Side hole punching die of U-shaped guide rod base of automobile driving axle

A drive axle and guide rod technology, which is used in perforating tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency and long production time, and achieve the effects of increasing production capacity, stabilizing concentricity, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

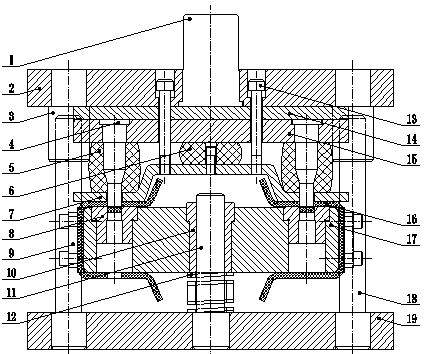

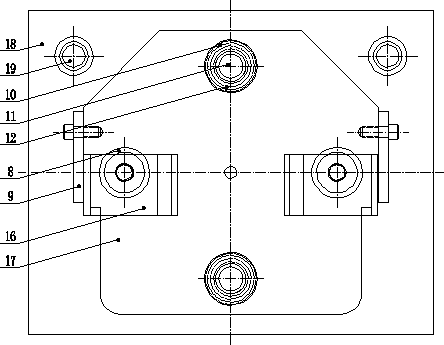

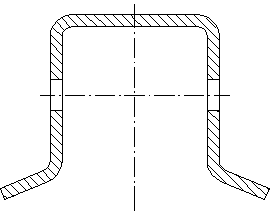

[0021] Example: see figure 1 —— Figure 4 .

[0022] The invention discloses a punching die for the side hole of a U-shaped guide rod seat of an automobile drive axle, which comprises an upper die and a lower die. Die backing plate 14, punch fixing plate 15, punching punch 4, side unloading rubber 5, middle unloading rubber 6, unloading plate 7; Die 8, die fixing plate 17, inner guide sleeve 10 of the die fixing plate, inner guide post 11 of the die fixing plate, support spring 12 of the die fixing plate, lower template 19, the left and right sides of the die fixing plate 17 A side positioning block 9 is respectively provided at the middle part of the side, and the overall weight of the die fixing plate 17 is carried on the support spring 12 of the die fixing plate.

[0023] A guide post guide sleeve structure is arranged between the upper die and the lower die, the guide sleeve 3 is connected to the upper template 2 through an interference fit, and the guide post 18 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com