Super-hydrophobic cement and preparing method and application thereof

A super-hydrophobic and cement technology, applied in the field of new building materials and their coating preparation, can solve the problems of easy freezing of ordinary concrete, easy ash on walls, poor durability, etc., achieve excellent anti-fouling, improve hydrophobic uniformity, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

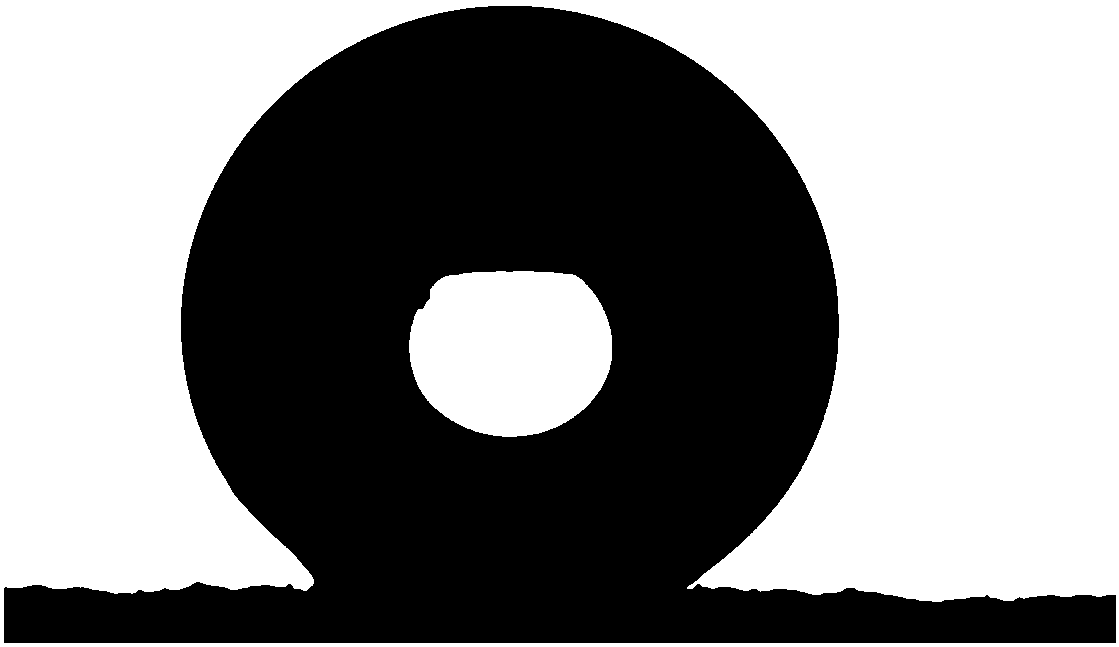

Embodiment 1

[0023] Under the condition of low-speed mechanical stirring at 500rpm, add 1 part of F-1061 fluorosilane, 50 parts of cement, and 50 parts of fine sand to 50 parts of absolute ethanol according to the mass ratio, and then stir at 2500 rpm for 12 hours to obtain cement fine sand solution. The modified cement fine sand solution was filtered, dried and crushed at 100°C to obtain 200-mesh superhydrophobic cement fine sand mixed powder. In order to highlight the hydrophobic effect of the modified super-hydrophobic cement fine-sand mixed powder, 50 parts of modified super-hydrophobic cement fine-sand mixed powder and 50 parts of unmodified ordinary cement fine-sand mixed powder were respectively Put it into an aqueous solution containing 1.2 parts of perfluoroacrylic acid copolymer surfactant (surfactant), 1 part of F-1061 fluorosilane, 0.5 part of hydroxyethyl methacrylate (dispersant) and 90 parts of water, and stir for 20 minutes to form Grout. Pour the stirred cement slurry in...

Embodiment 2

[0025] Under the condition of low-speed mechanical stirring at 100 rpm, 2.4 parts of fluorosilane, 150 parts of cement, and 50 parts of fine sand were successively added to 150 parts of absolute ethanol, and then stirred at a high speed of 2500 rpm for 18 hours to obtain a modified cement fine-sand solution. The modified cement fine sand solution was filtered, dried and crushed at 100°C to obtain 200-mesh superhydrophobic cement fine sand mixed powder. Under the condition of 1500rpm high-speed stirring, put the superhydrophobic cement fine sand mixed powder into the mixture containing 1.5 parts of fluorinated alkylsulfonate surfactant (surfactant), 0.6 part of fluorosilane, 0.8 part of sodium metasilicate (dispersant) , 70 parts of water in aqueous solution, stirring for 5 minutes to form cement slurry. The cement slurry was sprayed onto the surface of ordinary Portland cement blocks, and after drying naturally at room temperature, a superhydrophobic cement coating with a cont...

Embodiment 3

[0027] Under the condition of low-speed mechanical stirring at 300 rpm, 1.5 parts of alkyl siloxane, 100 parts of cement, and 150 parts of fine sand were successively added to 100 parts of absolute ethanol, and then stirred at a high speed of 2500 rpm for 48 hours to obtain a modified cement fine-sand solution. The modified cement fine sand solution was filtered, dried and crushed at 80°C to obtain 350-mesh superhydrophobic cement fine sand mixed powder. Under the condition of high-speed stirring at 1500rpm, put the superhydrophobic cement fine sand mixed powder into an aqueous solution containing 0.8 parts of fluorocarbon surfactant (surfactant), 1.5 parts of fluorosilane, 1.0 part of trisodium phosphate (dispersant), and 85 parts of water , a cement slurry was formed after stirring for 5 min. Brush the cement slurry to the facade of the exterior wall, and dry it naturally at room temperature to obtain a super-hydrophobic cement coating with a contact angle of 155° and a roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com