Modified silicon resin-doped neoprene rubber-based cable material and preparation method thereof

A technology of cable material and modified silicon, which is applied in the direction of insulating cables, rubber insulators, cables, etc., can solve the problems of restricting the safety and service life of cables, the incompatibility between hardness and toughness, and resistance to humidity, cold and heat, etc., to achieve stable product performance Uniform, excellent mechanical properties, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

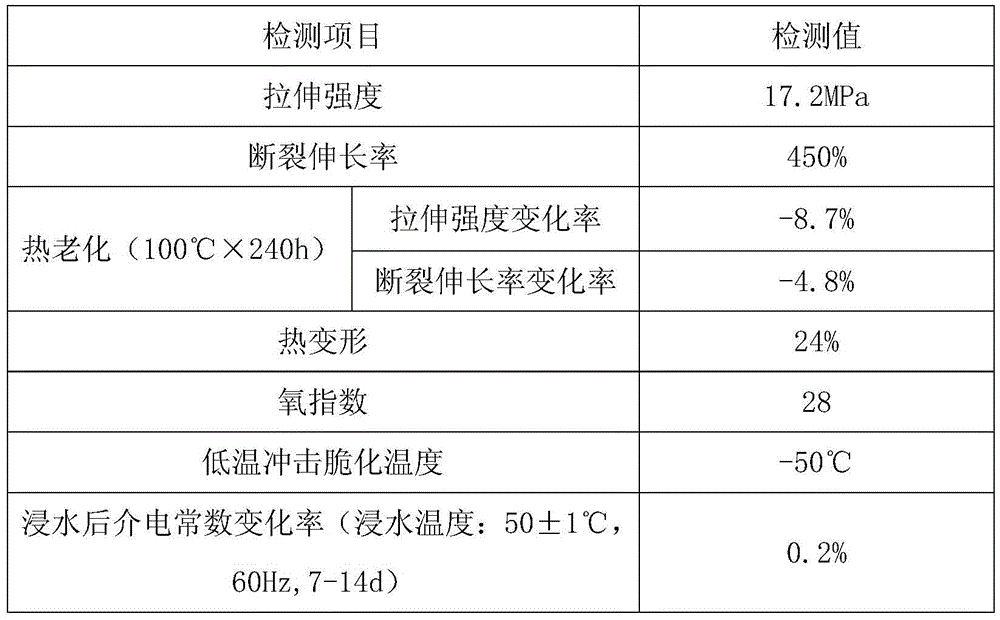

Examples

Embodiment

[0012] The cable material of this embodiment is made of the following raw materials by weight: neoprene rubber 54, titanium oxysulfate 3, palm oil 5, montan wax 8, silicone resin 16, EPDM rubber 28, calcium stearate 4, Activated calcium carbonate 42, antioxidant 2, dipropylene glycol dibenzoate 18, calcium gluconate 5, medium chain triglyceride 5, accelerator TMTD2, color masterbatch 10, additive 3.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: zinc borate 6, graphene oxide 3, polyaspartic acid 2, lithium iron phosphate 2, absolute ethanol 10, 800 mesh white carbon black 18, and the preparation method is as follows: First dissolve lithium iron phosphate in absolute ethanol, then add zinc borate, graphene oxide, and polyaspartic acid, stir and mix well, then add white carbon black, mix well, grind and disperse for 30 minutes, and then put the resulting mixture at room temperature Dry and remove absolute ethanol to obtain additives.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com