A kind of artificial quartz plate and its production method

A production method, quartz technology, applied in the field of artificial stone, to achieve high surface hardness and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

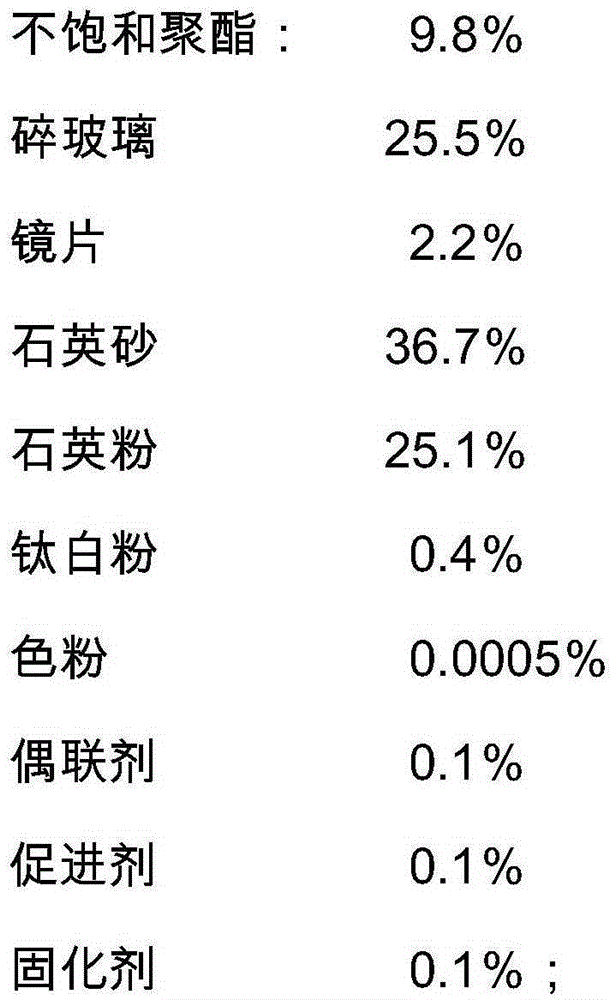

[0032] Example:

[0033] Prepare materials according to the following list: 84.56kg of unsaturated polyester "Yabang Quartz Stone Resin 7938", 218.9kg of broken glass, 18.9kg of broken lenses for flashing light, 361.1kg of quartz sand, 215.9kg of quartz powder, and 3.76kg of titanium dioxide , iron oxide yellow powder 5g, coupling agent methacryloxypropyltrimethoxysilane 0.785kg, accelerator manganese naphthenate 0.51kg, curing agent hexamethylene diisocyanate trimer (HDI) 0.58kg .

[0034] Prepare the following equipment: mixer, material bed, extrusion molding machine, oven, four-head calibrating machine, twelve-head polishing machine, cutting machine, film-coated packaging machine; in addition, prepare the mold in advance;

[0035] Weigh the ingredients according to the formula requirements, first pour the raw materials into the mixer for stirring, the order is: quartz sand--glass--quartz powder--lens--unsaturated polyester "Yabang quartz stone resin 7938", stir for 1~2 Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com