Patents

Literature

45results about How to "Increase wire diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

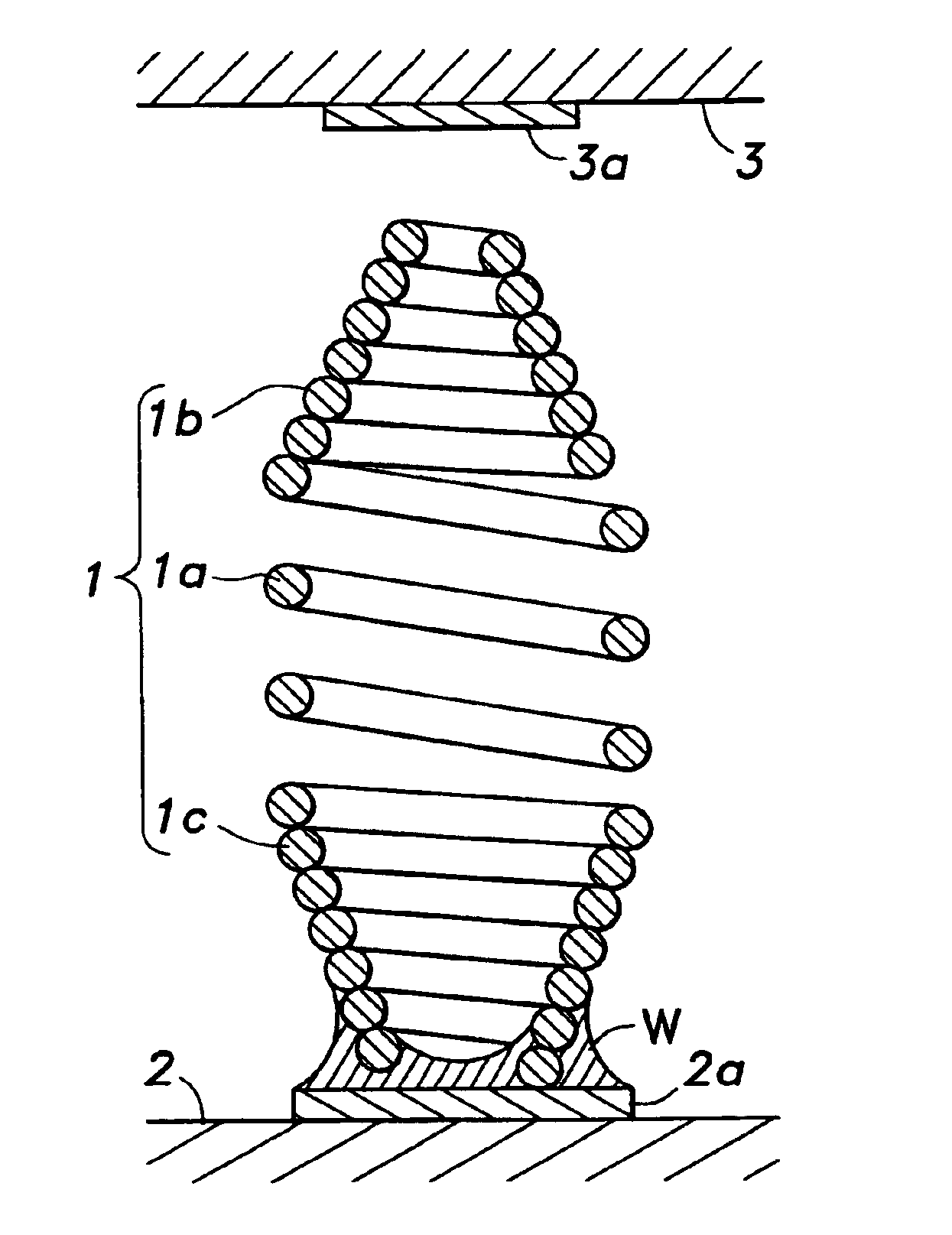

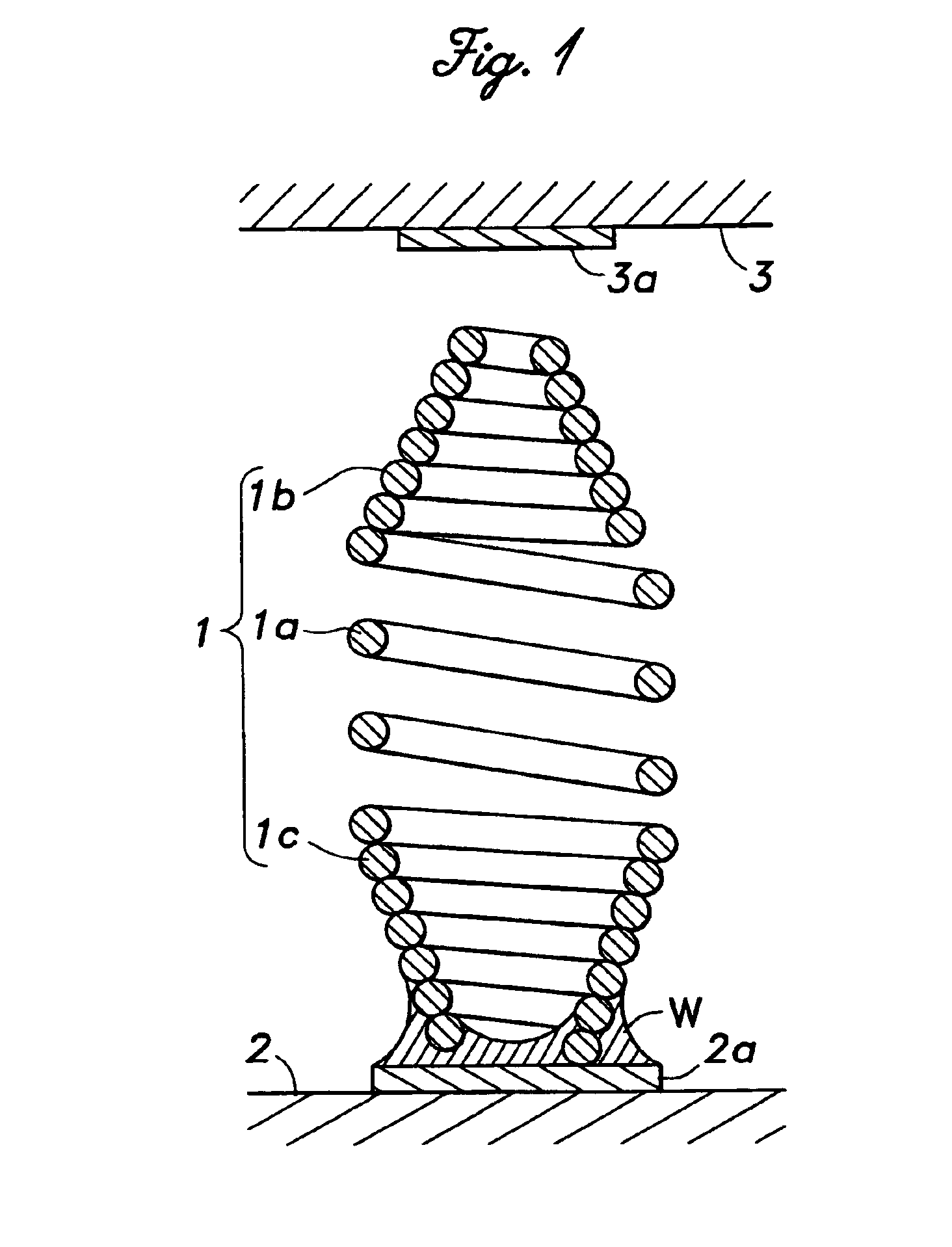

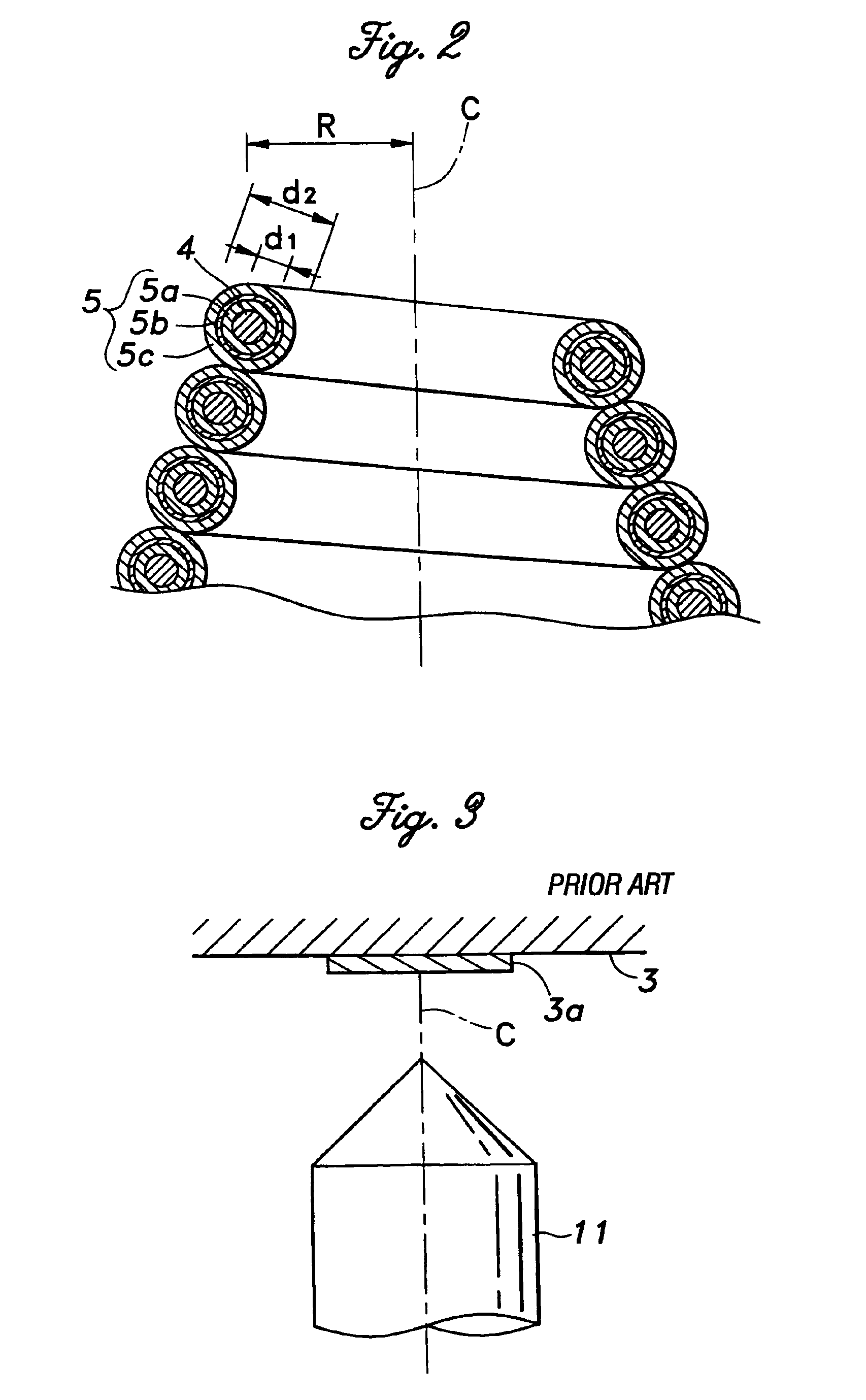

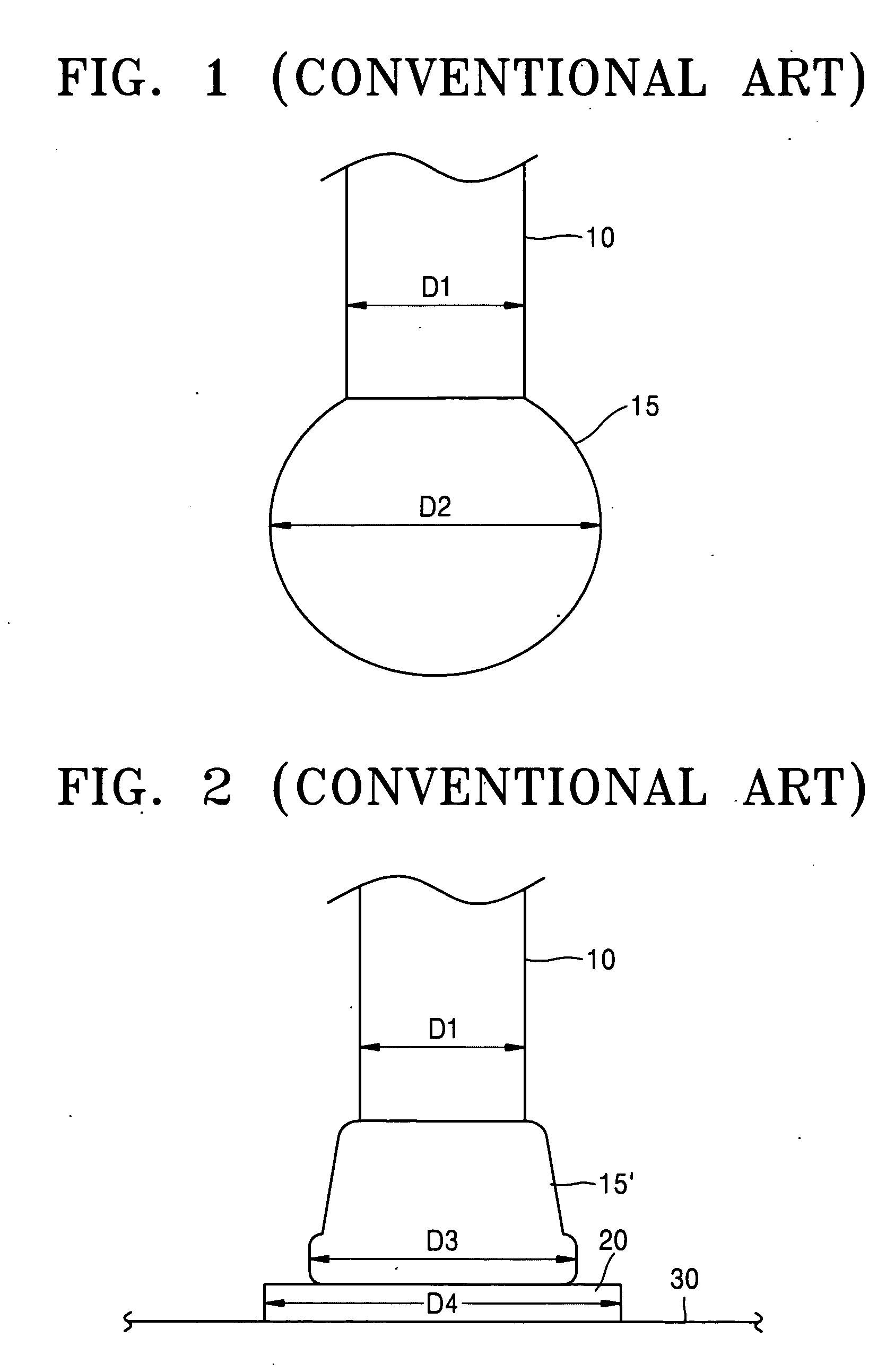

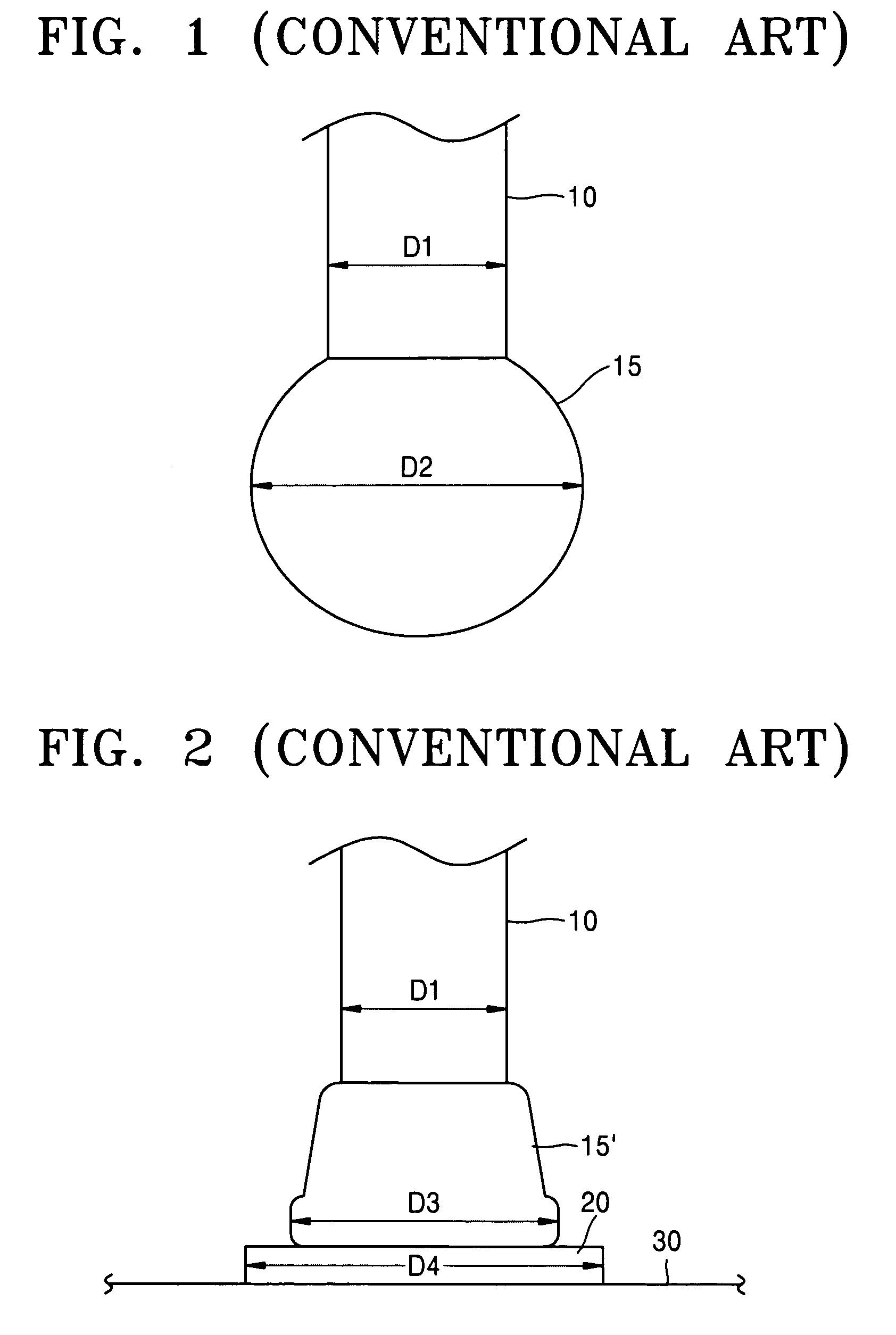

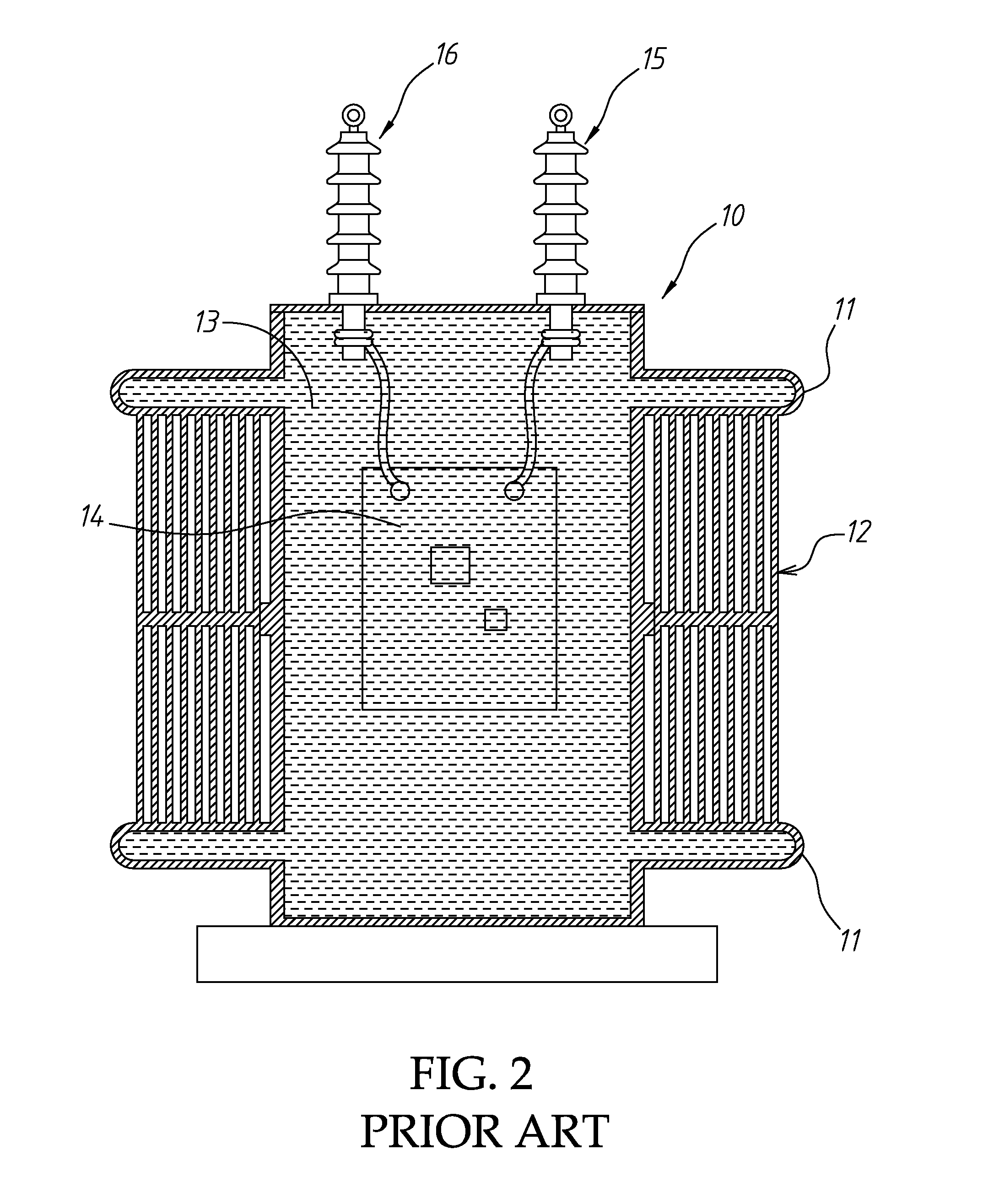

Conductive coil contact member

InactiveUS6873168B2Low electric inductanceLower resistanceElectrical measurement instrument detailsElectrical testingElectroplatingElectrical and Electronics engineering

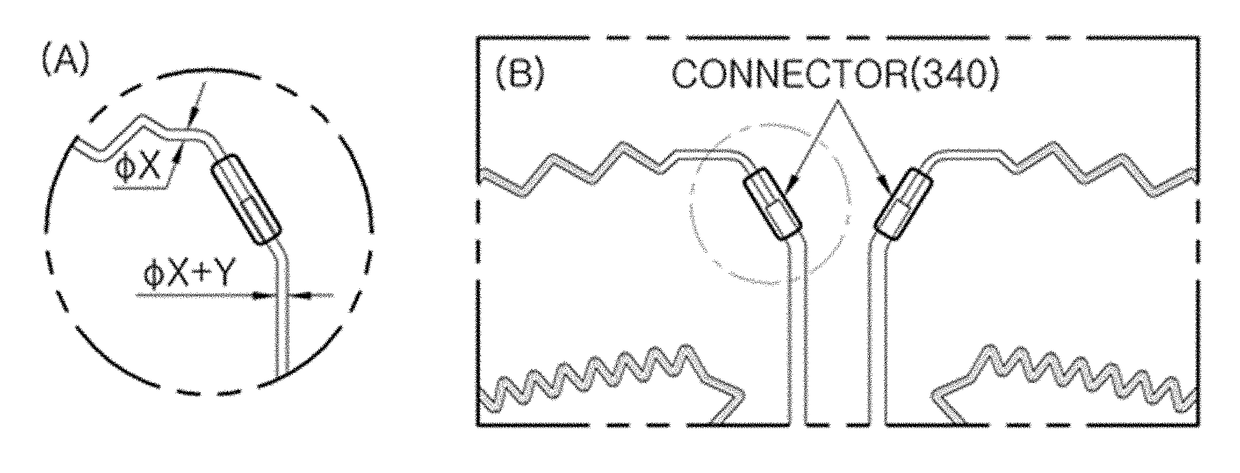

In a conductive coil contact member having at least one tapered end consisting of a plurality of turns of coil wire having a progressively smaller coil radius toward a free end thereof, the coil wire comprises a core wire and at least one highly electrically conductive layer formed over the core wire, a last turn of the coil wire at the free end having a smaller coil radius than would be possible by coiling the coil wire. Thus, the core wire is coiled to a smallest possible radius in the last turn, and the coil wire diameter is thereafter increased by forming layers formed by plating or other similar methods. The final result is that the last turn of the coil wire at the free end has a smaller coil radius than would be possible by coiling the coil wire. The reduction in the coil radius of the last turn contributes to the improvement in the positional accuracy of the free end of the tapered end of the conductive coil contact member.

Owner:NHK SPRING CO LTD

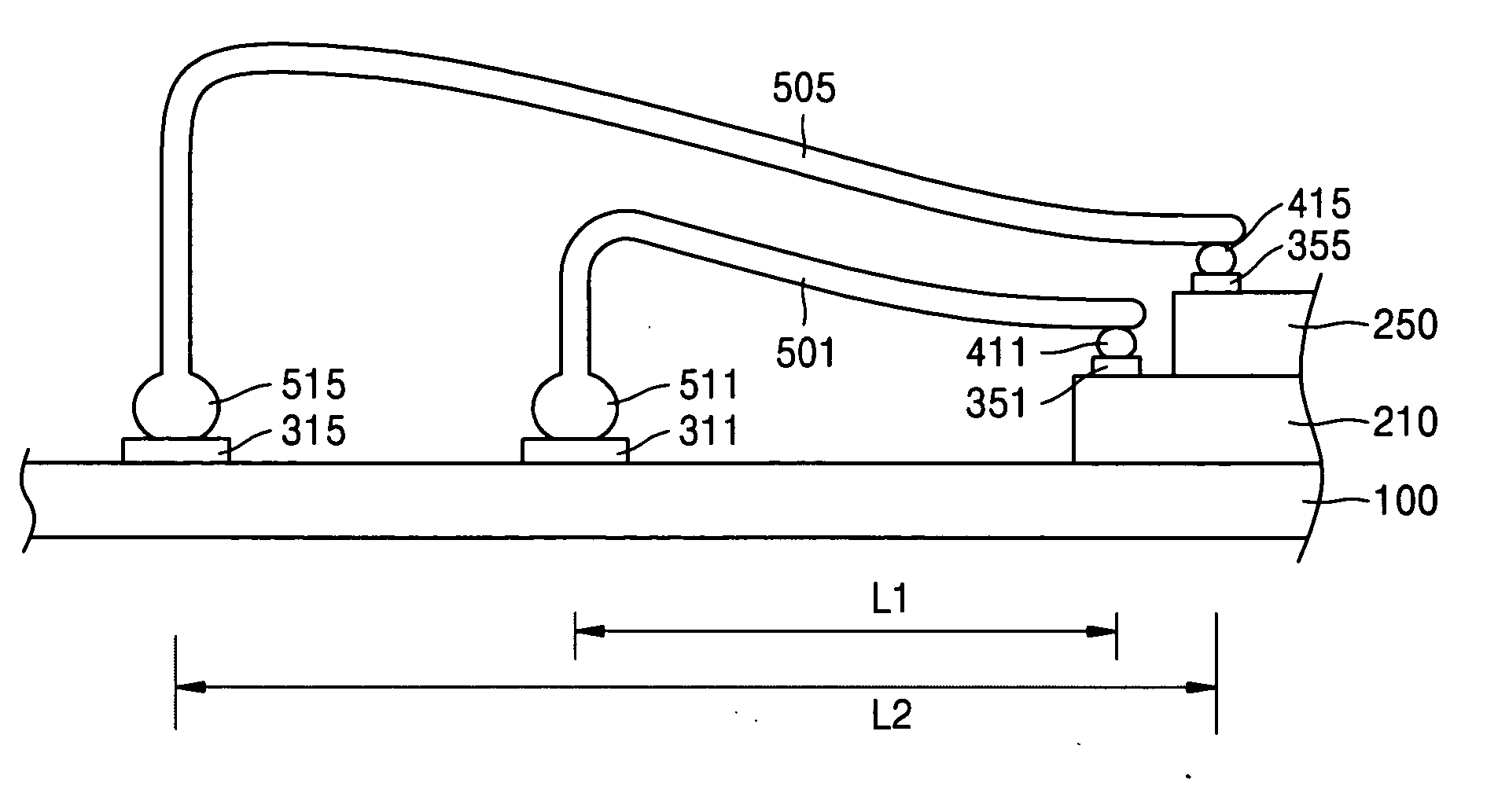

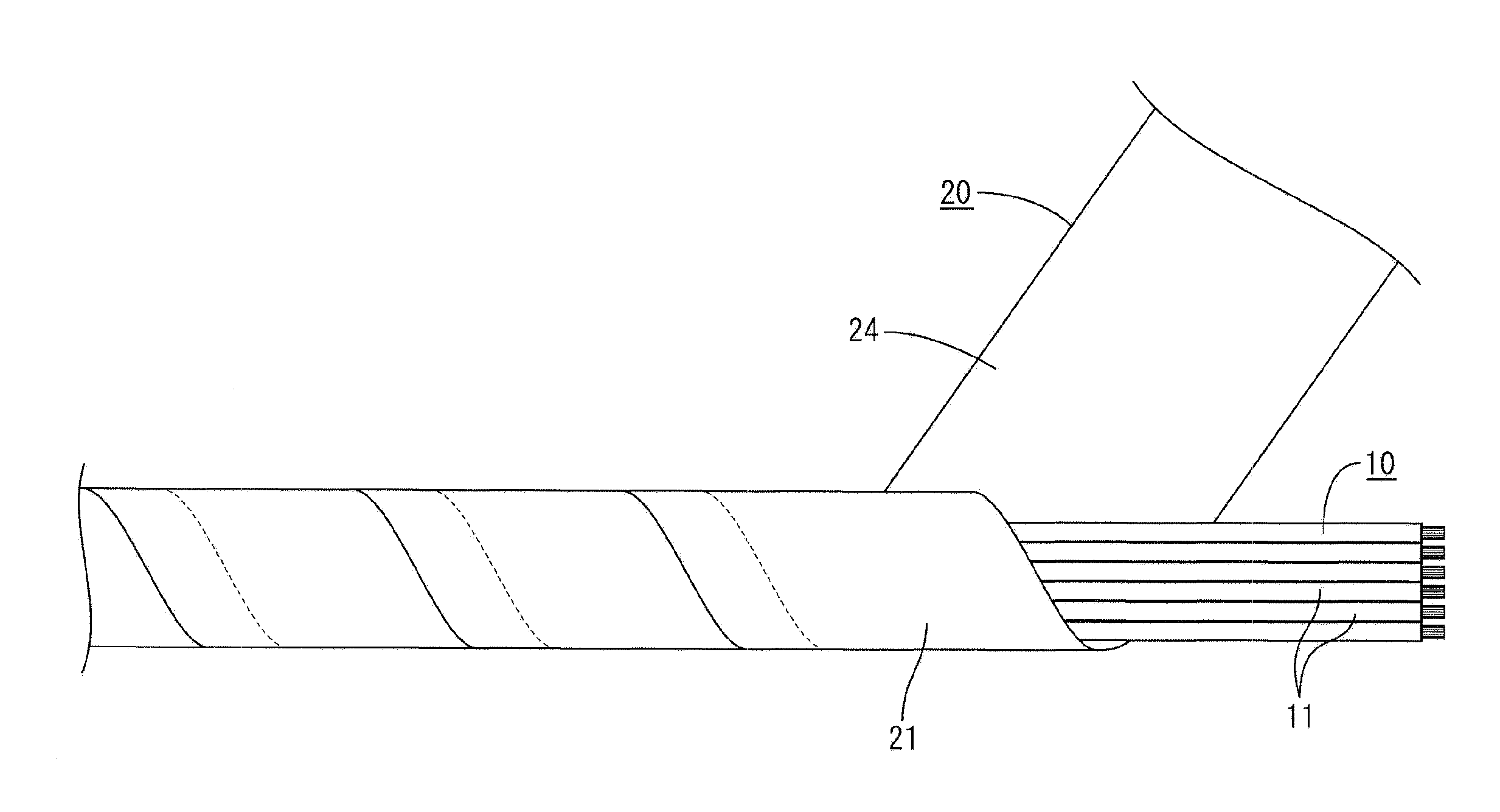

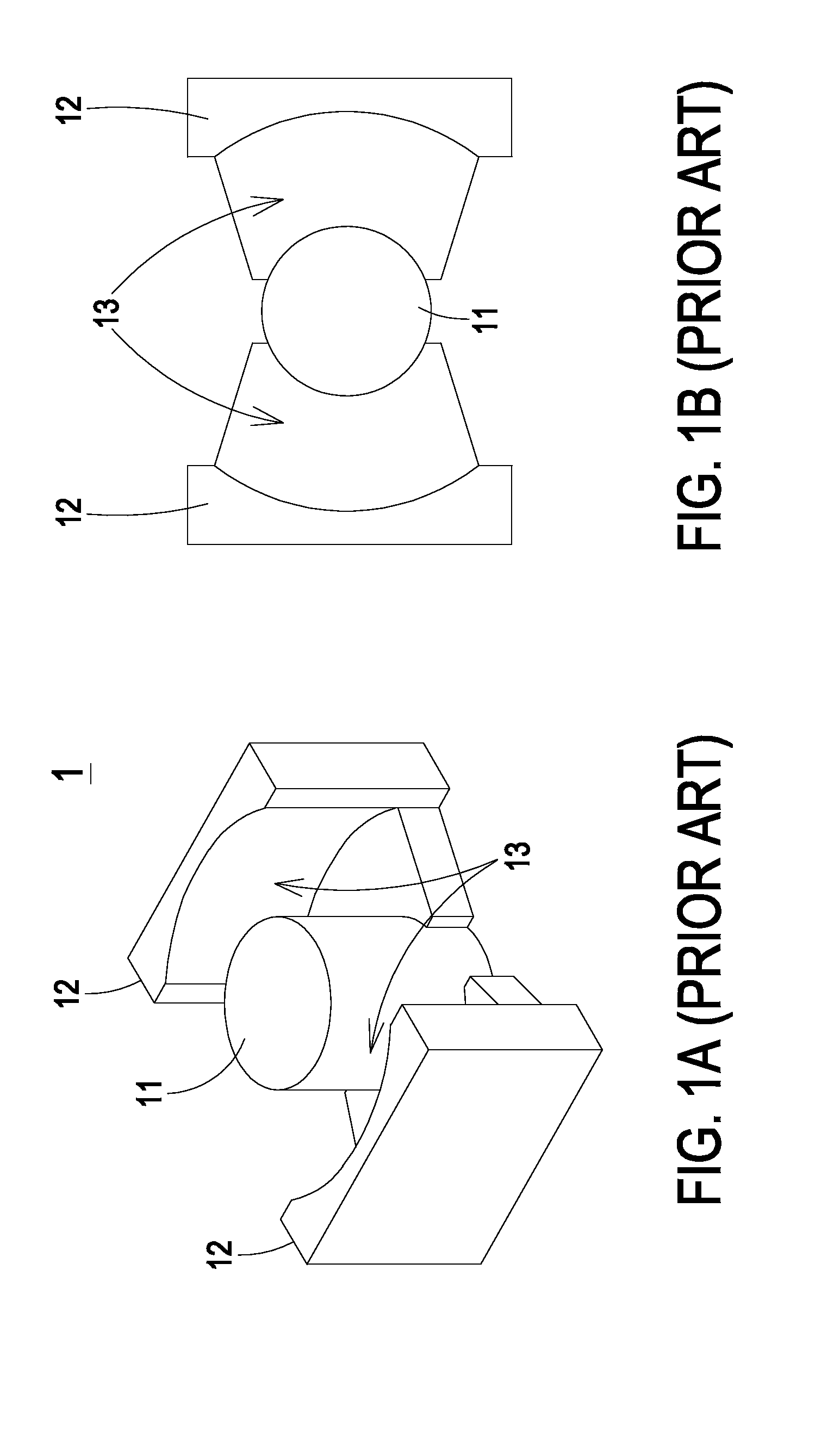

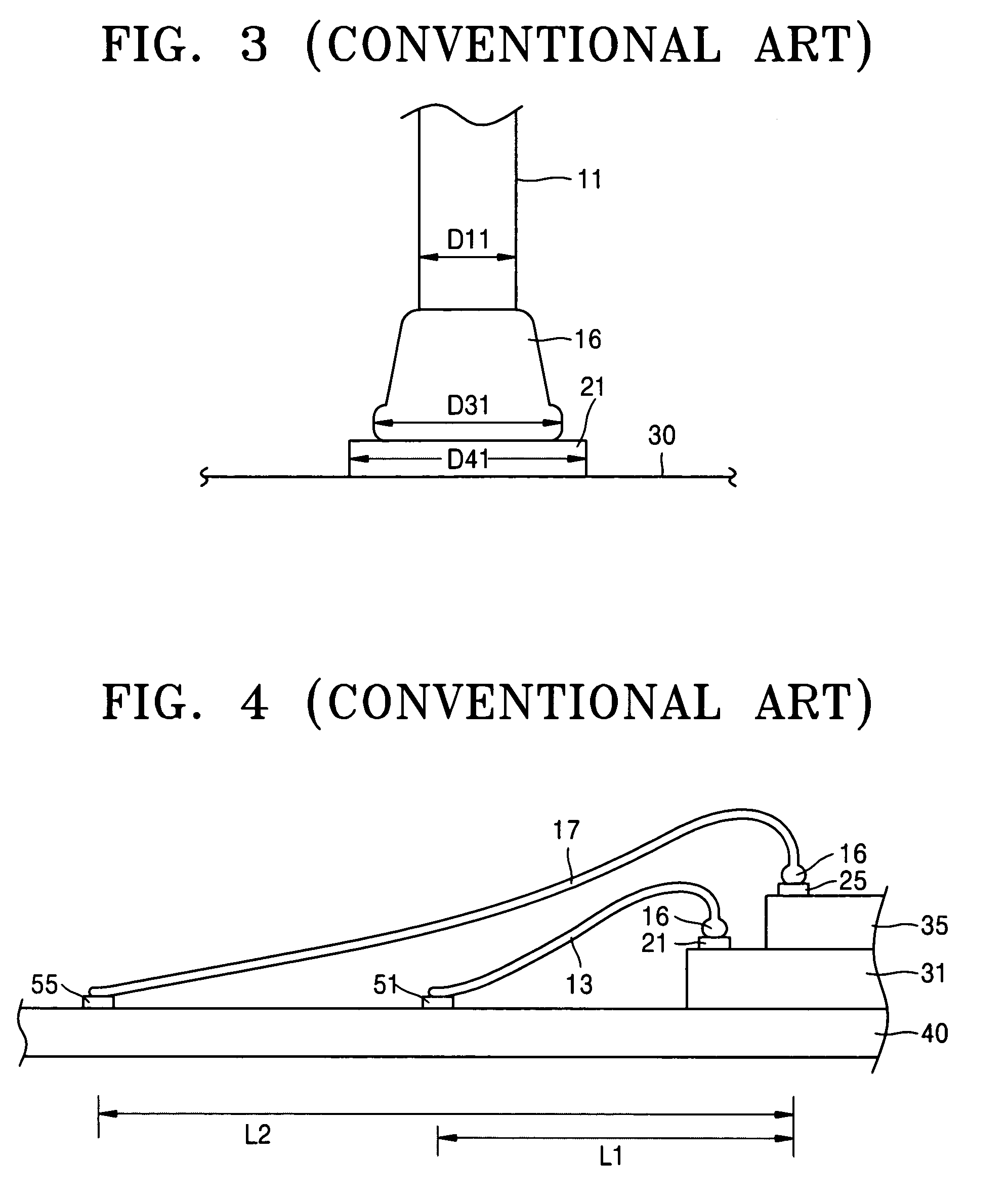

Method and apparatus for bonding a wire

InactiveUS20050200009A1Increase wire diameterSemiconductor/solid-state device detailsSolid-state devicesDevice formLead bonding

A method and apparatus for bonding a wire and a wire bond device formed by the same are disclosed. The method includes providing a carrier with at least a first pad, providing a semiconductor chip having at least the second pad, the at least second pad being smaller than the first a pad, forming a conductive stud bump on the second pad, and forming a bonding wire that has two terminal portions, which are respectively bonded to the first pad and the stud bump to electrically connect the first pad and the second pad. The stud bump is bonded to the second pad by a ball bonding method which uses a wire that has an approximately smaller diameter than the bonding wire. Further, a prominence formed on one end of the terminal portions is provided which has an approximately larger diameter than the stud bump.

Owner:SAMSUNG ELECTRONICS CO LTD

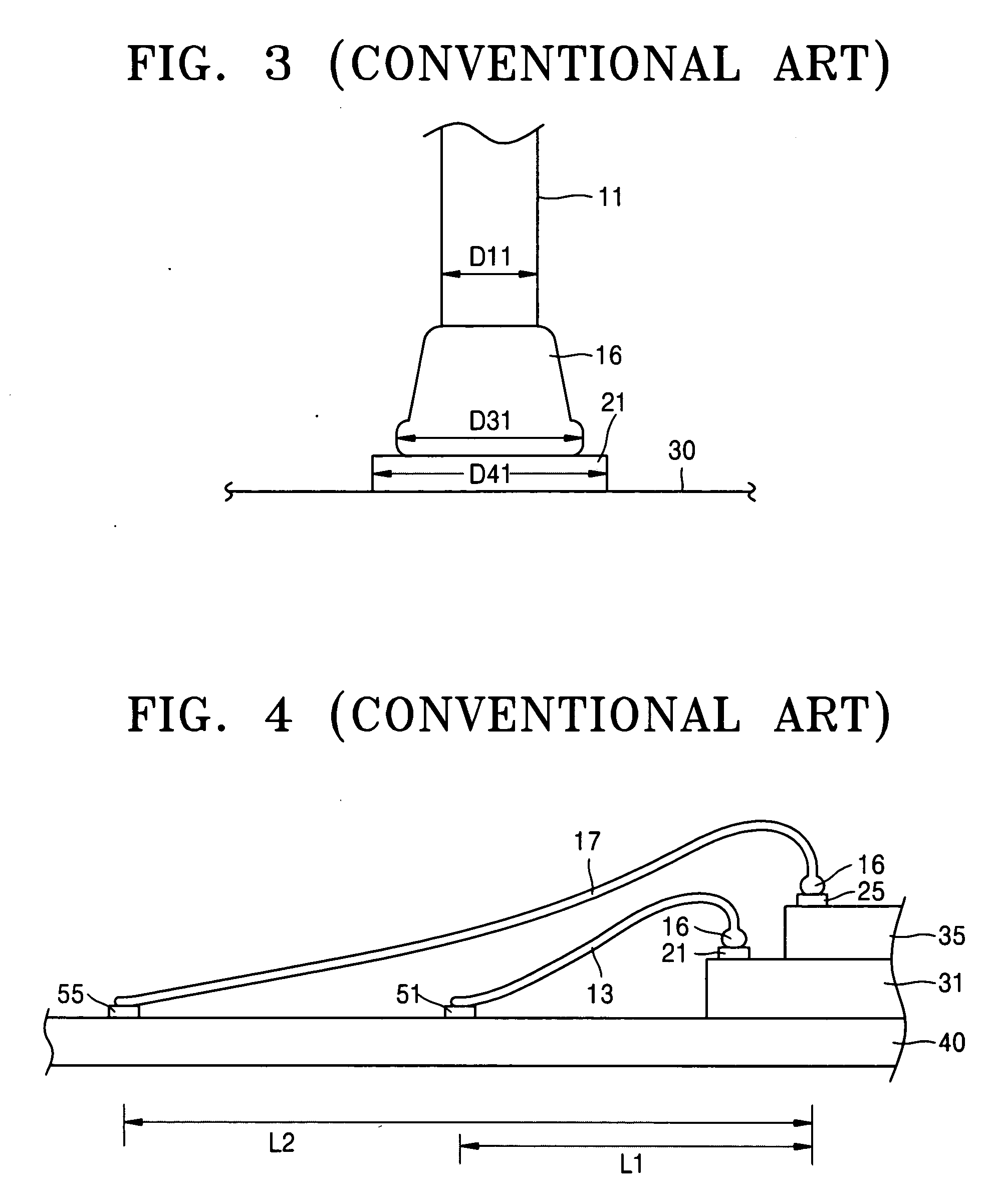

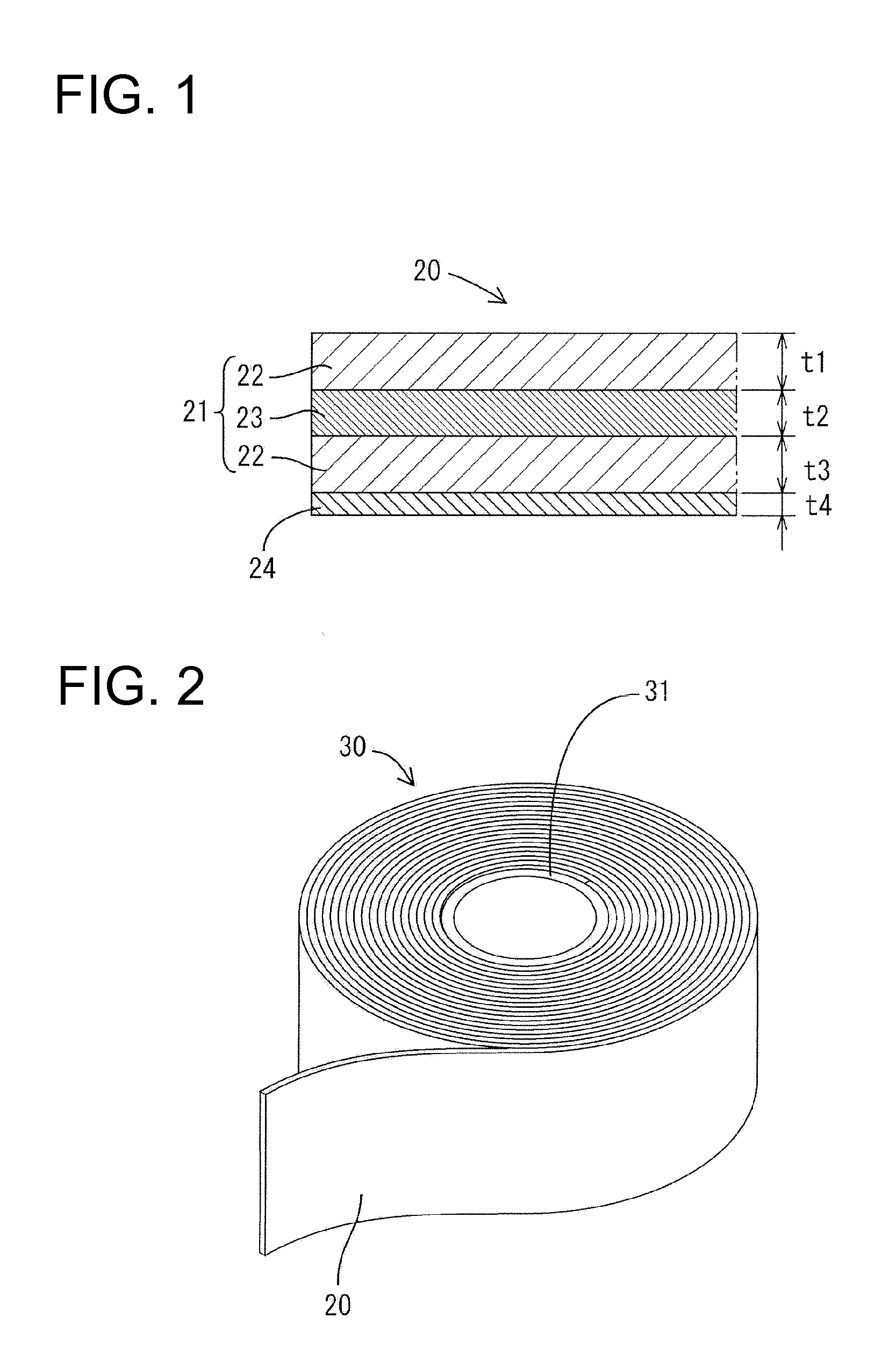

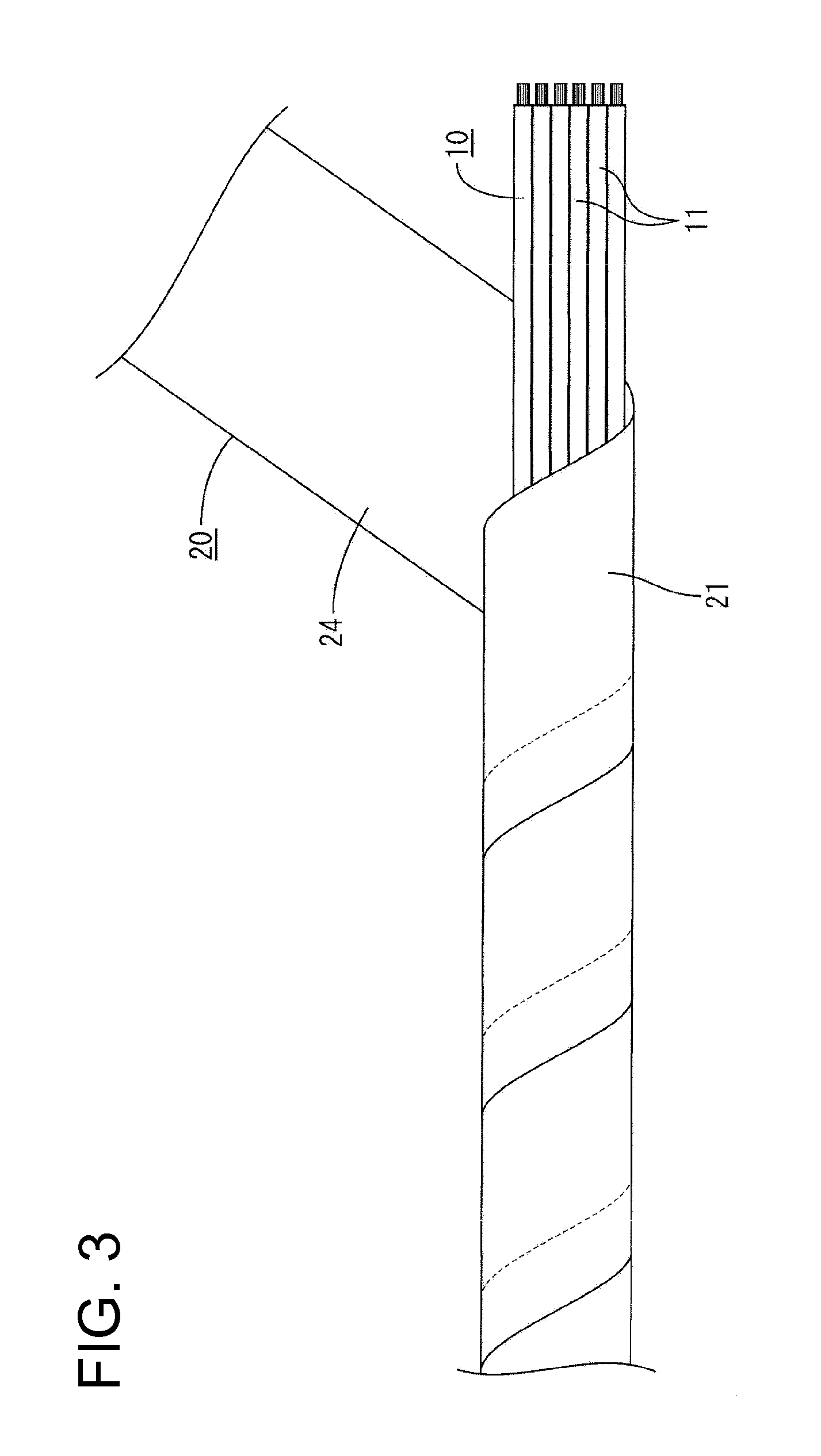

Wiring harness and method of forming a wiring harness

InactiveUS20100236827A1Improve wear resistanceEasy to cutFilm/foil adhesivesInsulated cablesAdhesive beltAdhesive glue

A protective tape (20) is composed of a three-layer base material (21) formed by bonding two knitted fabrics (22) by a glue (23) applied in dots, and an adhesive layer (24) formed on the underside of the base material (21). The base material (21) distributes an external load to the two knitted fabrics (22) for relaxing a stress. The protective tape (20) is difficult to abrade and also has a good hand cutting property. The protective tape (20) is wound spirally around the outer circumferential surface of a cable bundle (10) with lateral edges thereof overlapped while being dispensed from a roll (30), and the adhesive layer (24) on the underside is bonded to the outer circumferential surface of the cable bundle (10).

Owner:SUMITOMO WIRING SYST LTD

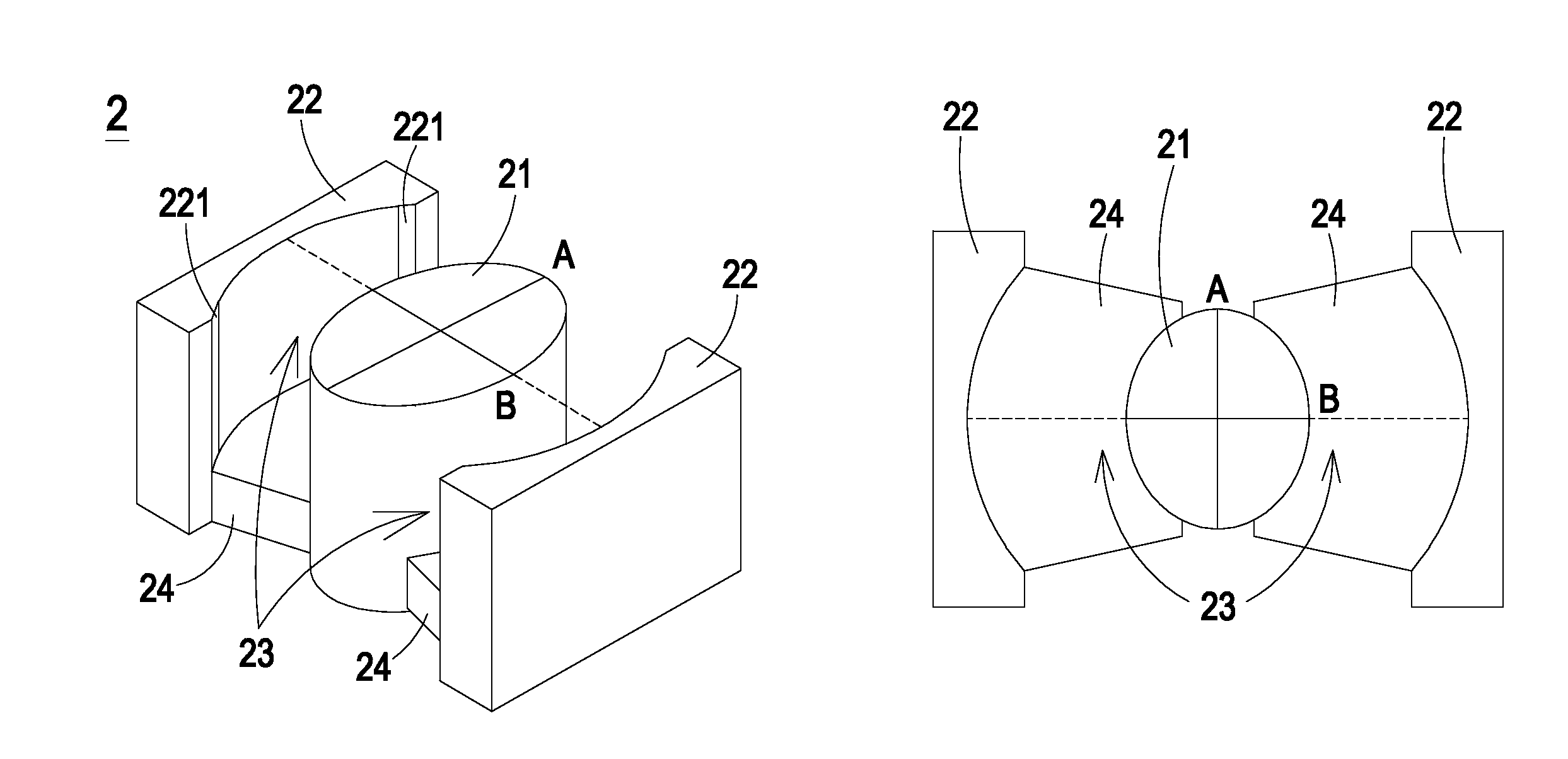

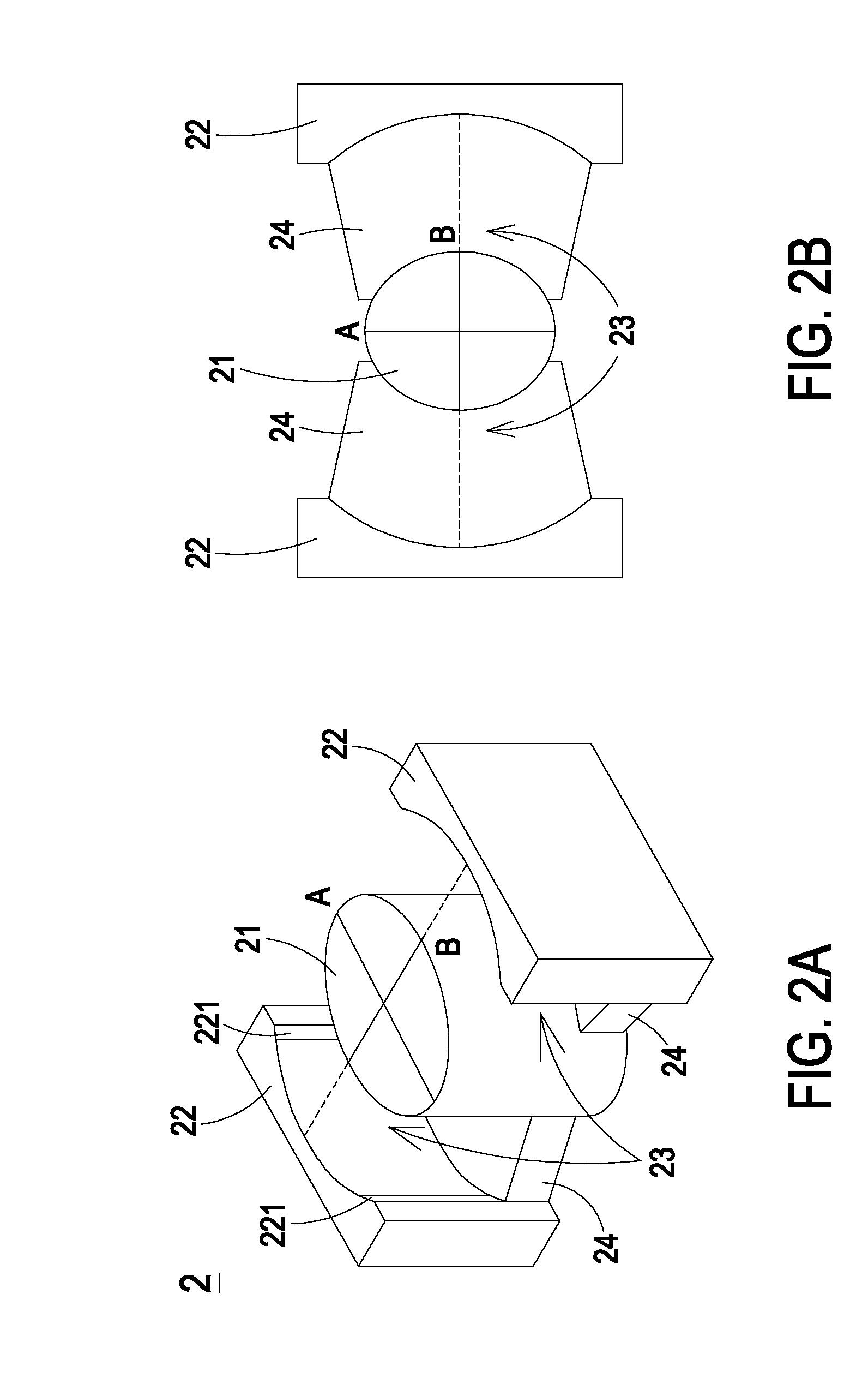

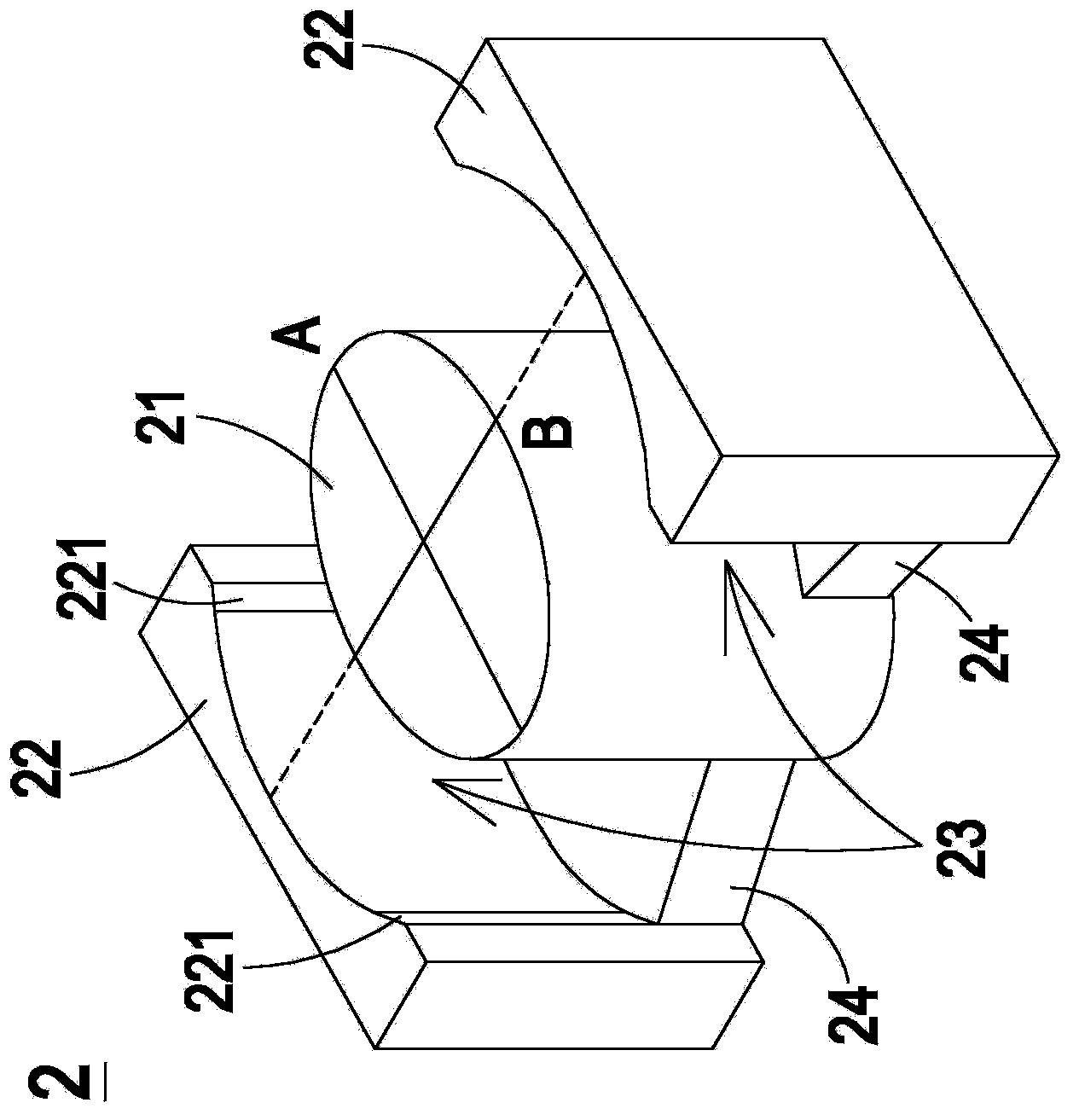

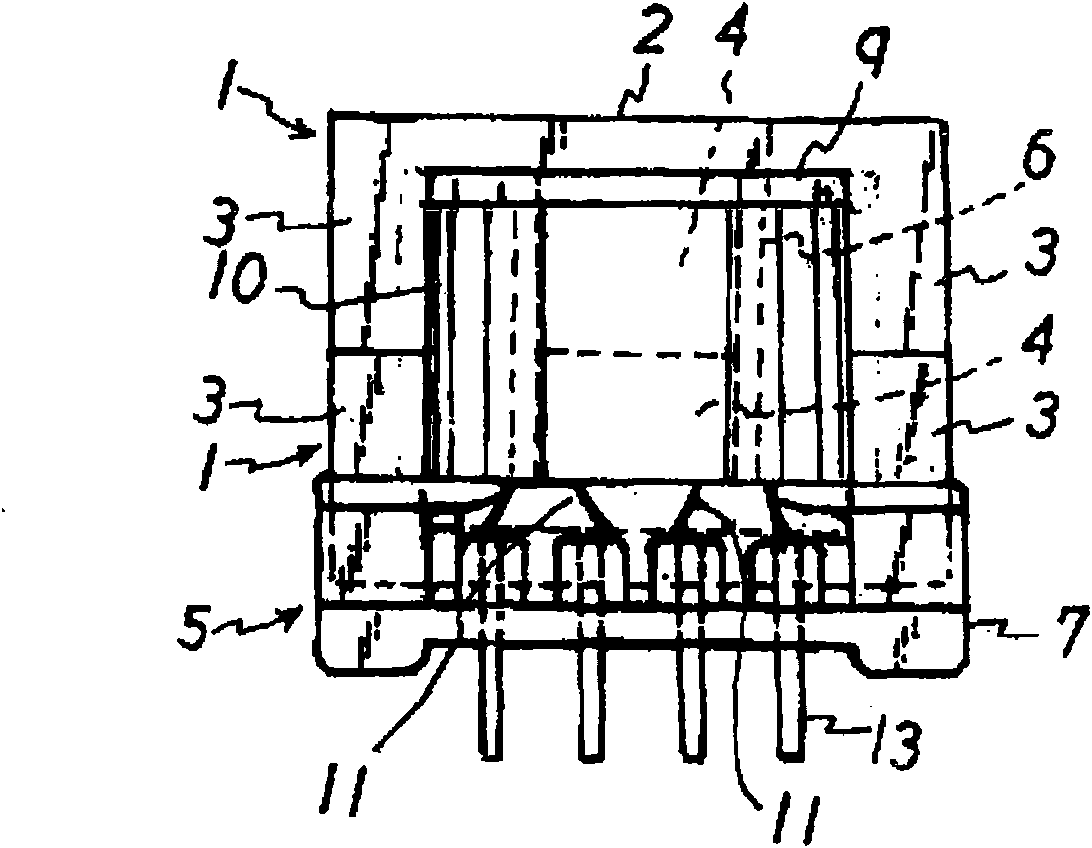

Magnetic core and magnetic element using same

InactiveUS20150002251A1Reduce magnetic inductionPoor magnetic performanceTransformers/inductances detailsCores/yokesBobbinEllipse

A magnetic core includes an ellipse-shaped central post and two side posts. The ellipse-shaped central post includes a long axis and a short axis. The length of the long axis is greater than the length of the short axis. The two side posts are disposed on two sides of the ellipse-shaped central post and opposite to each other. The two side posts are connected with the ellipse-shaped central post through two connecting portions respectively for defining at least one winding space with the ellipse-shaped central post. By utilizing the ellipse-shaped central post, the volume of the winding space is increased, the diameter of the wire of the winding coil can be increased, the temperature of the winding encapsulation is easy to be lowered, the over-volume issue of the winding encapsulation is avoided, and the safe distance between the bobbin and the winding encapsulation is increased, so that the present disclosure meets the safety regulation.

Owner:DELTA ELECTRONICS INC

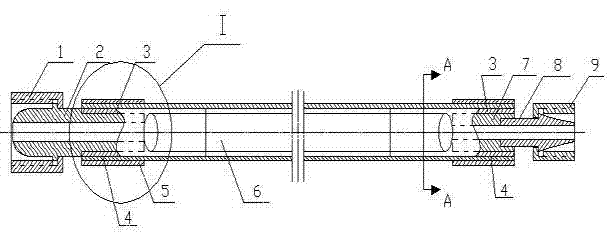

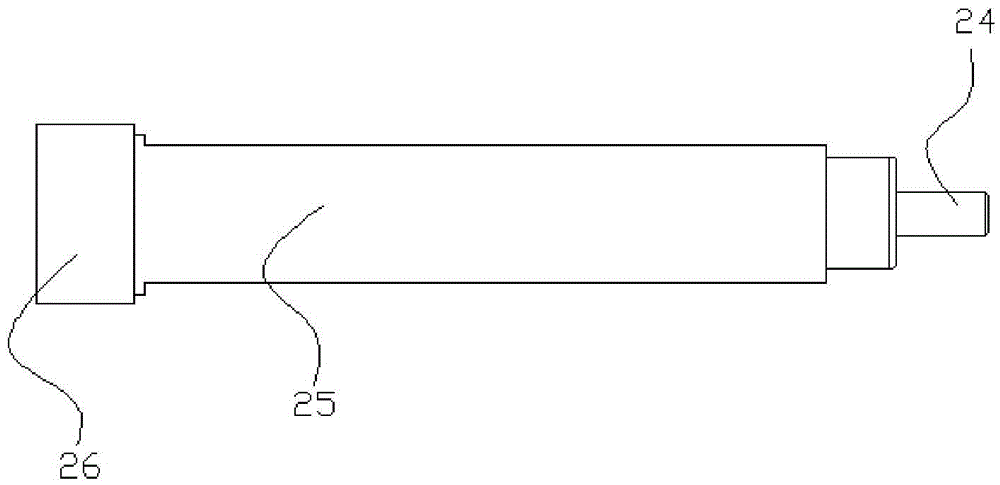

Flooding-type varnished wire cable for high-power handheld transformer winding

InactiveCN102930932AReduce volumeHigh powerTransformers/inductances coils/windings/connectionsFlexible cablesElectromagnetic inductionPolytetrafluoroethylene

The invention discloses a flooding-type varnished wire cable for a high-power handheld transformer winding. Two ends of a minuteness varnished wire harness cable are respectively stretched into two copper pipe center holes to achieve connection, and the sections of joints of two copper pipes and the minuteness varnished wire harness cable are in a semicircular shape in mould-pressing mode; a polytetrafluoroethylene sleeve is sleeved outside the two copper pipes and the minuteness varnished wire harness cable, and a cooling water channel used for passing of ion cooling water is formed between the minuteness varnished wire harness cable and the polytetrafluoroethylene sleeve; the wall of the first copper pipe of a section of gap between the left end of the minuteness varnished wire harness cable and the right end of a water inlet joint inside the first copper pipe center hole is provided with a water inlet; and the wall of the second copper pipe of a section of gap between the right end of the minuteness varnished wire harness cable and the left end of the water inlet joint inside the second copper pipe center hole is provided with a water outlet. The minuteness varnished wire harness cable is soaked in deion cooling water, and a large amount of work heat can be taken away.

Owner:JIANGSU UNIV OF SCI & TECH

Paint capable of shielding chromatic circle inductor and process for coating chromatic circle inductor

ActiveCN105609301ASmall change in inductance valueShield interferenceMagnetic paintsEncapsulation/impregnationDiluentEngineering

The invention provides paint capable of shielding a chromatic circle inductor and a process for coating the chromatic circle inductor. The paint capable of shielding the chromatic circle inductor is characterized by comprising the following materials in percentage by mass: 25-50% of chromatic circle inductor paint, 20-55% of soft magnetic ferrite magnetic powder, 10-30% of liquid curing agent and 10-30% of diluent; the manufacturing method for the paint capable of shielding the chromatic circle inductor and the process for coating the chromatic circle inductor comprise the steps of coating for two times by using the paint capable of shielding chromatic circle inductor, and then coating for two times by using the paint capable of shielding chromatic circle inductor. The paint capable of shielding the chromatic circle inductor and the process for coating the chromatic circle inductor have the advantages that interference on other parts caused by leakage flux generated in operating of the chromatic circle inductor can be effectively shielded; the cost of the coating can be greatly reduced; the inductance value can be increased; the self-resonance frequency is increased; and the paint is mainly suitable for packaging of the chromatic circle inductor.

Owner:深圳市同利科斯电子有限公司

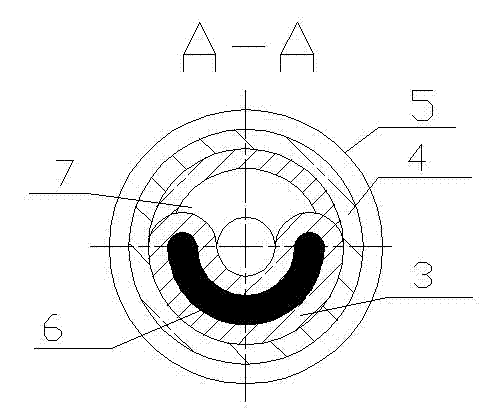

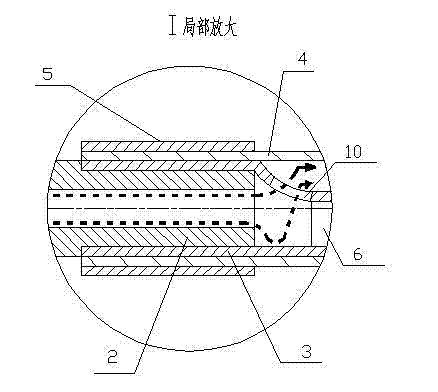

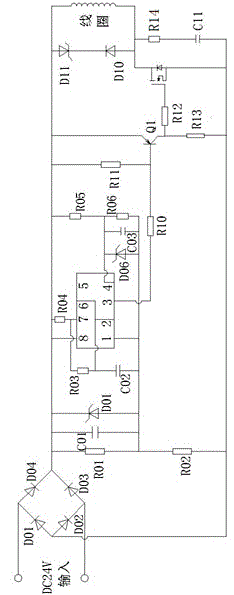

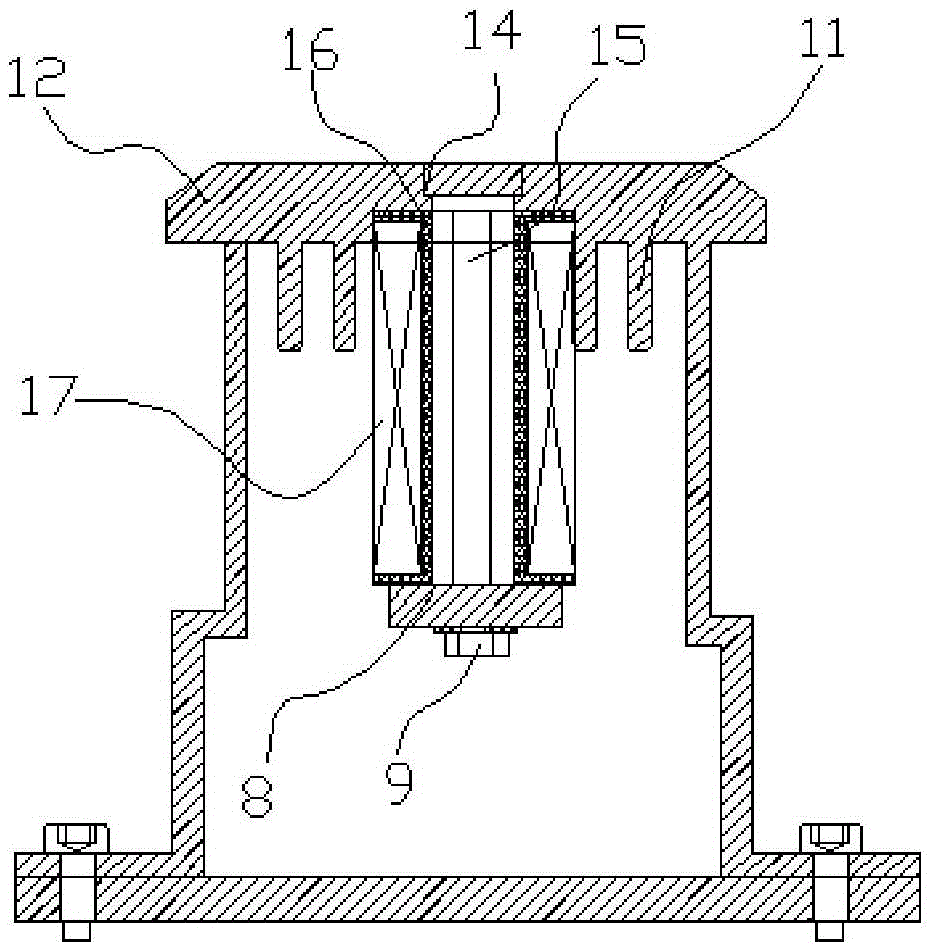

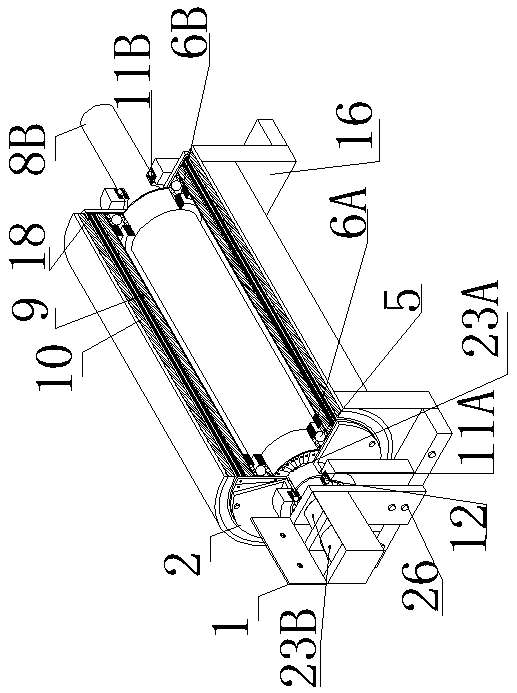

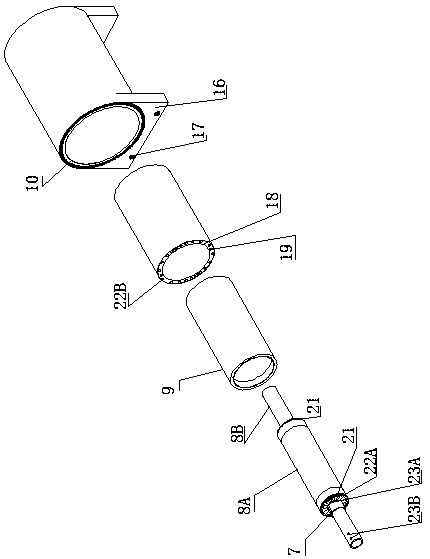

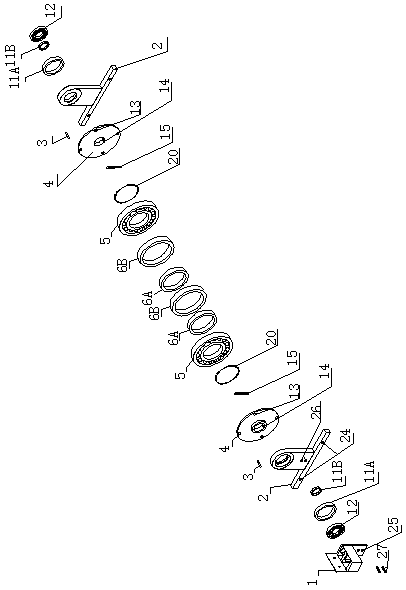

Low-temperature-rise great-thrust direct current electromagnet

ActiveCN104485196AReduced heating and temperature riseReduce temperature riseElectronic switchingElectromagnets with armaturesOxide semiconductorEngineering

The invention discloses a low-temperature-rise great-thrust direct current electromagnet, and belongs to the technical field of an electric control valve element. The electromagnet comprises a direct current power supply input end, a coil, an armature and an iron core, wherein a positive electrode of the power supply is connected to an input electrode of the coil, an MOS (metal oxide semiconductor) field-effect tube is connected between an output electrode of the coil and a negative electrode of the power supply, a broken triode Q1 provides triggering voltage for the MOS field-effect tube, and the triode is intermittently conducted and cut off, so that the MOS filed-effect tube works in an on-off state, voltage exerted at the two ends of the coil is pulse with a certain duty ratio, and the current of the coil in the armature maintaining state is lower than the current during the electromagnet starting. The low-temperature-rise great-thrust direct current electromagnet can achieve the great-thrust low-temperature-rise effects of the electromagnet.

Owner:安阳凯地磁力科技股份有限公司

Capacitor anode and production method for same

InactiveUS20160372268A1Increase wire diameterIncrease production costElectrolytic capacitor manufactureWire rodPowder mixture

An anode body for a capacitor and method for producing the same, which method includes compressing a powder mixture containing a tungsten powder and a high-oxygen-affinity metal powder into a compact with a wire rod planted therein, and firing the compact into a sintered compact. The high-oxygen-affinity metal has an oxygen affinity higher than that of tungsten. The content of the high-oxygen-affinity metal powder in the powder mixture is regulated so that the content of the high-oxygen-affinity metal in the sintered compact is 0.1 to 3% by mass based on the mass of the tungsten in the sintered compact. The wire rod includes tantalum or niobium. Also disclosed is an electrolytic capacitor including the anode body.

Owner:SHOWA DENKO KK

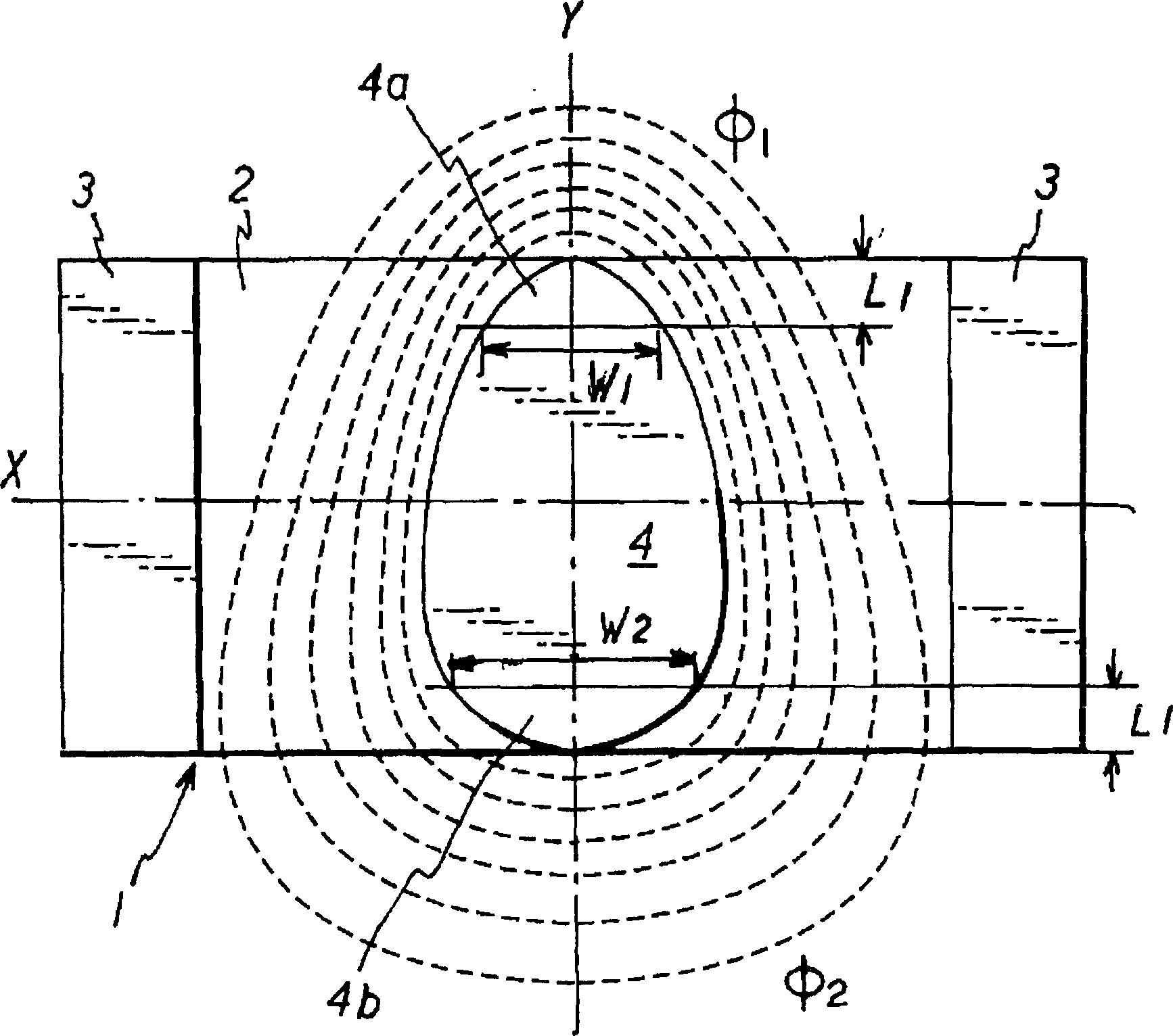

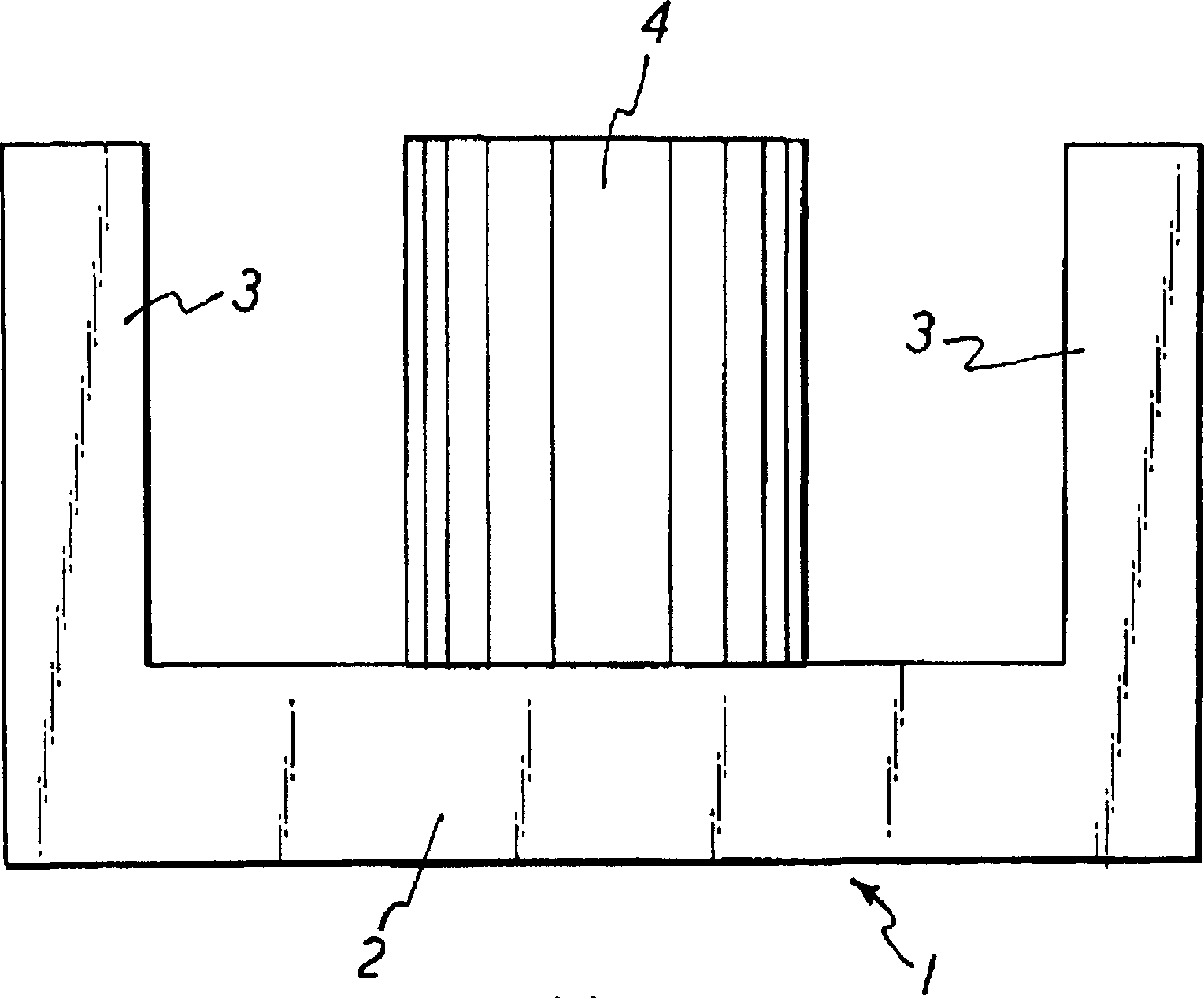

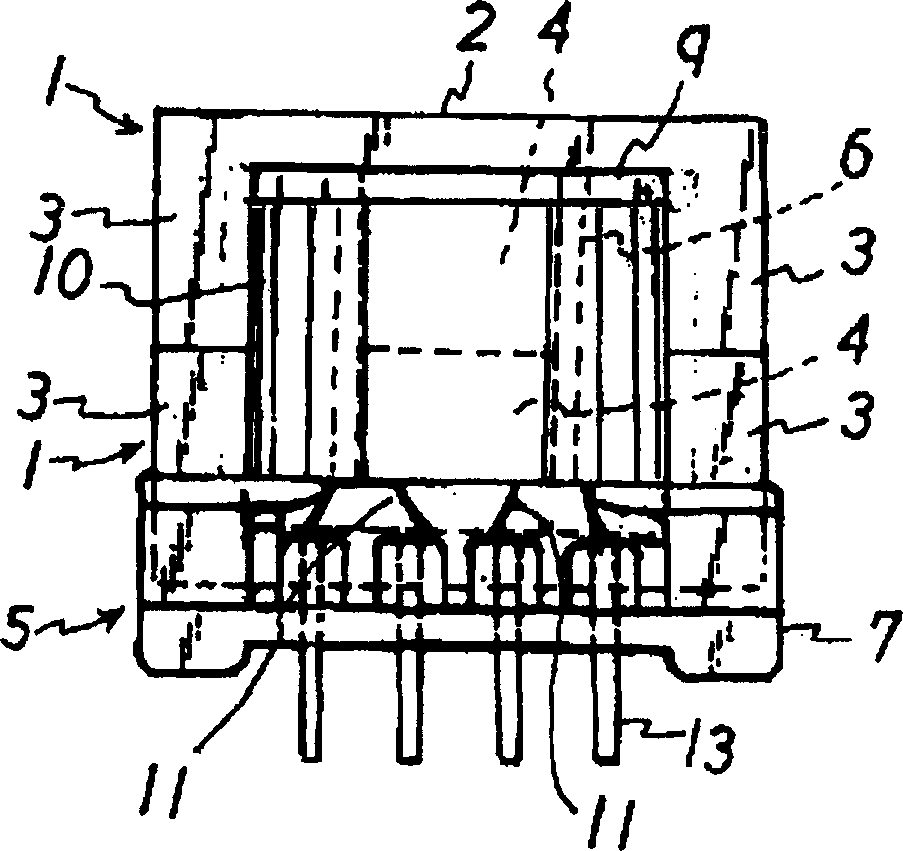

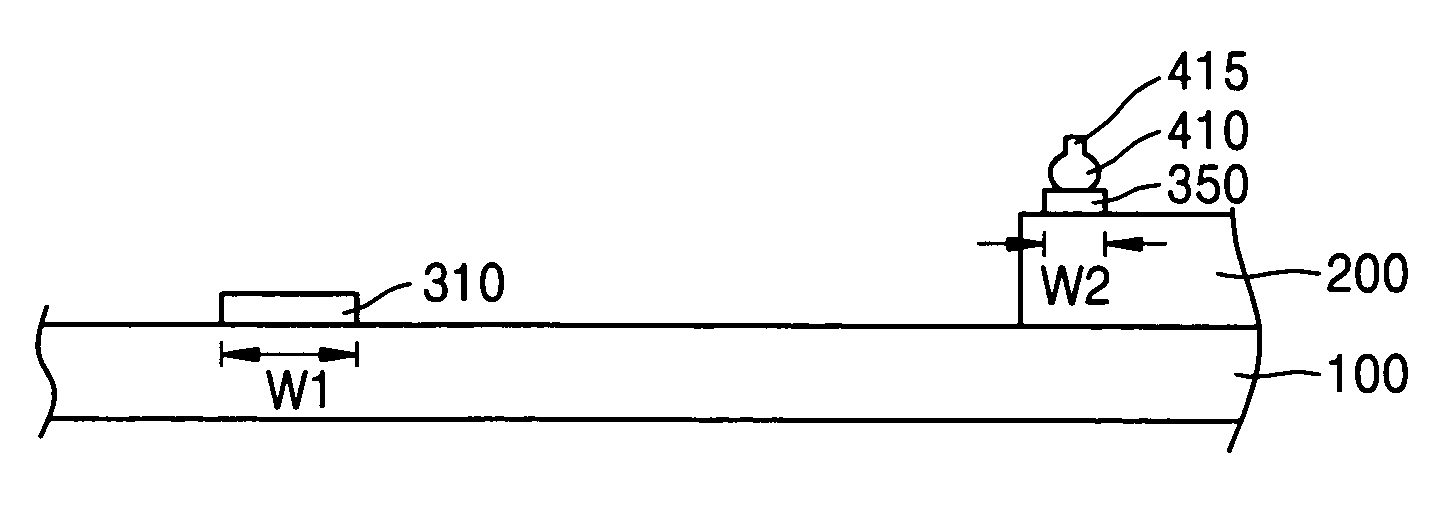

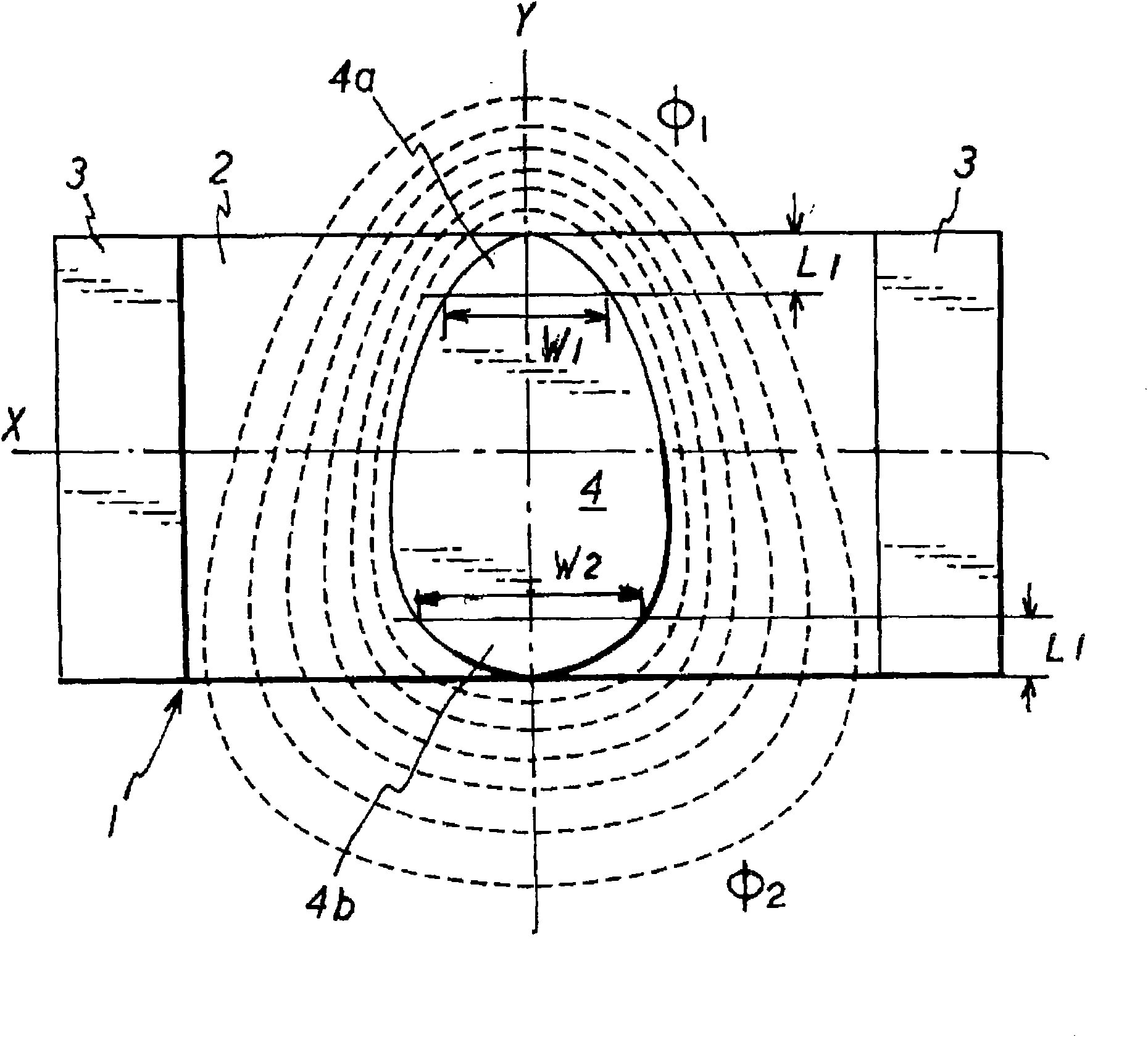

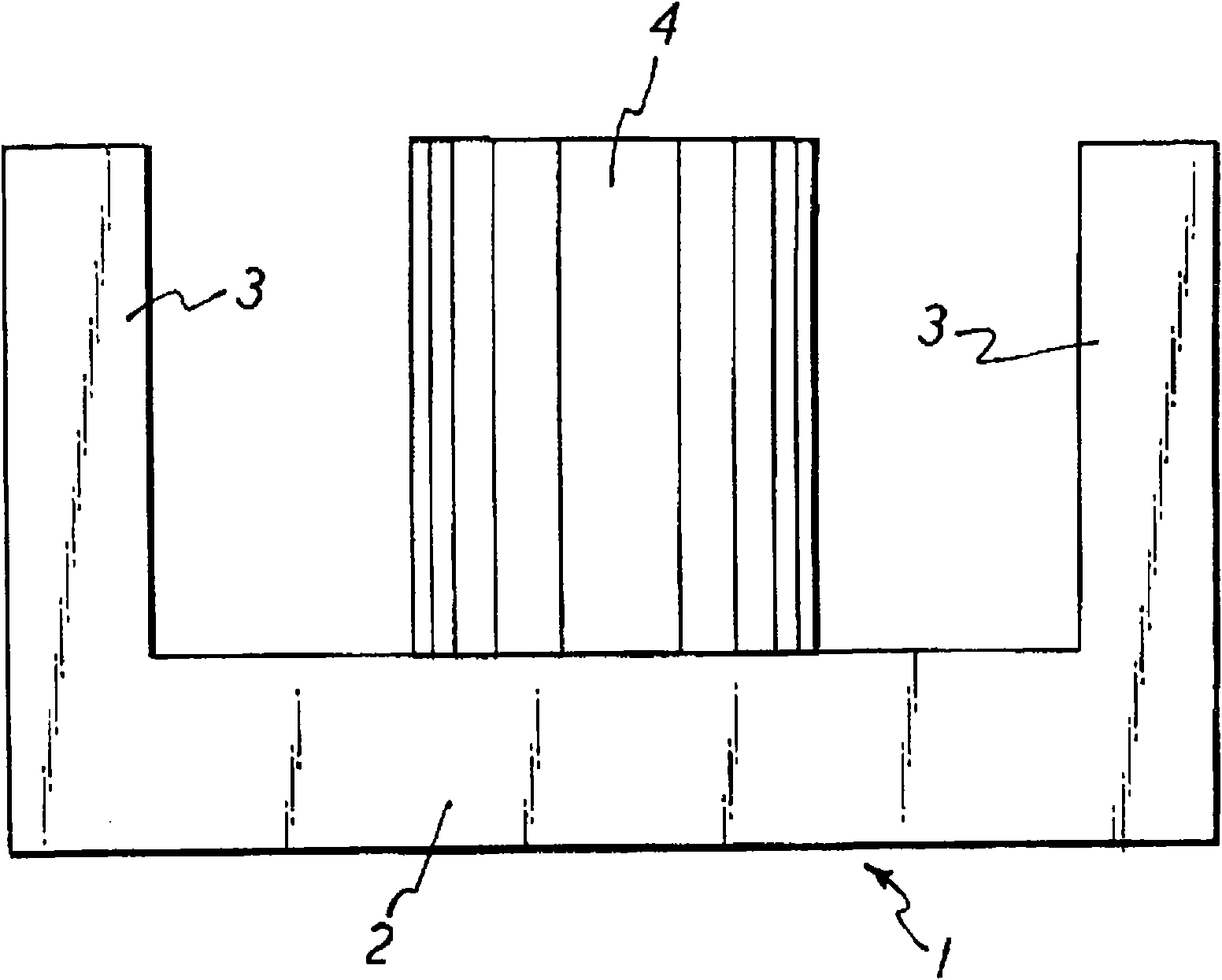

Ferrite core and transformer using the same

InactiveCN1855322AExempt from shieldingLow costTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

A ferrite core includes an end face portion, a pair of outer legs protruding from the end face portion, and a center leg protruding from the end face portion between the pair of outer legs. A width W1 close to one end portion of the center leg in a Y-axis direction perpendicular to a facing direction of the outer legs is smaller than a width W2 close to the other end portion. According to this configuration, a circuit component may be positioned close to the end portion. A transformer includes the ferrite core.

Owner:TDK CORPARATION

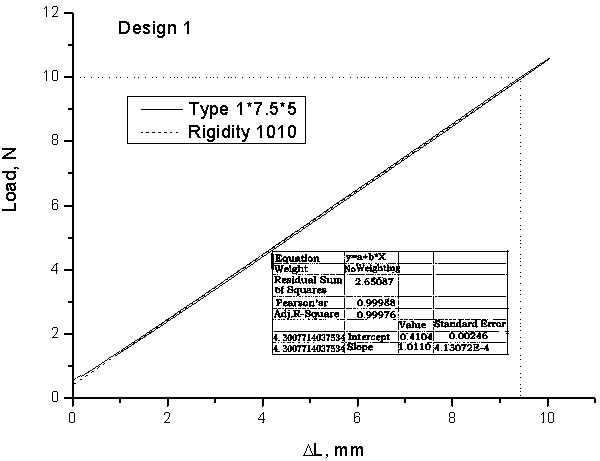

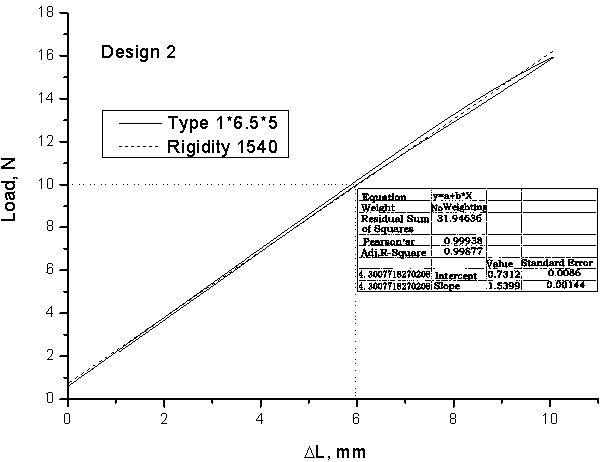

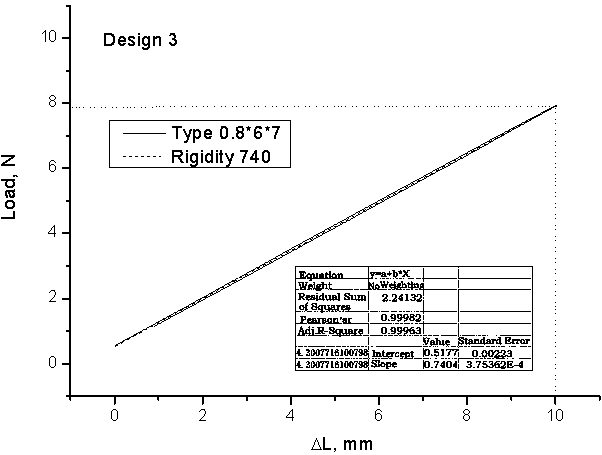

Low-rigidity TiNi alloy spring manufacturing technology

InactiveCN108723251AImprove elastic deformation abilityImprove corrosion resistanceFurnace typesHeat treatment furnacesManufacturing technologyWork performance

The invention discloses a low-rigidity TiNi alloy spring manufacturing technology, and relates to a spring manufacturing technology. According to the technology, dosing is carried out according to thetitanium alloy component, and then a TiNi alloy casting ingot is obtained through vacuum induction melting; an alloy rolling bar is obtained through free forging and hot rolling; the bar is subjectedto hot drawing to be then subjected to cold drawing; and a finished product wire material obtained after drawing is subjected to hot winding to manufacture a TiNi alloy spring. According to the low-rigidity TiNi alloy spring manufacturing technology, the TiNi memory alloy wire material is subjected to hot winding and hot hooking technologies to manufacture the low-rigidity TiNi alloy spring, theprocess is concise, the problems about large material consumption and high production cost are solved, the manufactured TiNi alloy spring has the good corrosion resistance and anti-fatigue performance, the working performance is more stable and reliable, and the technology can be applied to many fields such as oceanographic engineering, automobile making and aerospace.

Owner:SHENYANG UNIV

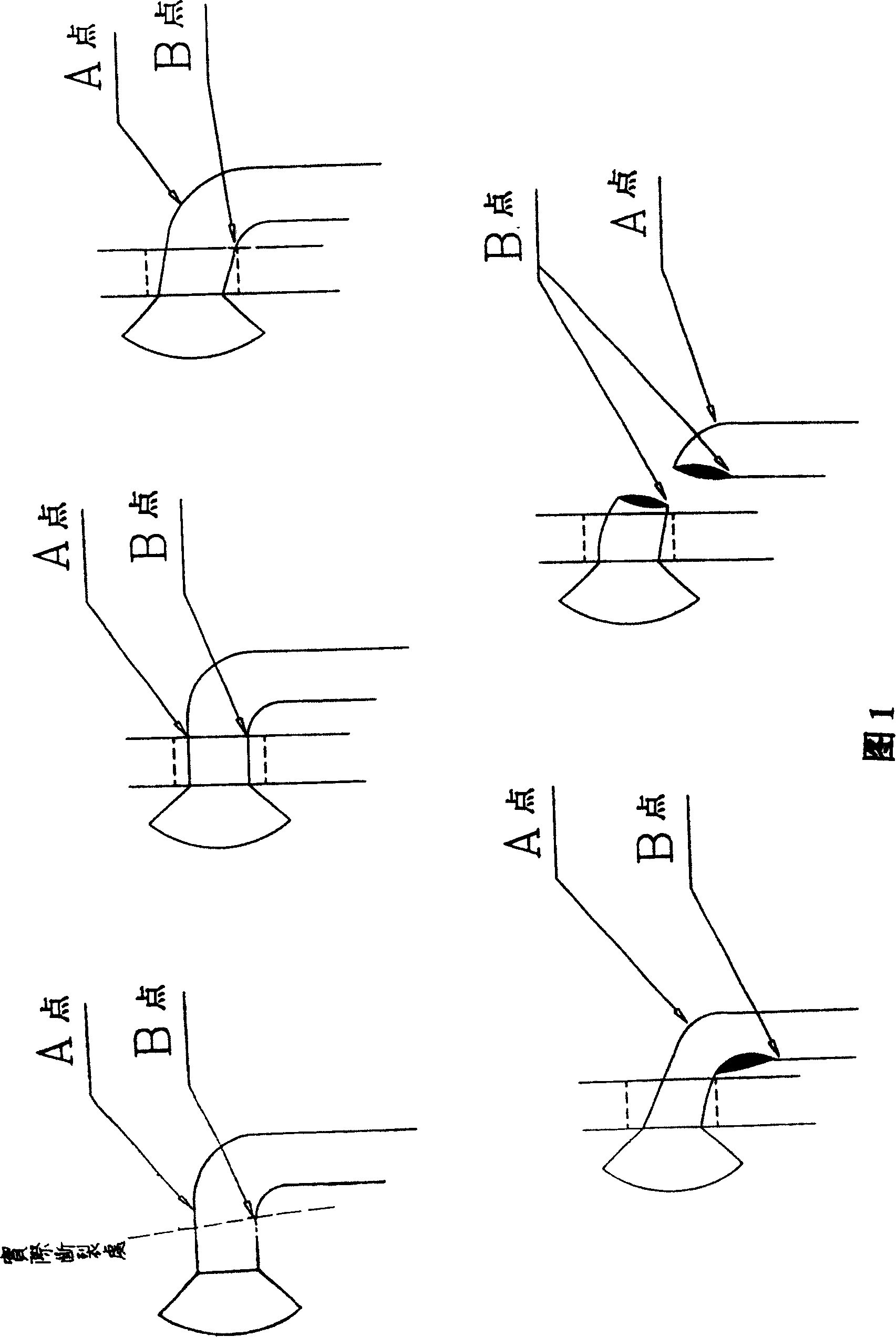

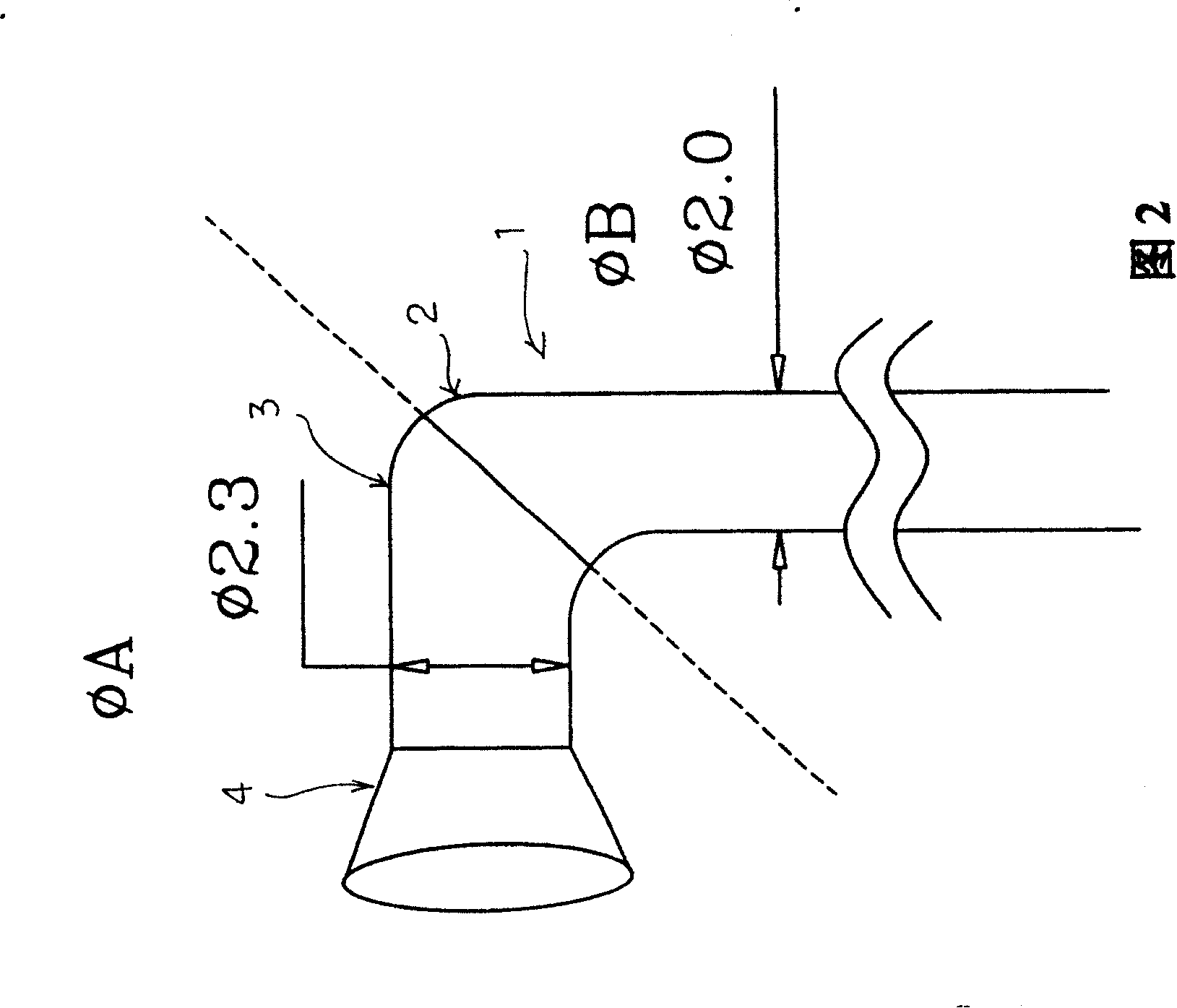

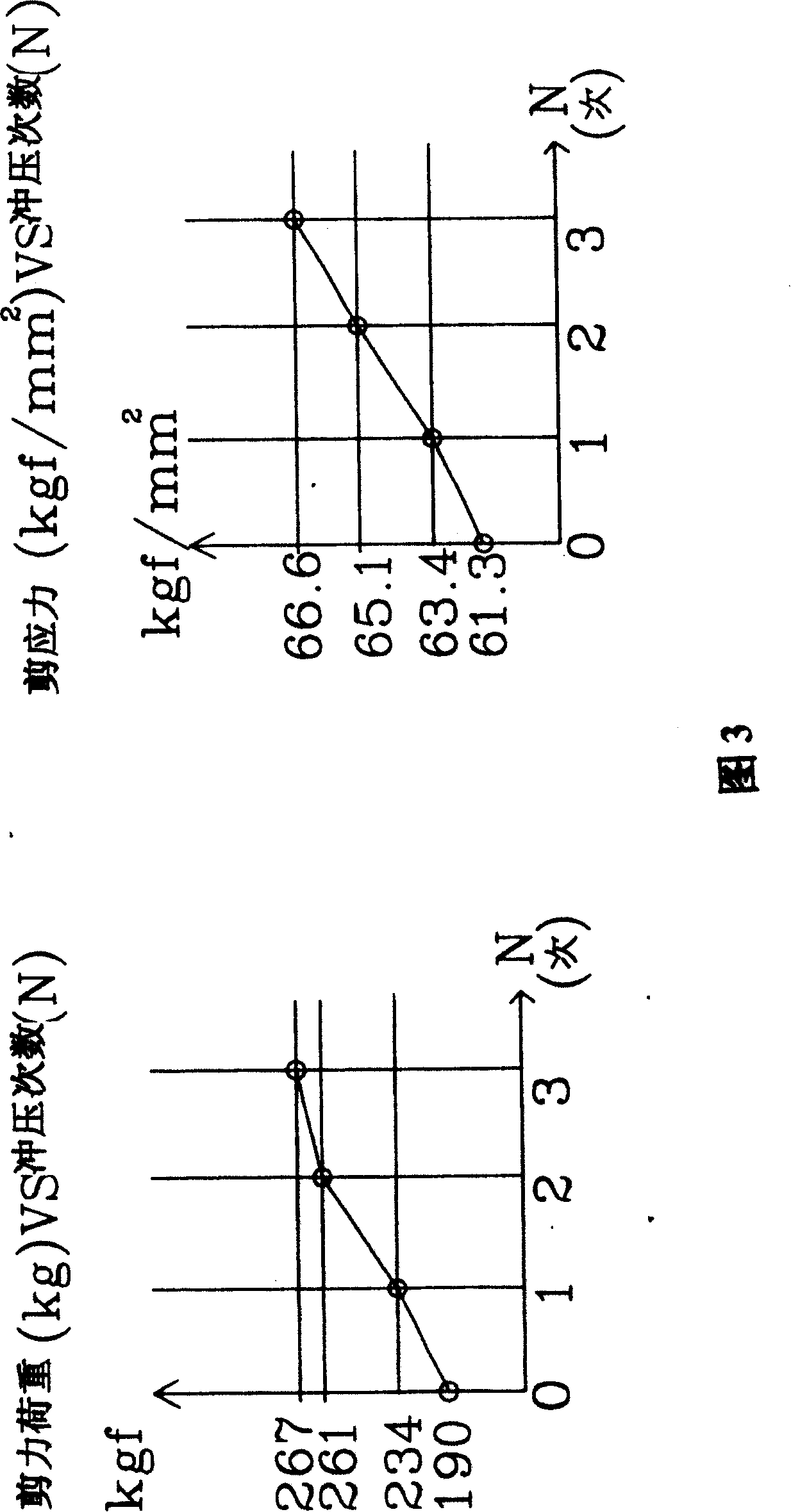

Method for reinforcing spoke structural strength of bicycle and motor vehicle

The invention provides a method for strengthening the spoke intensity of bicycle and car. It mainly use mechanical process method to upgrade the structure intensity of the spoke on the bent part, especially uses the theory using metal process and rigidification, with several times of punching and forming, makes the metal intensity at the bent position of the spoke being upgraded, at the same time, the wire radius is increased because of the squeezing effect; the shear load= shear strength X shear area, after the process, in actual test, the conclusion can be acquired that the pulling force intensity reaches to the metal material pulling force intensity.

Owner:协达车料股份有限公司

Optical fiber production method with characteristic of optical fiber cable manufacturing quality benefiting

InactiveCN104944761AControl stateControl speedGlass making apparatusGlass productionMeasuring instrumentFeedback circuits

The present invention discloses an optical fiber production method with the characteristic of optical fiber cable manufacturing quality benefiting. The method sequentially comprises: 1) placing a preform into a heating furnace so as to soften the preform, and 2) under traction force, leading out the optical fiber from the top end of the preform to obtain the coiled optical fiber product, wherein the step 2) further comprises an optical fiber wire diameter control process and an optical fiber coiling tensioning force adjusting process, wherein the optical fiber wire diameter control process comprises that a diameter measuring instrument and a winch for providing optical fiber leading out traction force are arranged on the movement path of the optical fiber, a feedback circuit is connected between the diameter measuring instrument and the winch, and the feedback circuit transmits the output value of the diameter measuring instrument to the control circuit of a winch drive device, such that the leading out speed of the optical fiber is controlled through the output value of the diameter measuring instrument. With the method of the present invention, the dynamical adjusting on the optical fiber wire diameter during the optical fiber drawing process can be achieved, and the optical fiber cable manufacturing quality is easily achieved.

Owner:成都亨通光通信有限公司

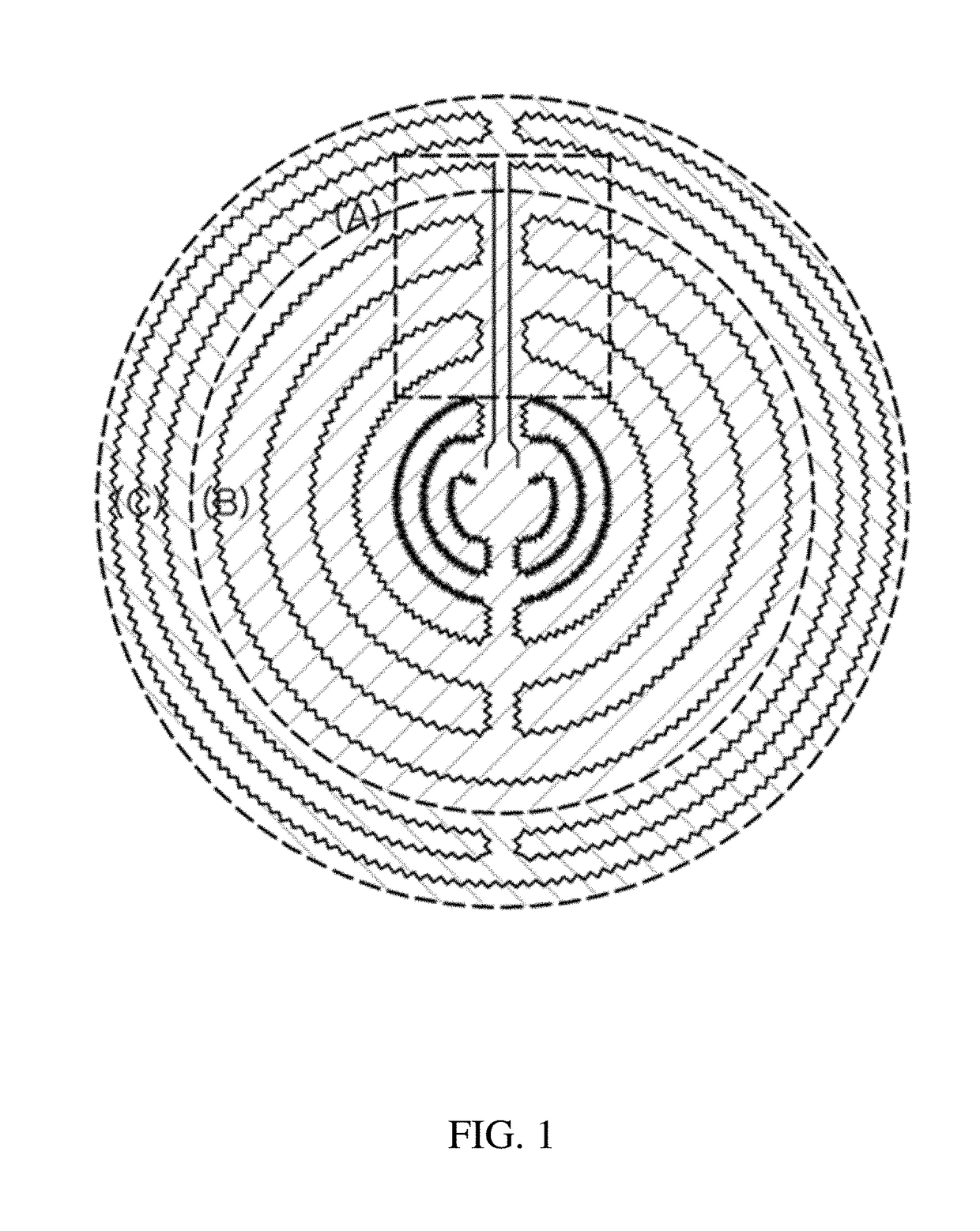

Substrate heating apparatus with enhanced temperature uniformity characteristic

ActiveUS20180254204A1Avoid overall overheatingMinimizing non-uniformityVacuum evaporation coatingSputtering coatingEngineeringSupply current

The present invention relates to a substrate heating apparatus. More specifically, the present invention relates to a substrate heating apparatus including a first heating element located in an inner region of the substrate heating apparatus, a second heating element located in an outer region, and a third heating element supplying current to the second heating element passing through the inner region, wherein the diameter of a wire constituting the third heating element is thicker than the diameter of a wire constituting the second heating element, thereby inhibiting the generation of an overheating region by the heating of the third heating element.

Owner:MICOCERAMICS LTD

Method and apparatus for bonding a wire

InactiveUS7371675B2Increase wire diameterSemiconductor/solid-state device detailsSolid-state devicesDevice formLead bonding

Owner:SAMSUNG ELECTRONICS CO LTD

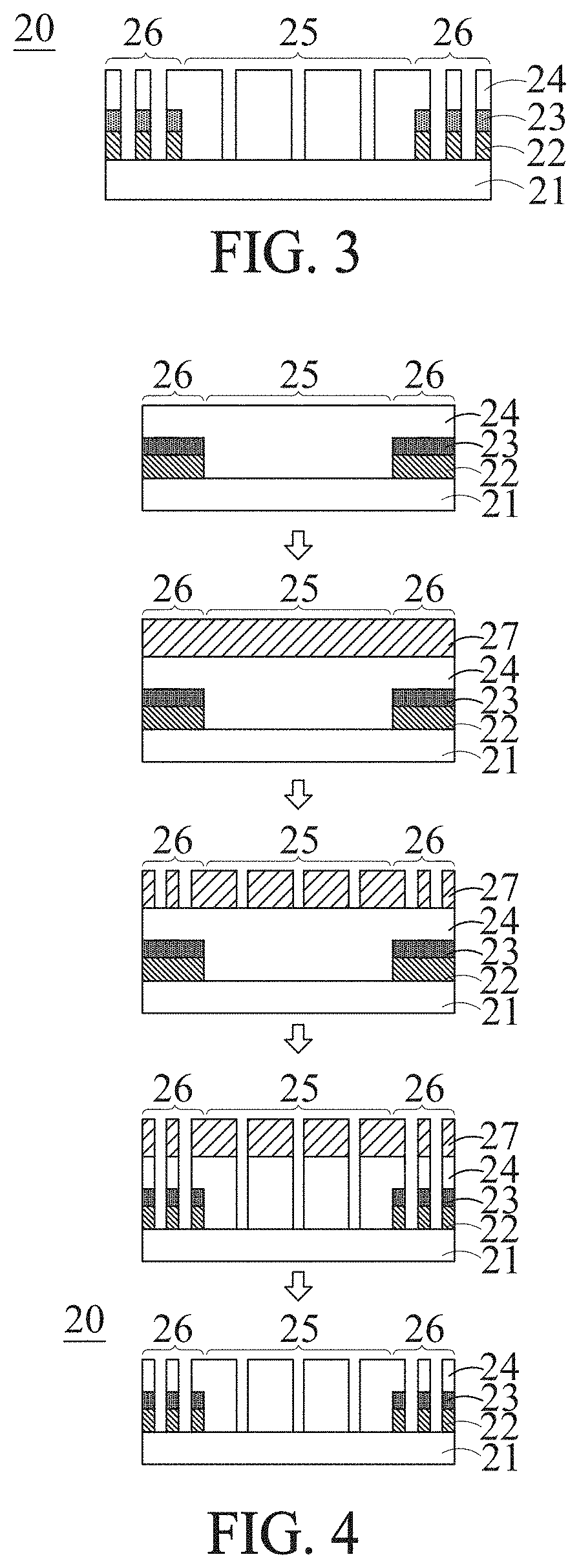

Stack structure and touch sensor

ActiveUS11360622B2Increase in sizeIncrease wire diameterInput/output processes for data processingEngineeringCopper

A stack structure includes: a substrate, a copper layer disposed on the substrate, a migration-proof layer disposed on the copper layer, and a silver-nanowire layer disposed on the migration-proof layer, wherein the migration-proof layer is made of materials between copper and silver in galvanic series. A touch sensor includes the stack structure.

Owner:CAMBRIOS FILM SOLUTIONS CORP

Electromagnetic shielding structure and manufacturing method thereof

ActiveCN111477611ARealize electromagnetic shielding functionSimple preparation processSemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor package

The embodiment of the invention provides an electromagnetic shielding structure and a manufacturing method of the electromagnetic shielding structure, and relates to the technical field of semiconductor packaging. The electromagnetic shielding structure comprises a substrate, a chip, a plastic package body and a shielding layer, wherein the chip is mounted on the substrate, and the plastic packagebody is arranged on one side, close to the chip, of the substrate; and a grounding circuit is arranged on the substrate. A grounding groove is formed in the substrate, a conducting layer is arrangedin the grounding groove, and the conducting layer is connected with a grounding circuit of the substrate; and the shielding layer covers the outer surface of the plastic package body and is connectedwith the conductive layer. The grounding groove is formed in the substrate and used for arranging the conducting layer so as to be connected with the shielding layer, and then the electromagnetic shielding function is achieved. Therefore, the short circuit between the conductive layer and the solder balls on the substrate can be avoided, the packaging efficiency is improved, the connection betweenthe conductive layer and the shielding layer is more reliable, and the electromagnetic shielding effect is better.

Owner:FOREHOPE ELECTRONICS NINGBO CO LTD

Titanium alloy for enclosed intrauterine device

ActiveCN103127558AReduce corrosionRelease stabilitySurgeryFemale contraceptivesIntrauterine deviceNiobium

The invention relates to a titanium alloy for an enclosed intrauterine device. The titanium alloy has an expression formula of Ti-X or Ti-X-Y, wherein X is one or more of the following isomorphic beta stable elements: molybdenum, niobium, tantalum and tungsten; X accounts for 0.001-70 percent of the total weight; Y is one or more of the following neutral elements, namely, tin, zirconium and hafnium; and Y accounts for 0.001-30 percent of total weight. The titanium alloy disclosed by the invention can be prepared into a titanium alloy wire which is used for manufacturing a stent of the intrauterine device.

Owner:LIAONING AIMU MEDICAL SCI&TECH

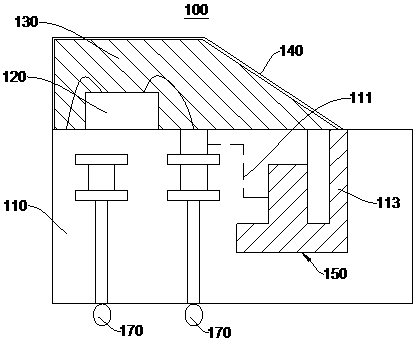

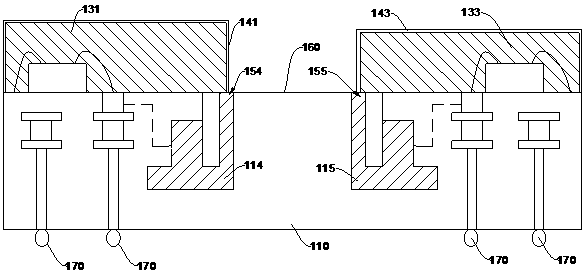

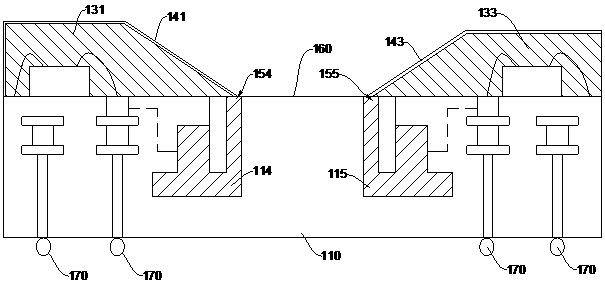

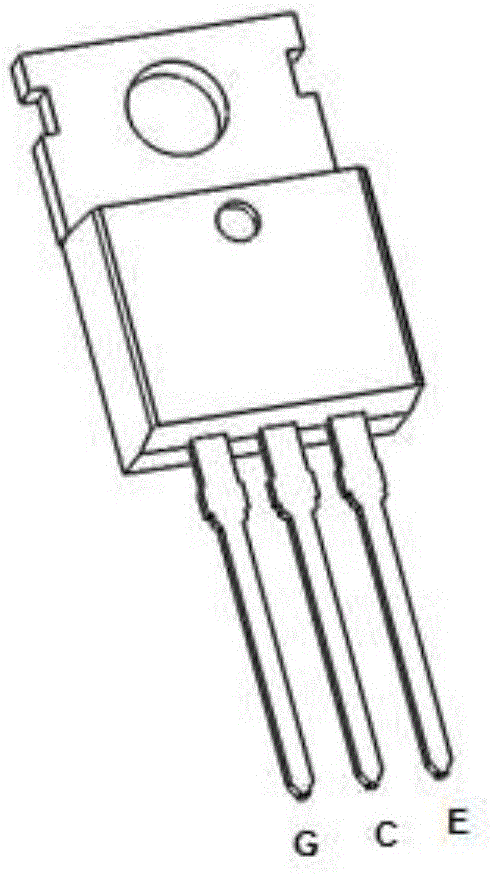

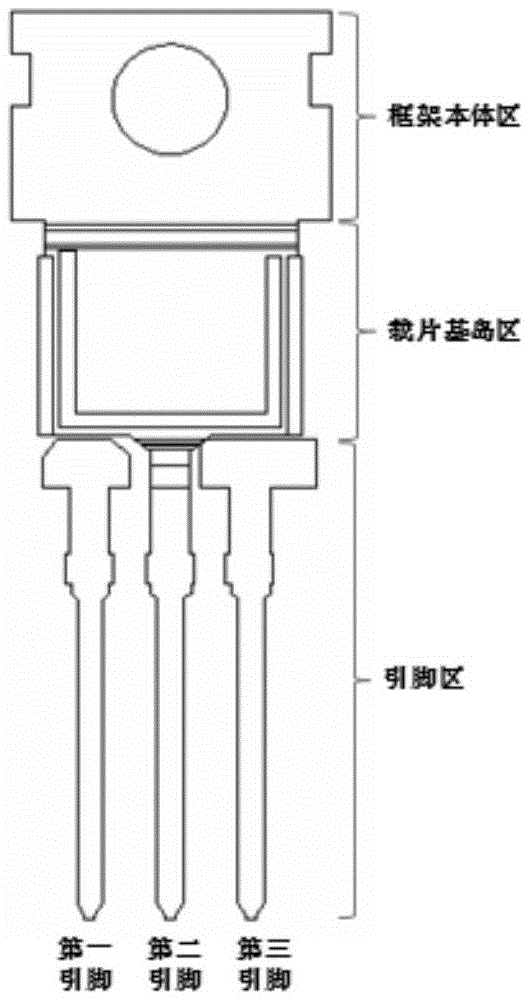

A semiconductor device with an improved packaging structure and its manufacturing method

ActiveCN103824834BIncrease the areaIncrease wire diameterSemiconductor/solid-state device detailsSolid-state devicesMOSFETSemiconductor chip

The invention discloses a semiconductor device with an improved packaging structure and a manufacturing method thereof. The semiconductor device includes a semiconductor chip, a lead frame and a packaging resin. The semiconductor chip is located in the base island area of the lead frame, and the lead frame includes a lead area, wherein the upper end of the second lead area is connected with a second bonding area. The semiconductor chip is electrically connected with the second bonding area through metal wires. The area of the second bonding area is larger than that of the prior art, so as to ensure that the maximum fusing current limited by the metal leads can be effectively increased when the chip is packaged, and the on-resistance of the device is reduced, thereby maximizing the actual use of the chip. current capability. The invention is applicable to MOSFET devices and IGBT devices.

Owner:无锡电基集成科技有限公司

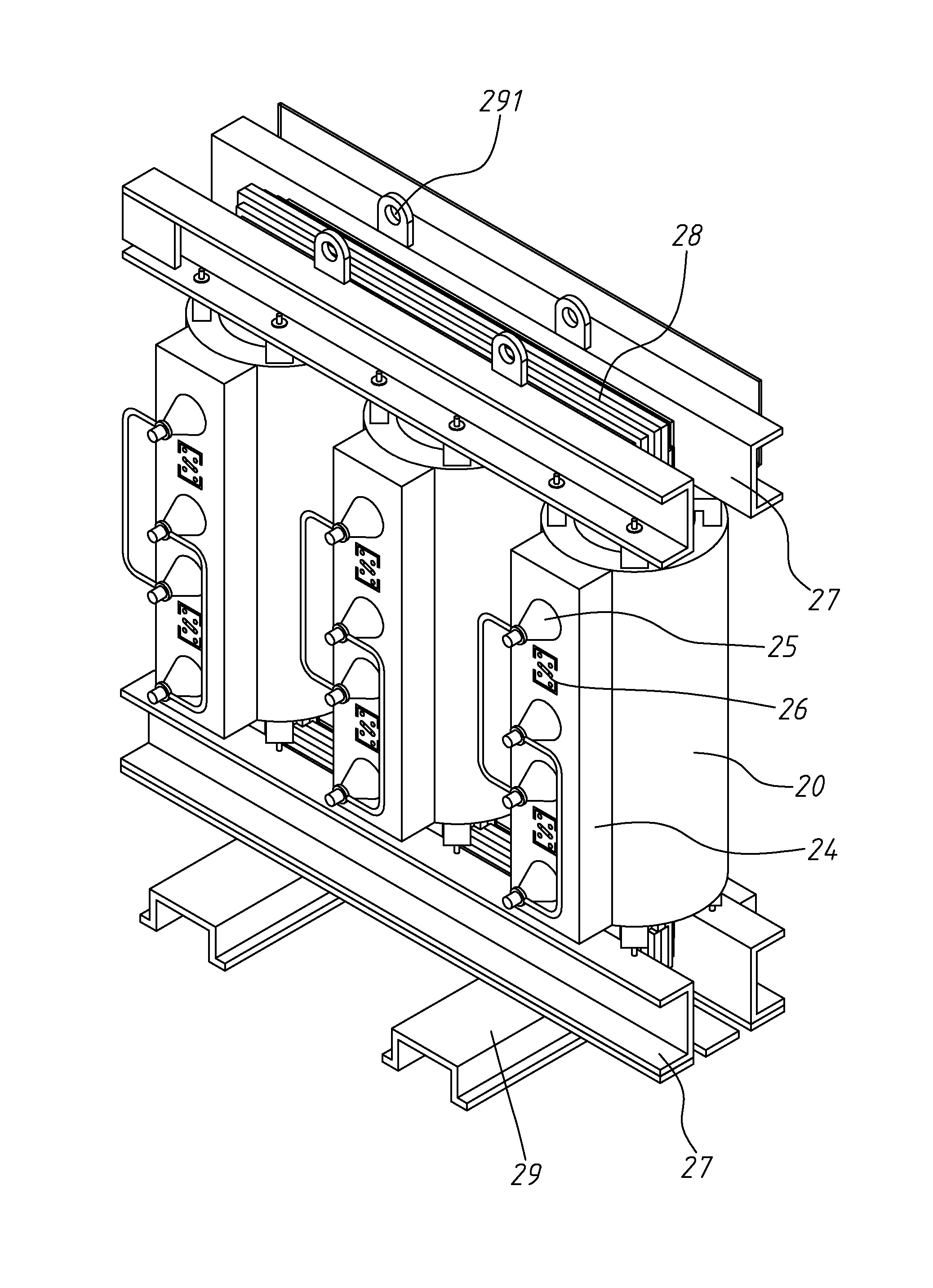

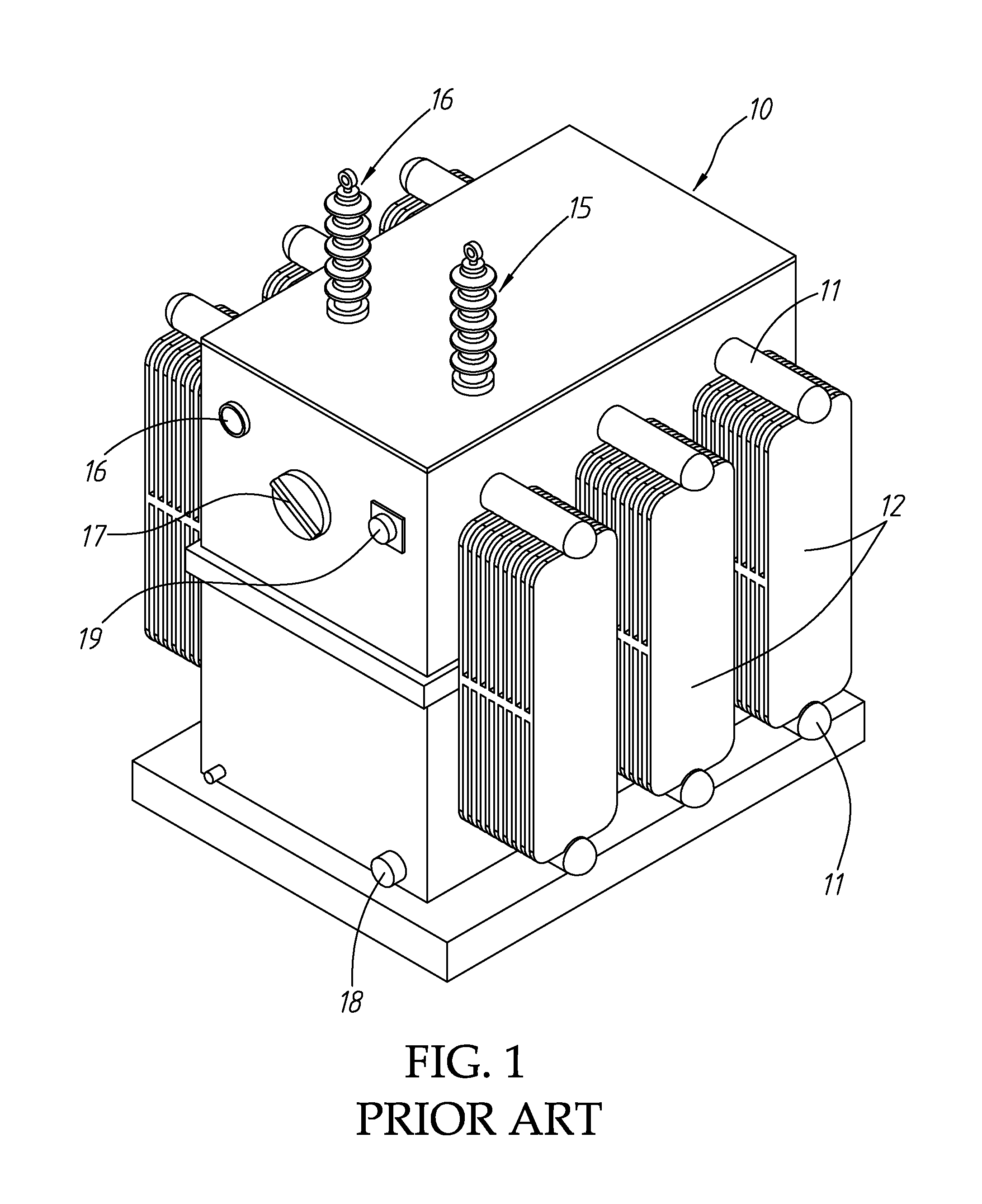

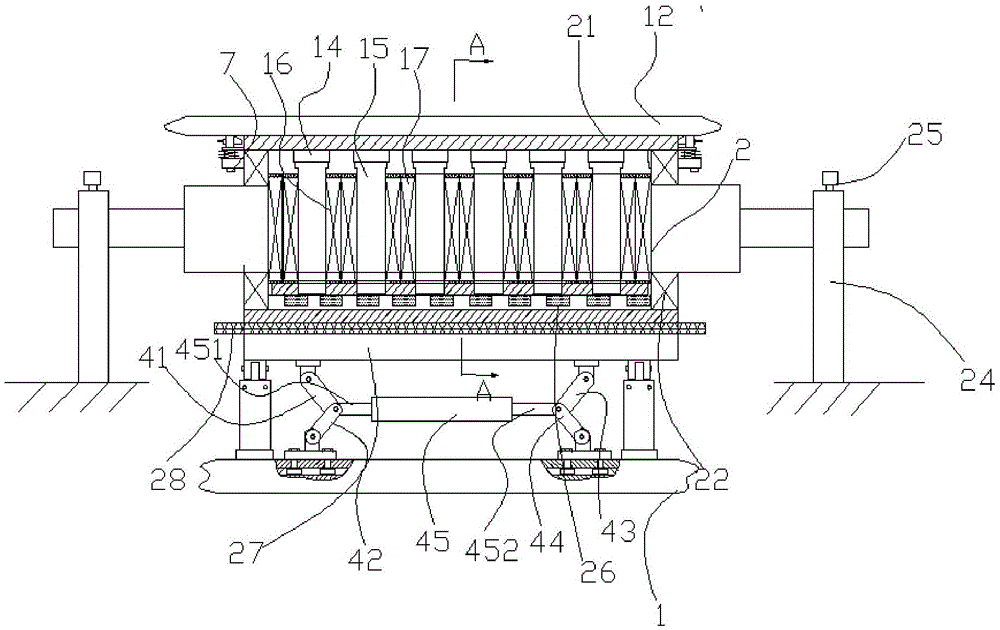

Dry type economizer

ActiveUS20150084728A1Eliminate useAvoid componentsTransformers/reacts mounting/support/suspensionTransformers/inductances coolingAtmospheric airEngineering

A dry type economizer includes an economizing unit formed of a plurality of bodies, each body including a silicon-steel layer, an insulating layer surrounding the silicon-steel layer, a plurality of windings surrounding the insulating layer, and reactance elements and reactance filter converters respectively electrically connected to the windings, each winding being formed of a wire material having an increased wire diameter larger than a standard wire diameter of 3.5 mm. Thus, each body eliminates the use of any insulating oil, and has an increased volume to provide a large surface area in contact with the atmosphere for quick dissipation of heat during operation of the reactance elements.

Owner:SHUN FU TECH

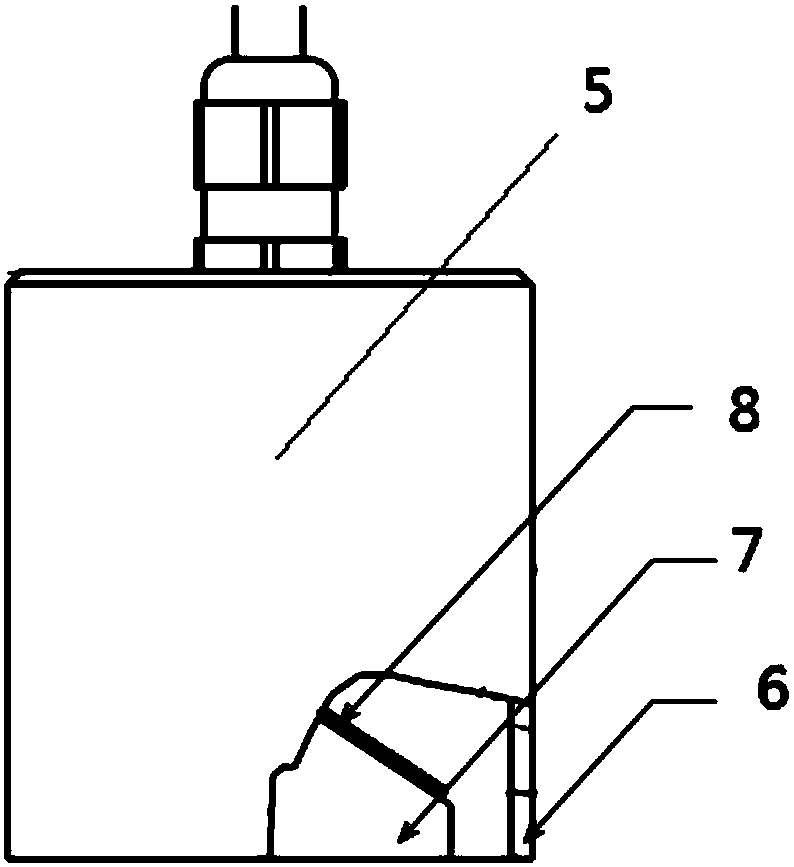

Phased array probe for automatic ultrasonic detection

PendingCN108020597AQuick changeGuaranteed wear resistanceMaterial analysis using sonic/ultrasonic/infrasonic wavesWaferingUltrasonic testing

The invention relates to the technical field of automatic ultrasonic detection of nuclear power plant equipment, and specifically discloses a phased array probe for automatic ultrasonic detection. Thephased array probe comprises a shell, a wedge block and probe wafers, wherein a plurality of the probe wafers and the wedge block are cured, and the cured product is integrally assembled into the stainless steel shell, such that the scanning surface of the wedge block is flush with the edge of the shell. According to the present invention, the electric cable connection of the phased array probe uses the segmented structure, such that the rapid and waterproof replacement of the phased array probe in the radioactive environment is achieved without the replacement of the electric cable; the total length of the electric cable is more than or equal to 40 m, such that the remote ultrasonic detection can be achieved; and the probe uses the wedge block built-in type integral structure, and the shell is made of the stainless steel material, such that the probe and the wedge block are protected from wear, the wear resistance and the radiation resistance of the probe are improved, and the structure integrity of the probe is ensured.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

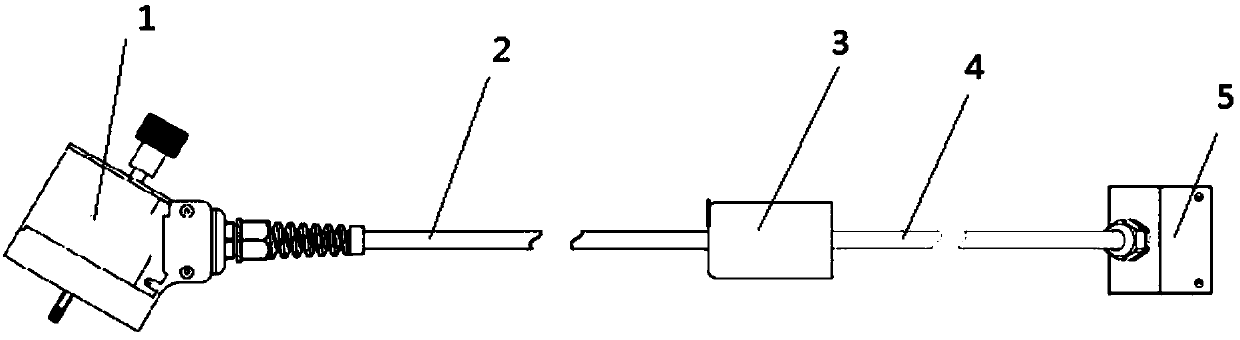

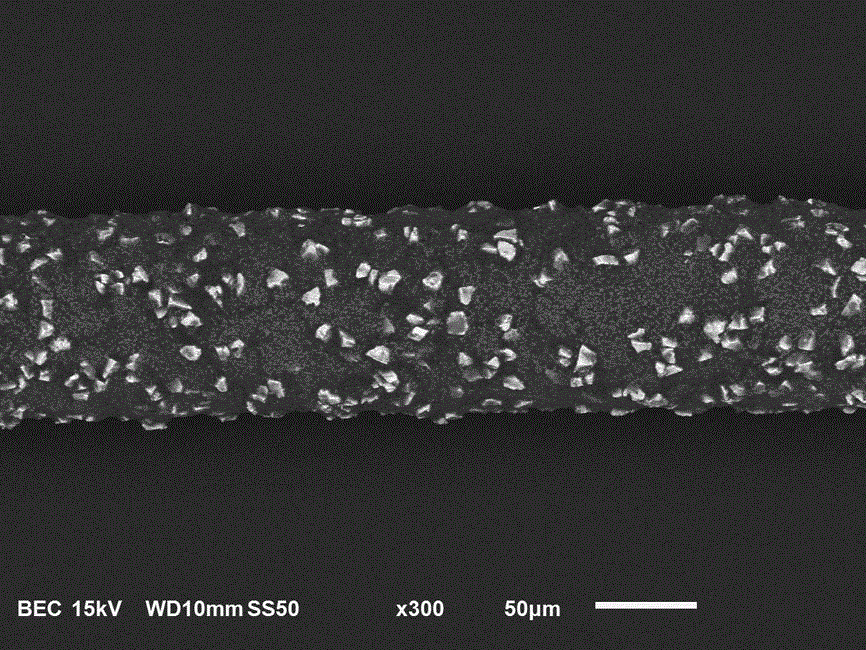

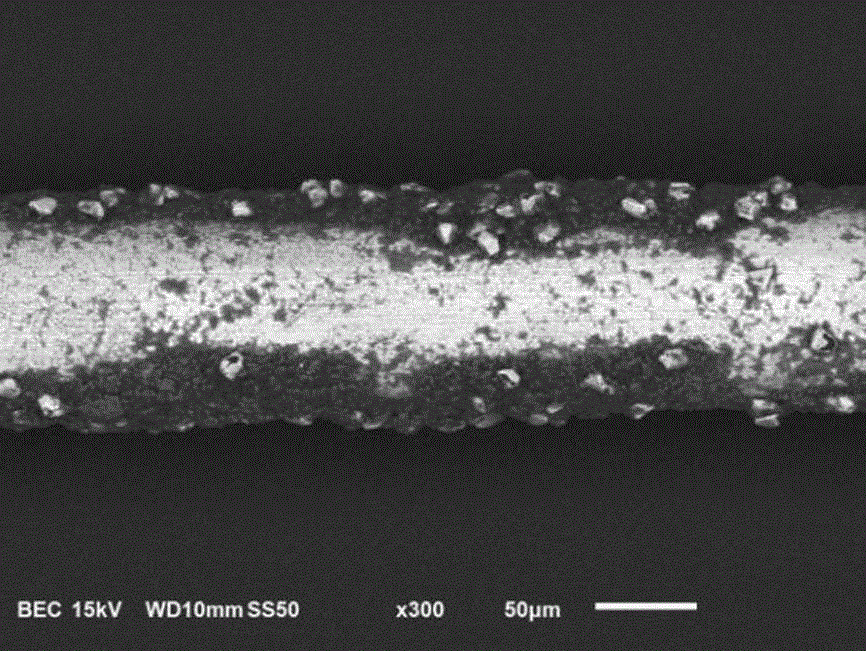

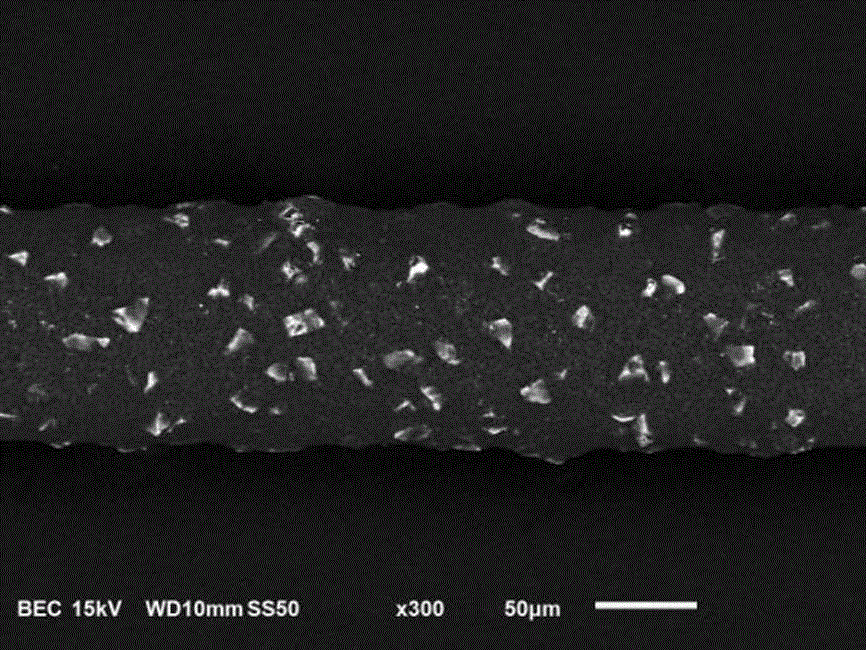

Production method of continuous long-distance resin diamond wire saw

InactiveCN106826597AIncrease in the number of controlsIncrease wire diameterAbrasion apparatusGrinding devicesLiquid viscosityDiamond wire saw

The invention discloses a production method of a continuous long-distance resin diamond wire saw, which comprises the steps of raw material selection, resin mixture preparation, core wire treatment, wire preparation, pre-curing, secondary curing and the like. The present invention effectively controls the final stage of line production by selecting thermoplastic resins and thermosetting resins with molecular weights within a suitable range; selecting suitable fillers, coupling agents, polymerization inhibitors, and dispersants; and controlling the appropriate initial viscosity of the resin mixture. The increase in the viscosity of the mixed liquid can effectively prevent the diameter of the diamond wire saw from becoming larger in the later stage of wire production, avoid the problem of local light caused by the gel particles of the mixed liquid blocking the drawing die, control the increase in the number of diamond micropowders, and ensure the quality of the product consistency. Ultimately solve the key technical problems in the continuous long-distance production of more than 70km.

Owner:HENAN XINDAXIN SCI & TECH

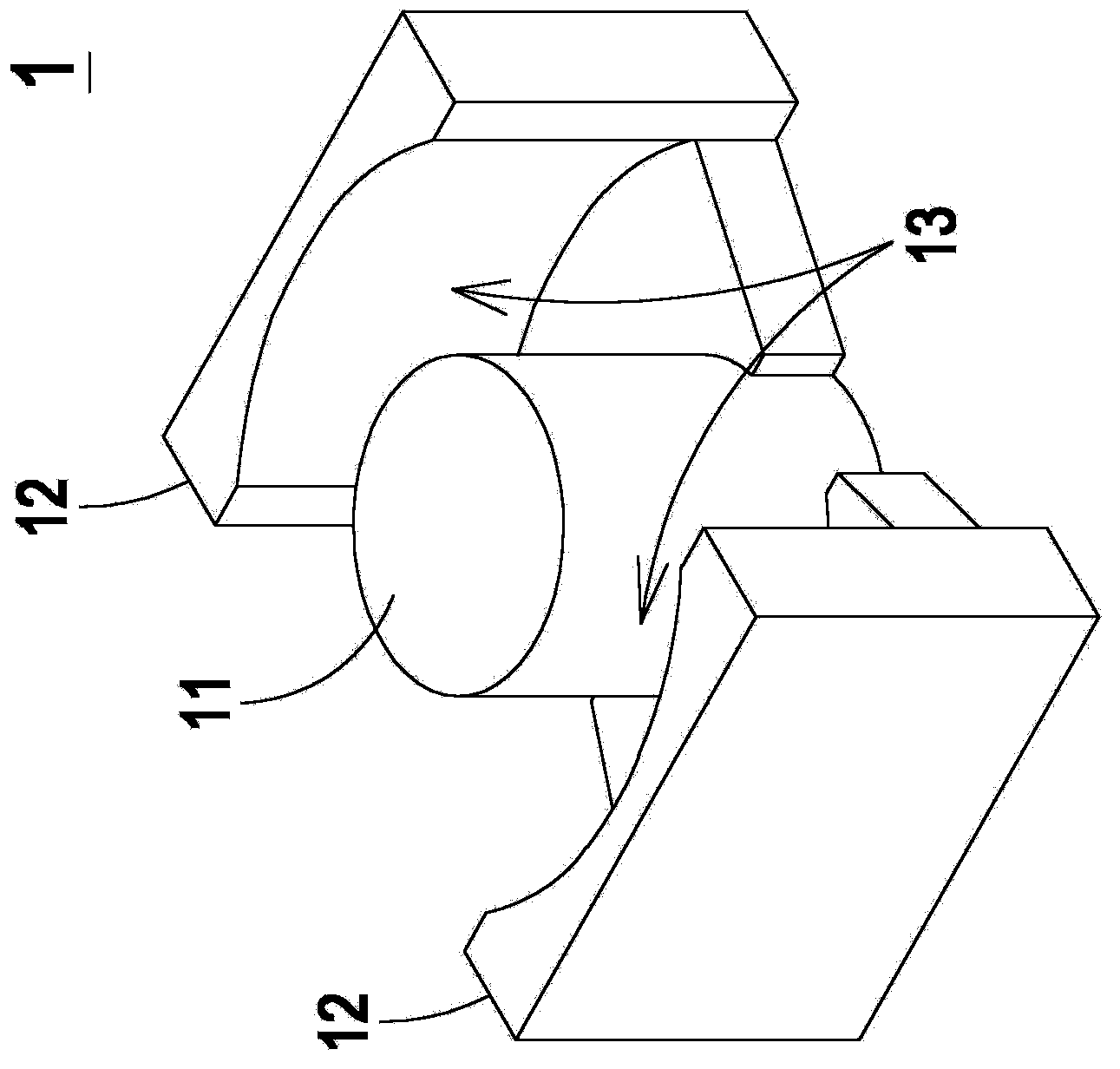

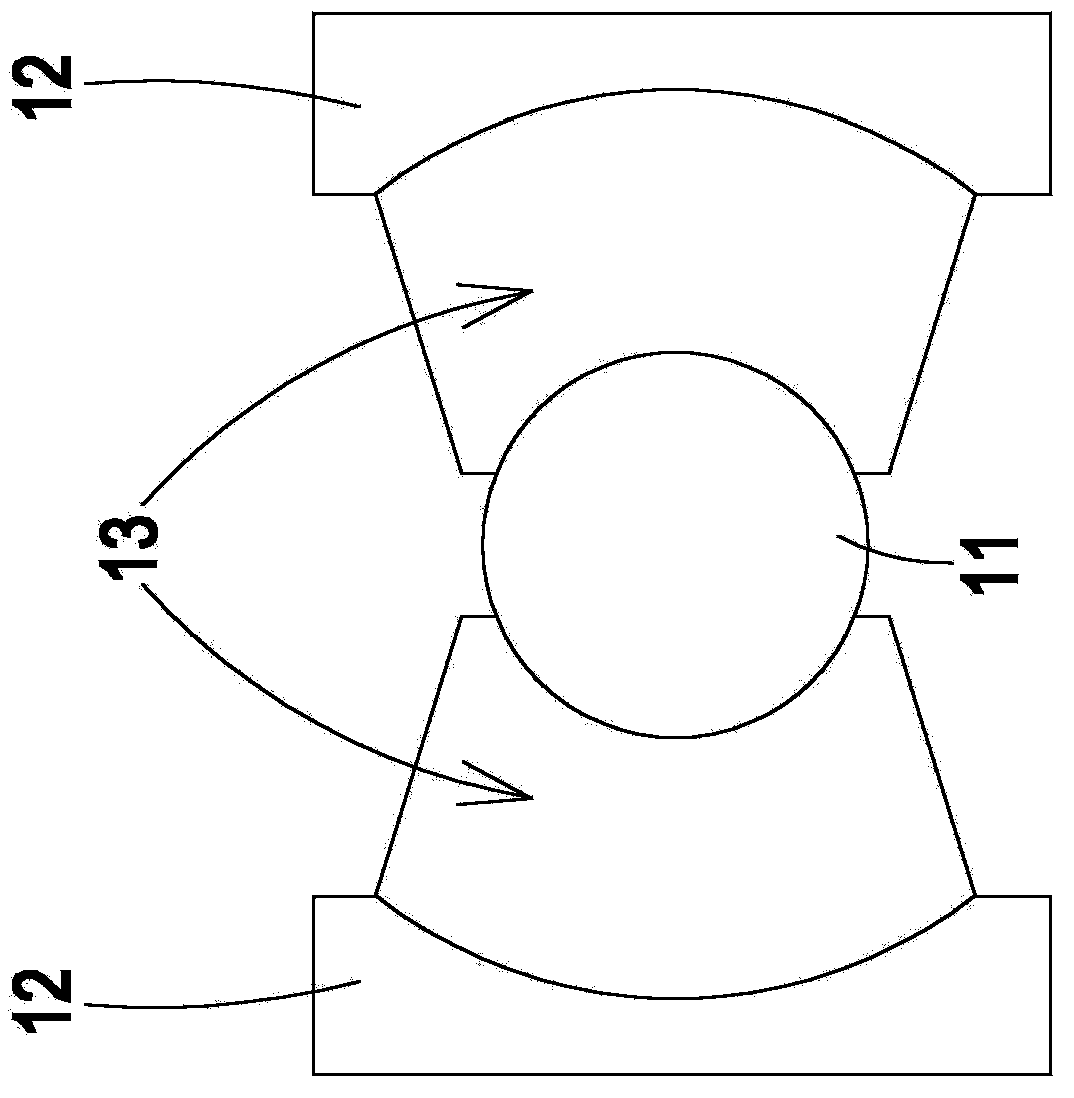

Magnetic core and applicable magnetic element of magnetic core

InactiveCN104252951ASmall diameterSave space for windingTransformers/inductances magnetic coresInductance with magnetic coreLong axisSafety specification

The invention discloses a magnetic core and an applicable magnetic element of the magnetic core. The magnetic core at least comprises an oval center post and two side posts, wherein the oval center post is provided with a long shaft and a short shaft; the length of the long shaft is greater than that of the short shaft; the two side posts are oppositely arranged at two sides of the oval center post, are connected with the oval center post, and define at least one winding space together with the oval center post. Through the arrangement of the oval center post, the magnetic core has the advantages that the winding space is enlarged, the diameter of a wining coil is increased, the temperature of a winding solenoid is lowered, the winding solenoid is prevented from being oversize, and the safety distance between the winding solenoid and a reel is increased to accord with the safety specification.

Owner:DELTA ELECTRONICS INC

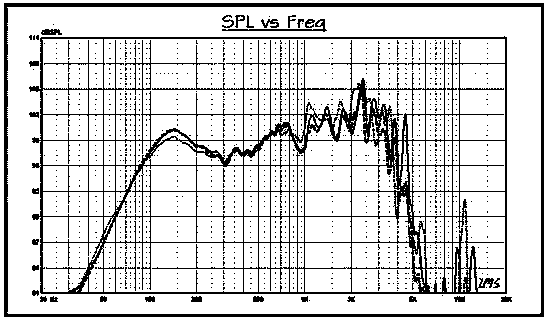

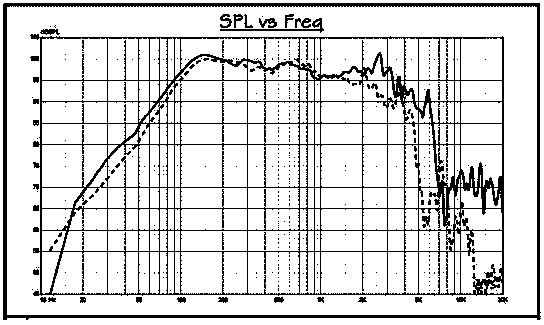

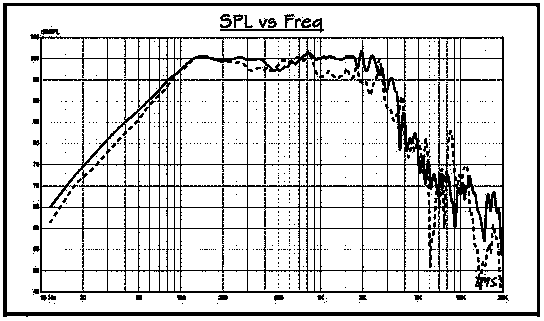

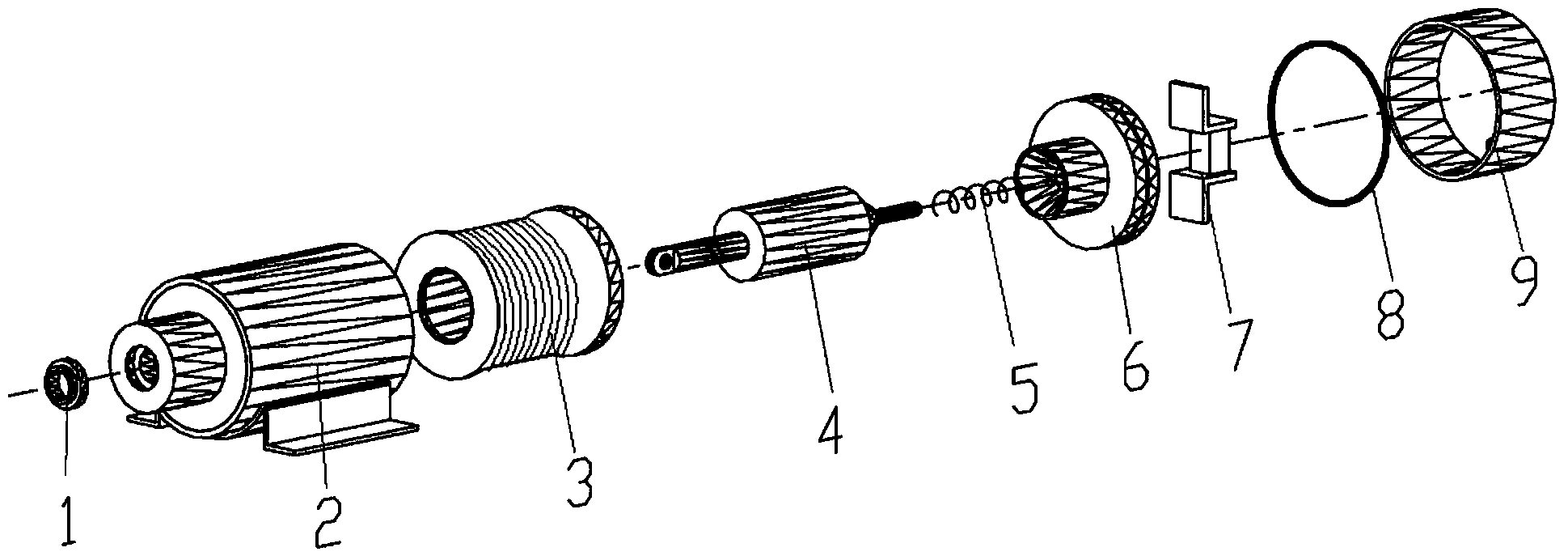

Ultra-long magnetic field moving-coil speaker

InactiveCN104219606AIncrease the lengthIncrease volumeElectrical transducersRelative displacementPower flow

The invention discloses an ultra-long magnetic field moving-coil speaker comprising a frame, a magnetic circuit system and a vibrating system. The magnetic circuit system comprises an upper clamp plate, a lower clamp plate, a core and a magnet; a magnetic gap forms between the inside of a center hole of the upper clamp plate and the outside of the upper end of the core; the vibrating system comprises a voice coil, a damper and a paper cone; the lower end of the voice coil is inserted into the magnetic gap; the voice coil is 1-32ohm in impedance; the diameter of the frame is defined as R, and the thickness of the upper clamp plate is defined as H; the diameter R of the frame and the thickness H of the upper clamp plate meet the specific conditions. The ultra-long magnetic field moving-coil speaker has the advantages that the greater length of the magnetic cap ensures that the diameter of the voice coil needs to be increased on the premise of ensuring impedance uniformity, the length of a conductor of the voice coil in the magnetic field is increased as the diameter of the voice coil is increased, the longer a coil winding in the magnetic field, the higher the kinetic energy produced by the injected audio current of the magnetic circuit system, cutting magnetic lines of force, and the higher the efficiency; the length of the magnetic cap is increased, relative displacement ratio of the voice coil in the magnetic field is decreased, and distortion can be effectively decreased.

Owner:NINGBO SOUNDKING ELECTRONICS

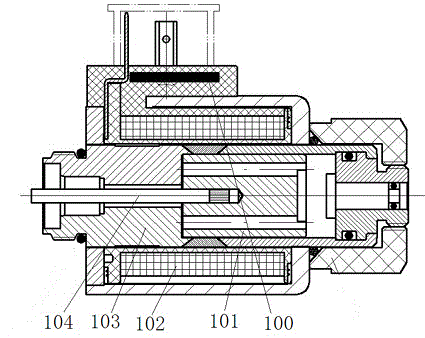

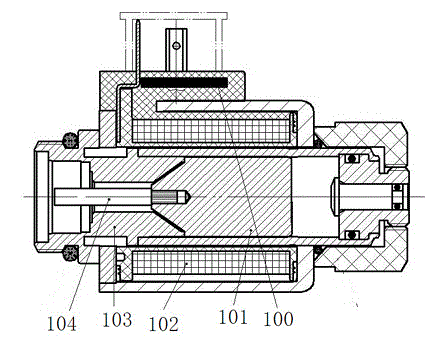

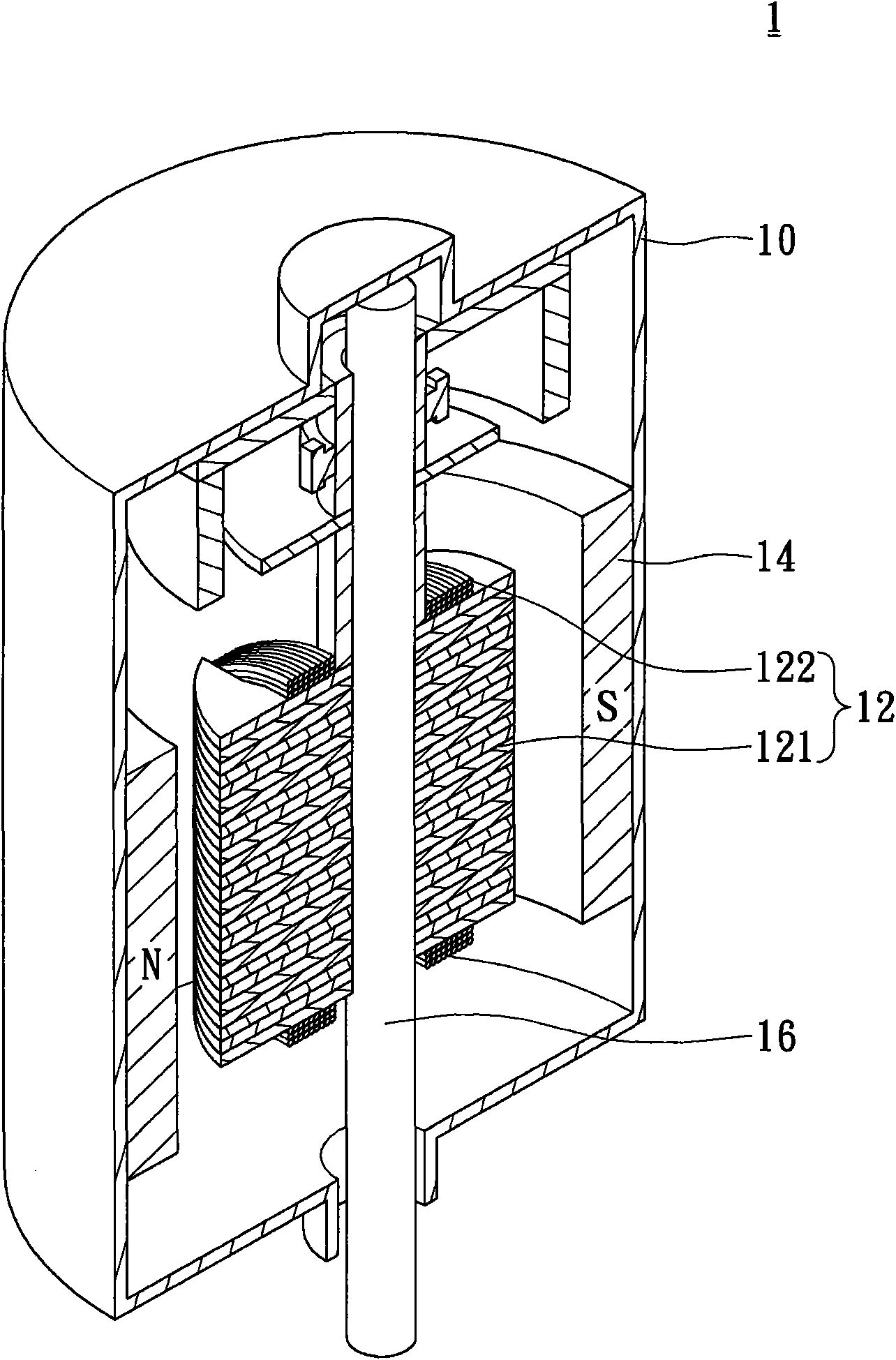

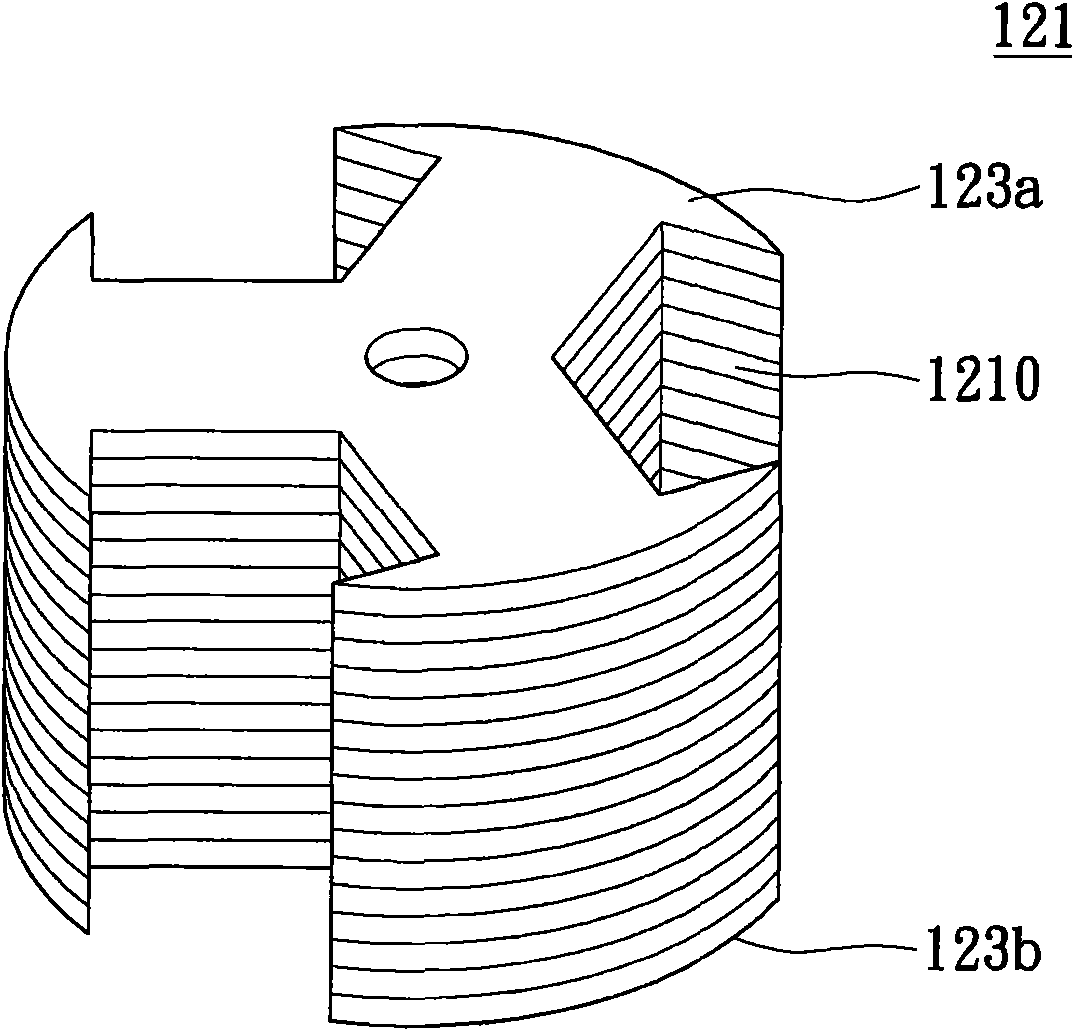

Motor device

InactiveCN102255409AIncrease torqueIncrease speedMagnetic circuit rotating partsMagnetic energyConductor Coil

The invention discloses a motor device, comprising a stator part and a rotor part, wherein the rotor part is arranged in an inner ring of the stator part; magnetic action is generated between the rotor part and the stator part so that the rotor part rotates in the inner ring of the stator part; the rotor part comprises a rotor iron core; the rotor iron core is integrally formed from magnetic powder through a powder metallurgy process; the magnetic powder is a soft magnetic material with a core-shell structure; and the soft magnetic material comprises a core main body for supplying magnetic force and a shell layer for supplying connection intensity. According to the motor device disclosed by the invention, the rotor part is structurally improved; therefore, the rotor part is not influenced by a coil; the winding turn number or wire diameter can be increased; the motor torque and rotation speed can be increased; the magnetic energy loss can be reduced effectively; on the premise of having the same unit output power, the size of the motor is reduced; and the design concept of the traditional motor rotor is broken through.

Owner:CHESHIRE ELECTRIC COMPANY

Magnetic table of rotary screen printing machine

InactiveCN105584199AReduce consumptionReduce coefficient of frictionScreen printersScreen printingEngineering

The invention discloses a magnetic table of a rotary screen printing machine. The magnetic table comprises a tank, a roller, a magnetic table top and a magnetic table base. A plurality of iron core holes are formed in the magnetic table top. An iron core is inserted in each iron core hole in the tank. Each iron core is sleeved with a frame, a coil is wound on each frame, a permanent magnet is arranged on the bottom face of the tank, the two ends of the tank are connected to a support through positioning screws, and the support is fixed to the bottom face. The tank is sleeved with the roller through bearings, the wall of the roller is located between the permanent magnet and a magnetic bar, and the outer wall of the roller makes contact with a printing guide belt. The permanent magnet is fixed to the bottom face of the magnet base with the position capable of being adjusted in the circumferential direction. The magnet base is sleeved with the roller through the bearings, so that on the premise that the permanent magnet and the magnetic bar attract each other, rolling friction is achieved through the roller and the printing guide belt, the friction coefficient between the roller and the printing guide belt is reduced, abrasion is reduced, production efficiency is improved, and energy consumption is reduced.

Owner:HUNAN JICHANG SILK

Preparation process of special aluminum electrolytic capacitor for electric vehicle controller

PendingCN113593916AImprove nailing effectReduce feverLiquid electrolytic capacitorsWinding capacitor machinesAutomotive engineeringCapacitance

The invention discloses a preparation process of a special aluminum electrolytic capacitor for an electric vehicle controller, and aims to solve the technical problems that the service life of the electric vehicle controller is greatly restricted and the reliability of the electric vehicle controller is greatly reduced due to the fact that the magnitude of current borne by the aluminum electrolytic capacitor used by the existing electric vehicle controller is relatively common. The process roughly comprises the following steps of: nailing positive and negative aluminum foils to a leading-out wire, pasting a negative electrode pad foil at a negative electrode riveting position through a nailing machine, and winding a core package by intermediate pad electrolytic paper on an automatic winding machine; placing the core package in a high-temperature drying box to be dried, then taking out the core package and placing in electrolyte, and soaking the core package in the electrolyte in a vacuumizing and air pressurization mode; packaging the core package absorbed with the electrolyte by using an aluminum shell and a rubber sealing plug; and sleeving the packaged naked capacitor with an outer sheath sleeve with insulation and protection effects, and arranging the packaged naked capacitor in parallel according to positive and negative polarities for charging repair to obtain the aluminum electrolytic capacitor.

Owner:安远秦旭科技有限公司

Method using slicing machine to cut high-standard seed crystal of ingot

InactiveCN103921362AReduce chippingIncrease wire diameterFine working devicesCrystallographyMetallurgy

The invention discloses a method using a slicing machine to cut a high-standard seed crystal of an ingot. The method comprises the step one of bonding a raw material bar of the seed crystal to be cut on a resin plate, the step two of placing the bonded raw material bar into the slicing machine to be cut, the step three of carrying out debonding after cutting is finished, the step four of cleaning, the step five of drying and the step six of checking and packaging. According to the method, the slicing machine originally cutting a silicon chip with the thickness of about 0.2mm is utilized for cutting the high-standard seed crystal with the cutting thickness of 17mm.

Owner:NANTONG ZONGYI NEW MATERIAL

Ferrite core and transformer using the same

InactiveCN101640112AExempt from shieldingLow costTransformers/inductances coils/windings/connectionsBobbinSplit lines

A ferrite core includes an end face portion, a pair of outer legs protruding from the end face portion, and a center leg protruding from the end face portion between the pair of outer legs. A width W1close to one end portion of the center leg in a Y-axis direction perpendicular to a facing direction of the outer legs is smaller than a width W2 close to the other end portion. According to this configuration, a circuit component may be positioned close to the end portion. A transformer includes the ferrite core. And a coil frame for the transformer includes a cylindrical bobbin; wherein the division line based on any direction and position divides the cross section vertical to the coiling direction of at least the chamber and the periphery into two areas which are unsymmetrical.

Owner:TDK CORPARATION

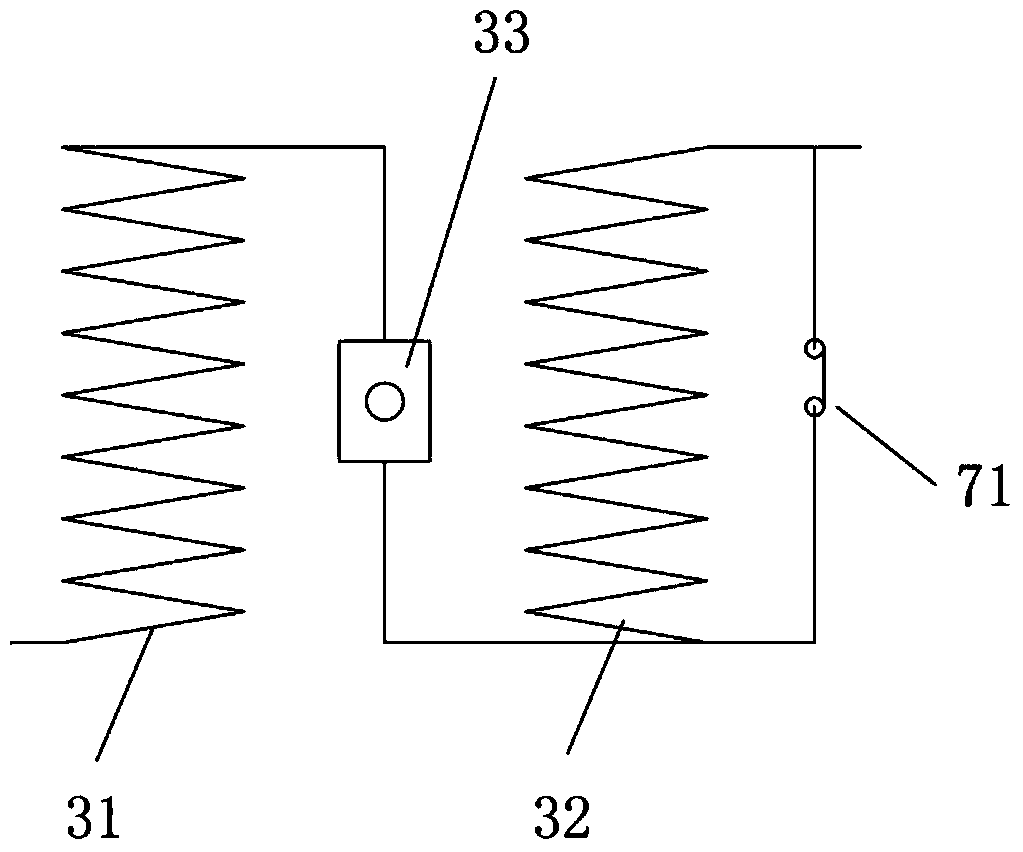

Direct current electromagnet

InactiveCN103811146AIncrease the number of turnsIncrease working tensionElectromagnets without armaturesCoilsPull forceDirect current

The invention provides a direct current electromagnet which comprises a coil, an iron core arranged in the coil in a sleeved mode, a reset spring arranged at one end of the iron core in a sleeved mode and a limiting backseat. The coil, the iron core, the reset spring and the limiting backseat are arranged coaxially. The direct current electromagnet is characterized in that the direct current electromagnet further comprises a closed shell and a relay switch, the coil comprises a first coil body and a second coil body, normal close contacts of the relay switch are connected to the two ends of the second coil body, and the first coil body and the second coil body are connected through a heat protector. According to the direct current electromagnet, the two coil bodies are adopted so that the direct current electromagnet can work continuously for a long time and large operation tensile force can be provided; the two coil bodies are connected through the heat protector so that the direct current electromagnet can work safely in the high-temperature operation environment for a long time; the closed shell is adopted so that the strength and the waterproof performance of the direct current electromagnet can be guaranteed and the direct current electromagnet can work in the humid environment for a long time.

Owner:SHANGHAI KUKAI REFRIGERATION EQUIP

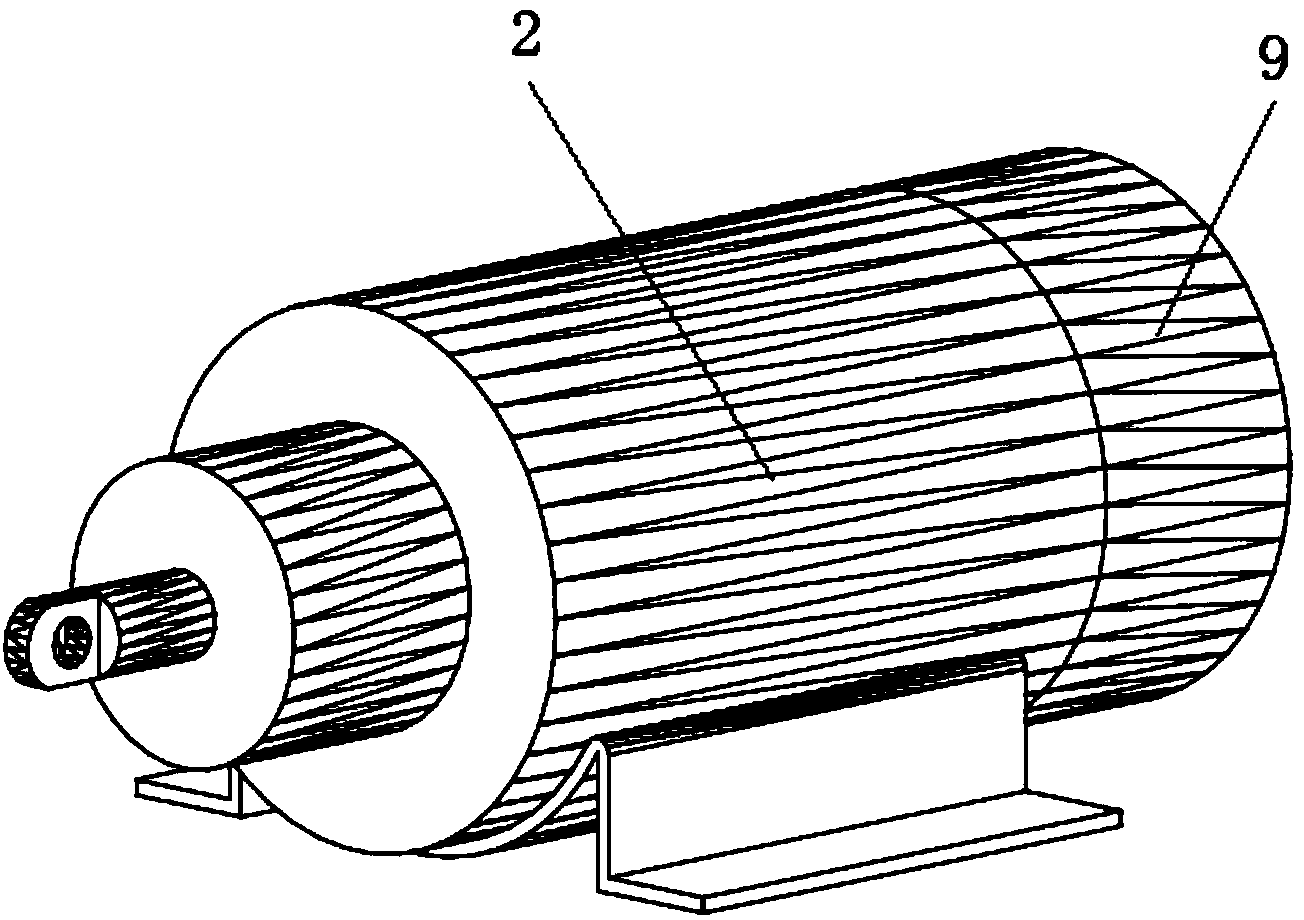

Variable-current variable-speed non-commutated permanent magnet direct current motor

PendingCN108322001ASmall frictional resistanceExtended service lifeMagnetic circuit rotating partsElectric machinesElectric vehicleDynamo

The invention discloses a variable-current variable-speed non-commutated permanent magnet direct current motor, belongs to the field of direct current motors, and solves the problem that the existingdirect current motor consumes a lot of electric energy so as to overcome a magnetic pull of a permanent magnet stator to a rotor. The variable-current variable-speed non-commutated permanent magnet direct current motor comprises a pedestal, a coil inner rotor, a permanent magnet inner stator, a coil outer rotor and a permanent magnet outer stator, and further comprises a rotor shaft, rotor shaft supports, a rotor shaft magnetic levitation inner sleeve, a rotor shaft magnetic levitation outer sleeve, a support magnetic levitation inner sleeve and a support magnetic levitation outer sleeve, wherein the two ends of the rotor shaft are arranged inside support bearings of the two rotor shaft supports; the rotor shaft is tightly sleeved inside the inner cavity of the coil inner rotor; the rotorshaft magnetic levitation inner sleeve is sleeved inside external-diameter openings of the two ends of the coil inner rotor; the rotor shaft magnetic levitation outer sleeve is tightly sleeved insideinternal-diameter openings of the two ends of the permanent magnet inner stator. A high-power ultrahigh-speed permanent magnet direct current motor or generator can be manufactured as required; the variable-current variable-speed non-commutated permanent magnet direct current motor is applicable to the field, which needs power or power generation, of electric vehicles, industrial and mining enterprises and the like.

Owner:甘肃永动电子科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com