Automobile air conditioner hose, preparation process thereof and automobile air conditioner hose assembly

A technology for automotive air conditioners and hoses, applied in the direction of hoses, pipes/pipe joints/fittings, pipes, etc., can solve the problems of no air-conditioning hose refrigerant penetration performance research, safety accidents, etc., achieve excellent anti-penetration performance, prevent hollow Collapse, good continuity and consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

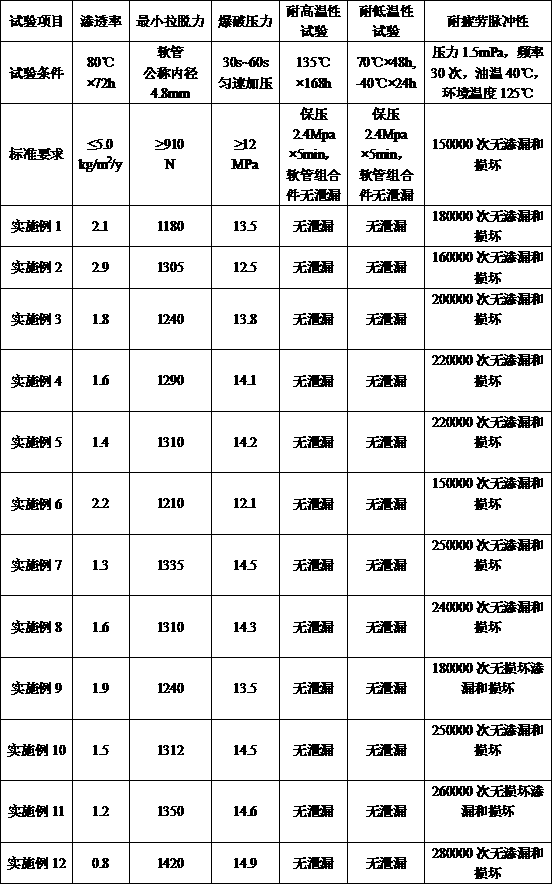

Examples

Embodiment 1

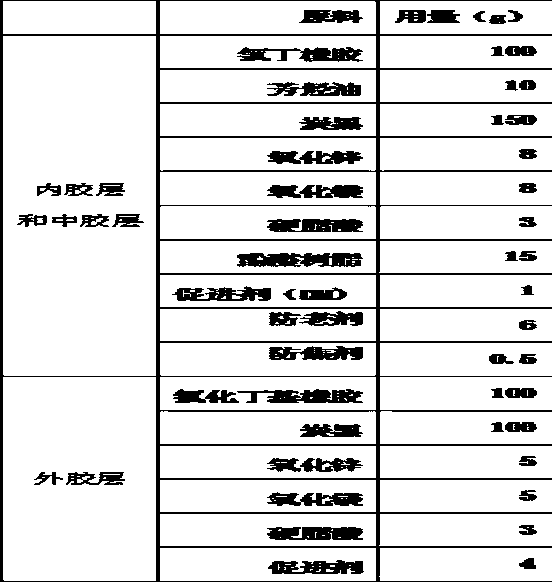

[0067] The automobile air-conditioning hose provided in Example 1, the air-conditioning hose is sequentially composed of an inner rubber layer, a nylon shielding layer, a middle rubber layer, a polyester fiber reinforced layer, and an outer rubber layer from the inside to the outside. The automobile air-conditioning hose provided in Embodiment 1 The raw material composition and ratio of the inner rubber layer, middle rubber layer and outer rubber layer of the pipe are shown in Table 2, and the raw material of the nylon shielding layer is 100g of nylon 6.

[0068] The raw material composition and proportioning of table 2 embodiment 1

[0069]

[0070] The preparation method of the automobile air-conditioning hose provided by embodiment 1 comprises the following preparation steps:

[0071] S1, inner rubber layer, middle rubber layer, outer rubber layer rubber mixing:

[0072] S1.1 Preparation of rubber materials for inner rubber layer and middle rubber layer: Add neoprene, p...

Embodiment 2

[0089]The raw material composition and ratio of the inner rubber layer, middle rubber layer and outer rubber layer of the air-conditioning hose provided in Example 2 are shown in Table 3. The raw material of the nylon shielding layer is 100 g of nylon 6, and the preparation method is the same as in Example 1.

[0090] The raw material composition and proportioning of table 3 embodiment 2

[0091]

Embodiment 3

[0093] The raw material composition and ratio of the inner rubber layer, middle rubber layer and outer rubber layer of the air-conditioning hose provided in Example 3 are shown in Table 4. The raw material of the nylon shielding layer is 100 g of nylon 6, and the preparation method is the same as in Example 1.

[0094] The raw material composition and proportioning of table 4 embodiment 3

[0095]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com