mobile frame The bottom of 33 is fixedly equipped with lifting platform 38, and the bottom of described lifting platform 38 is fixedly installed with some suction cups 34, and the bottom of described platform 9 is fixedly connected with supporting feet 14, and described supporting feet 14 is provided with six groups, and the bottom of described platform 9 The top is fixedly connected with two sets of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com