Cold resistant and high-temperature resistant aerospace cable

An aerospace and high-temperature-resistant technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as life safety of astronauts, easy damage to the internal structure of cables, and large temperature difference between day and night. It achieves strong tensile resistance, excellent cold resistance, The effect of extended working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

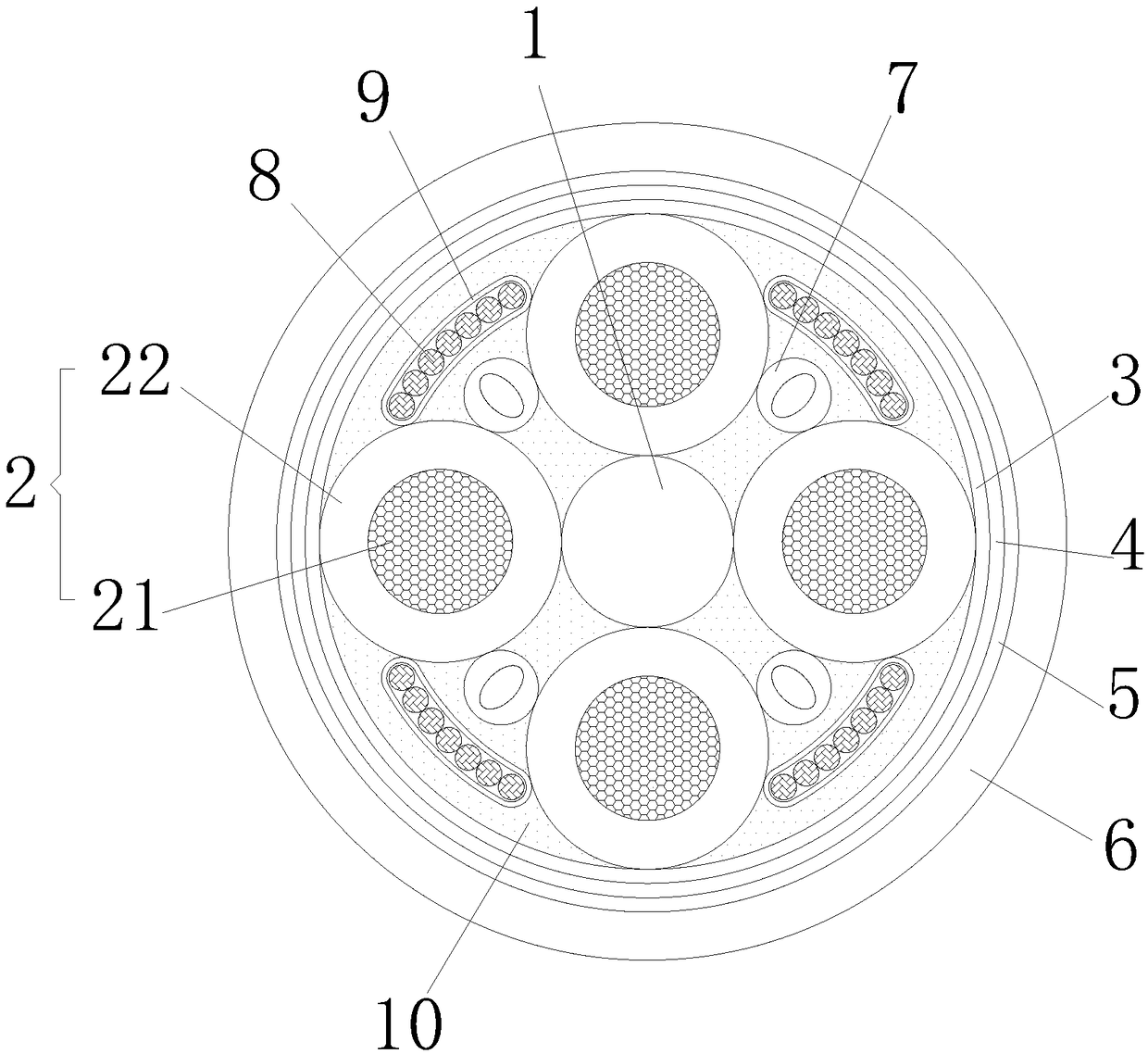

[0020] Such as figure 1 As shown, a cold- and high-temperature-resistant aerospace cable includes a filler core 1. A plurality of cores 2 are uniformly distributed on the outside of the filler core 1 along the circumferential direction, and the outer parts of the plurality of cores 2 are jointly covered with The outer covering layer 3, the refractory layer 4, the shielding layer 5 and the radiation cross-linked polyolefin outer sheath 6 are distributed in sequence.

[0021] An elastic hose 7 is squeezed between adjacent wire cores 2, and the inner contour of the elastic hose 7 is oval.

[0022] The adjacent cores 2 are provided with a row of galvanized steel wire ropes 8 distributed in an arc shape, and the exterior of the row of galvanized steel wire ropes 8 is jointly covered with a nitrile insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com