Plug hole type decompression drainage pipe pile and its preparation process

A technology for drainage pipe piles and pipe piles, which is applied in the direction of manufacturing tools, sheet pile walls, and foundation structure engineering, and can solve problems affecting construction, floating and offset of adjacent pile heads, and horizontal direction of soil uplift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

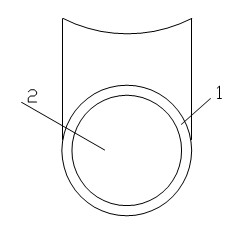

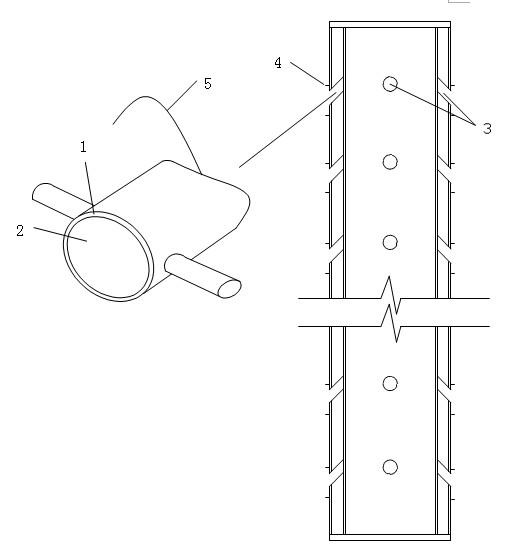

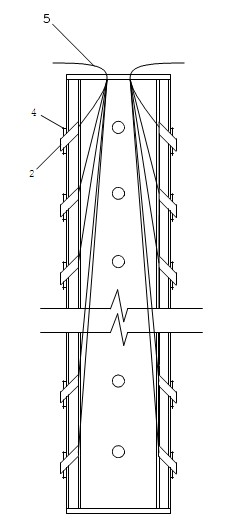

[0025] A plug hole type decompression drainage pipe pile, comprising: a pipe pile body 6 and a pile cap. The pipe pile body 6 is provided with at least one row of plug holes 3 distributed along the axis of the pipe pile body, and the plug holes 3 are provided For the plug 2, a pull cable 5 is connected to one end of the plug 2 located on the inner wall of the pipe pile body, and the pull cable 5 extends in the pipe of the pipe pile body to the top of the pipe pile body. In this embodiment, the central axis of the plug hole 3 intersects or crosses the central axis of the pipe pile body, and the end of the plug hole 3 located on the inner wall of the pipe pile body is higher than the end of the plug hole 3 located on the outer wall of the pipe pile body. In an embodiment, the angle between the central axis of the plug hole 3 and the central axis of the pipe pile body may be 45 degrees, and a silicon leather sleeve 1 is provided on the outside of the plug 2.

Embodiment 2

[0027] A preparation process of a plug-hole type decompression drainage pipe pile, the steps are as follows:

[0028] Step 1 Reserve an oblique 45° hole in the axial direction around the template of the factory standardized production pipe pile as a through hollow hole for the plug hole, and weld steel rods around each through hollow hole on the template, and then make several one-end tethers In addition, a silicon leather sleeve is sheathed on the outside, the diameter is equal to the through hollow hole on the template, the length is greater than the thickness of the template tube, and a plug with a straight steel rod is radially arranged near the top.

[0029] Step 2 Put the processed steel cage into the prepared template, and insert the plug of the tight-fitting silicon holster through the steel cage into the reserved hollow hole on the template, against the inner template, and expose the plug For the formwork, the pulling cable is pulled out from the inner formwork of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com