Can washing liquid production device used for canned food packaging

A technology for canned food and packaging, which is used in mixer accessories, dissolving, mixers, etc., can solve the problems of unsatisfactory configuration of the preparation device, and achieve the effect of ensuring normal development, simplifying floor space and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

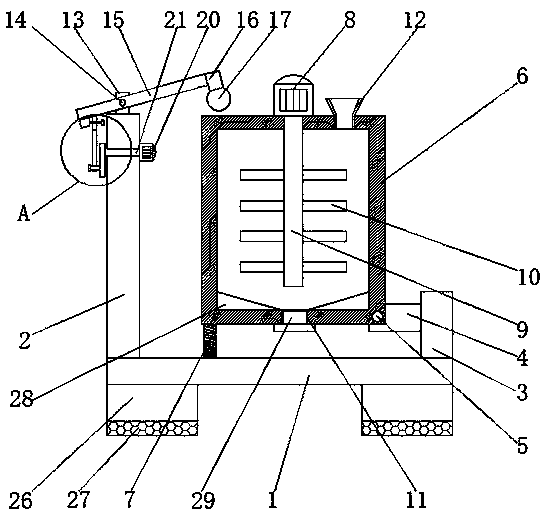

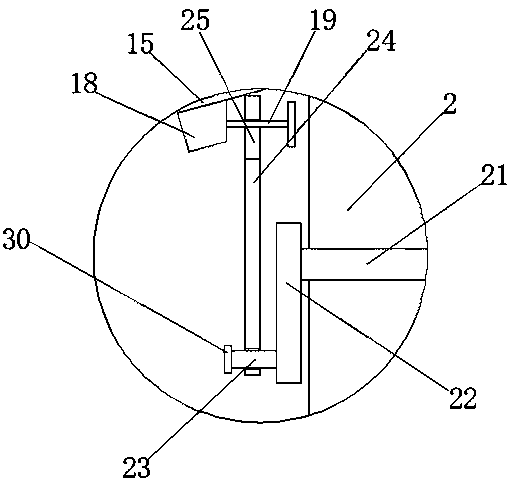

[0017] First implementation: see Figure 1-2 , a can washing liquid preparation device for canned food packaging, comprising a base 1, the left and right sides of the bottom of the base 1 are fixedly connected with support legs 26, and the bottom of the support legs 26 is fixedly connected with an anti-slip block 27, by setting the anti-slip block 27, Effectively avoiding the sliding of the configuration device due to vibration during operation, the left side of the top of the base 1 is fixedly connected with the support column 2, and the right side of the top of the base 1 is fixedly connected with the first fixed block 3, and the first fixed block 3 The left side is fixedly connected with the first fixed plate 4, the front side of the first fixed plate 4 is fixedly connected with the first fixed shaft 5, the surface of the first fixed shaft 5 is movably connected with the preparation box 6, and the left and right sides of the inner wall of the preparation box 6 The bottoms a...

no. 2 approach

[0020]Second embodiment: as shown in claim 1, a can washing liquid preparation device for canned food packaging, comprising a base 1, the left side of the top of the base 1 is fixedly connected with a support column 2, and the top of the base 1 is The right side is fixedly connected with a first fixed block 3, the left side of the first fixed block 3 is fixedly connected with a first fixed plate 4, and the front side of the first fixed plate 4 is fixedly connected with a first fixed shaft 5, so The surface of the first fixed shaft 5 is movably connected with a preparation box 6, and the left side of the bottom of the preparation box 6 is fixedly connected with a support spring 7, and the bottom of the support spring 7 is fixedly connected with the top of the base 1. The preparation box 6. A stirring motor 8 is fixedly connected to the midpoint of the top, and a stirring shaft 9 is fixedly connected to the output shaft of the stirring motor 8. The bottom of the stirring shaft 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com