Novel solar cell backplate and preparation method thereof

A technology for solar cells and back sheets, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve problems such as power generation efficiency decline, loss of protection of components, delamination of bubbles, etc., to improve hydrolysis resistance, reduce product cost, The effect of good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

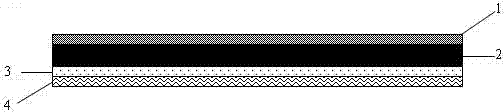

Image

Examples

Embodiment

[0032] Add a certain amount of methyltrihydroxysilane into a reactor, and then add excess ammonia water (1mol / L) drop by drop. After aging for a certain period of time at room temperature, methyltrihydroxysilane undergoes self-condensation to form Si atoms. The methyl group is connected to form a polymeric network system with repeated Si—O—Si as the skeleton, and a sufficient amount of ethanol is added, and the polysiloxane sol is obtained by ultrasonic dispersion for 30 minutes. Use the slit coating method to evenly coat the polysiloxane sol solution on one side of the biaxially oriented polyester film 2, dry it in a 100°C oven, cool and wind it, and then pass the micro gravure on the biaxially oriented polyester film. 2 The other side is evenly coated with polyurethane adhesive, and the polyolefin film is combined by dry lamination method to cool and wind up. The obtained new solar cell backsheet has good hydrolysis resistance and mechanical properties, and no yellowing of do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com