Direct current electromagnet

A DC electromagnet and iron core technology, applied in the field of DC electromagnets, can solve the problems of inability to meet the requirements of long-term continuous work and can not work continuously for a long time, achieve large working tension, ensure strength and waterproofness, and increase working tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

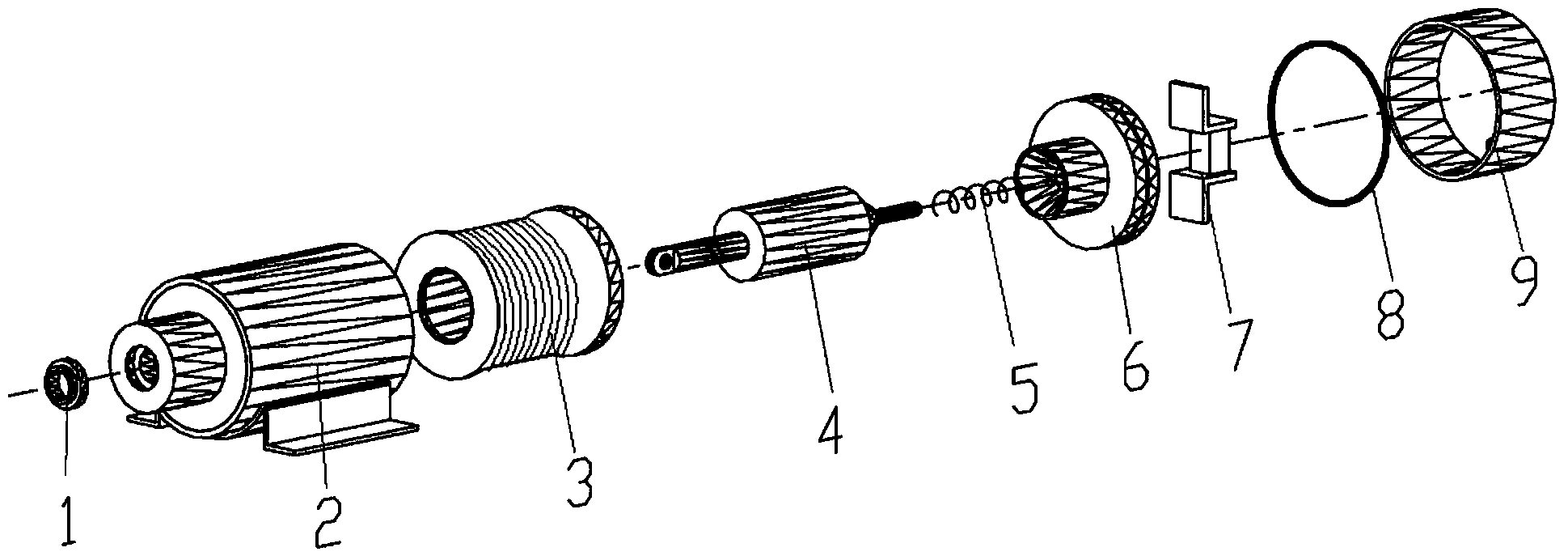

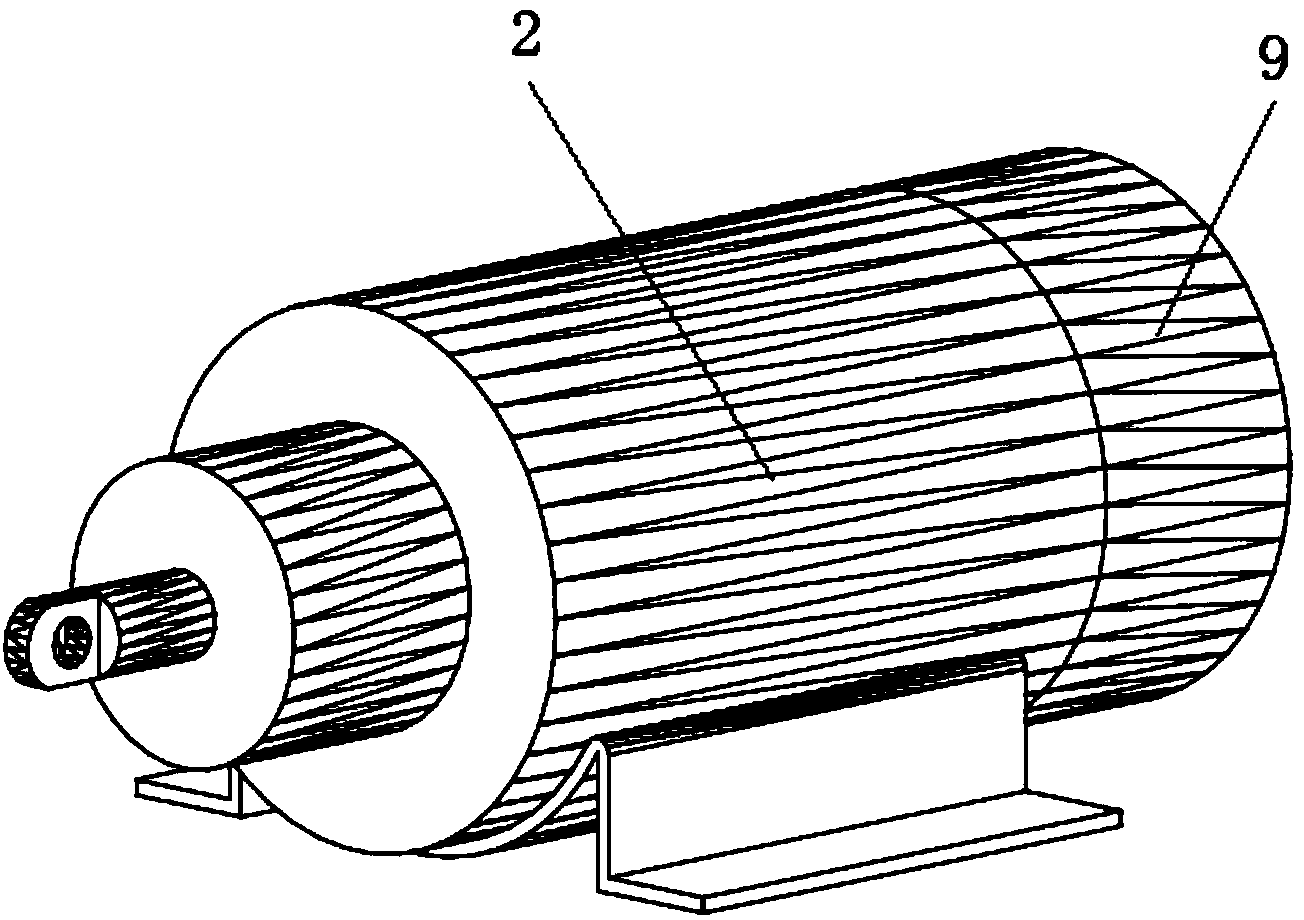

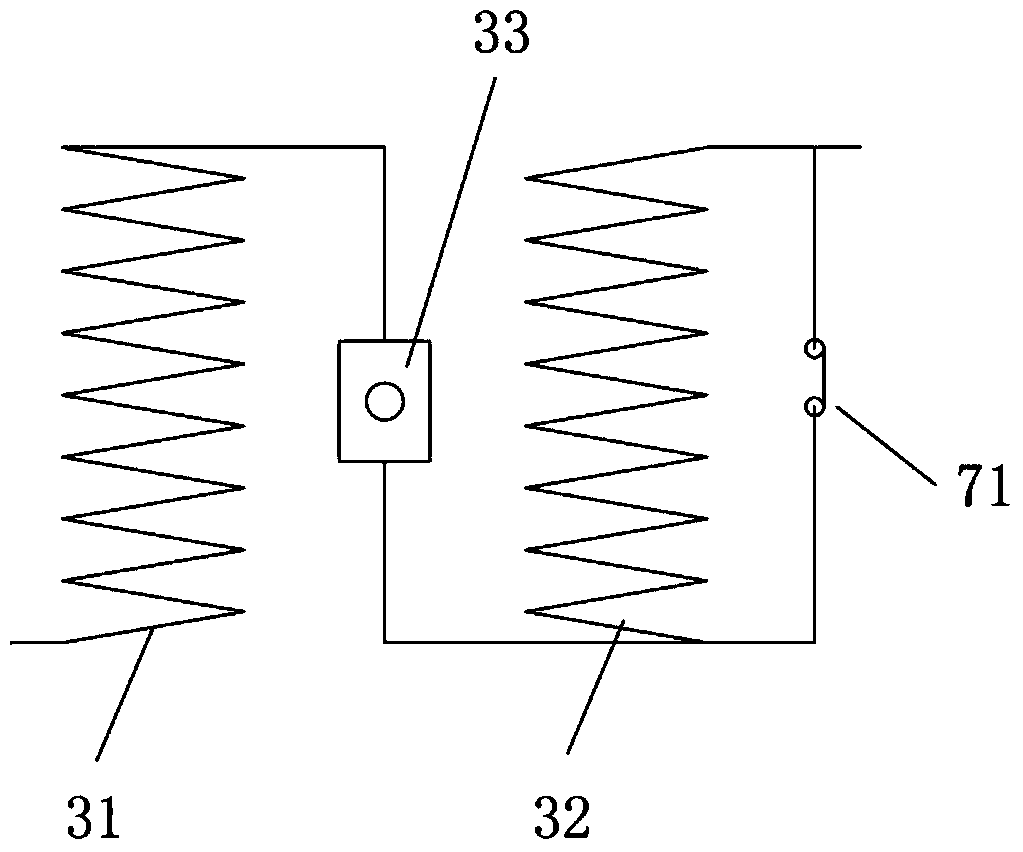

[0030] Such as figure 1 , figure 2 As shown, the DC electromagnet in one embodiment of the present invention includes a coil 3, an iron core 4 sleeved in the coil, a return spring 5 sleeved at one end of the iron core and a position-limiting rear seat 6, the coil 3, the iron core Core 4, return spring 5 and limit rear seat 6 are coaxially arranged, and it is characterized in that, DC electromagnet also includes closed shell and relay switch 7, as image 3 As shown, the coil 3 includes a first coil 31 and a second coil 32, the normally closed contact 71 of the relay switch 7 is connected to both ends of the second coil 32, and the first coil 31 and the second coil 32 are connected through a thermal protector 33 .

[0031] The DC electromagnet in this embodiment adopts two groups of coils to provide a large working tension; the two groups of coils are connected through a thermal protector 33, so that the DC electromagnet can work safely for a long time in a high-temperature w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com