Wallboard stuffing and wallboard

A technology of filling materials and wall panels, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of low compressive strength and flexural standards, and achieve the effects of improving mechanical strength, space optimization, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

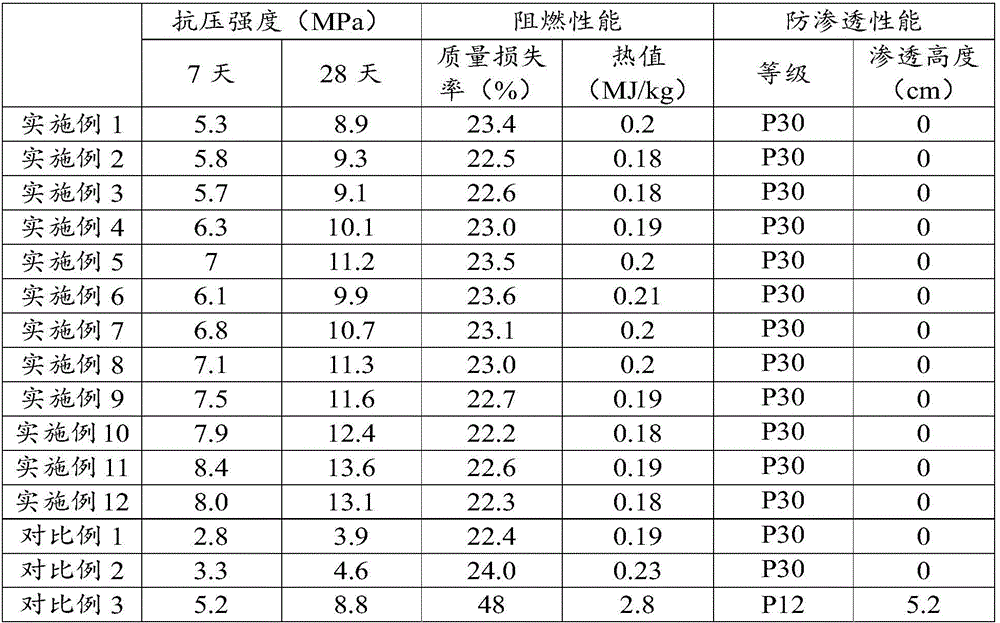

Examples

Embodiment 1

[0030] The present embodiment provides a kind of wallboard, and it is made by the following steps:

[0031] S1: Add 390kg of cement, 276kg of fly ash, 301kg of construction waste micropowder, 5kg of water reducing agent, 5kg of waterproofing agent, 5kg of flame retardant, 5kg of air-entraining agent and 380L of water into the mixer for mixing. Add 13 kg of ethylene particles into the mixer for further mixing and stirring to obtain wallboard filler.

[0032] S2: Pump the above-mentioned wallboard filler into the mould, and finish closing the surface after a slight shock.

[0033] S3: After standing still for 15-30 hours, the formwork is removed, packaged, maintained, and the wallboard is obtained.

Embodiment 2

[0035] This embodiment provides a wallboard, its preparation steps refer to the first embodiment, and the raw materials and dosage are as follows:

[0036]390kg of cement, 280kg of fly ash, 287kg of fine powder of construction waste, 11kg of polystyrene particles, 6kg of water reducing agent, 10kg of waterproofing agent, 8kg of flame retardant, 6kg of air-entraining agent and 350L of water.

Embodiment 3

[0038] This embodiment provides a wallboard, its preparation steps refer to the first embodiment, and the raw materials and dosage are as follows:

[0039] 420kg of cement, 285kg of fly ash, 258kg of construction waste powder, 10kg of polystyrene particles, 7kg of water reducing agent, 5kg of waterproofing agent, 10kg of flame retardant, 2kg of air-entraining agent and 320L of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com