Die frame with stripper plate and guide posts

A stripping plate and mold frame technology, which is applied in the direction of perforating tools, manufacturing tools, metal processing equipment, etc., can solve the problems of precision parts not meeting the requirements, molds not working for a long time, and punching pins breaking, etc., to achieve high precision and structure The effect of novelty and high precision of hole distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

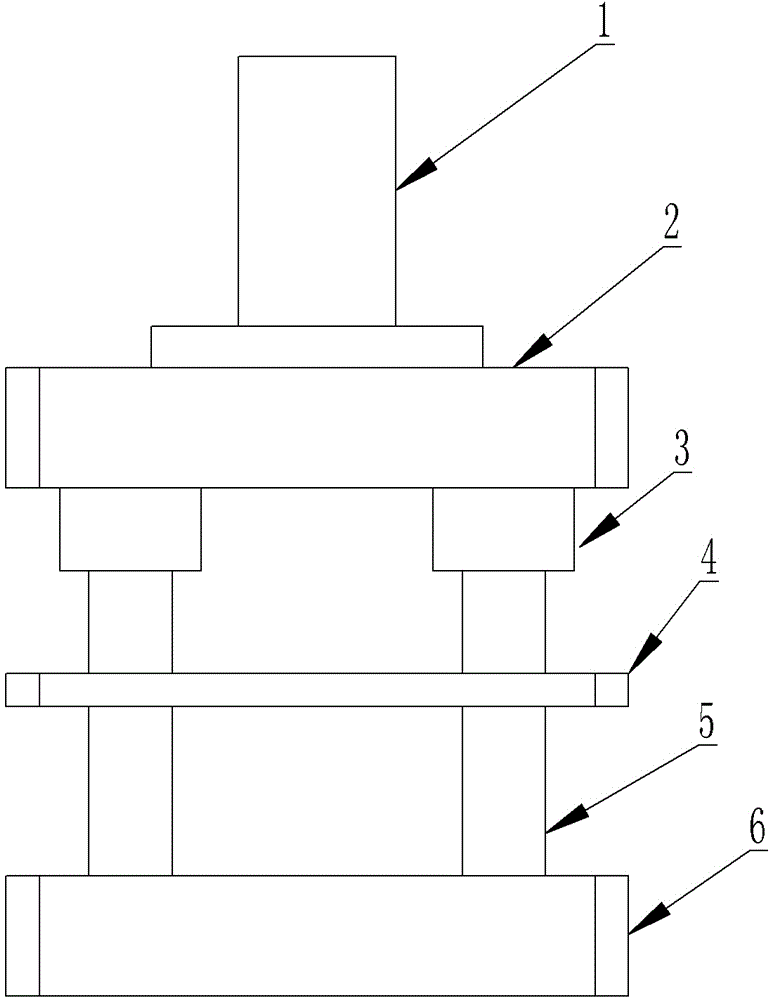

[0014] like Figure 1-2 As shown, a new stripping plate guide column type mold frame includes: mold handle 1, punch fixing plate 2, guide sleeve 3, stripping plate 4, guide post 5, die fixing plate 6, and is characterized in that: The die handle 1 is arranged on the punch fixed plate 2, the guide sleeve 3 is arranged on the punch fixed plate 2, the stripper plate 4 is arranged on the guide post 5, and the guide The column 5 is fixed on the die fixing plate 6 .

[0015] In a new type of die frame of the stripping plate guide column according to the present invention, the mold handle 1 is set on the punch fixing plate 2, the guide sleeve 3 is set on the punch fixing plate 2, and the stripping The material plate 4 is arranged on the guide post 5 , and the guide post 5 is fixed on the die fixing plate 6 .

[0016] A new type of die frame of the guide column of the stripping plate is applied in the present invention. The stripping plate is guided by the guide post of the mold fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com