Rear axle locking gasket die capable of punching 24 holes in two steps and machining process of die

A rear axle lock washer, punching punch technology, applied in the direction of piercing tools, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the service life of the mold, punching convex, concave gap uneven, mold precision decline, etc., to achieve The effect of improving product quality, stabilizing the punching process, and improving the life of the die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

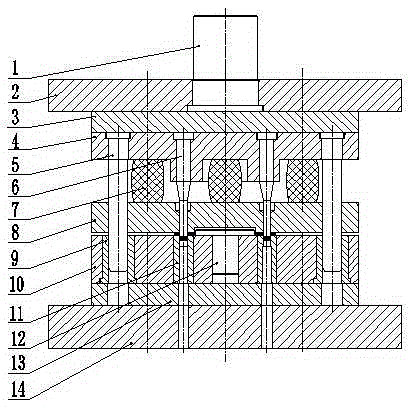

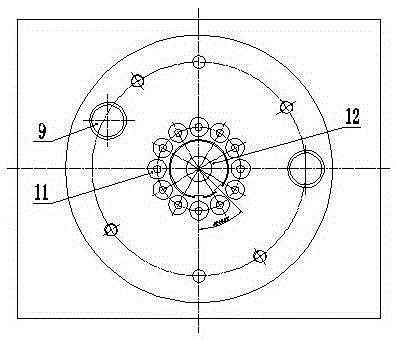

[0027] Example: Take the processing of N900 heavy truck rear axle lock washer as an example: see figure 1 — Figure 4 .

[0028] A rear axle lock washer two-step punching 24-hole mold, including an upper mold and a lower mold, the upper mold includes a mold handle 1, an upper template 2, an upper backing plate 3 and Punch fixed plate 4;

[0029] The punch fixing plate 4 is a stepped structure, the steps are large up and down, the lower step of the punch fixing plate 4 is cylindrical, and the punch fixing plate 4 is evenly provided with ten holes around the circumference of the cylindrical step. Two punching punches 6,

[0030] The lower mold includes a die fixing plate 10, a lower mold backing plate 13 and a lower mold plate 14 that are sequentially fastened and connected from top to bottom,

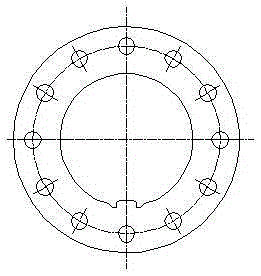

[0031] The die fixing plate 10 is evenly provided with twelve die positioning holes along the circumferential direction of the center, and a punching die 11 is arranged in the die po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com