Patents

Literature

47results about How to "Guaranteed long-term work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

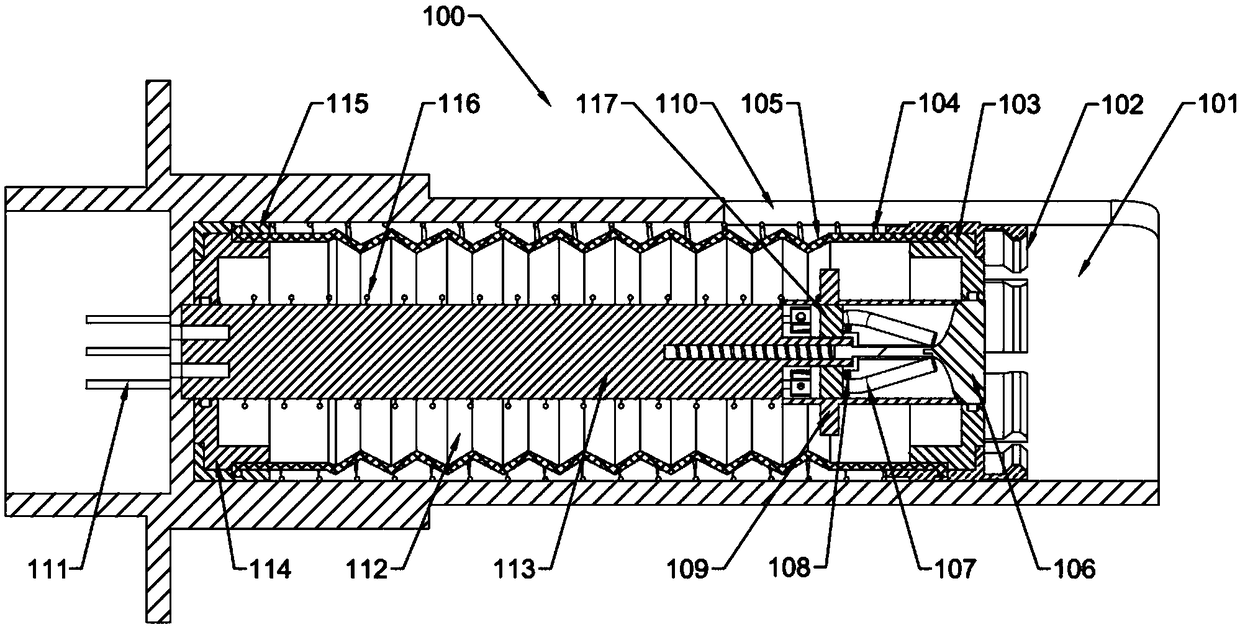

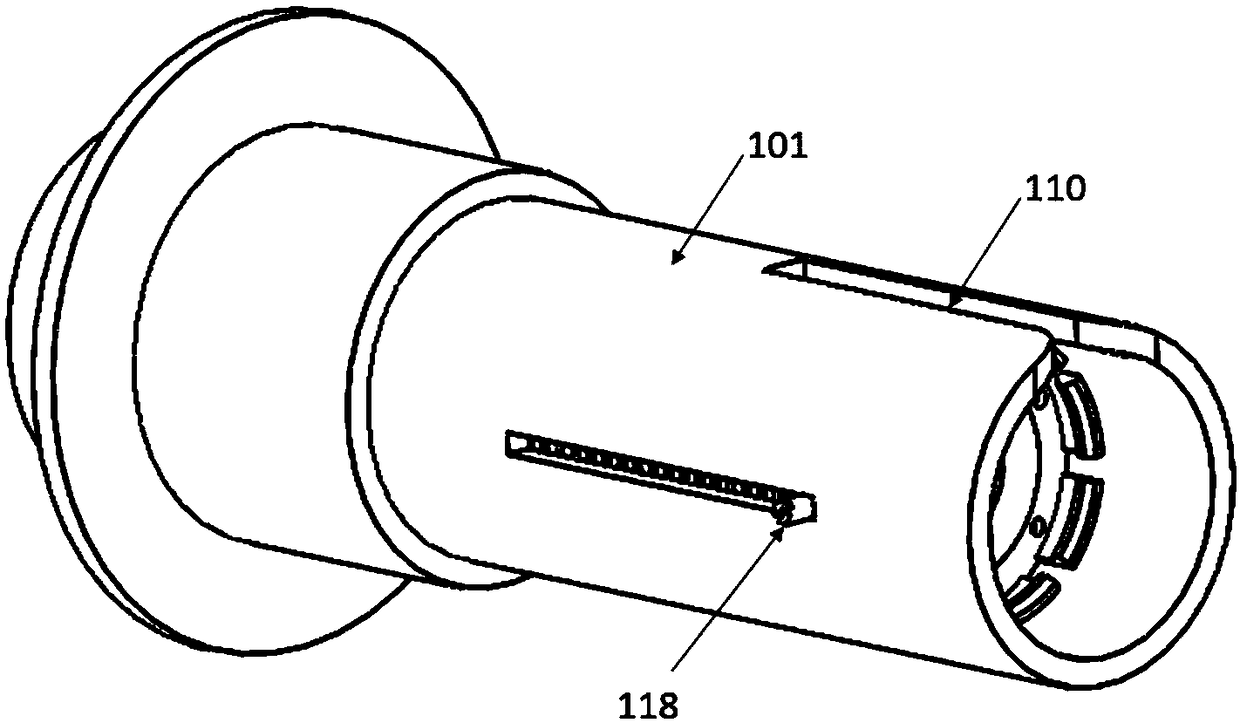

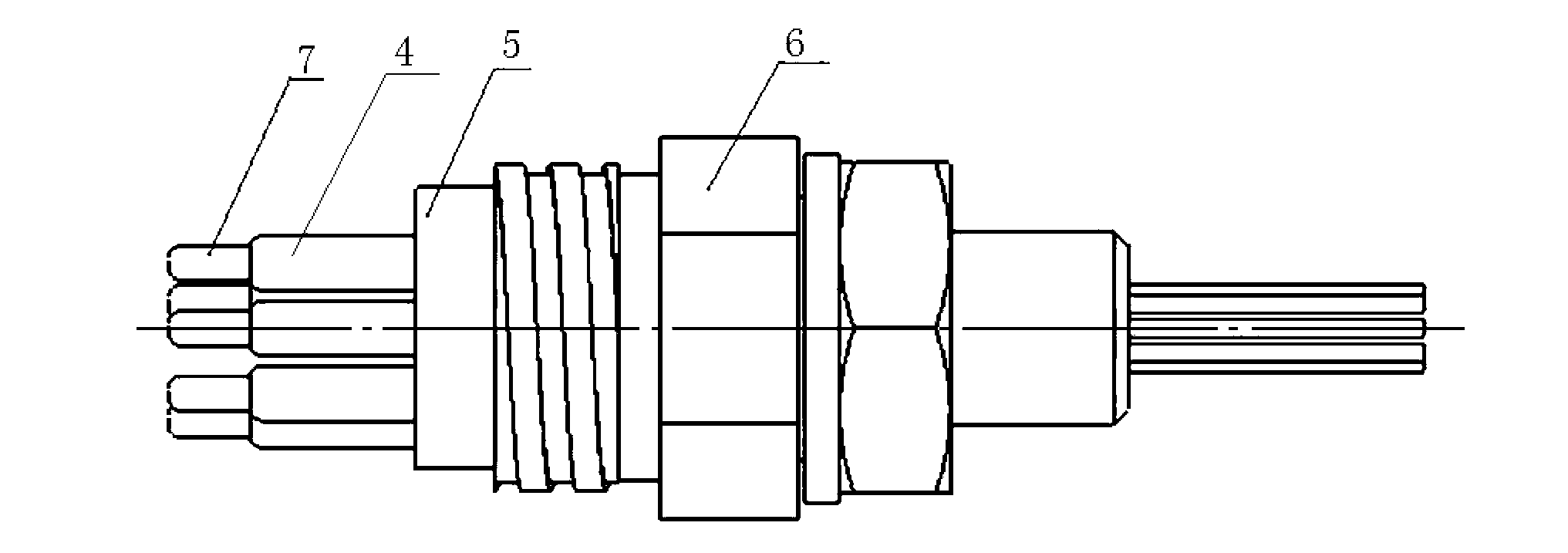

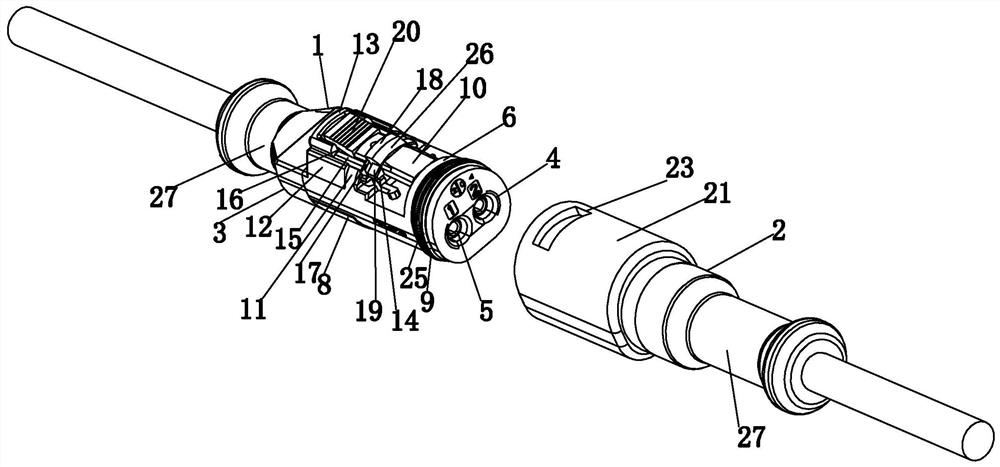

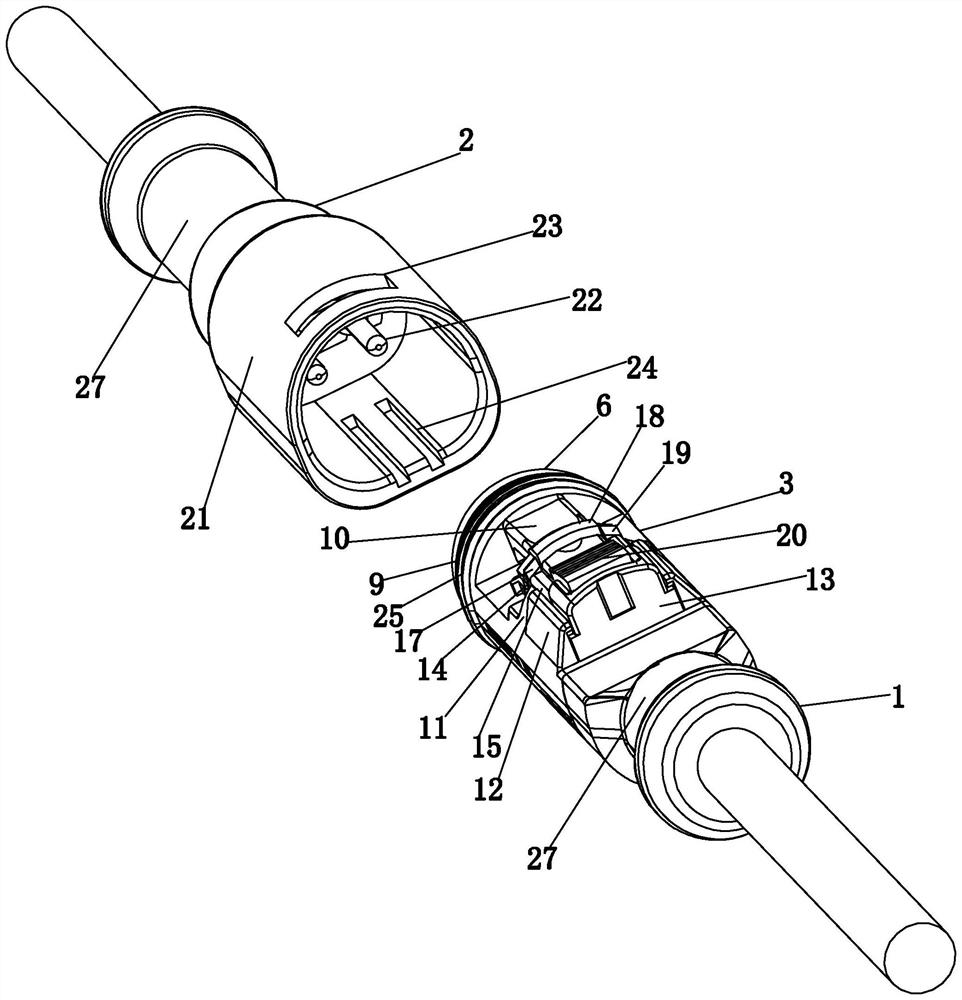

An open-close deep-sea plug-and-pull photoelectric composite connector

ActiveCN109244711AReduce internal and external pressure differenceSmall insertion forceCoupling contact membersCouplings bases/casesElectric power transmissionEngineering

The invention discloses an open-close deep-sea plug-and-pull photoelectric composite connector, which comprises a plug and a socket used for plug-and-match. The main body of the socket part is a socket opening and closing core, which is fixed on a rotating bracket through a hinge connection mode. When the plug and the socket are inserted, the socket opening and closing core can be opened under thepush of an umbrella-shaped curved surface of a plunger, the position of the largest opening angle is parallel to the central axis, and is connected with the photoelectric core inside the plug. The plug and the socket of the invention are respectively provided with a variable-volume bellows and a rubber bag as a pressure balancing device; The O-shaped sealing ring arranged in pairs is used for realizing the sealing in the inoperative state; The invention integrates optical signal and electric power transmission, fully considers internal and external pressure balance, has simple structure and simple insertion process, and can ensure reliable connection of deep water environment.

Owner:SOUTHEAST UNIV

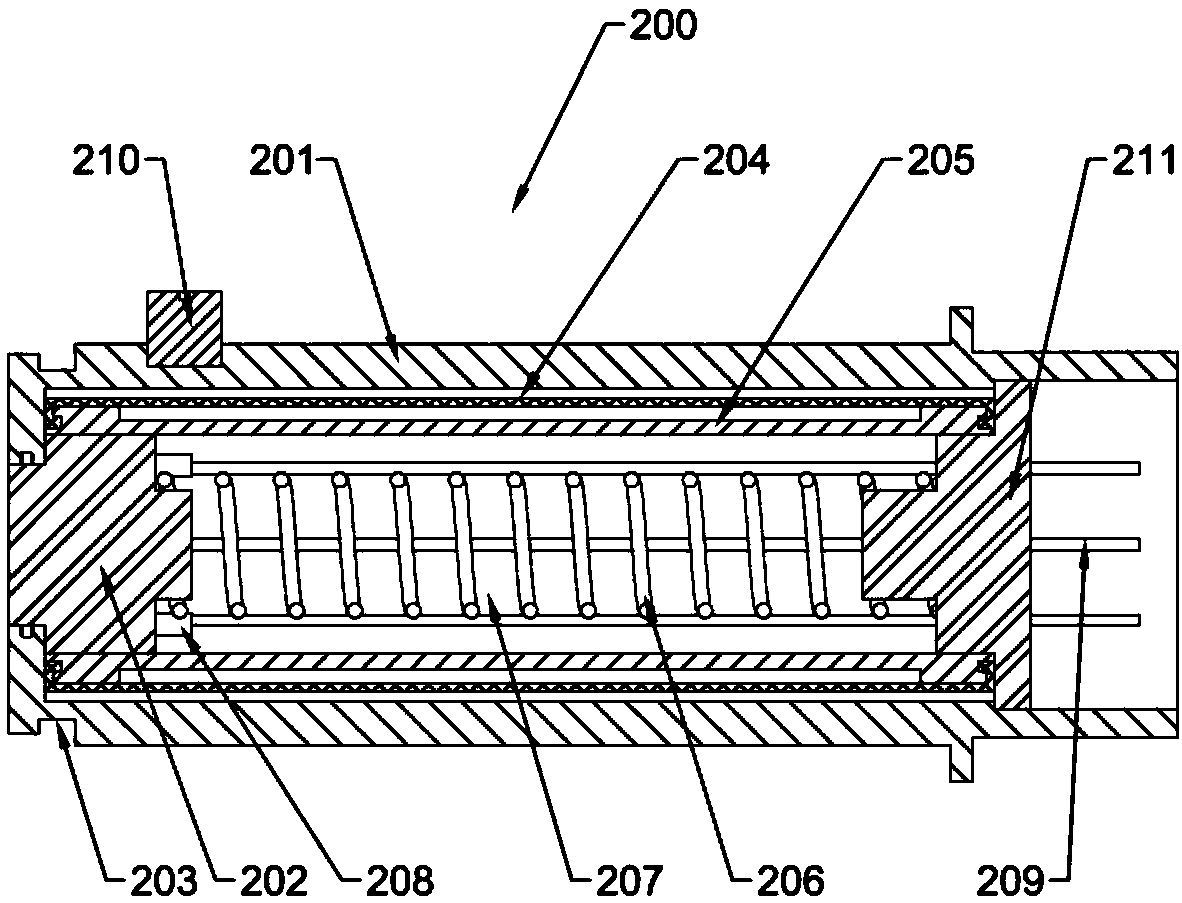

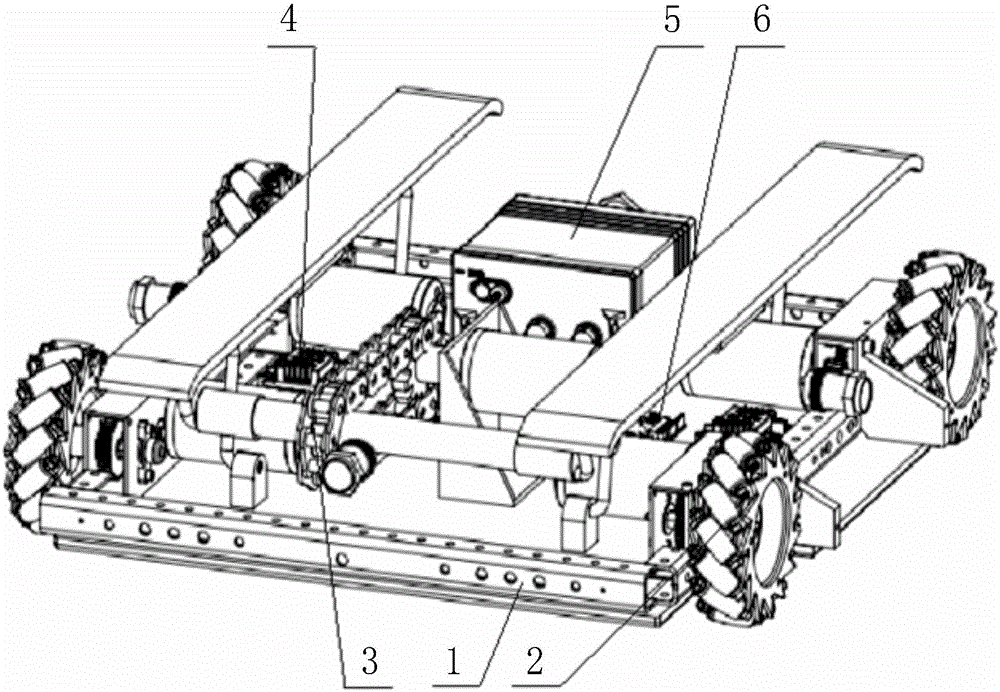

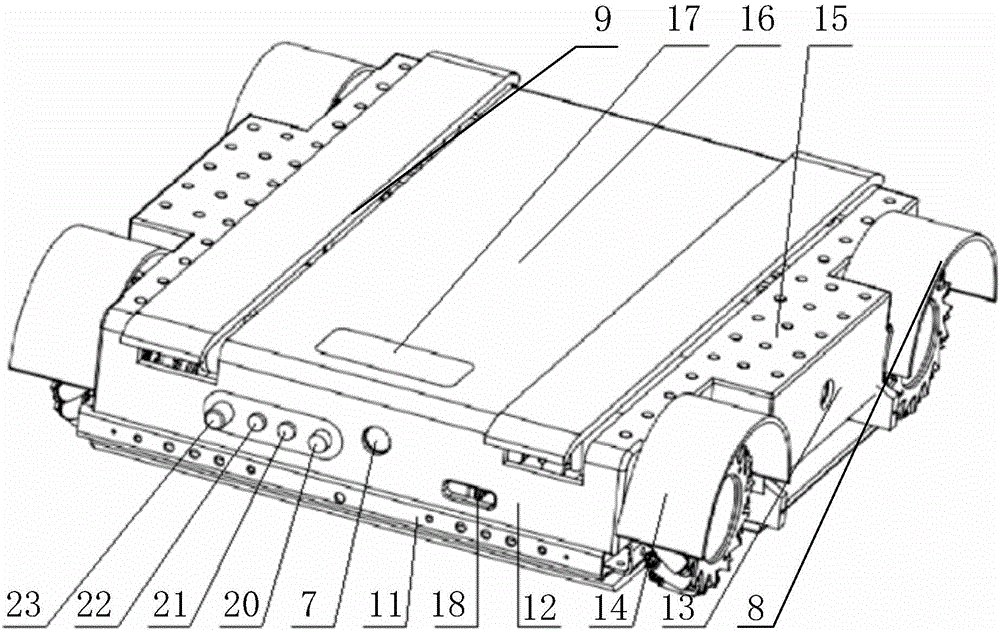

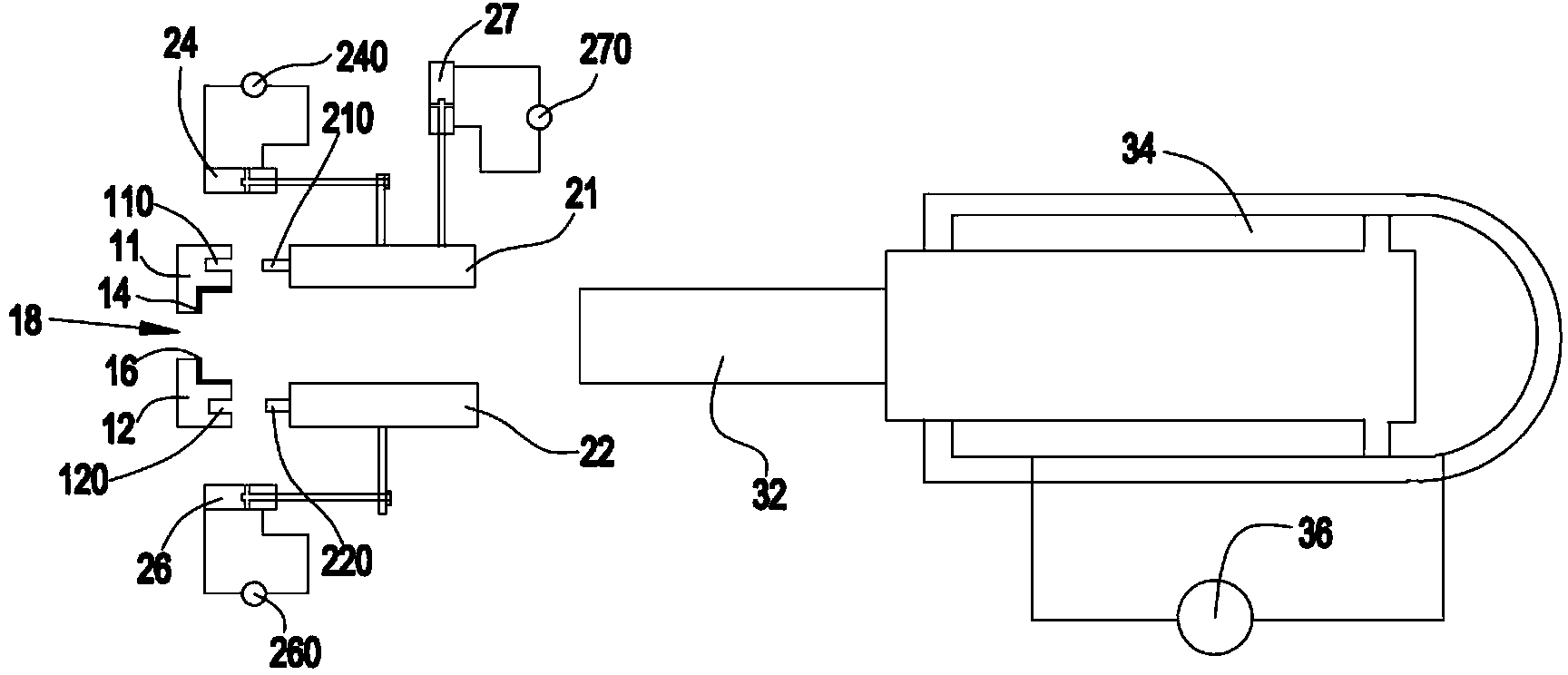

Energy-saving shuttle vehicle capable of steering in all-around mode

The invention discloses an energy-saving shuttle vehicle capable of steering in an all-around mode. The energy-saving shuttle vehicle comprises a vehicle body as well as a steering device, a lifting device, a control system, a super-capacitor power source, a communication module and a sensor system mounted on the vehicle body, wherein the sensor system comprises an infrared distance-measuring sensor, an anti-collision sensor and a pressure sensor; the infrared distance-measuring sensor is used for measuring a distance between the vehicle and a cargo tank; the anti-collision sensor is used for detecting whether the shuttle vehicle is collided or not; the pressure sensor is used for detecting whether the cargo is completely placed on a storage rack or not; the super-capacitor power source is separately in conductor jointing with the control system and the communication module; the control system is connected with the super-capacitor power source and the steering device to form steering drive for driving the steering device to rotate; and the control system is connected with the super-capacitor power source and the lifting device to form lifting drive for driving the lifting device to lift. The energy-saving shuttle vehicle enables the shuttle vehicle to realize an all-around combined motion mode of forwarding, drawing-back, horizontal-moving, rotating and the like, and has the characteristics of being quick and flexible.

Owner:NANJING UNIV OF SCI & TECH

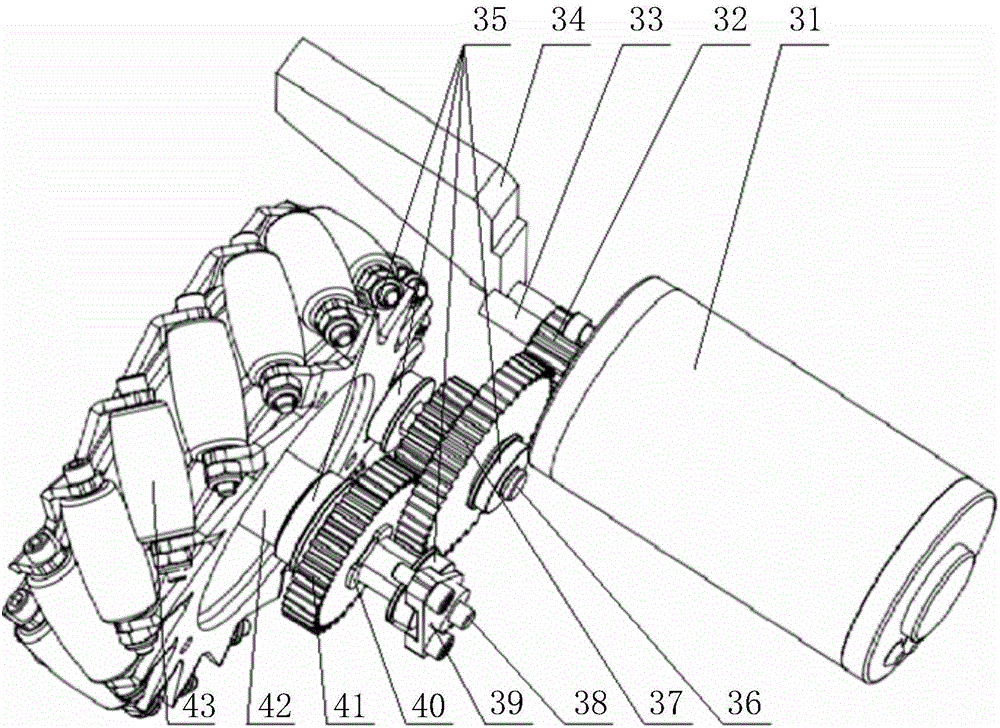

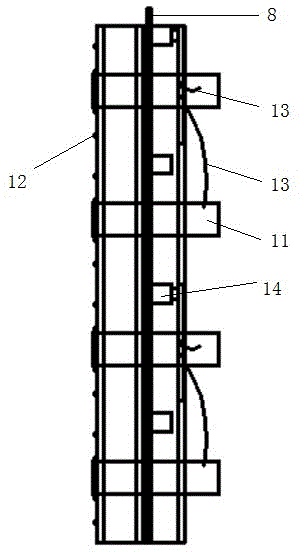

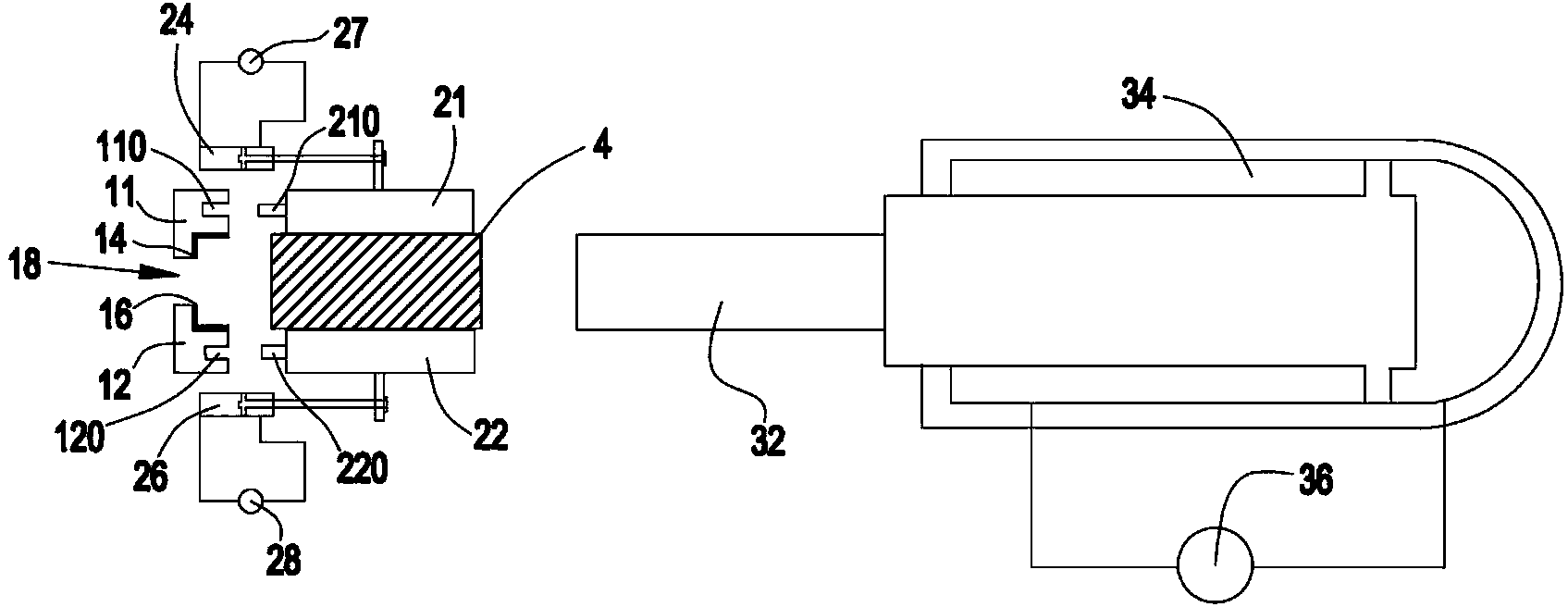

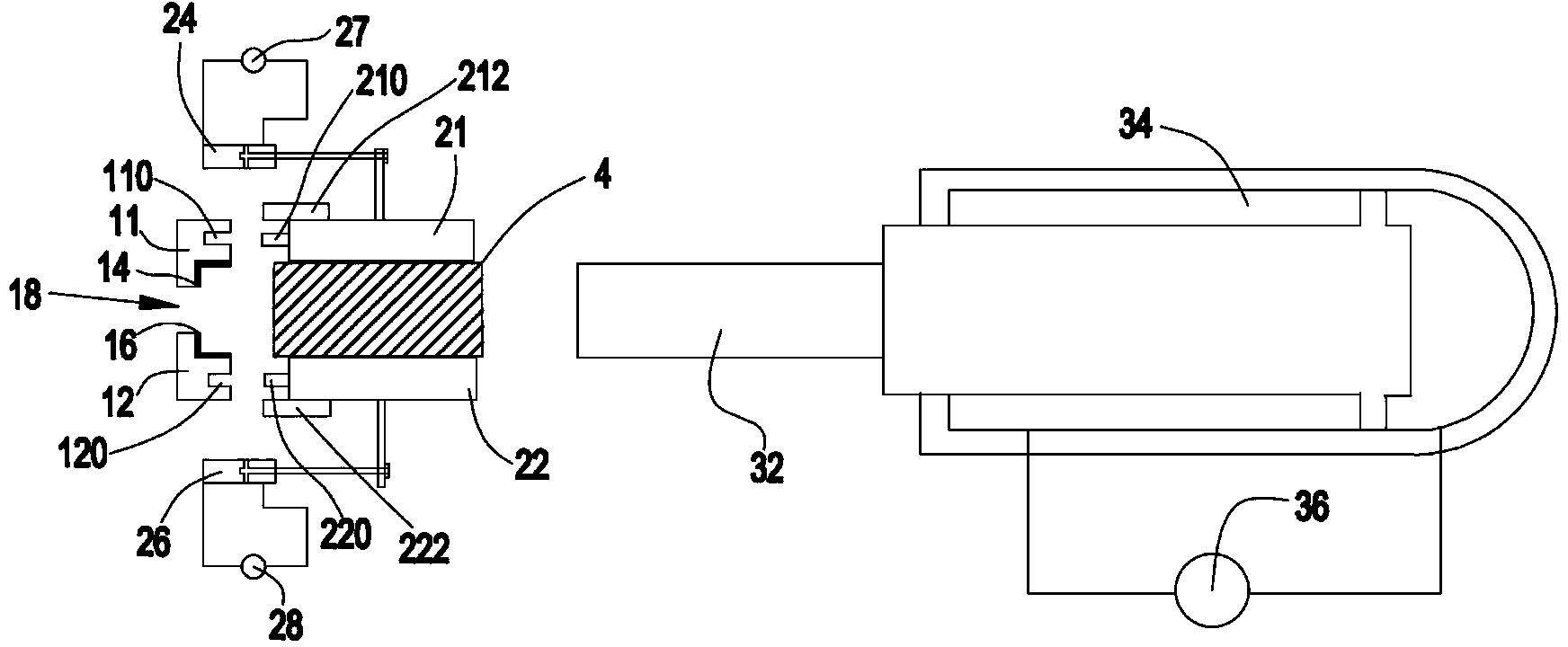

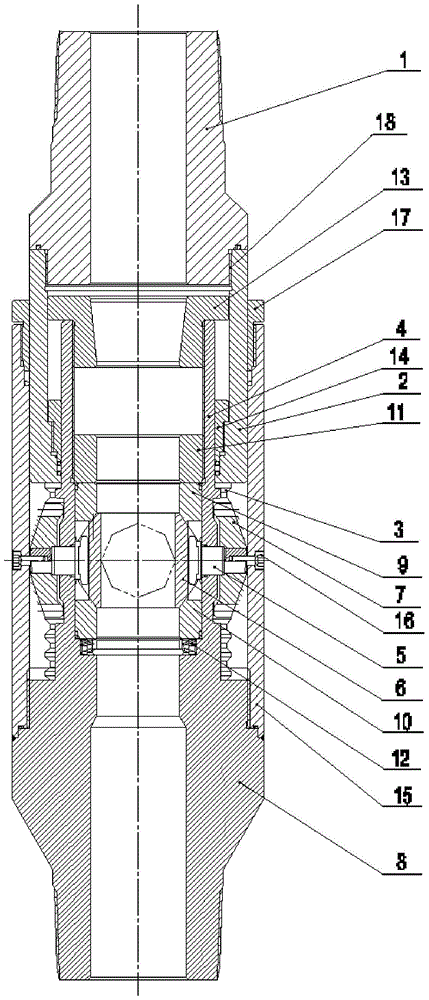

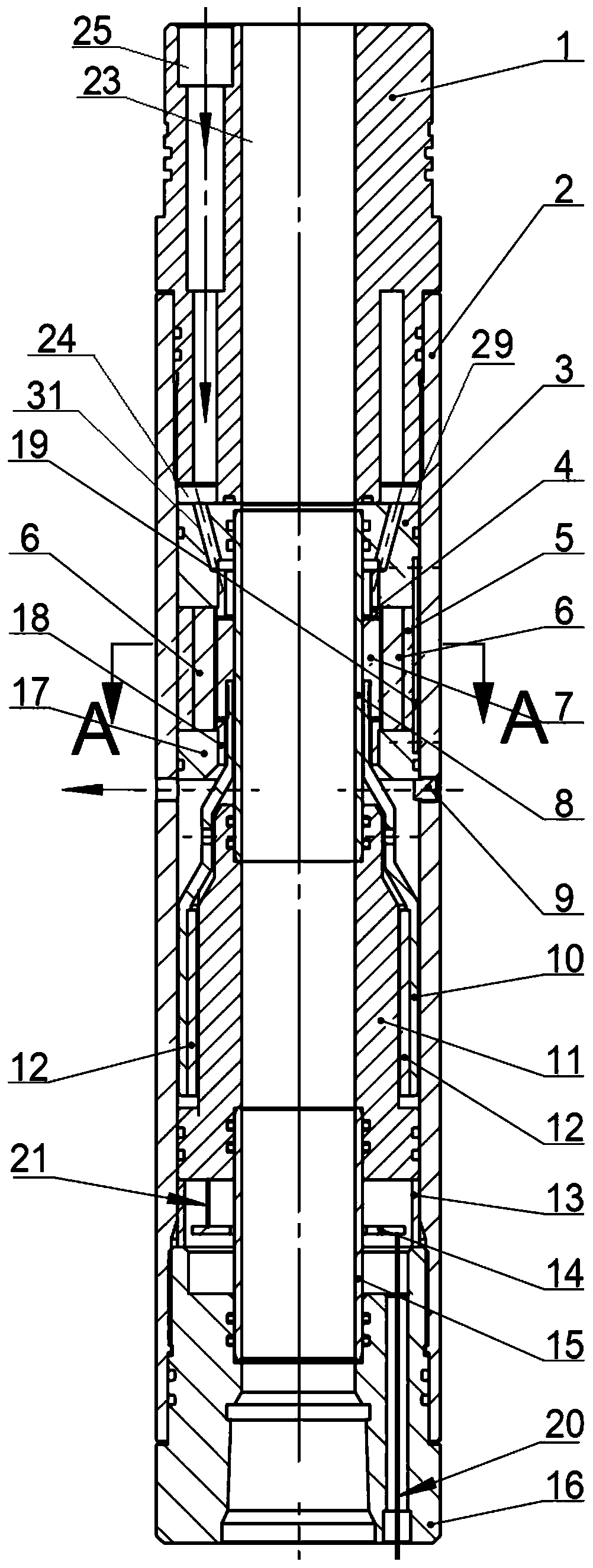

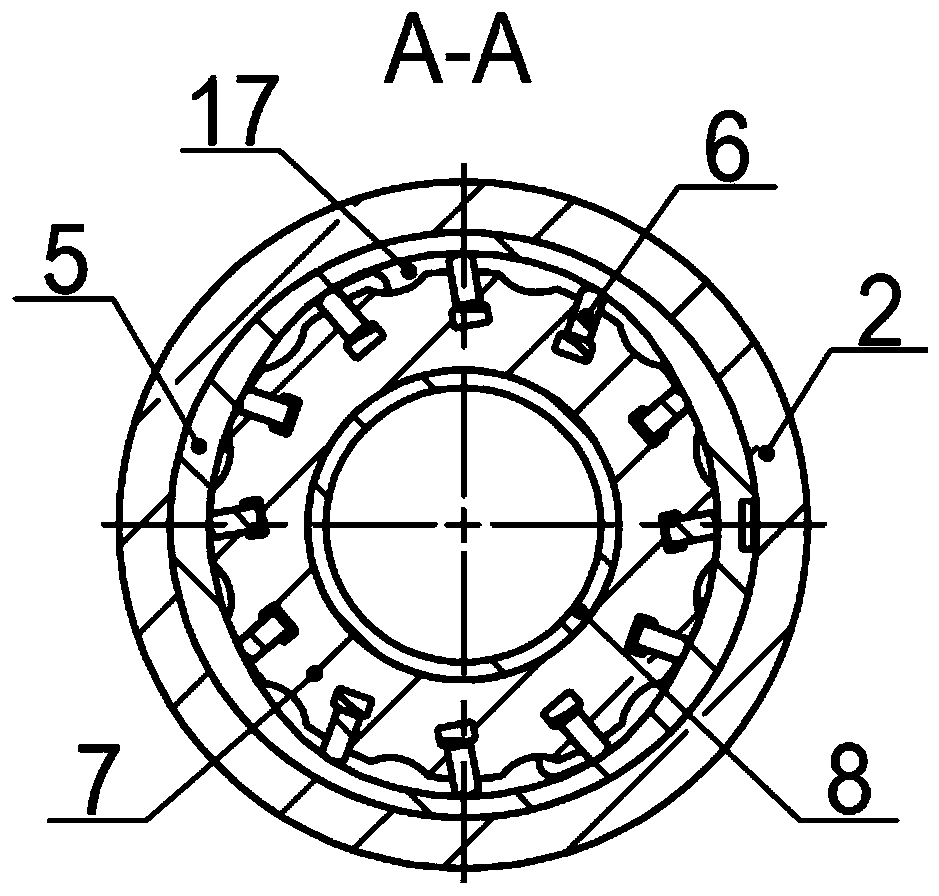

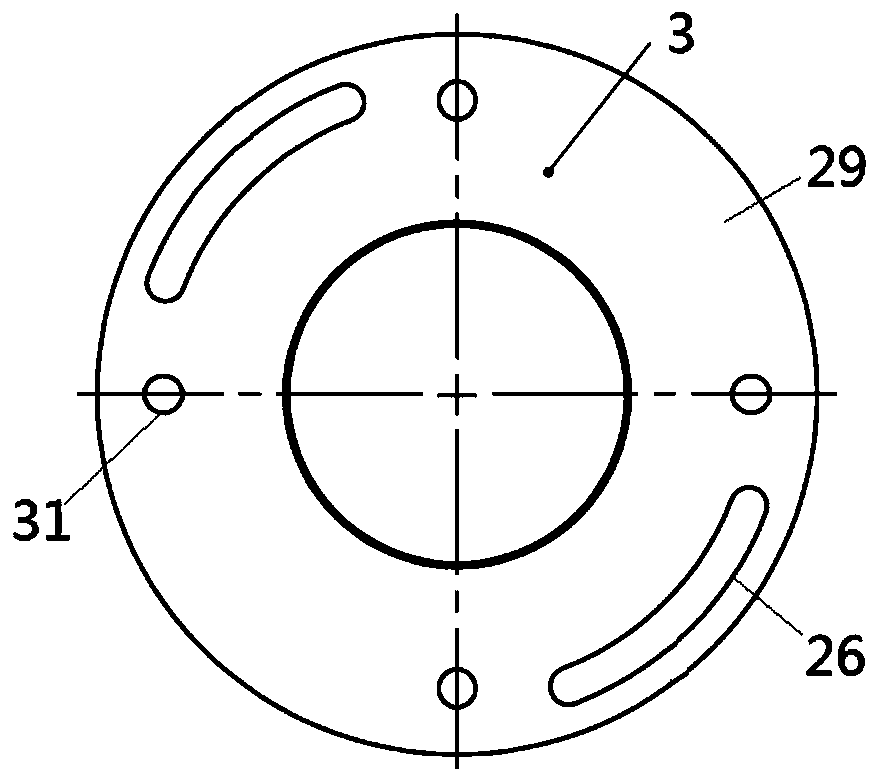

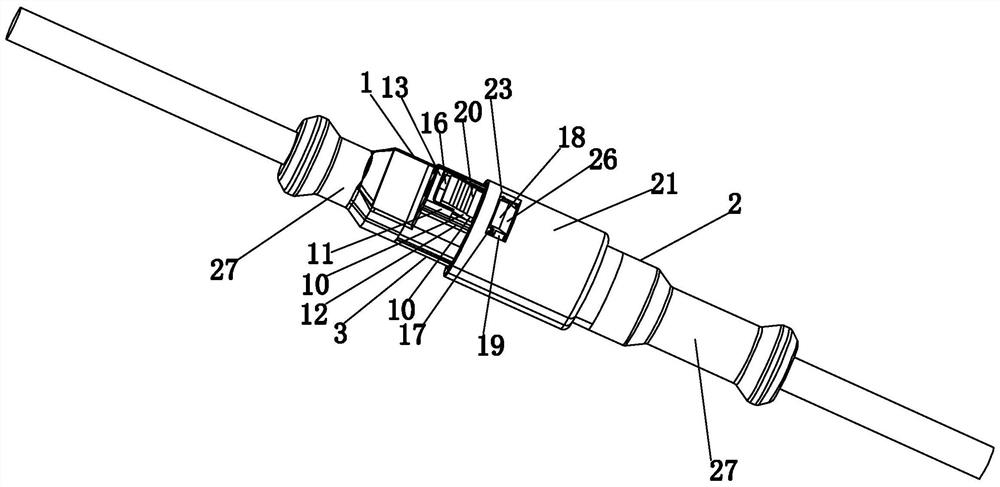

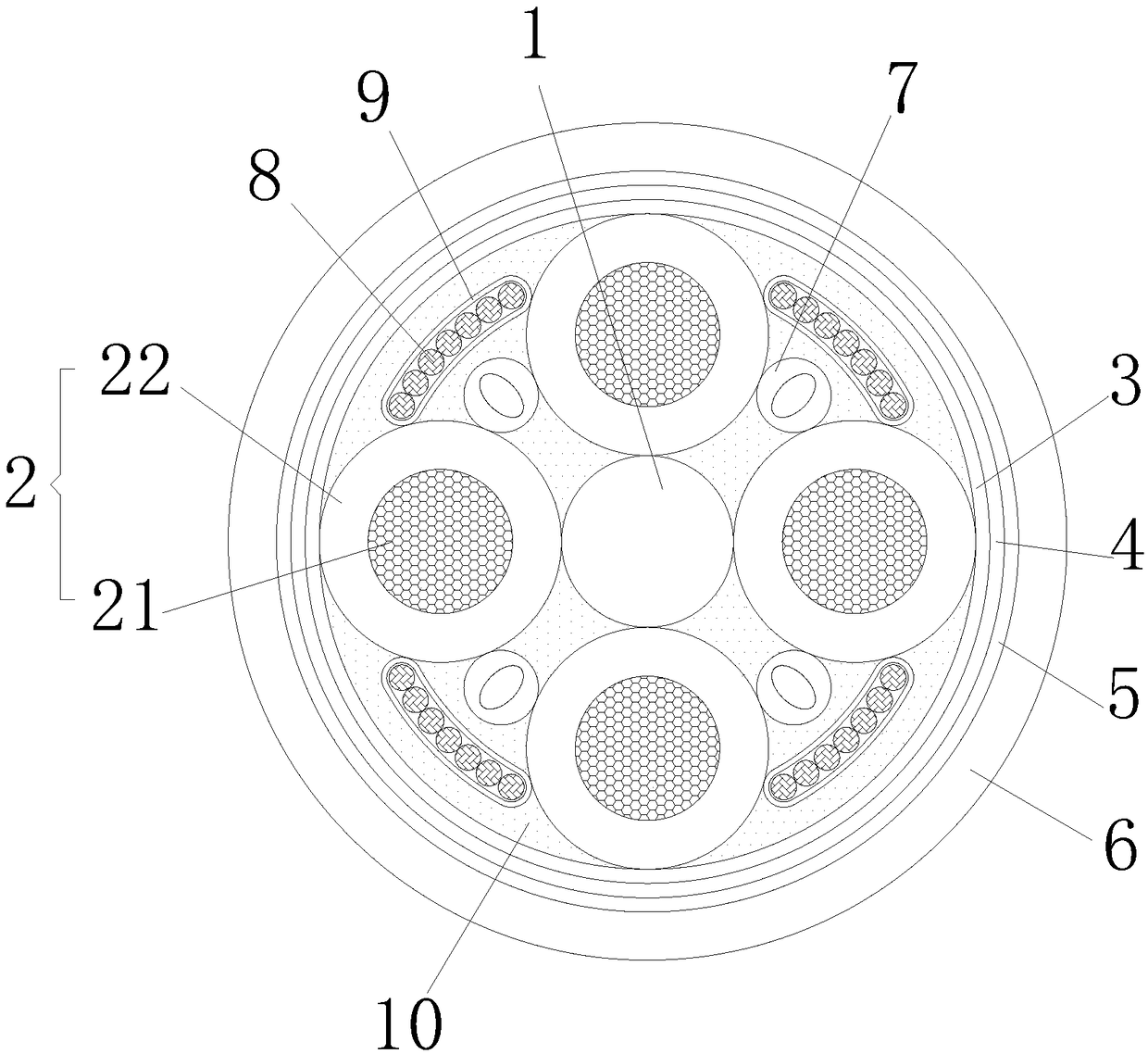

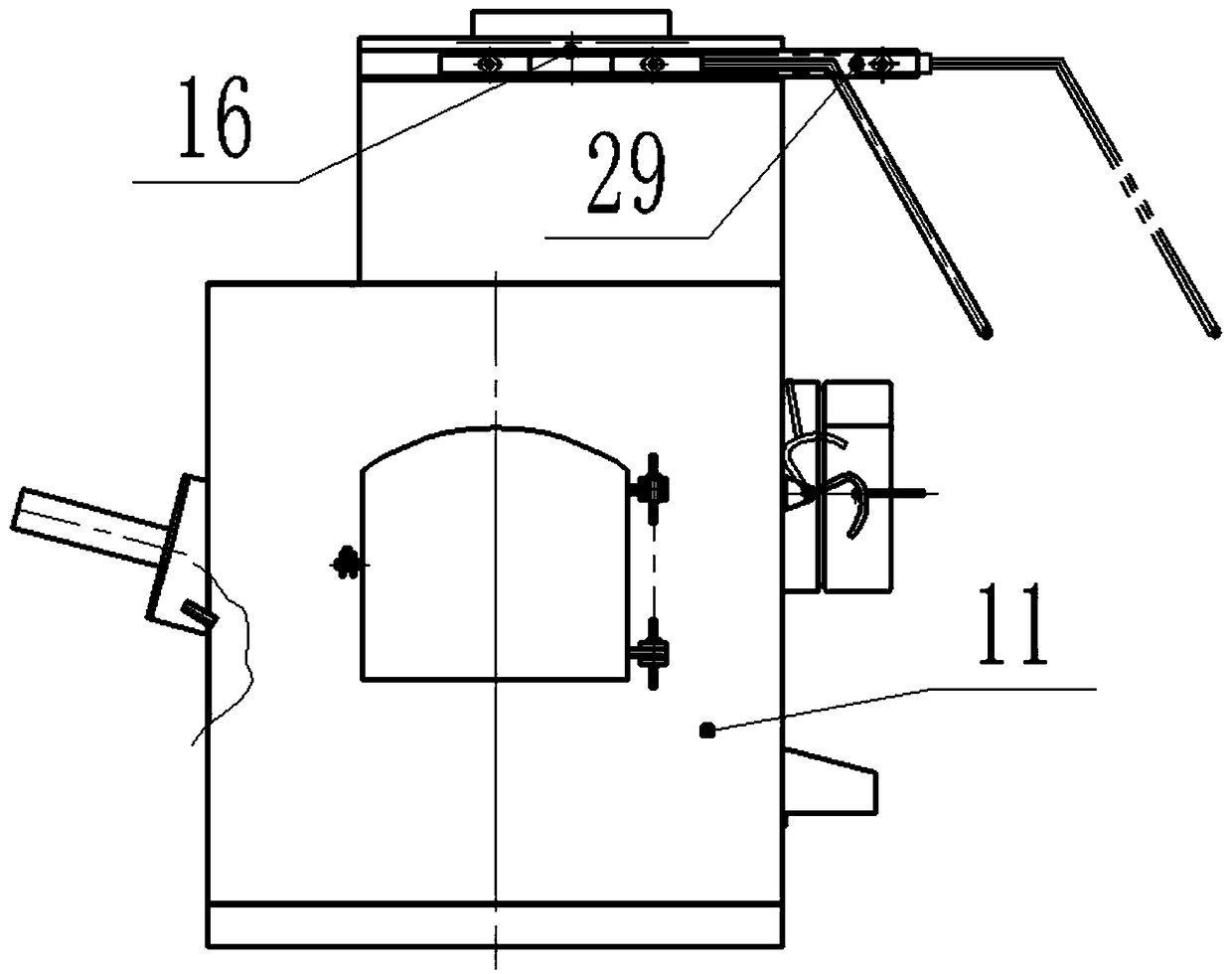

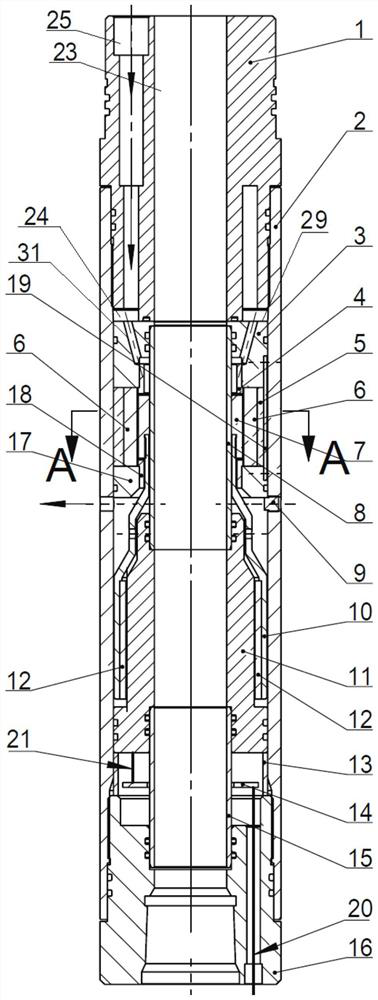

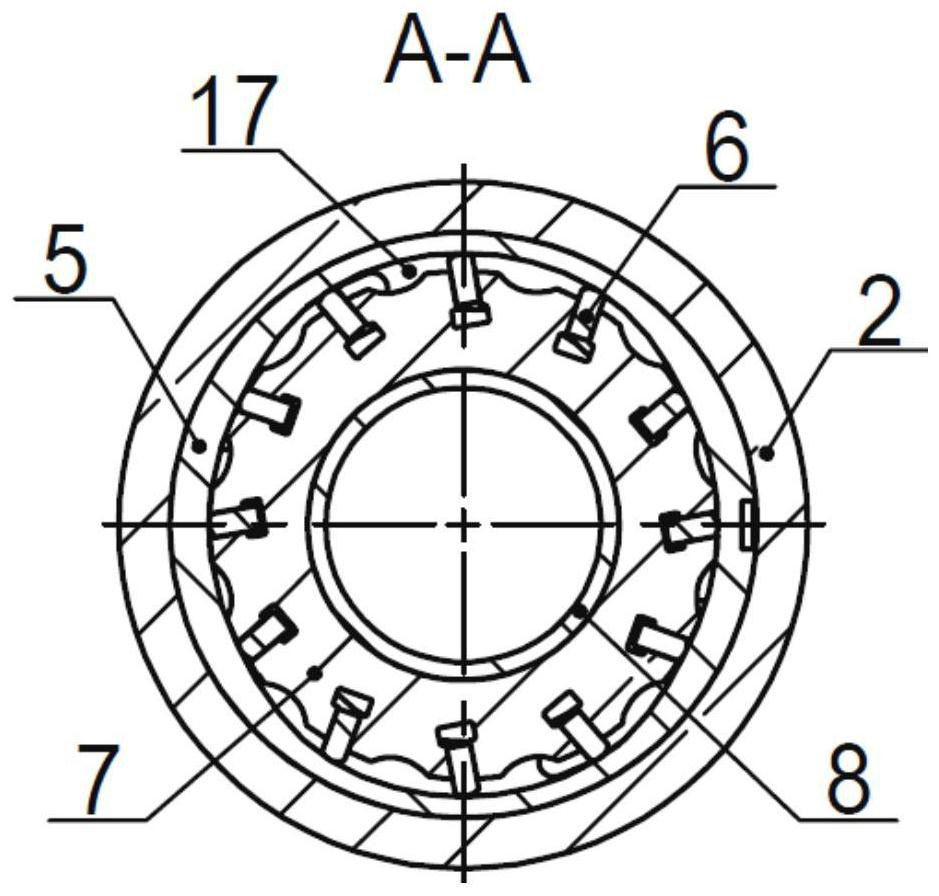

Multifunctional ball valve assembly for thickened oil thermal production well

ActiveCN104864162AGuaranteed long-term workMeet the operational needs of protectionOperating means/releasing devices for valvesWell/borehole valve arrangementsGear drivePush pull

The invention relates to a multifunctional ball valve assembly for a thickened oil thermal production well. The multifunctional ball valve comprises an upper connector of which the upper rend can be connected with an oil pipe connector, a push-pull sleeve of which the upper end is fixedly connected with the lower end of the upper connector, two gear racks symmetrically and fixedly arranged at the lower end of the push-pull sleeve and extending in the axial direction, a ball valve sleeve of which the upper end is sleeved by the push-pull sleeve and capable of sliding up and down relative to the push-pull sleeve, a ball valve core rotatably mounted in the cavity of the ball valve sleeve through two symmetrically and fixedly arranged ball valve rods, and two gears mounted outside the ball valve sleeve and fixedly connected with the two ball valve rods respectively, wherein a lower connector in sealed connection with an anchor is further arranged at the lower end of the ball valve sleeve; the gear racks at the lower end of the push-pull sleeve are meshed with the gears all the time. In the lifting or pressing process of the upper connector, the gear racks drive the gears to rotate, the gears drive the ball valve rods fixedly connected with the gears to rotate together, and the ball valve rods drive the ball valve core to rotate, so that the opening and closing of the ball valve assembly is realized. The multifunctional ball valve assembly can be widely applied to production operation of the thickened oil thermal production well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Anti-glaring floodlight

InactiveCN101907271AGood anti-vibration effectSimple structureProtective devices for lightingOptoelectronicsLight head

The invention relates to an anti-glaring floodlight, which comprises a light holder shell, a transparent part, a luminous body and a light holder fixed plate, wherein the transparent part is connected with the light holder shell; the luminous body is arranged in the light holder shell by a light holder; the light holder fixed plate comprises a connection plate, a first buffer plate which extends along one side of the connection plate in an inclined way, and a second buffer plate which horizontally extends along the tail end of the first buffer plate; the connection plate is fixed on an inner wall of the light holder shell; and the light holder is fixed on the second buffer plate. The anti-glaring floodlight of the invention provides all-directional high buffering for the luminous body through the light holder fixed plate, can instantly reset after external impacts are removed and therefore has a good anti-vibration effect and can work effectively in a strongly vibrating environment for a long time; and the anti-glaring floodlight has a simple structure and low cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

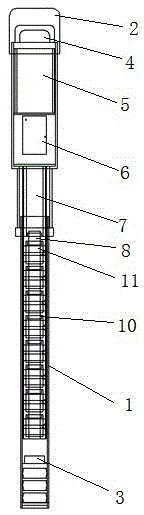

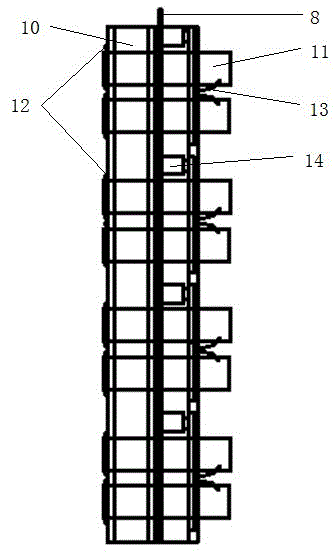

Integrated adjustable automatic soil longitudinal water recording instrument

InactiveCN104950012AImprove monitoring accuracyRealize continuous observationMaterial analysis by electric/magnetic meansCommunication interfaceData connection

The invention discloses an integrated adjustable automatic soil longitudinal water recording instrument which comprises a sealing shell, wherein an electronic element and a measuring assembly are arranged in the shell; the electronic element comprises a communication interface, a power supply and a mainboard; the mainboard comprises a controller and a storing device; the measuring assembly comprises an installation framework; a plurality of pairs of electrodes are arranged on the installation framework; the electrodes can slide along the installation framework; a limiting device is also arranged on the installation framework; each pair of electrodes is in data connection with the mainboard by a flexible cable; data output by the electrodes are transferred into the controller; the controller transfers the data into the storing device for storing; the power supply is used for powering the electronic element; the communication interface is connected with the controller. According to the instrument, an integrated design is adopted, the power supply, the mainboard and the communication part are packaged in the shell; the data can be recorded and stored for a long time; meanwhile, the measuring depths of different soil layers can be adjusted according to needs, so that the monitoring requirements of users on water at the different soil layers can be met.

Owner:NANJING AUTOMATION INST OF WATER CONSERVANCY & HYDROLOGY MINIST OF WATER RESOURCES

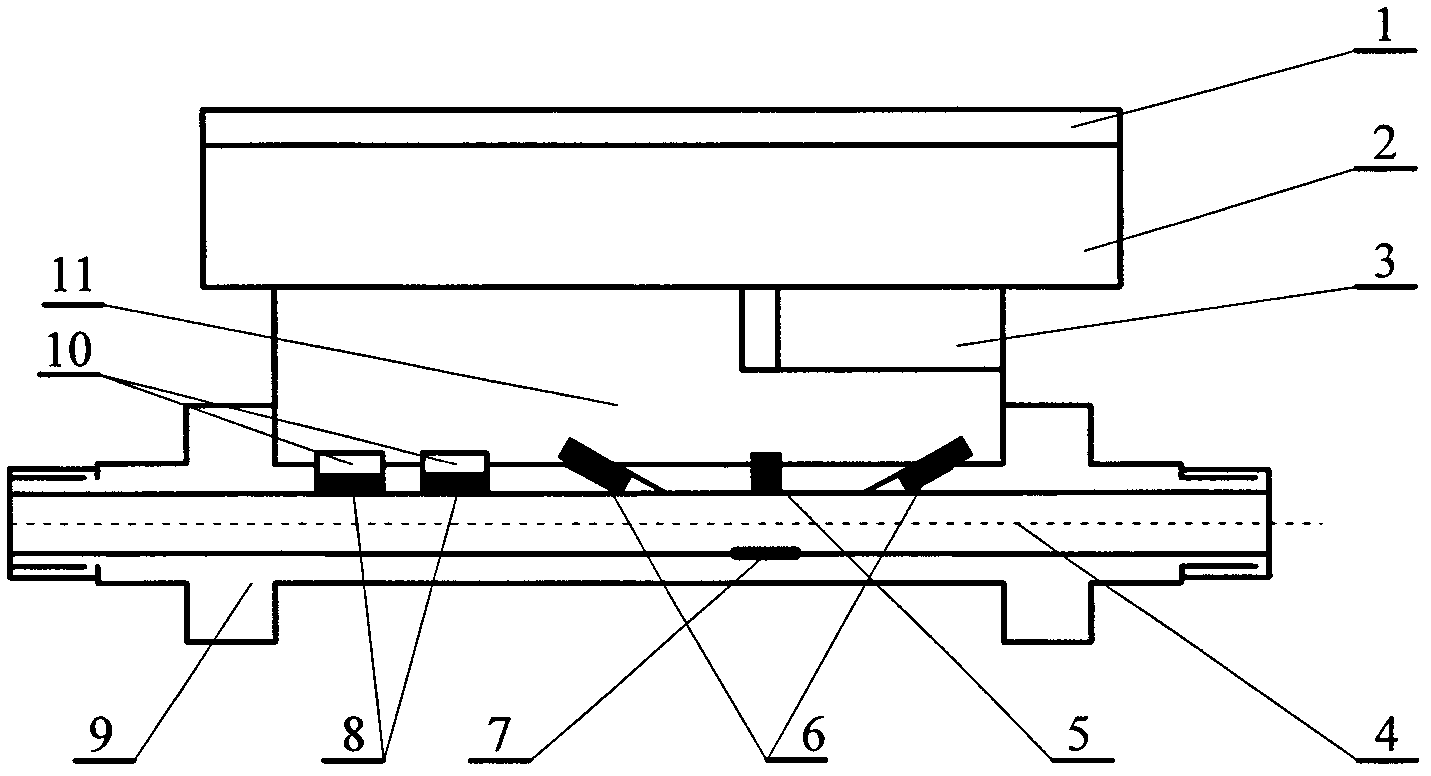

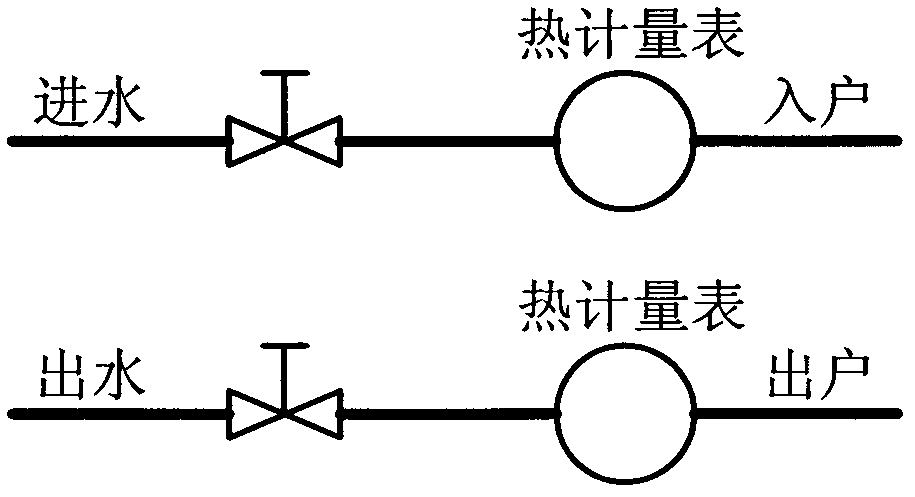

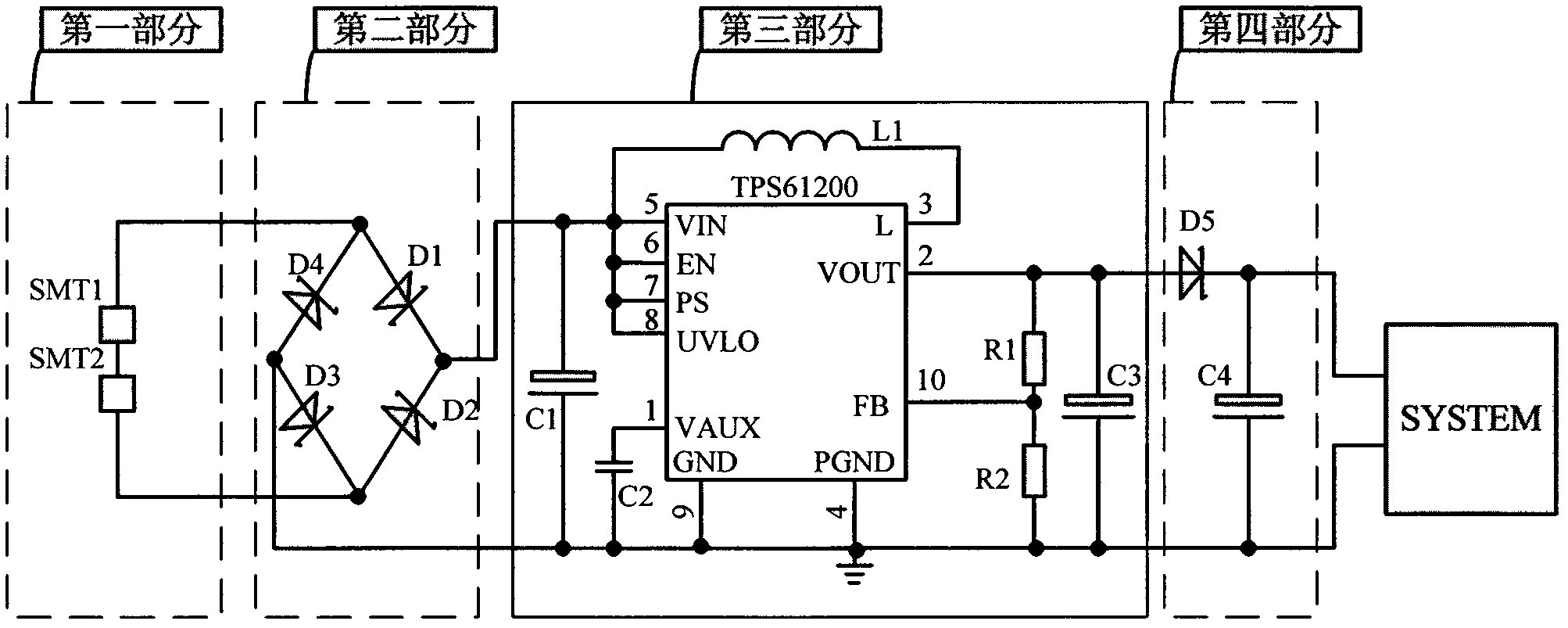

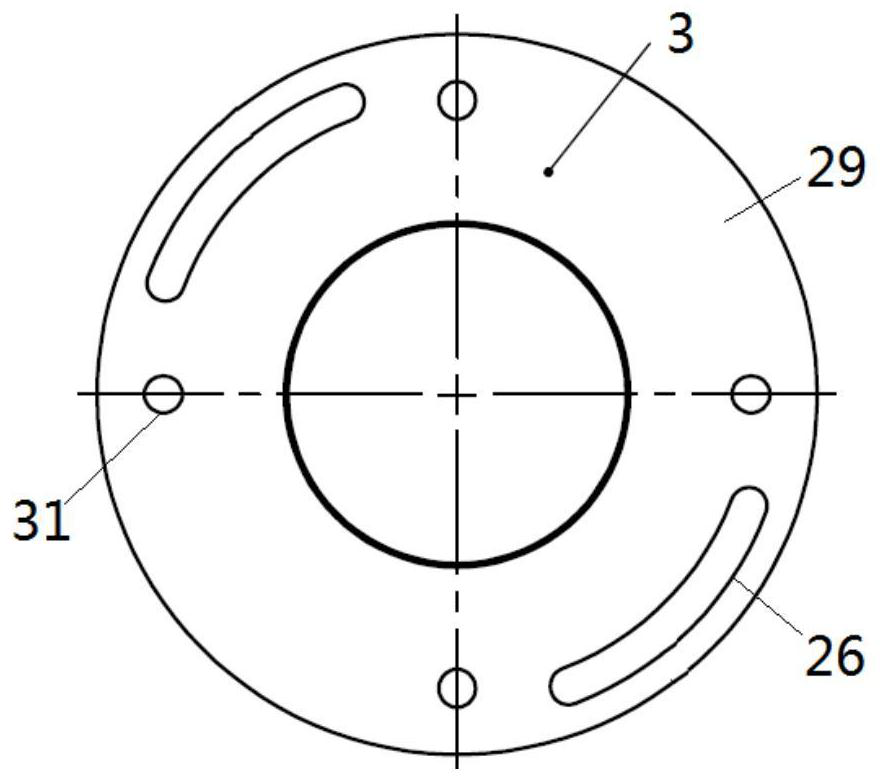

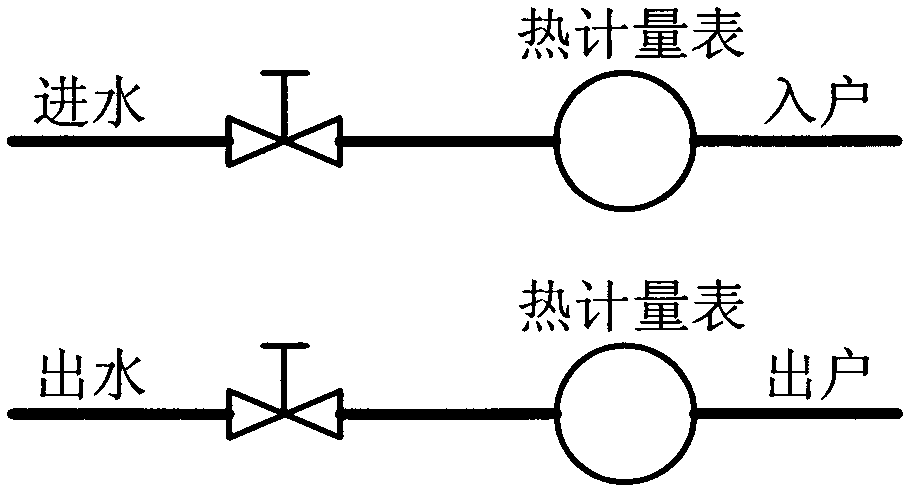

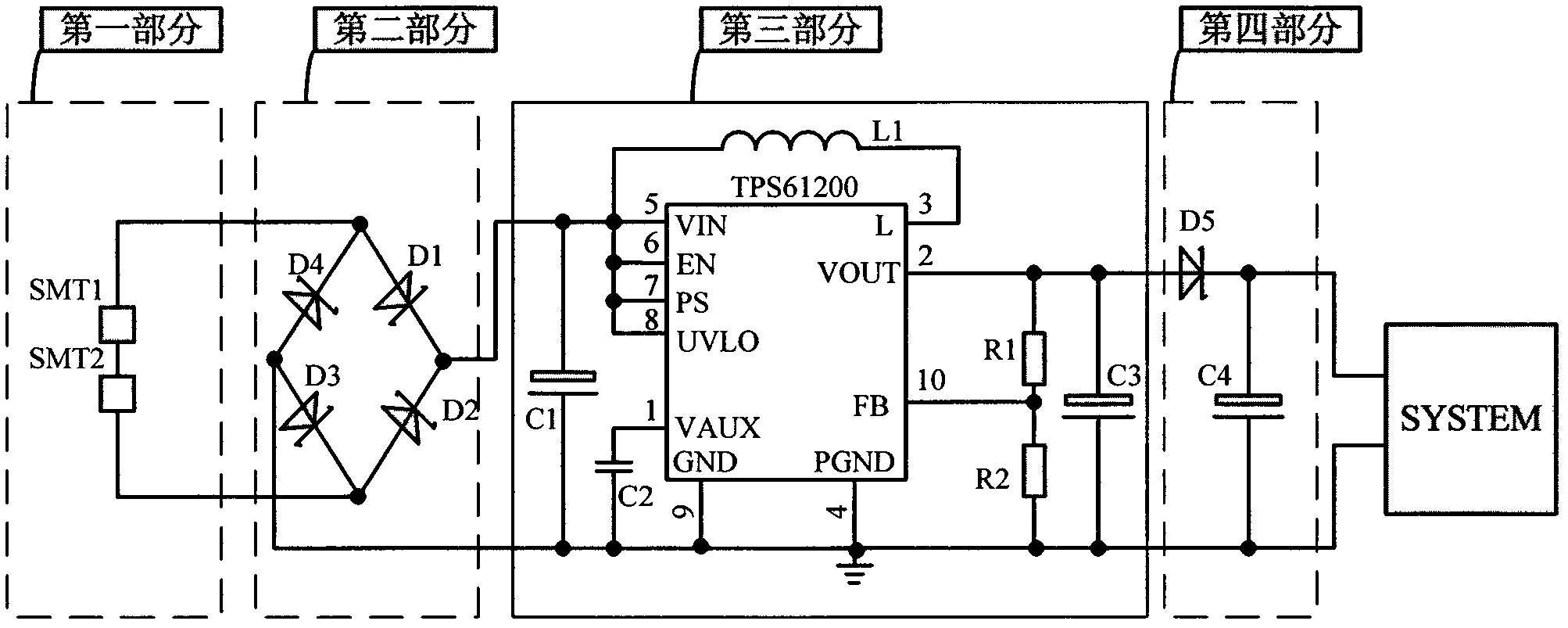

Passive heat metering device and heat metering system working by passive heat metering devices

InactiveCN102840932AGuaranteed long-term workTransmission systemsCalorimeterCommunication interfacePower mode

The invention aims to provide a passive heat metering device and a heat metering system working by the passive heat metering devices. The heat metering device comprises a temperature difference power supply system, a reflection type ultrasonic flowmeter, a temperature sensor, a communication interface, a ZigBee controller and a liquid crystal display (LCD). By using characteristics of a concentrative heating and cooling system, the passive heat metering device automatically supply power through the temperature difference power supply system; a power supply is not required to be regularly replaced, so that the passive heat metering device is energy-saving and environment-friendly; the heat metering system works by two same passive heat metering devices provided by the invention; the two devices run in a low-power mode; the working modes of a main node and a slave node are regularly changed; under the conditions of heating and cooling, the system selects different metering programs to match different power supply capacities of a power supply system; and the passive heat metering device can be simultaneously suitable for heat metering of the heating and cooling system.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

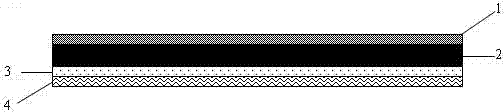

Novel solar cell back panel and preparation method thereof

InactiveCN103311341AAvoid pollutionImprove defects with poor mechanical propertiesSynthetic resin layered productsPhotovoltaic energy generationPolyesterAdhesive

The invention relates to the technical field of solar cell back panels, in particular to a novel solar cell back panel and a preparation method thereof. The solar cell back panel is prepared by a fluorine-containing polymer, a polyacrylate polymer layer and a two-way stretch polyester film through multilayer co-extrusion coating technology. According to the novel solar cell back panel and the preparation method thereof, the technique is simple, the production cycle is short, the continuous industrial production is facilitated, the harm to the health of operating staff and the pollution to environment, caused by organic solvent type adhesive, is effectively avoided, the defect of poorer mechanical property of the solar cell back panel prepared by the multilayer co-extrusion technology is improved, and the polyacrylate polymer layer with hydrolysis resistance and ageing-resistant property is adopted, has good weather resistance ability, moisture barrier property, mechanical property and interlaminar peel strength, and can effectively guarantee the long-term operation of a solar component.

Owner:CHANGZHOU HUITIAN NEW MATERIALS

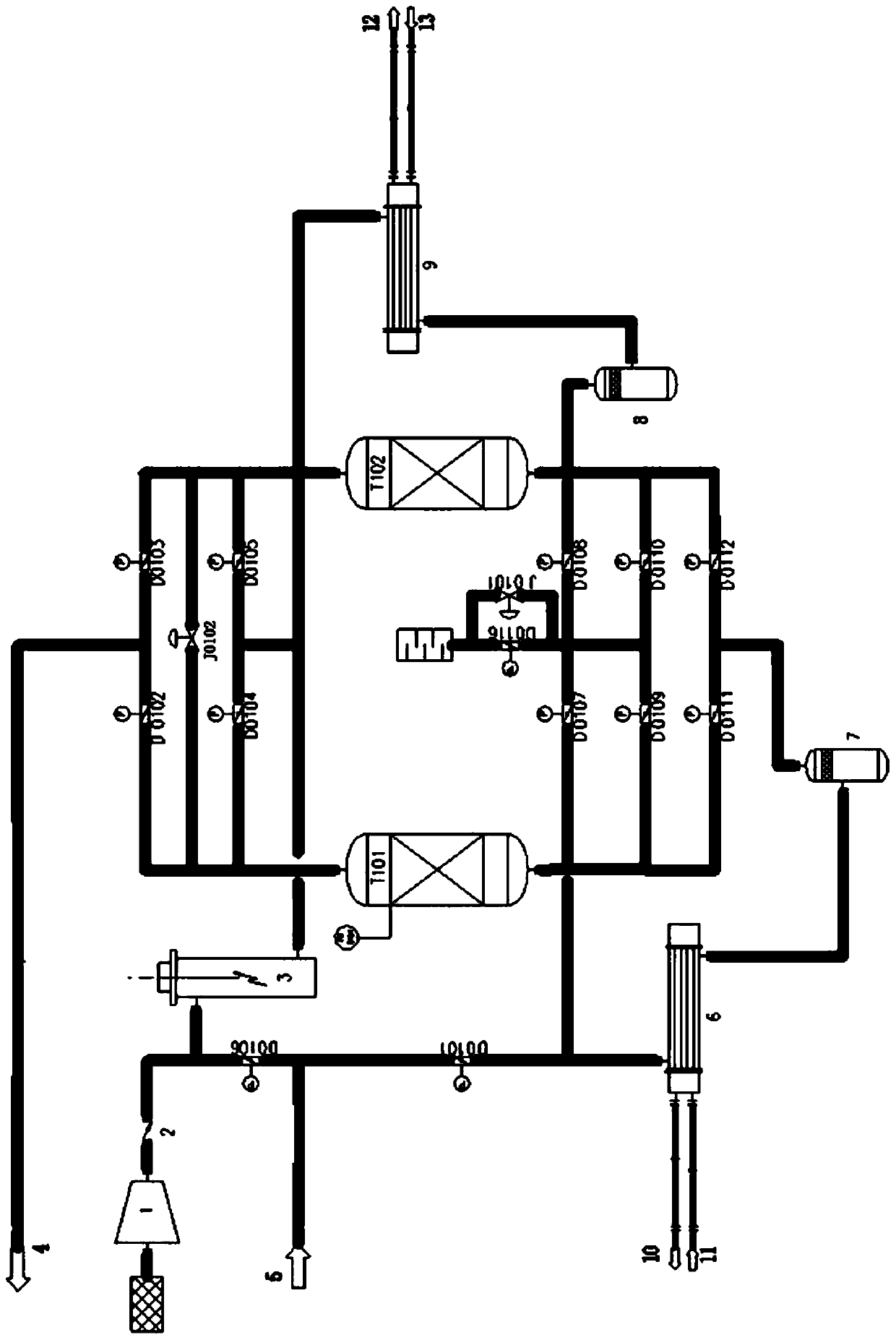

Low energy consumption general multi-mode smart adsorption drying method for preparing compressed air

ActiveCN110237646AReduced operating lifeAdjust adsorptionGas treatmentDispersed particle separationSorbentOptimal control

The invention relates to a preparation technology of compressed air and aims to provide a low energy consumption general multi-mode smart adsorption drying method for preparing compressed air. An adsorption drying system is targeted at parallel operation of a double adsorption barrel and a multi-adsorption barrel; air flow organization of hot air flows are performed from an upper part of a regeneration adsorption barrel downwards to realize regeneration of an adsorption agent; the method includes a heating and regenerating stage for waste heat of compressed air, a voltage discharging stage, fanning, deepening and heating stage and a circulating and cooling stage. The method disclosed by the invention has the advantages of (1) low energy consumption, fully utilizing compressed waste heat and environmental cooling capability; (2) multi-module design, realizing multi-layered dew point control; (3) multi-module regeneration, ensuring long-time work of a drying agent; (4) self-adjusting capability; and (5) digitalized efficient analysis. According to the method provided by the invention, optimal control of the drying agent monitored in real time based on the wet height of adsorption barrels is utilized, long-time and smooth operation of the whole adsorption technology is ensured, long-time and stable work of the drying agent is ensured, and the replacement cost is greatly reduced.

Owner:HANGZHOU ZETA TECH +1

Aluminium profile extrusion device

InactiveCN103537508AAchieve mutual positioningGuaranteed extrusion effectExtrusion diesExtrusion containersExtrusionAluminium

The invention provides an aluminium profile extrusion device which comprises an extrusion rod and an aluminium profile extrusion chamber matched with the extrusion rod, wherein the aluminium profile extrusion chamber is defined by a first mould base, a second mould base, a first material liner and a second material liner together; a discharge hole for molding a product is formed between the first mould base and the second mould base; mold inserts are fixed in the first mould base and the second mould base; first matching parts are arranged on the first material liner and the second material liner; second matching parts are arranged on the first mould base and the second mould base; the first matching parts and the second matching parts are respectively formed on contact surfaces between the material liners and the mould bases. The mould bases and the material liners are respectively provided with concave parts and convex parts which are matched with each other, so that the relative location between the mould bases and the material liners can be realized, the mould bases and the material liners are prevented from being staggered from each other along the vertical direction, and furthermore, the extrusion effect of aluminium profiles and the long-term operation of the extrusion device are guaranteed.

Owner:张家港市昊天金属科技有限公司

Novel solar cell backplate and preparation method thereof

InactiveCN103618015AImprove hydrolysis resistanceAvoid stickingFinal product manufactureLaminationPolyesterHydrophobic polymer

The invention relates to the technical field of solar cell backplates, and particularly discloses a new solar cell backplate and a preparation method thereof. The solar cell backplate is prepared from an ultra-drainage polymer layer, a double-way stretching polyester film base material, a bonding agent layer and a polyolefine bonding layer by coating a composite technology. The new solar cell backplate and the preparation method thereof provided by the invention have the advantages that the ultra-drainage polymer layer is adopted, the new solar cell backplate has an ultra-drainage property, water bubbles are avoided adhering on the surface of the backplate, the hydrolysis resistance property of the backplate is improved, and the long term operation of a solar energy assembly is guaranteed effectively.

Owner:CHANGZHOU HUITIAN NEW MATERIALS

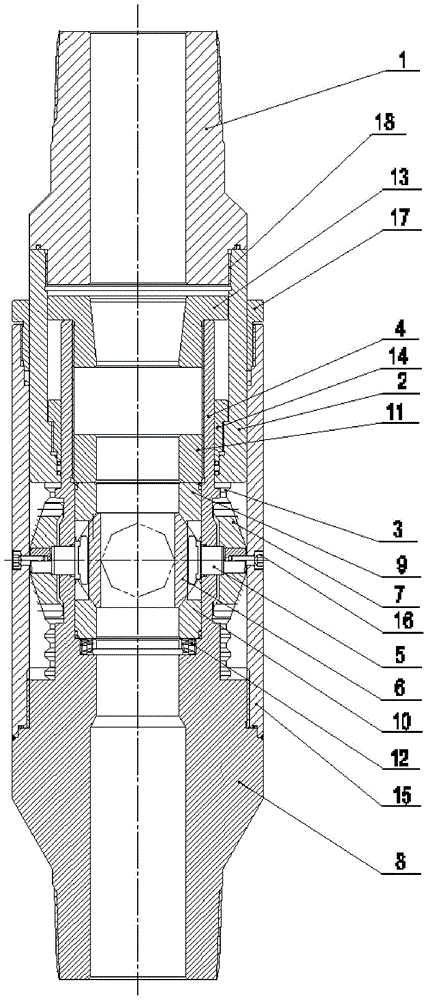

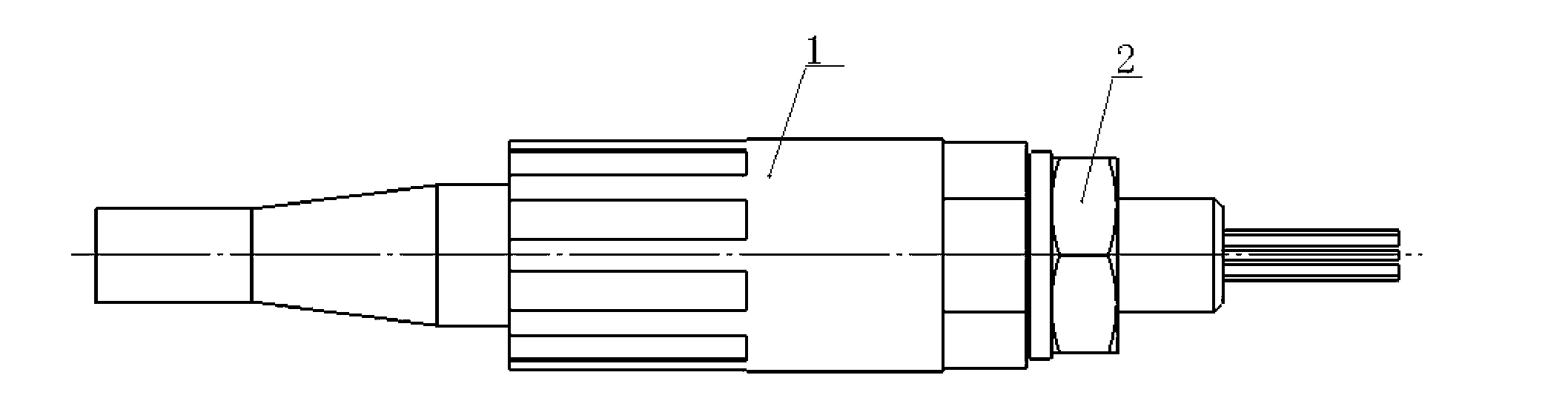

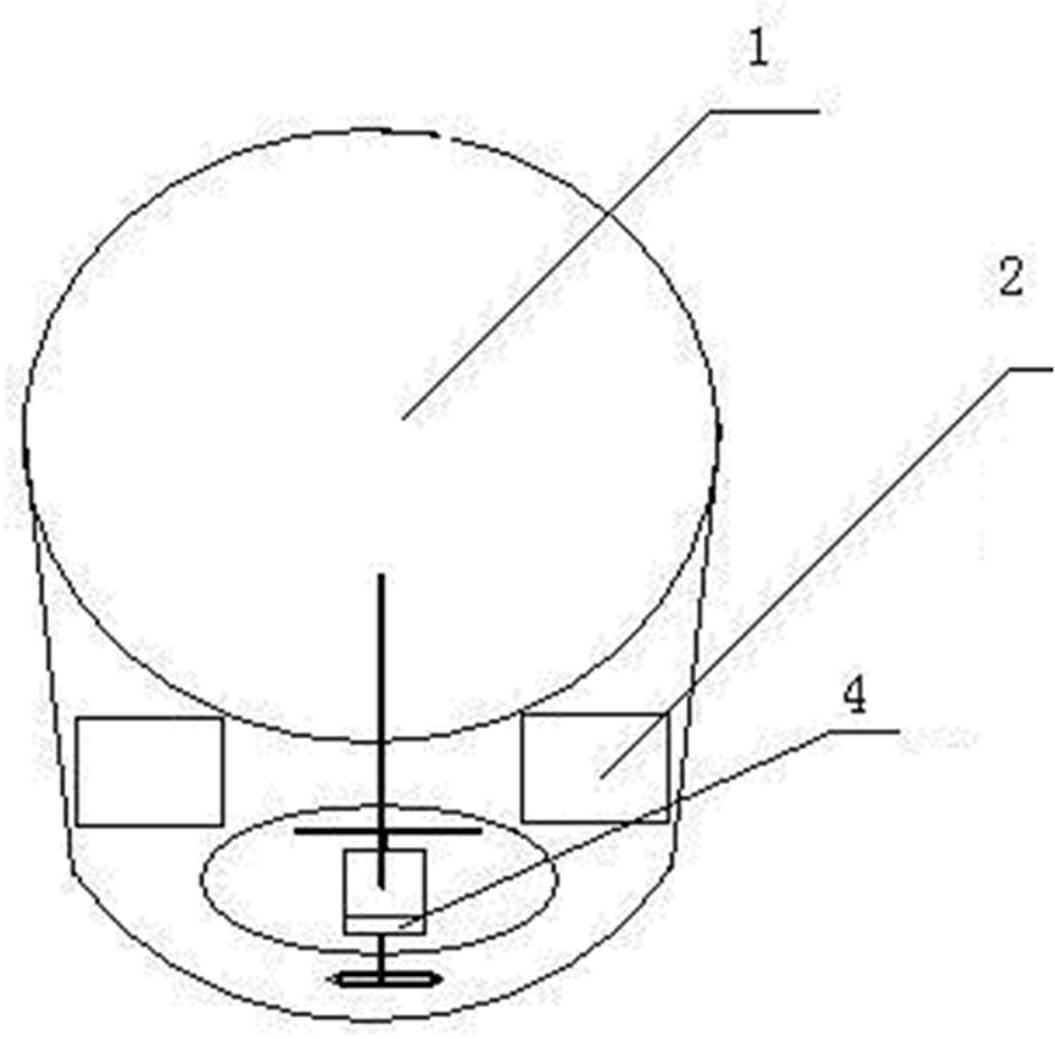

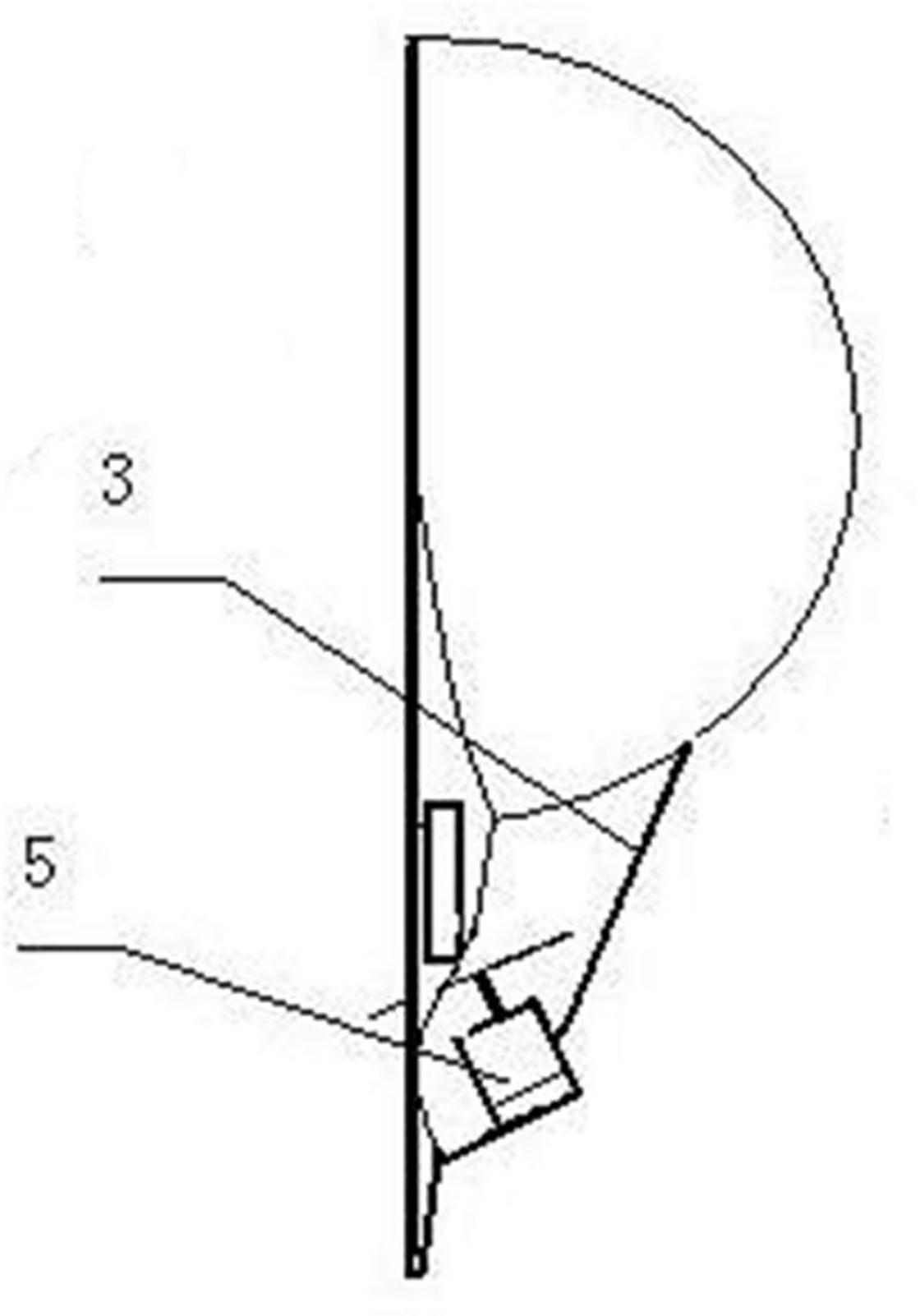

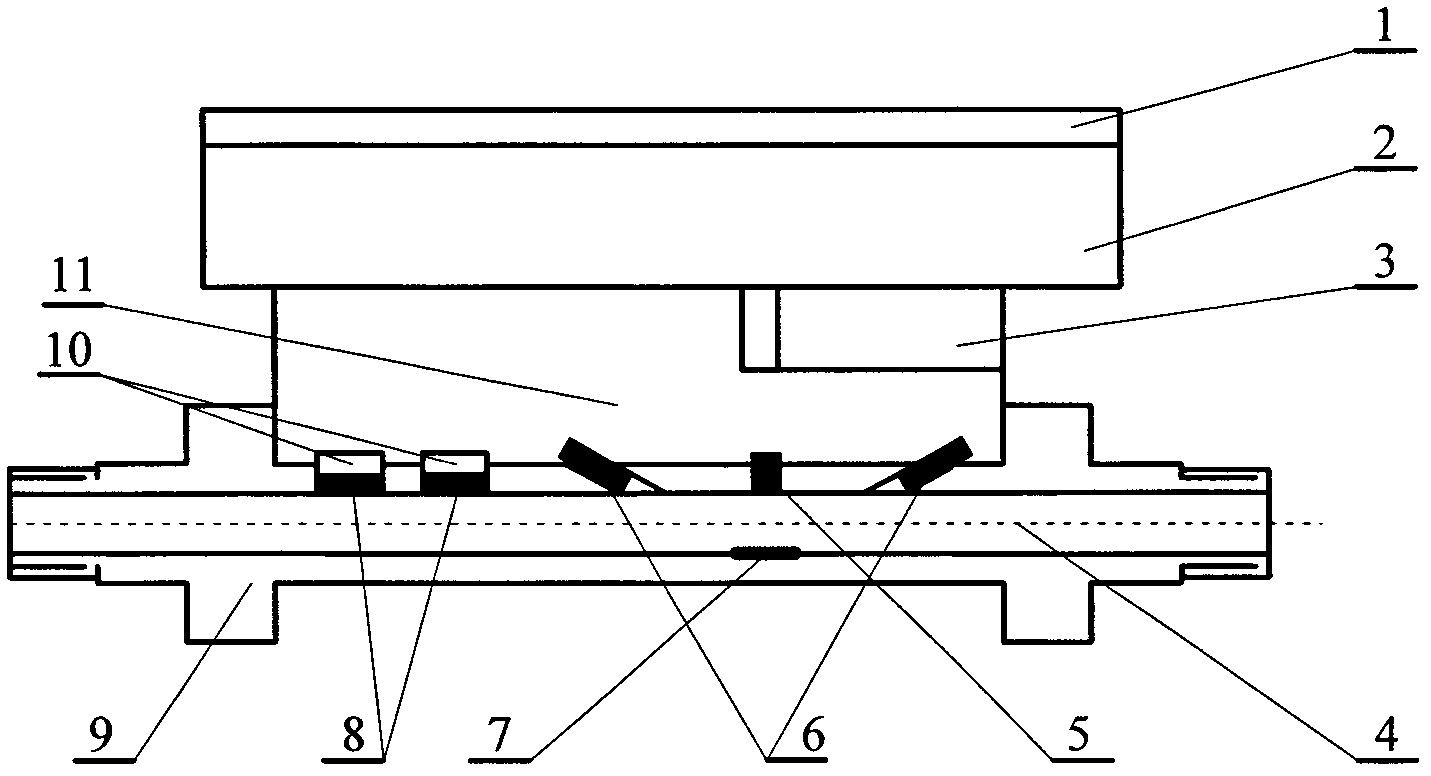

Underwater connector capable of being plugged and unplugged wetly

InactiveCN103022797AHas wet-mating characteristicsReliable WatertightnessSecuring/insulating coupling contact membersVulcanizationMarine engineering

The invention relates to an underwater connector capable of being plugged and unplugged wetly. Projecting cylindrical projections (4) are arranged on the surfaces of contact pins (7), seal rings (8) are arranged in jacks (3) matched with the cylindrical projections (4) on the surfaces of contact pins (7), and after the contact pins (7) are plugged into the jacks (3), the seal rings (8) are squeezed on the cylindrical projections (4) on the surfaces of contact pins (7). The underwater connector capable of being plugged and unplugged wetly has the advantages that the underwater connector is capable of being plugged and unplugged wetly by the aid of the principle of 'isolation from a water body', has reliable water tightness as a plug (1) and a socket (2) are integrally formed by vulcanization, and is guaranteed to be capable of bearing underwater 1000-meter pressure when working in an underwater environment for a long time, and since the plug (1) made of nonmetal materials is nonconductive to magnetism, the underwater connector is usually used for detection equipment such as underwater robots and underwater lighting and marine animal tracking equipment.

Owner:沈阳兴华航空电器有限责任公司

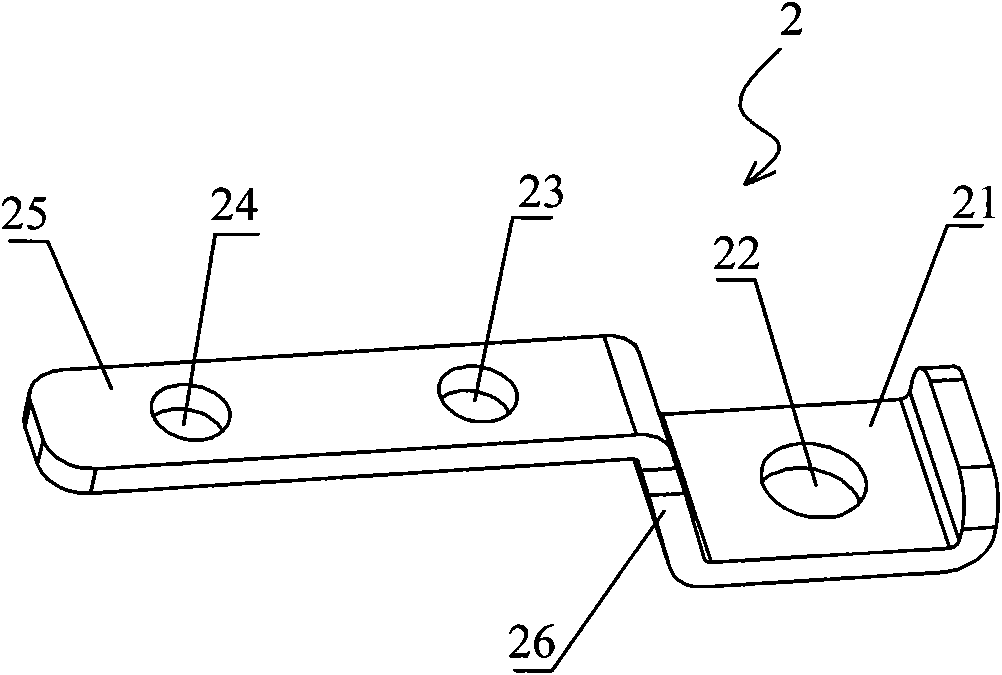

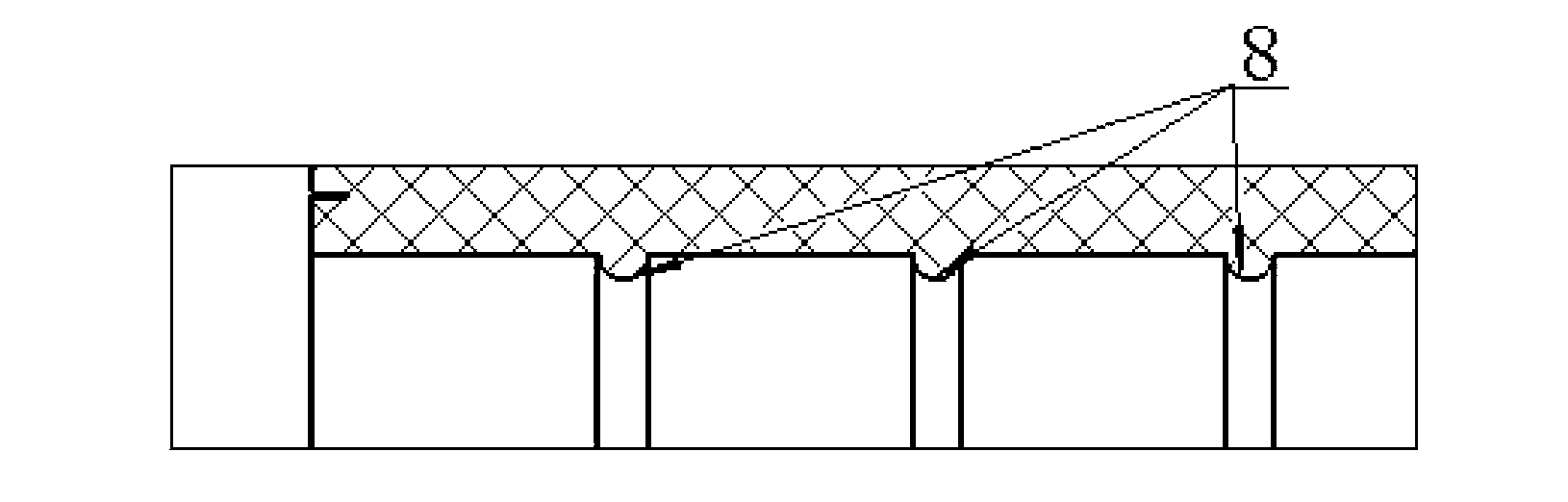

Welded base of surge protector

ActiveCN106300313AAvoid accidental exitCompact structureEmergency protective arrangements for limiting excess voltage/currentElectricityComputer module

The invention discloses a welded base of a surge protector. The welded base comprises a base body; a mounting groove accommodating a protector module is formed in the base body; a connector is formed in the bottom of the mounting groove; a welding pin is arranged in the connector; the lower end of the welding pin protrudes out of the bottom of the base body; the upper end of the welding pin is connected with a plug pin of the protector module; clamping buckles are also arranged on the mounting groove; clamping blocks matched with the clamping buckles are arranged on the protector module. The welded base is simple and compact in structure, small in occupied area, directly welded onto a PCB via a welding pin, suitable for limited mounting space, free of arrangement of components such as a guide rail mechanism, low in mounting cost, high in assembly efficiency, and good in mounting stability; the condition that the surge protector comes off accidentally is avoided effectively; favorable electric connection is guaranteed; the protector module can work normally for a long time effectively; a stable protection function is provided; the use safety is improved.

Owner:SICHUAN ZHONGGUANG LIGHTNING PROTECTION TECH

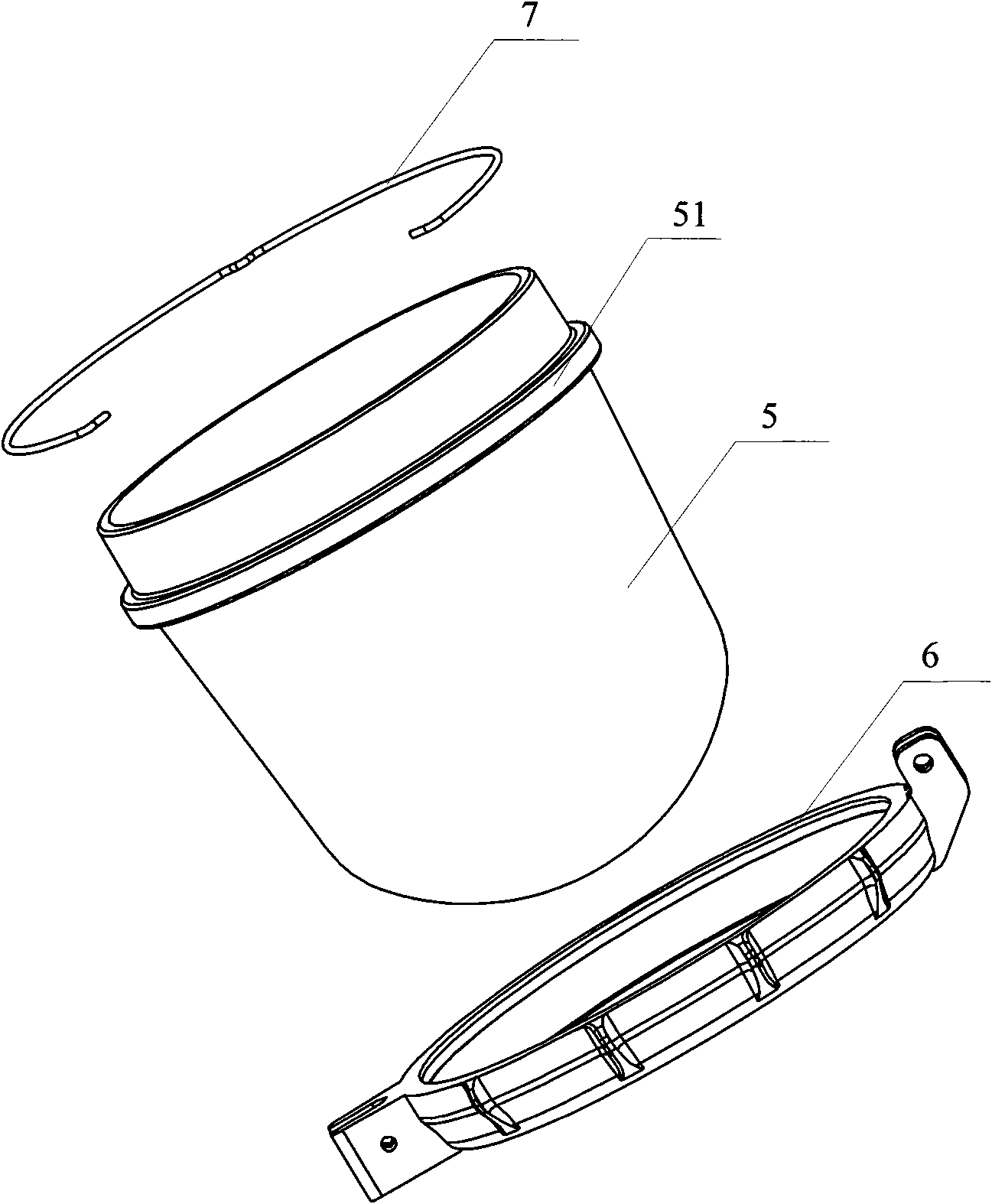

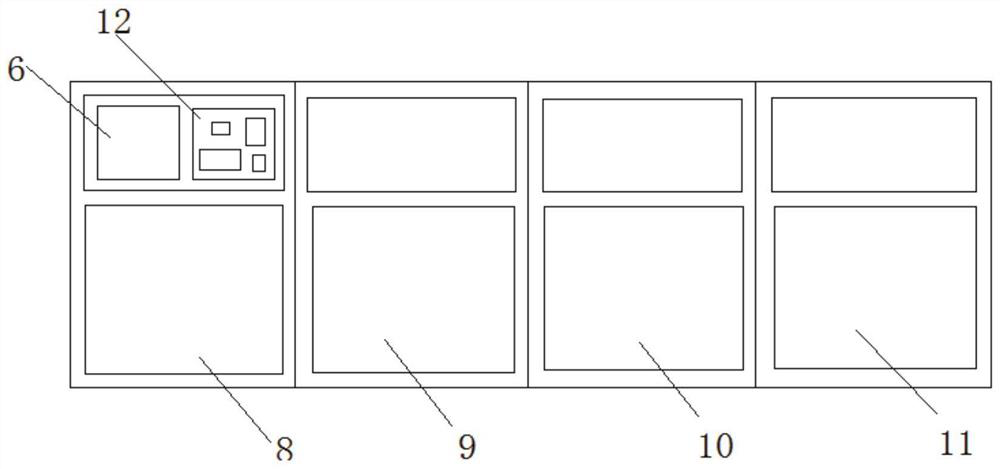

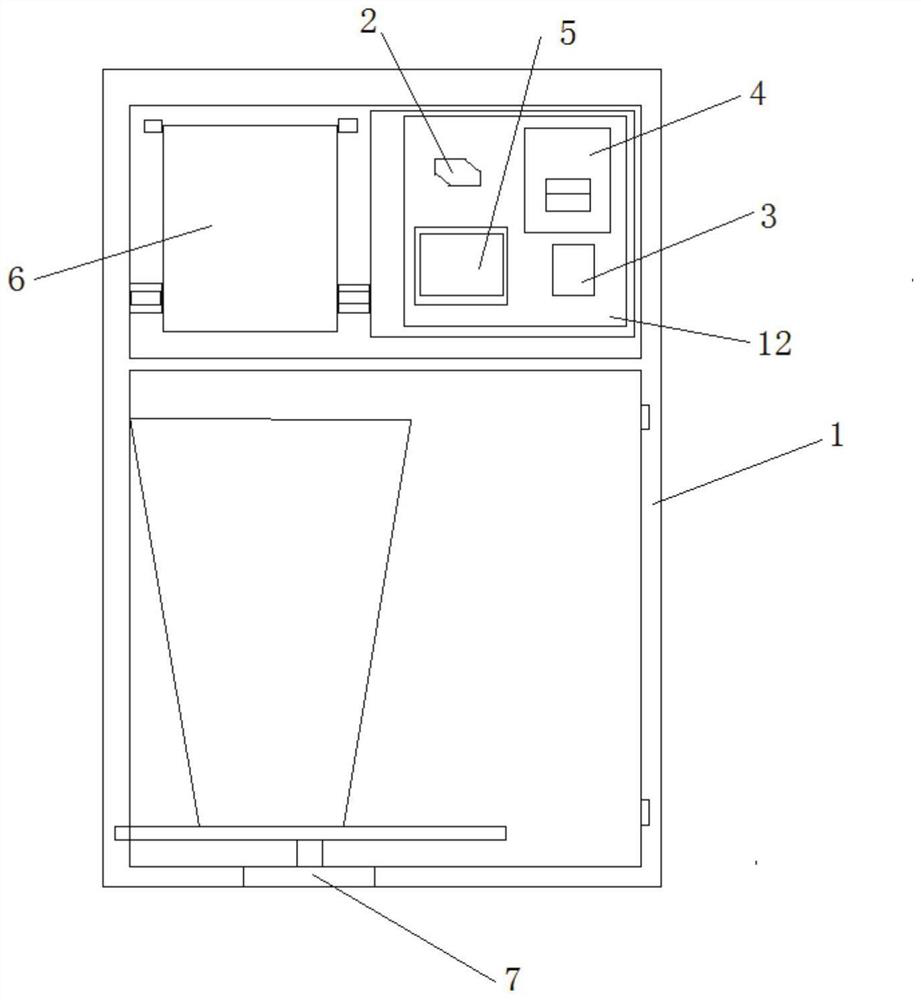

Mobile intelligent garbage classification and recovery device and system

InactiveCN111724528AEasy payment processingIncrease pointsSensing by electromagnetic radiationReturnable containers actuationEngineeringCloud data center

The invention discloses a mobile intelligent garbage classification and recovery device and system. The mobile intelligent garbage classification and recovery device comprises the mobile intelligent garbage classification and recovery device and an intelligent garbage classification and recovery system. The intelligent garbage classification and recovery system comprises a member management system, an image acquisition system, a cloud data center and an image AI recognition system. The mobile intelligent garbage classification and recovery device comprises a control device and a garbage can. The device and the system are high in intelligent degree, effectively reduce equipment energy consumption, can be movably and quickly deployed, adopt an energy-saving and environment-friendly technology, intelligently make equipment be started and stopped, reduce product energy consumption, can be powered by a safety battery, ensure that a product can be movably and quickly deployed, and are safe and reliable, and a battery voltage is lower than a human body safety voltage.

Owner:天津美拓科技有限公司

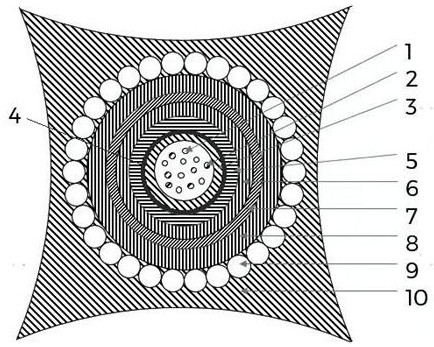

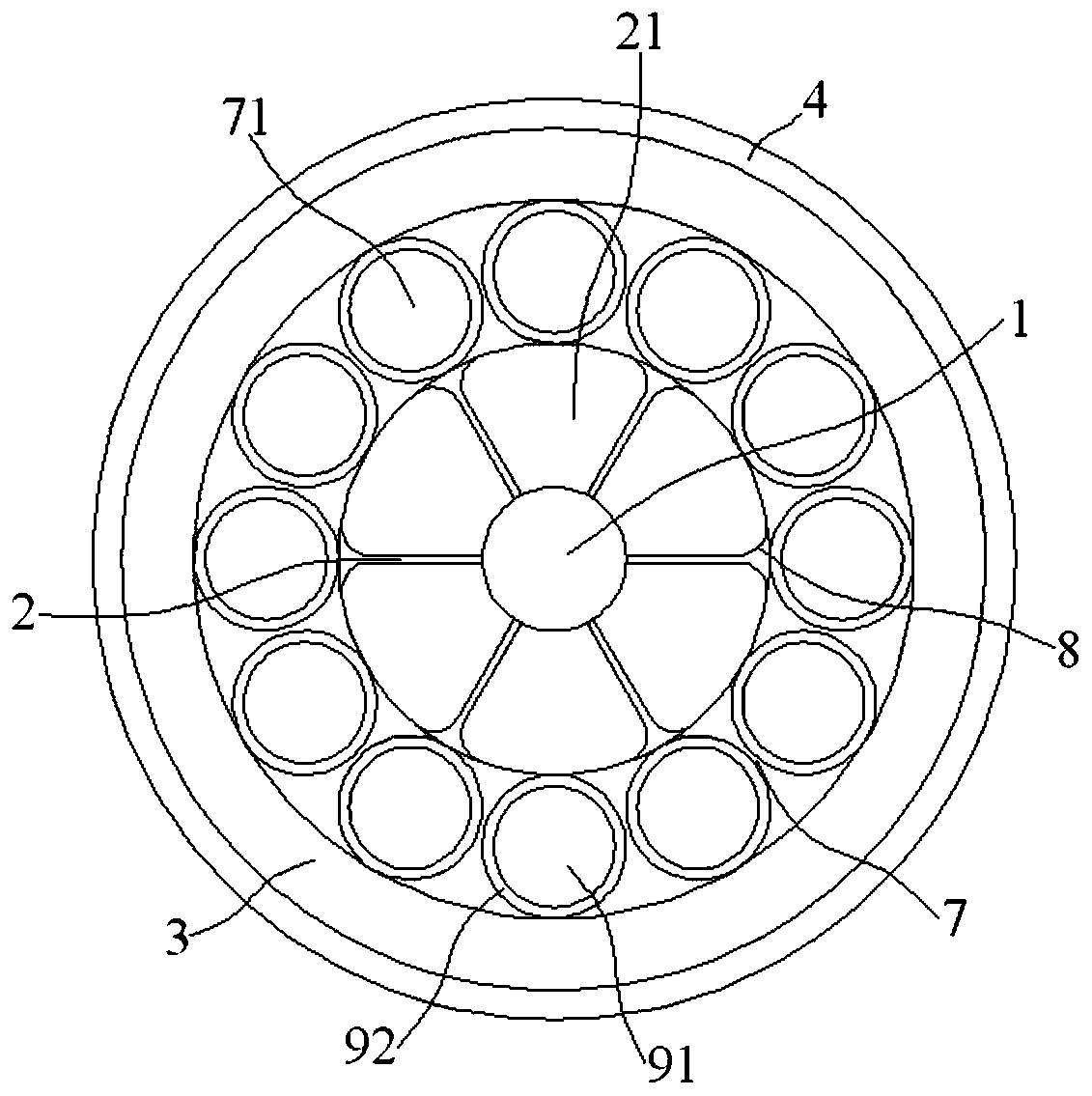

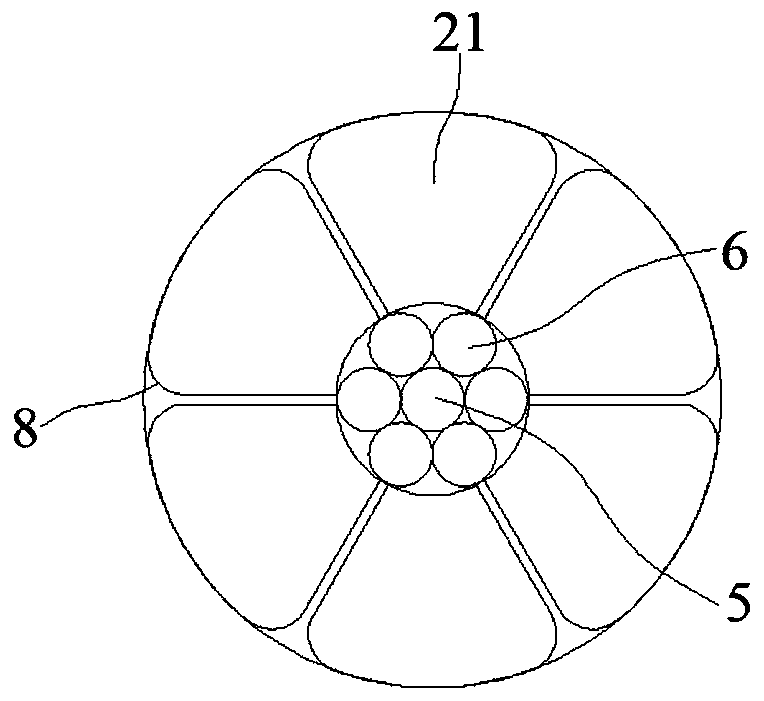

Thermal-shock-proof high-voltage-resistant optical cable

ActiveCN114779421AGuaranteed compression performanceGuaranteed tensionFibre mechanical structuresFiberBi layer

The optical cable comprises an optical cable subunit, a PI film, fiber paste, an inner-layer steel pipe, a foaming layer, an outer-layer steel pipe and an outer sheath which are sequentially arranged from inside to outside, the optical cable subunit comprises a subunit sheath and a plurality of optical fibers, the PI film wraps the outer surface of the subunit sheath, the inner-layer steel pipe, the foaming layer and the outer-layer steel pipe, and the outer-layer steel pipe wraps the PI film. The thickness of the outer-layer steel pipe ranges from 0.9 mm to 1.0 mm, the thickness of the foaming layer ranges from 1.0 mm to 1.5 mm, and the thickness of the inner-layer steel pipe ranges from 0.25 mm to 0.3 mm. Through the inner and outer double-layer steel pipes, the compression resistance of the optical cable is ensured, the tensile property of the optical cable is also ensured, the optical cable can cope with a high-temperature and high-pressure environment, the foaming layer provides buffering, thermal insulation and other effects for the optical cable, the survival ability of the optical cable is further improved, and the service life of the optical cable is prolonged. The optical cable has the characteristics of high voltage endurance capability, strong tensile capability, corrosion resistance, high temperature resistance and the like.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD +1

A multifunctional ball valve assembly for heavy oil thermal recovery wells

ActiveCN104864162BGuaranteed long-term workMeet the operational needs of protectionOperating means/releasing devices for valvesWell/borehole valve arrangementsGear drivePush pull

The invention relates to a multifunctional ball valve assembly for a thickened oil thermal production well. The multifunctional ball valve comprises an upper connector of which the upper rend can be connected with an oil pipe connector, a push-pull sleeve of which the upper end is fixedly connected with the lower end of the upper connector, two gear racks symmetrically and fixedly arranged at the lower end of the push-pull sleeve and extending in the axial direction, a ball valve sleeve of which the upper end is sleeved by the push-pull sleeve and capable of sliding up and down relative to the push-pull sleeve, a ball valve core rotatably mounted in the cavity of the ball valve sleeve through two symmetrically and fixedly arranged ball valve rods, and two gears mounted outside the ball valve sleeve and fixedly connected with the two ball valve rods respectively, wherein a lower connector in sealed connection with an anchor is further arranged at the lower end of the ball valve sleeve; the gear racks at the lower end of the push-pull sleeve are meshed with the gears all the time. In the lifting or pressing process of the upper connector, the gear racks drive the gears to rotate, the gears drive the ball valve rods fixedly connected with the gears to rotate together, and the ball valve rods drive the ball valve core to rotate, so that the opening and closing of the ball valve assembly is realized. The multifunctional ball valve assembly can be widely applied to production operation of the thickened oil thermal production well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

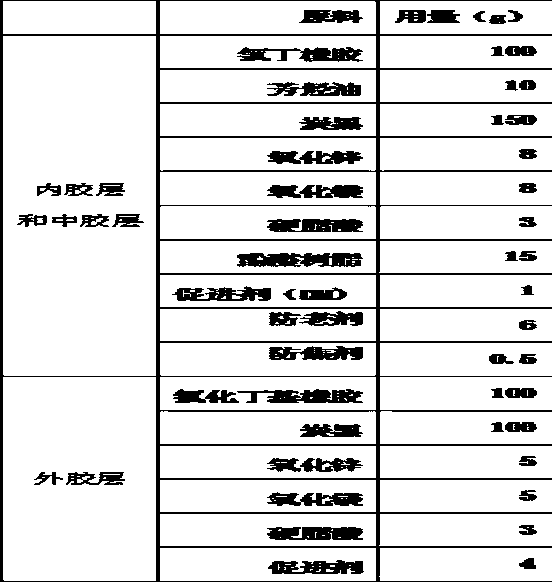

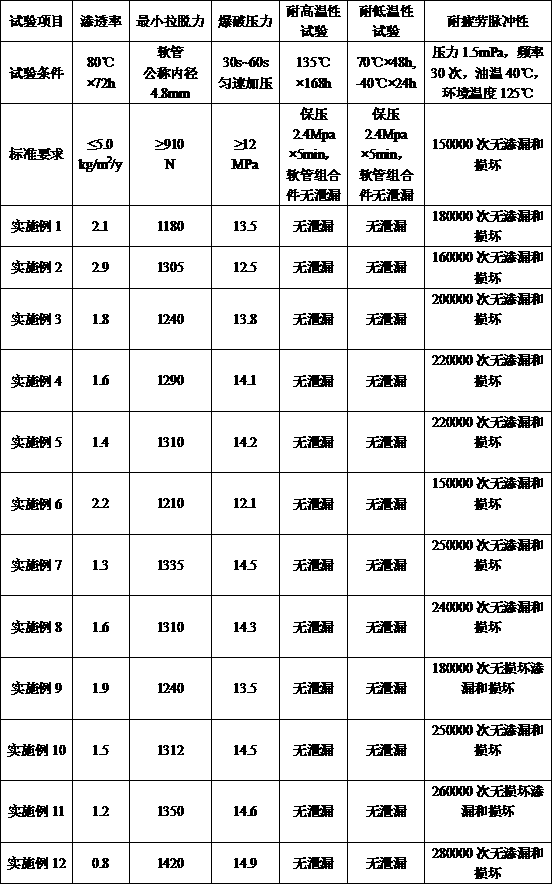

Automobile air conditioner hose, preparation process thereof and automobile air conditioner hose assembly

ActiveCN111076000AExcellent anti-penetrationImprove penetration resistanceSynthetic resin layered productsFlexible pipesPolyesterFiber

The invention discloses an automobile air conditioner hose, a preparation process thereof and an automobile air conditioner hose assembly, and belongs to the field of automobile air conditioner pipelines. The air conditioner hose sequentially comprises an inner rubber layer, a nylon shielding layer, a middle rubber layer, a polyester fiber reinforcing layer and an outer rubber layer from inside tooutside; the inner rubber layer and the middle rubber layer are prepared from the following raw materials of, in parts by weight, 100 parts of chloroprene rubber, 3-10 parts of aromatic hydrocarbon oil, 50-150 parts of carbon black, 2-8 parts of zinc oxide, 2-8 parts of magnesium oxide, 1-3 parts of stearic acid, 5-15 parts of phenolic resin, 0.3-1 part of accelerants, 2-6 parts of anti-aging agents and 0.3-0.5 parts of scorch retarders; the outer rubber layer is prepared from the following raw materials of, in parts by weight, 100 parts of chlorinated butyl rubber, 50-100 parts of carbon black, 2-5 parts of zinc oxide, 0.5-5 parts of magnesium oxide, 1-3 parts of stearic acid and 1-4 parts of accelerants. The provided automobile air conditioner hose has the advantage of low permeabilityof an R1234yf refrigerant, and can stably work for a long time under the condition of -40-135 DEG C.

Owner:ZHEJIANG JUNHE RUBBER TECH

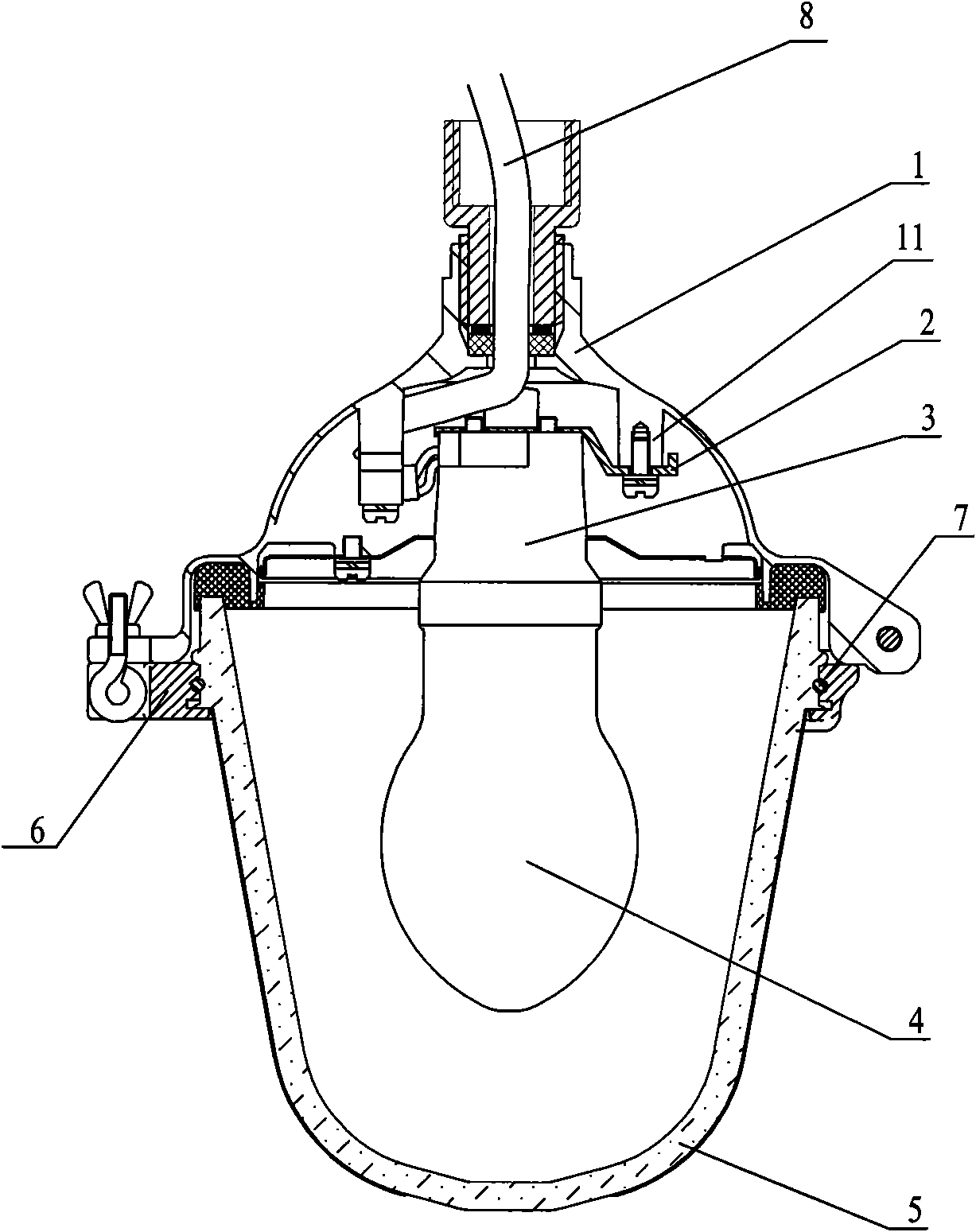

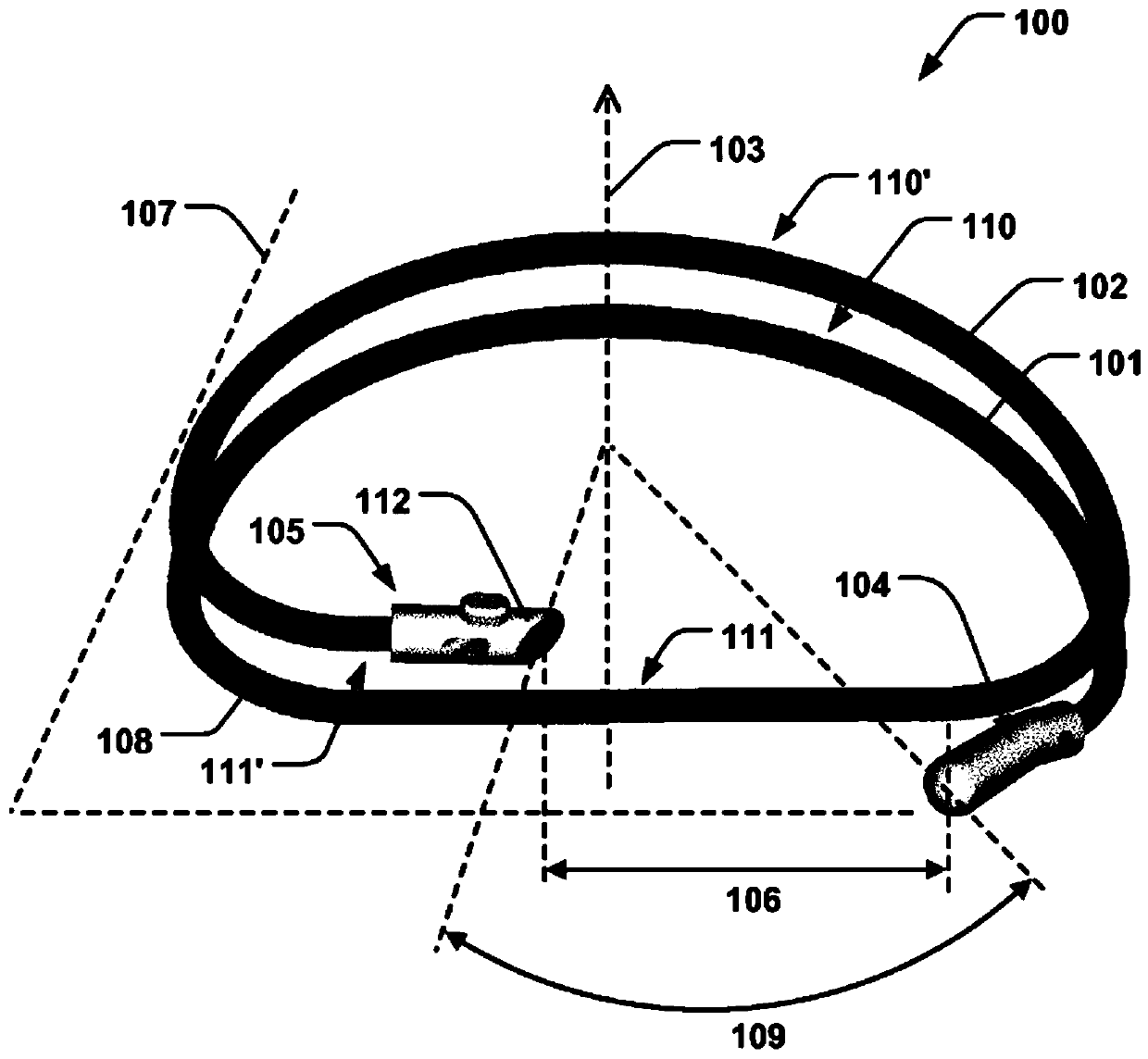

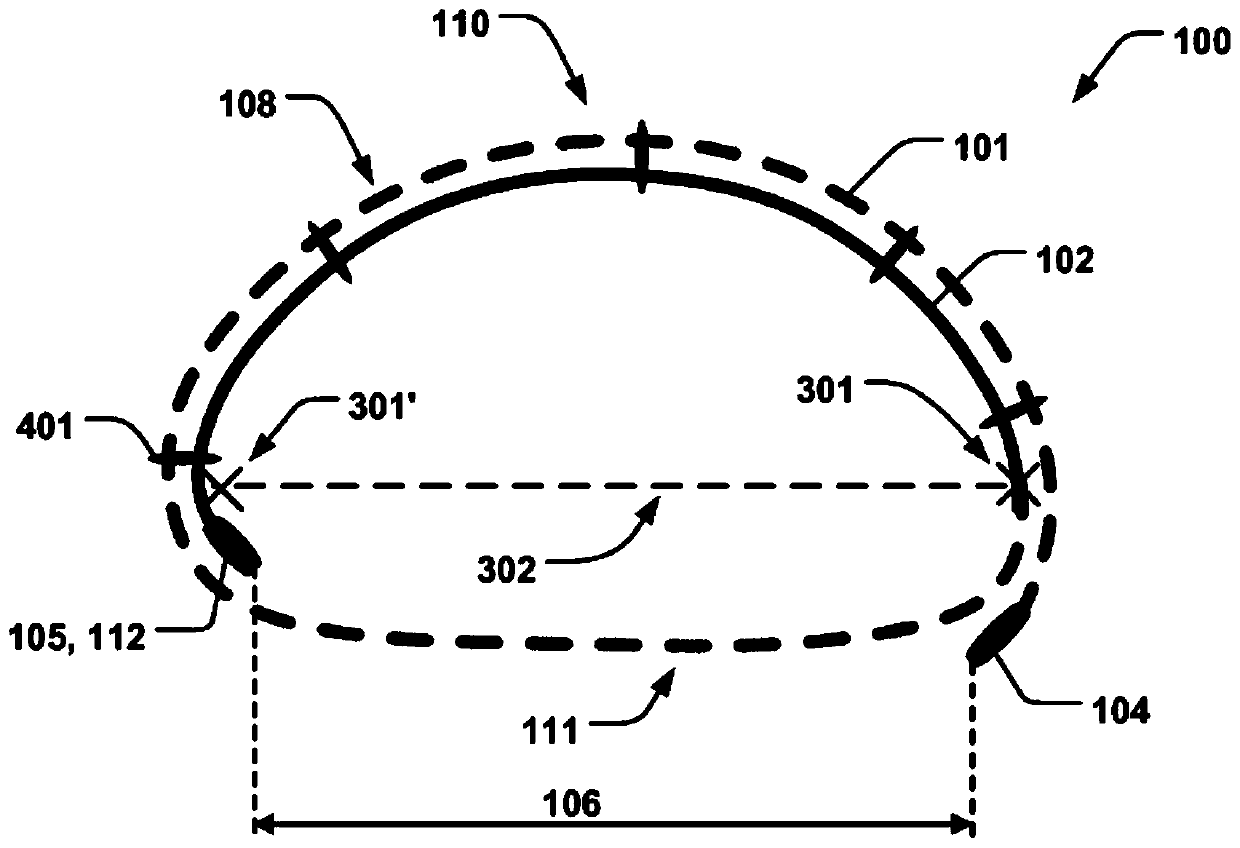

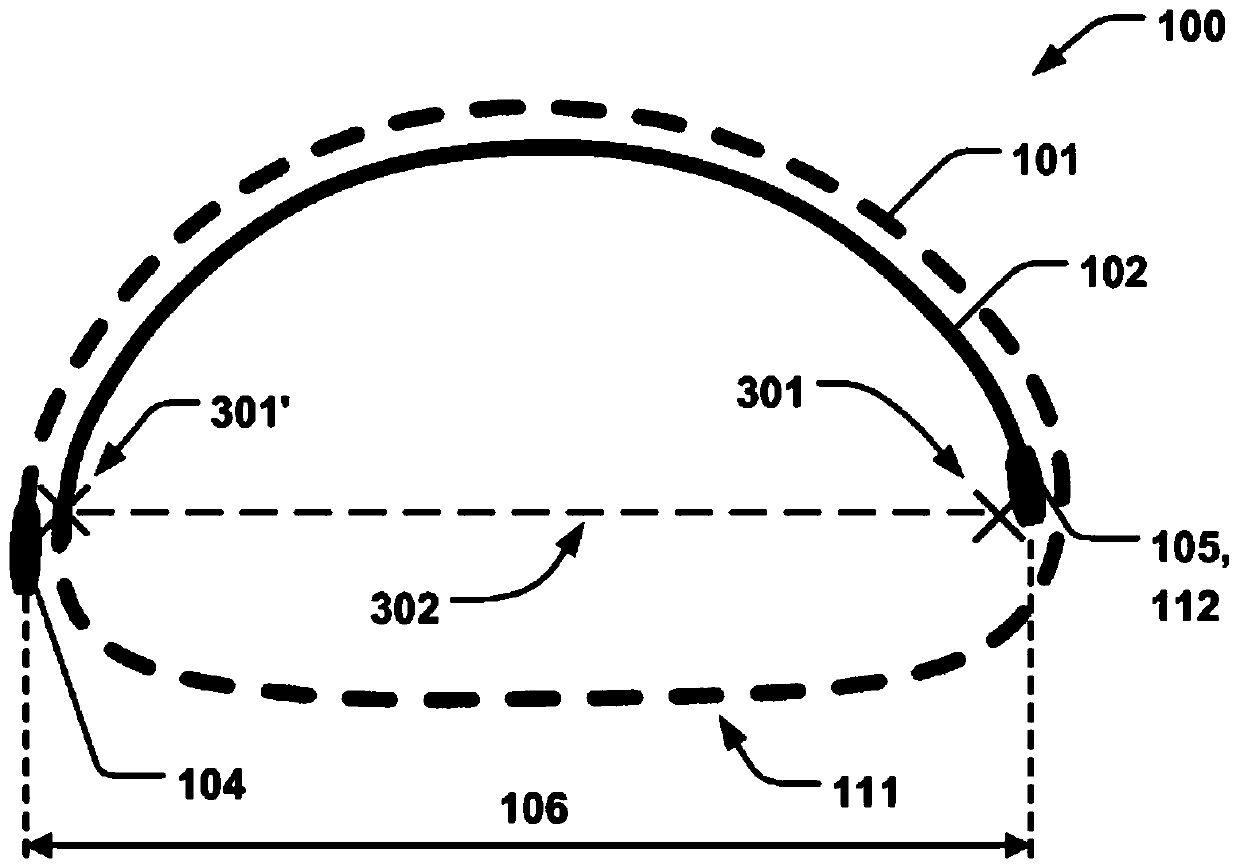

Annuloplasty implant

ActiveCN110573113AEasy to fixReduce time consumptionAnnuloplasty ringsWing configurationSet distance

An annuloplasty implant is disclosed comprising first and second support members having a coiled configuration in which the first and second support members are arranged as a coil, with two free ends,around a central axis, wherein, in said coiled configuration, said two free ends are displaced from each other with a peripheral off-set distance extending in a coil plane, said coil plane being substantially parallel to an annular periphery of said coil and perpendicular to said central axis, wherein the first and second support members and the respective free ends are configured to be arrangedon opposite sides of native heart valve leaflets of a heart valve. A method of implanting an annuloplasty implant at a target site in the heart is also disclosed.

Owner:MEDTENTIA INT LTD OY

Solar traveling cap with fan

A solar traveling cap with a fan comprises a traveling cap body, a solar battery and a bracket; the solar battery is arranged on the brim of the traveling cap body; the bracket is arranged on the brim and provided with the fan; a hole is arranged on the brim, the fan is arranged in the hole and faces towards the brim, and a power output end of the fan is connected with an output end of the solar battery. The solar traveling cap with the fan can work for longer time, has environment protection, and can obviously reduce electricity consumption and prolong the service life of a motor while ensuring the long-time work.

Owner:常州锦旸太阳能科技有限公司

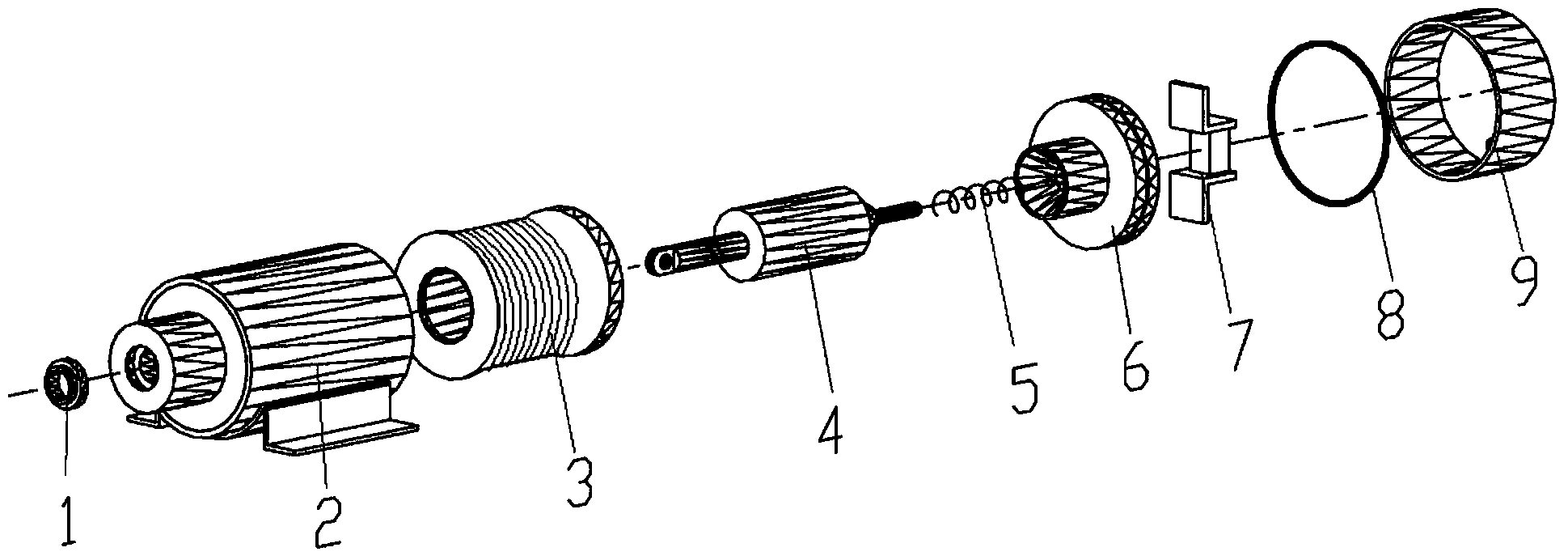

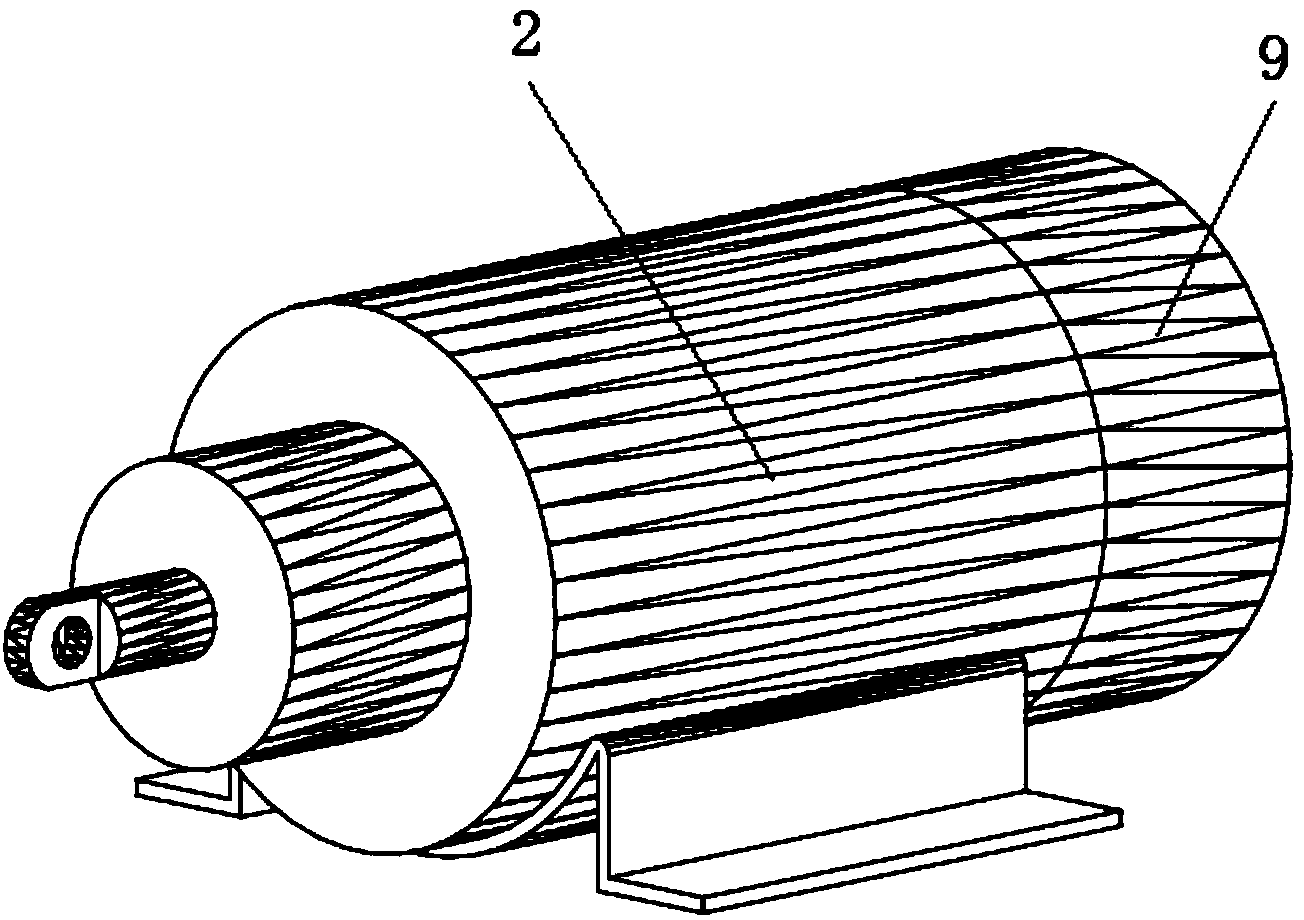

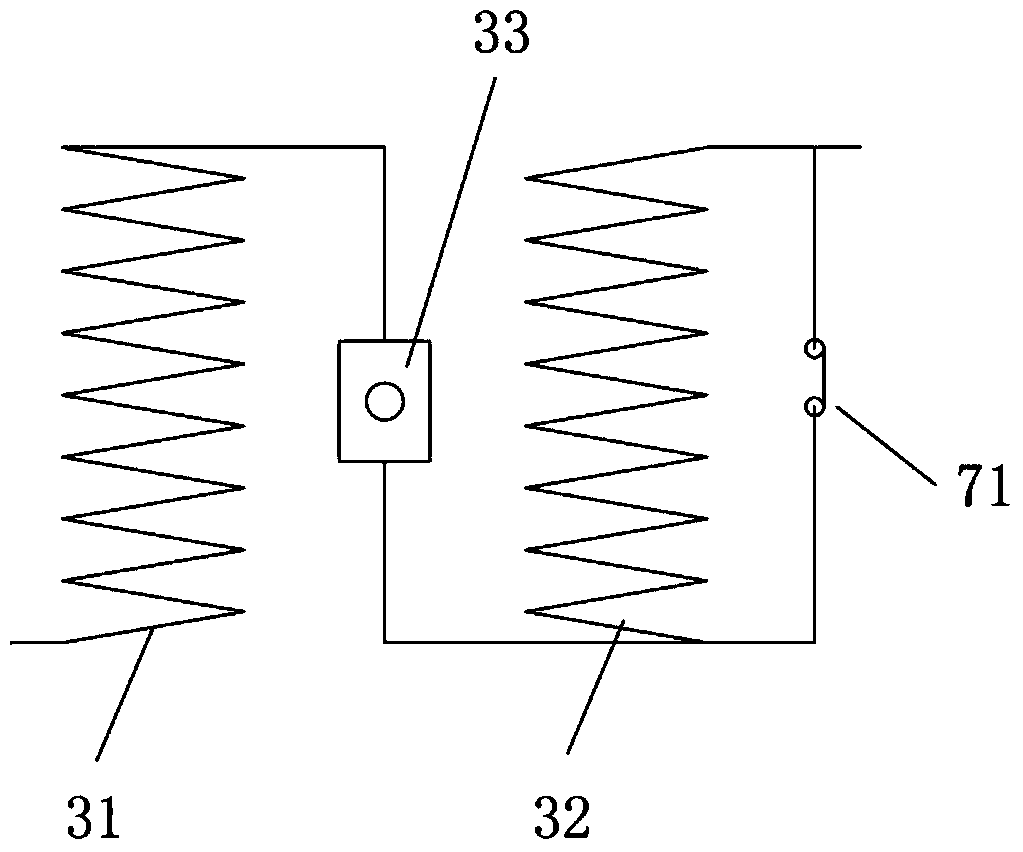

Direct current electromagnet

InactiveCN103811146AIncrease the number of turnsIncrease working tensionElectromagnets without armaturesCoilsPull forceDirect current

The invention provides a direct current electromagnet which comprises a coil, an iron core arranged in the coil in a sleeved mode, a reset spring arranged at one end of the iron core in a sleeved mode and a limiting backseat. The coil, the iron core, the reset spring and the limiting backseat are arranged coaxially. The direct current electromagnet is characterized in that the direct current electromagnet further comprises a closed shell and a relay switch, the coil comprises a first coil body and a second coil body, normal close contacts of the relay switch are connected to the two ends of the second coil body, and the first coil body and the second coil body are connected through a heat protector. According to the direct current electromagnet, the two coil bodies are adopted so that the direct current electromagnet can work continuously for a long time and large operation tensile force can be provided; the two coil bodies are connected through the heat protector so that the direct current electromagnet can work safely in the high-temperature operation environment for a long time; the closed shell is adopted so that the strength and the waterproof performance of the direct current electromagnet can be guaranteed and the direct current electromagnet can work in the humid environment for a long time.

Owner:SHANGHAI KUKAI REFRIGERATION EQUIP

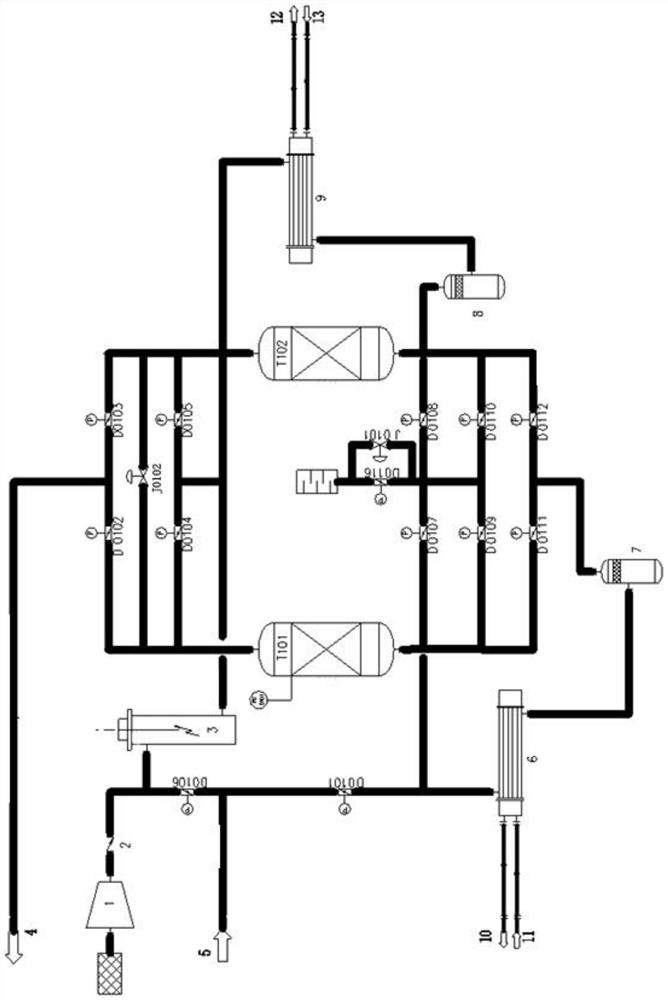

Novel oilfield water injection system of positive displacement underground generating set and novel water injection system comprising same

ActiveCN111550361AImprove performanceImprove featuresFluid removalMechanical energy handlingOil fieldElectric generator

The invention relates to a novel oilfield water injection system of a positive displacement underground generating set. The novel oilfield water injection system comprises a main cavity and a positivedisplacement underground power generating set body, wherein a water injection channel and a power generator cavity are formed inside the main cavity, the positive displacement underground power generating set body is located in the power generator cavity, the upper end of the generator cavity communicates with the water injection channel of the main cavity through an independent channel, the positive displacement underground power generating set body is assembled in the generator cavity in a mode that a hollow inner cavity of the positive displacement underground power generating set body andthe water injection channel are coaxially arranged, therefore, the drift diameter of a channel section, corresponding to the positive displacement underground power generating set body, on the waterinjection channel is almost unchanged in the axial direction, and a liquid column flowing through the channel section is not affected by hole shrinkage caused by assembling of the positive displacement underground power generating set body.

Owner:河北中清永晟石油科技有限公司

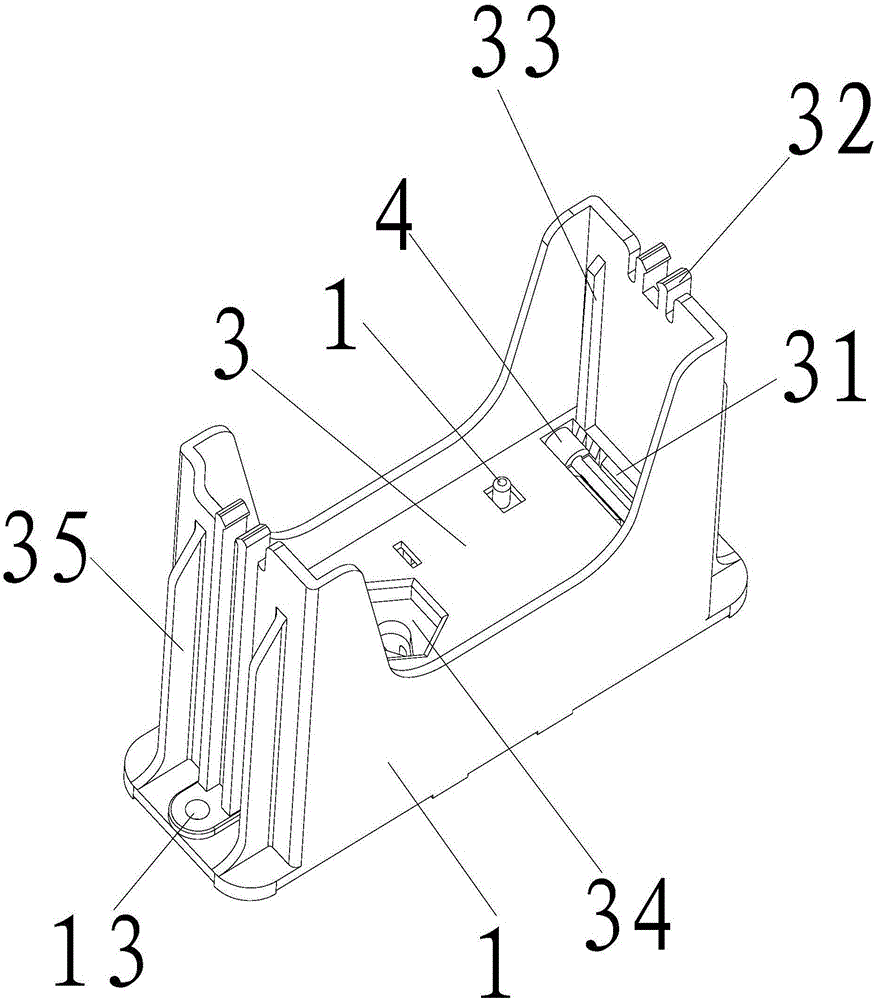

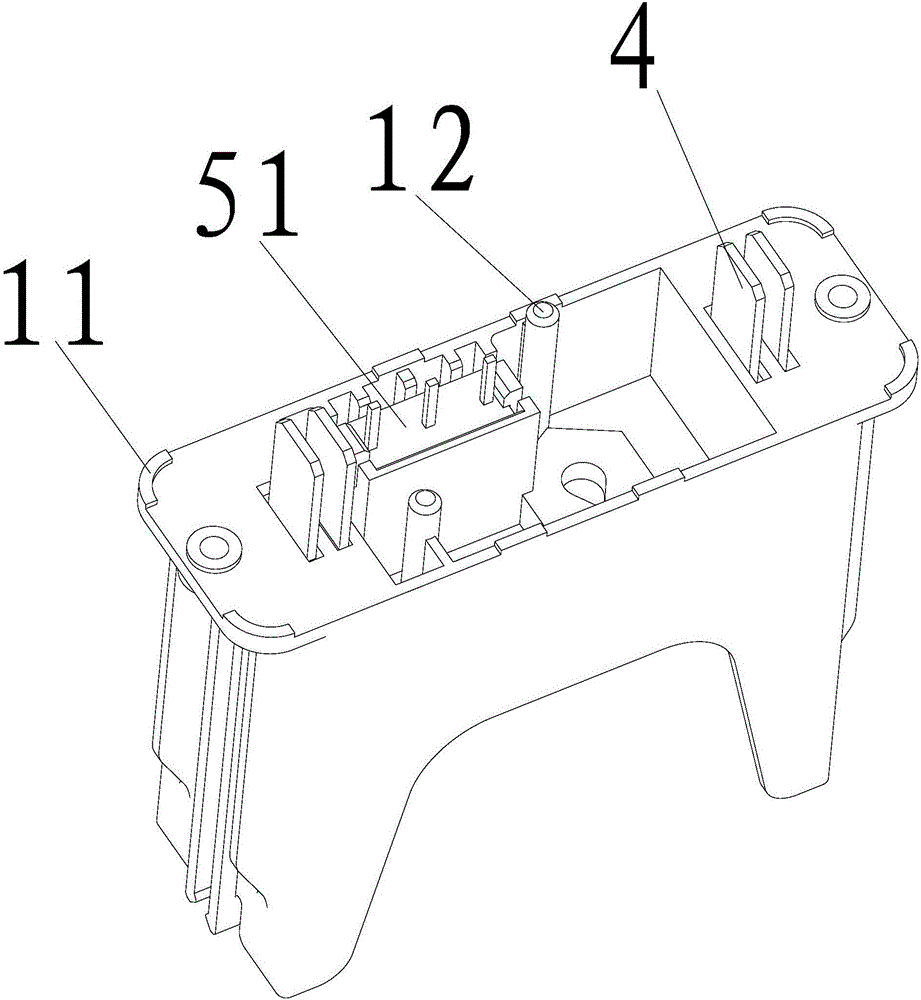

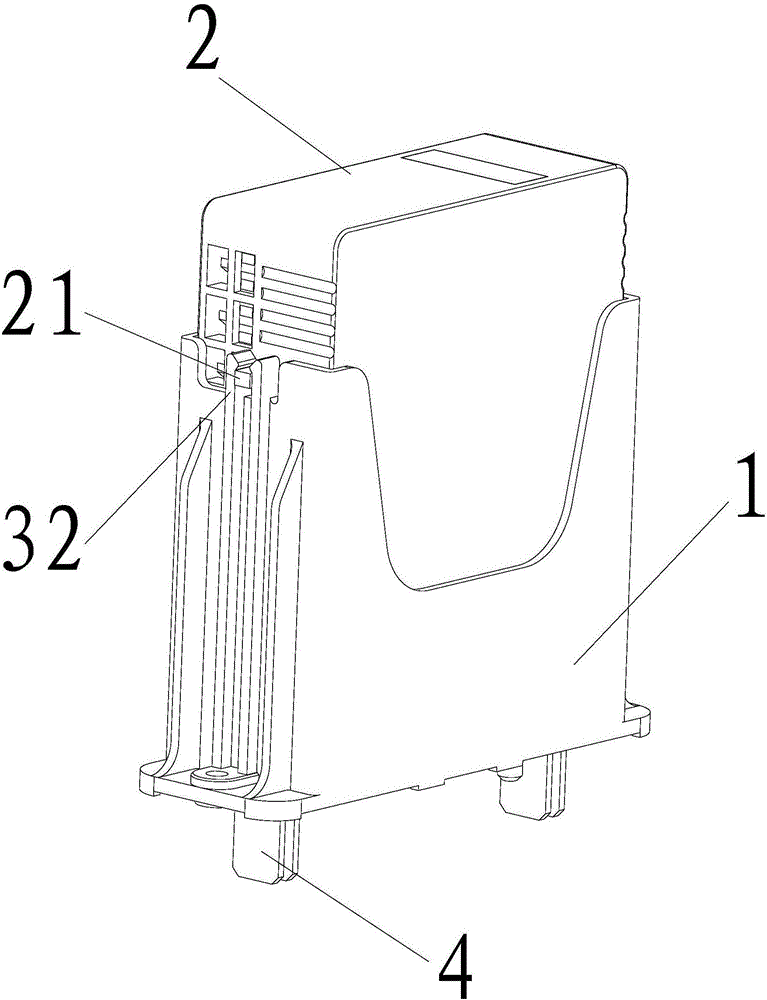

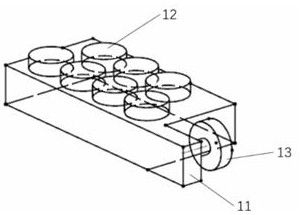

Novel waterproof connector for ABS wire harness

PendingCN112490749AGuaranteed long-term workEasy to plug and unplugCouplings bases/casesTwo-part coupling devicesEngineeringStructural engineering

The invention discloses a novel waterproof connector for an ABS wire harness, and the connector employs a plurality of types of limiting structures and matching combinations, and the limiting structures comprise a piston part, an insertion strip, a lower limiting arc block, a movable strip, a side seat, an upper limiting arc block, a positioning seat, a supporting block, a hook strip, a pressing cavity, a locking block, a stop block, a pressing block, a locking hole, and a strip-shaped slot. Through the locking structure design of pressing, clamping and plugging between a plug and a plug bush,external water vapor is blocked outside the plugging position of the probe and the plug bush, plugging and plugging are convenient, combination is tight, the waterproof performance is high, the structural strength is high, the protection level can reach IPX9K, long-acting work of the ABS function of a used vehicle is guaranteed, and driving safety is guaranteed.

Owner:苏州特斯创汽车电子有限公司

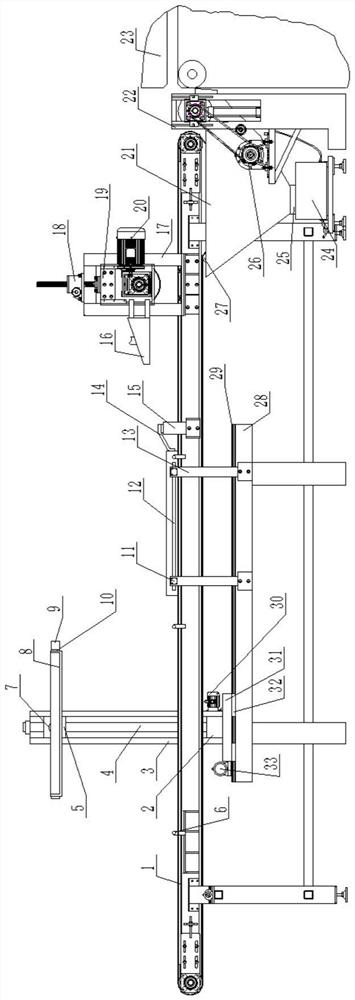

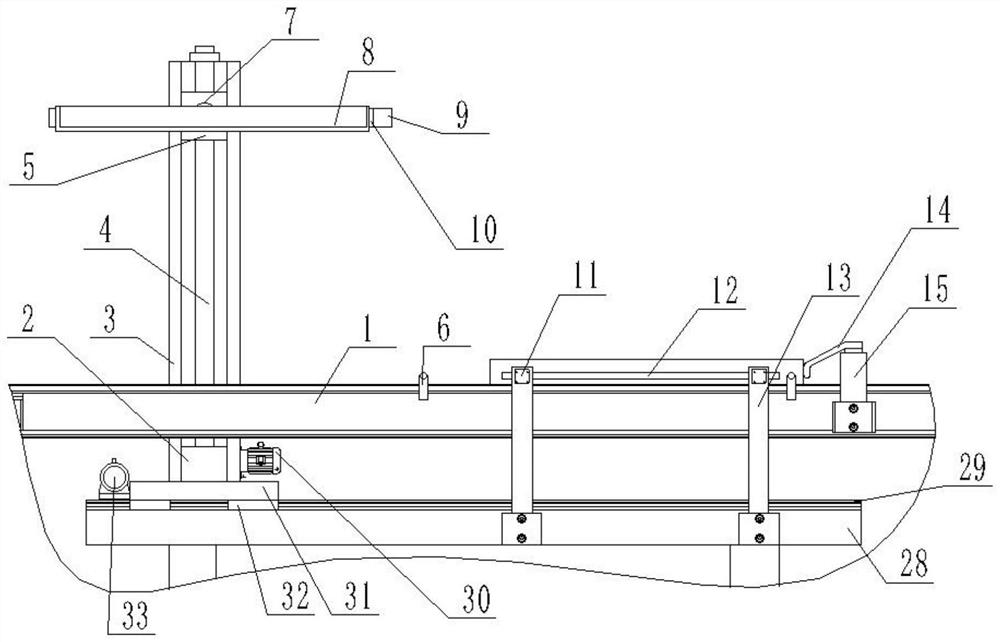

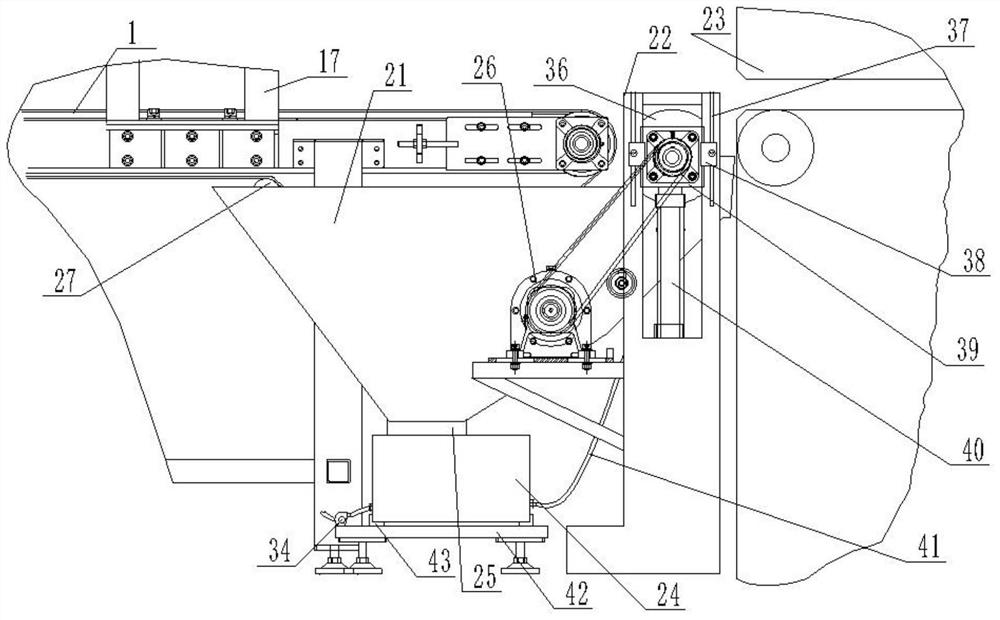

Automatic conveying, overturning and covering device for cleaning plate

ActiveCN113263737AEnsure stabilityEasy to reinforceCleaningCleaning using toolsClassical mechanicsSupport plane

Owner:山东晶承净化科技有限公司

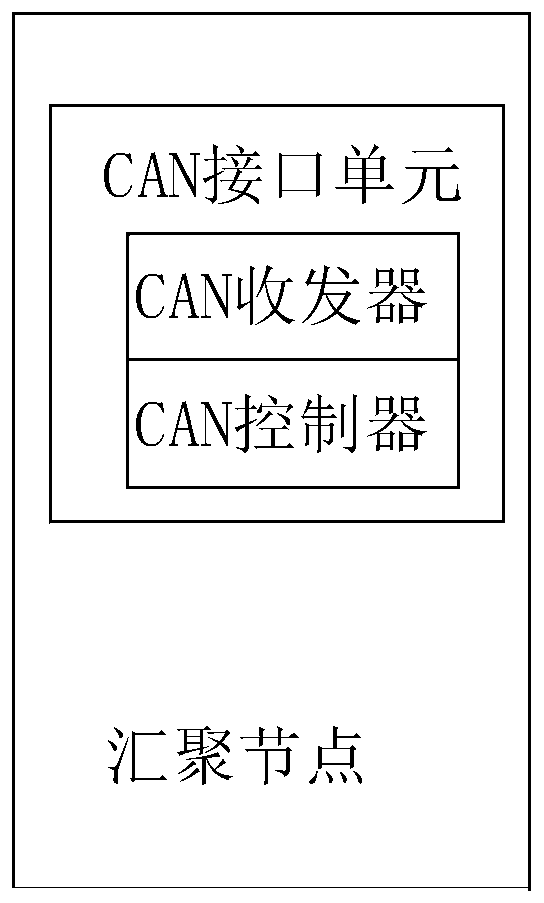

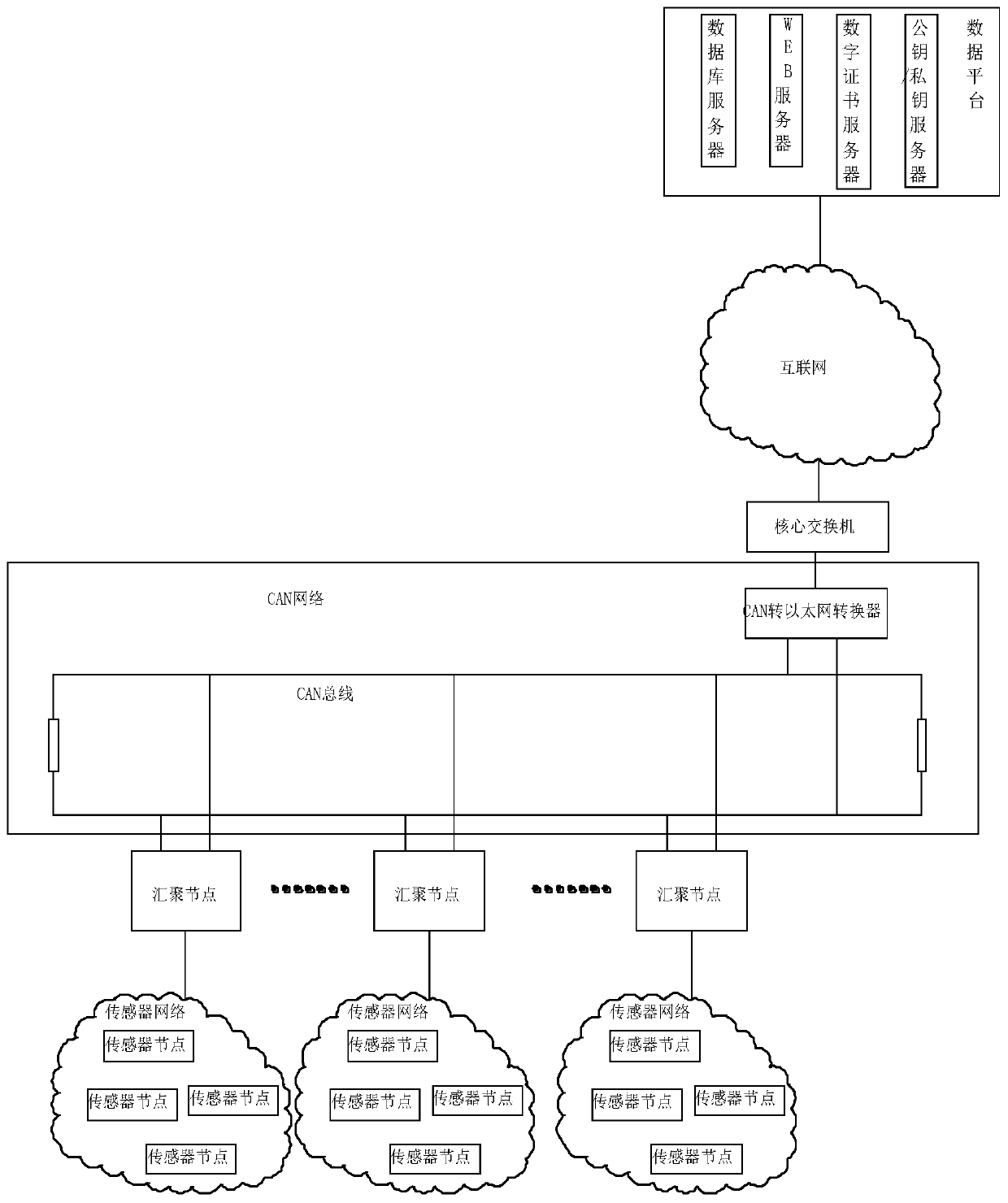

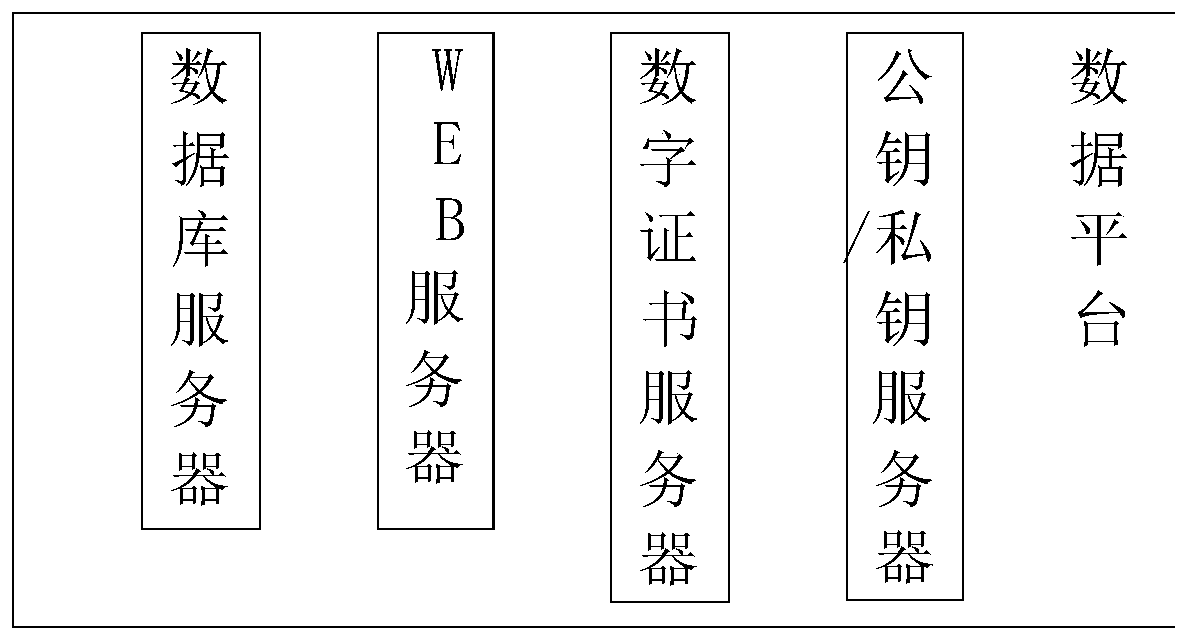

Environmental process warehouse communication system

InactiveCN110769391AReduction of launch range requirementsReduce energy consumptionPower managementParticular environment based servicesData platformThe Internet

The invention discloses an environmental process warehouse communication system. The environmental process warehouse communication system comprises an environmental process warehouse network system, the environmental technology network warehouse system comprises a sensor network and a CAN network. The sensor network comprises a plurality of sensor nodes which are wirelessly interconnected; the CANnetwork includes a CAN bus, the plurality of sensor networks are respectively connected to the aggregation node in a multi-hop manner. The aggregation node is connected to a CAN bus of a CAN networkthrough the CAN interface unit. A plurality of sensor networks and a CAN network form a combined network through aggregation nodes, and the CAN network of a CAN bus is connected with a core switch through a CAN-to-Ethernet converter, is connected to the Internet through the core switch, and is interconnected with a data platform through the Internet; through common networking of the separated sensor network and the on-site CAN network, the network architecture is optimized, the requirement for the coverage range of the wireless sensor nodes is reduced, the node energy consumption is reduced, and the method is worthy of vigorous popularization.

Owner:云南昊协科技有限公司

Cold resistant and high-temperature resistant aerospace cable

InactiveCN108109746AExcellent cold resistanceExtended working hoursInsulated cablesInsulated conductorsFire hazardWork time

A cold resistant and high-temperature resistant aerospace cable of the present invention comprises a filling core, a plurality of wire cores are uniformly distributed on the exterior of the filling core along a circumferential direction, and a wrapping layer, a fireproof layer, a shielding layer and an irradiation cross-linked polyolefin outer sheath which are distributed orderly from inside to outside wrap the exteriors of the plurality of wire cores jointly. The elastic flexible pipes are extruded between the adjacent wire cores, a row of galvanized steel wire ropes is arranged in front of the adjacent wire cores, and a butyronityile insulating sheath wraps the exterior of the row of galvanized steel wire ropes jointly. Hemp ropes are filled between the wire cores and the wrapping layer,and each wire core comprises a conductor and an irradiation cross-linked polyolefin insulating layer. Compared with a conventional cable, the cold resistant and high-temperature resistant aerospace cable of the present invention has the more excellent cold resistance, high-temperature resistance and flame resistance, can guarantee the long-term work under a high temperature or low temperature environment, enables the working time under a fire hazard condition to be prolonged effectively, guarantees the safety of the internal structures of the cable, is strong in resistance to tension, can cope with the complex environments, such as the weightlessness, etc., and facilitates the aerospace work.

Owner:新宇电缆集团股份有限公司

Metal recycling and feeding method

ActiveCN109385529ASimple designAvoid heavy smashingCrucible furnacesProcess efficiency improvementEngineeringMetal recycling

The invention discloses a metal recycling and feeding method. When a feeding device does not feed a material to a discharging device, a material guiding plate enables an upper plate surface of the material guiding plate to squeeze a lower port of a material guiding drum under the action of the gravity of a balancing weight, so that the discharging device is in a closed state; when the feeding device feeds a material to the discharging device, a metal recycling material enters the material guiding drum through a feeding hopper and falls onto the material guiding plate; when the weight of the fed metal recycling material is greater than that of the balancing weight, the material guiding plate rotates around a hinged portion and tilts downwards, so as to guide the metal recycling material onthe material guiding plate onto a furnace bottom of a melting chamber; when the metal recycling material on the material guiding plate is all poured into a furnace, the material guiding plate blocks the lower port of the material guiding drum again under the action of the gravity of the balancing weight.

Owner:龙南县瑞博金属再生资源有限公司

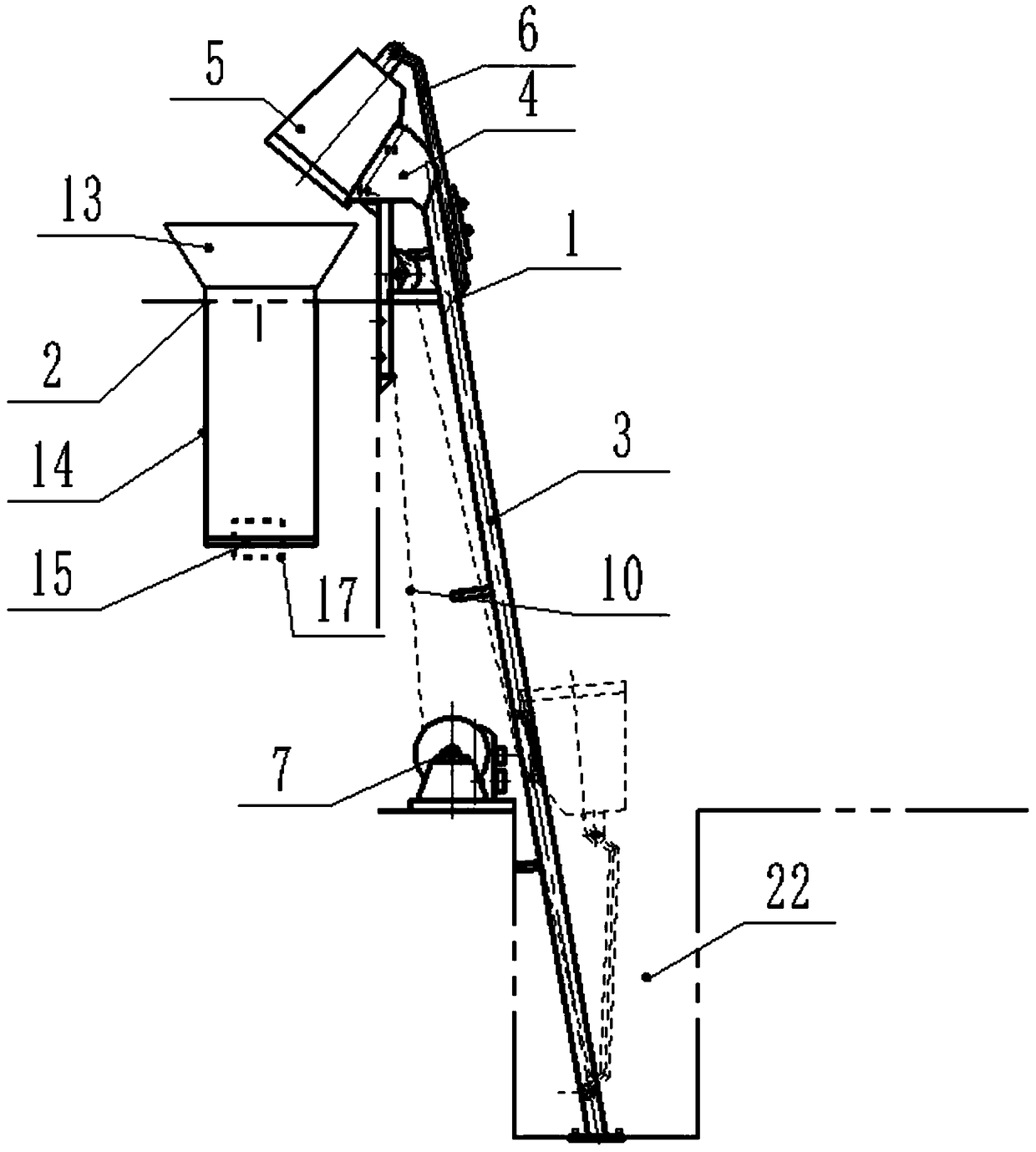

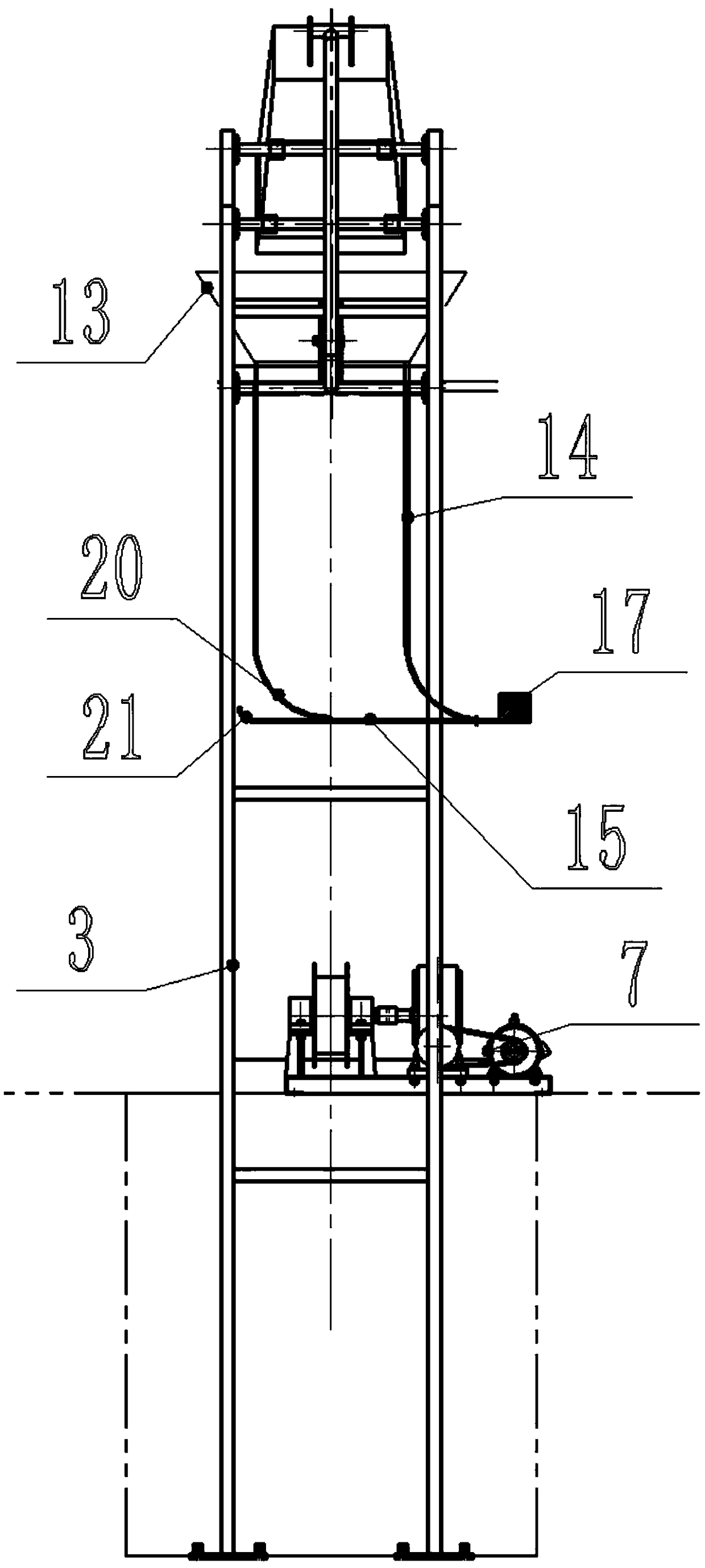

Lifting conveyor

InactiveCN104444232AGuaranteed long-term workAvoid frictional damageCleaningAdditivesTetrahydropalmatineWater vapor

The invention discloses a lifting conveyor. The lifting conveyor comprises a metal framework and a conveyor belt. The conveyor belt is provided with conveying rollers. The conveying rollers are provided with lubricating oil. The lubricating oil comprises, by weight part, 6.5 parts of overbased calcium sulphonate, 1.4 parts of tetrahydropalmatine, 2.3 parts of modified polyurea, 3.1 parts of phenylcarbinol, 1.7 parts of zinc dialkyl dithiophosphate and1.2 parts of oleanonic acid. According to the lifting conveyor, the conveying rollers are provided with the lubricating oil, so that the conveying rollers are protected against frictional damage effectively, the corrosion resistance and high temperature resistance of the conveying rollers are enhanced, the conveying rollers are also effectively prevented from being affected by water and steam, and therefore long-term operation of the lifting conveyor is guaranteed.

Owner:常熟市诚达港务机械设备厂

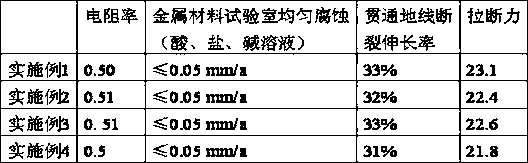

Copper-clad aluminum alloy integrated grounding cable

ActiveCN109102923BImprove plasticityIncrease the elongation factorNon-insulated conductorsPower cablesCopper conductorGadolinium

The invention discloses a copper-clad aluminum alloy comprehensive ground cable, which includes a centrally located round copper conductor, 5 to 7 trapezoidal copper conductors and 10 to 14 cop-clad aluminum conductors, the 5 to 7 trapezoidal copper conductors are stranded on the outer surface of the round copper conductor to form an intermediate conductive layer, and the outer surface of the non-soldering type copper alloy sheath is provided with a metal passivation layer, the corners at both ends of the long bottom edge of the trapezoidal copper conductor are circular arc corners, and the stranding directions of the trapezoidal copper conductor and the copper-clad aluminum conductor are opposite. The copper, white copper, tin, nickel, beryllium, titanium and composite rare earth are placed in a low-frequency electric furnace, heated to 1100-1200 DEG C, and continuously cast horizontally to form a hollow billet, and the composite rare earth is formed by mixing lanthanum, gadolinium and yttrium according to a weight ratio of 10: 4: 1; the cast hollow billet is extruded into a blank tube. The copper-clad aluminum alloy comprehensive ground cable of the invention improves the plasticity of the metal, greatly improves the elongation coefficient of the metal, is favorable for the strength and hardness of the metal to decrease, improves the plasticity and toughness, is more convenient for the stretching processing of the stretching die, prolongs the service life and the conductivity, and greatly enhances the corrosion resistance.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

A new volumetric downhole power generation device and a new oilfield water injection system including it

ActiveCN111550361BImprove performanceImprove featuresFluid removalMechanical energy handlingThermodynamicsOil field

Owner:河北中清永晟石油科技有限公司

A general multi-mode smart adsorption drying method with low energy consumption for compressed air preparation

ActiveCN110237646BGuaranteed long-term workCapable of self-adaptive adjustmentGas treatmentDispersed particle separationSorbentDesiccant

The invention relates to compressed air preparation technology, and aims to provide a general multi-mode intelligent adsorption drying method with low energy consumption for compressed air preparation. The present invention is aimed at the adsorption drying system with double adsorption cylinders or multiple adsorption cylinders running in parallel. The air flow organization of the hot air flow is carried out from the upper part of the regeneration adsorption cylinder downwards to realize the regeneration of the adsorbent; it includes the regeneration stage of compressed air waste heat heating, the pressure release stage, The air blast goes deep into the heating stage and the circulation blowing cooling stage. The advantages of the present invention are: (1) low energy consumption, making full use of compression waste heat and environmental cooling capacity; (2) multi-module design, realizing multi-level dew point control); (3) multi-mode regeneration, ensuring long-term operation of the desiccant; (4) ) has adaptive adjustment capability; (5) digital energy efficiency analysis. The present invention utilizes desiccant optimization control based on real-time monitoring of the humidity of the adsorption cylinder to ensure that the overall adsorption process runs smoothly for a long time, ensures long-term stable operation of the desiccant, and greatly reduces its replacement cost.

Owner:HANGZHOU ZETA TECH +1

Passive heat metering device and heat metering system working by passive heat metering devices

InactiveCN102840932BGuaranteed long-term workTransmission systemsCalorimeterCommunication interfacePower mode

The invention aims to provide a passive heat metering device and a heat metering system working by the passive heat metering devices. The heat metering device comprises a temperature difference power supply system, a reflection type ultrasonic flowmeter, a temperature sensor, a communication interface, a ZigBee controller and a liquid crystal display (LCD). By using characteristics of a concentrative heating and cooling system, the passive heat metering device automatically supply power through the temperature difference power supply system; a power supply is not required to be regularly replaced, so that the passive heat metering device is energy-saving and environment-friendly; the heat metering system works by two same passive heat metering devices provided by the invention; the two devices run in a low-power mode; the working modes of a main node and a slave node are regularly changed; under the conditions of heating and cooling, the system selects different metering programs to match different power supply capacities of a power supply system; and the passive heat metering device can be simultaneously suitable for heat metering of the heating and cooling system.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com