Phased array probe for automatic ultrasonic detection

A phased array probe and ultrasonic testing technology, applied in the field of phased array probes, can solve problems such as unsatisfactory, unable to meet the requirements of wear resistance and radiation resistance, and easy to be worn, so as to improve wear resistance and resistance Irradiation, improve anti-interference, reduce the effect of the number of cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

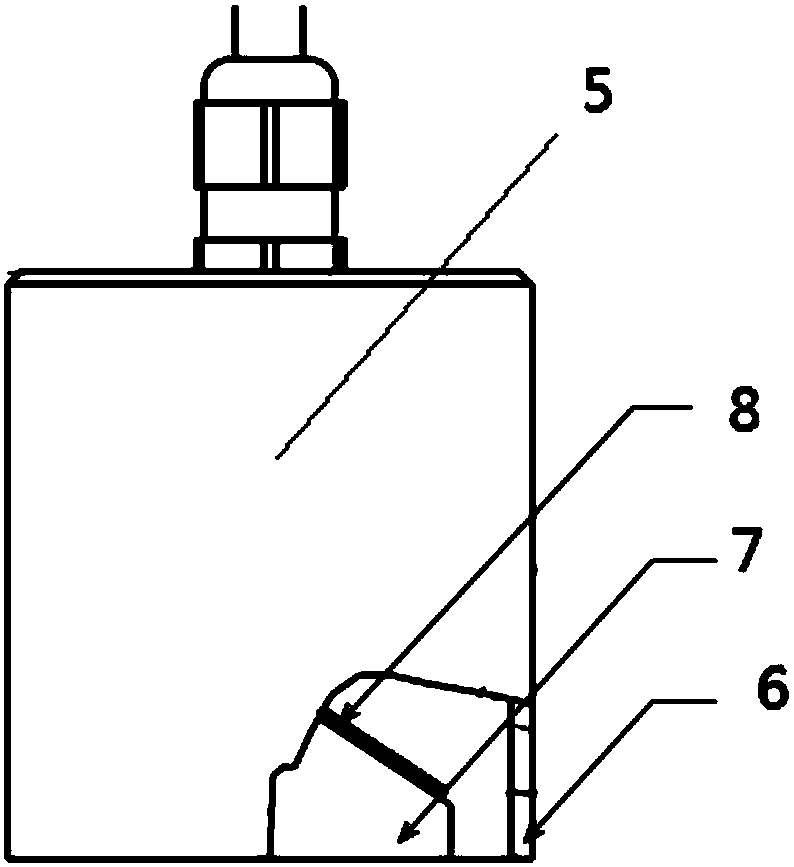

[0020] like figure 1 As shown, a phased array probe 5 for automatic ultrasonic testing includes a housing 6, a wedge 7 and a probe wafer 8, and several probe wafers 8 and wedges 7 are solidified and assembled into a housing 6 made of 0Cr18Ni9Ti stainless steel. , where 20 probe chips 8 with a width of 30mm and the wedge angle θ 1 =36.2 o The wedge 7 is fixed in the shell 6 as a whole, and the scanning surface of the wedge 7 is flush with the edge of the shell 6. The shell 6 is an integral structure, the shell wall thickness is ≥ 1mm, and the edge of the shell 6 forms an arc chamfer. .

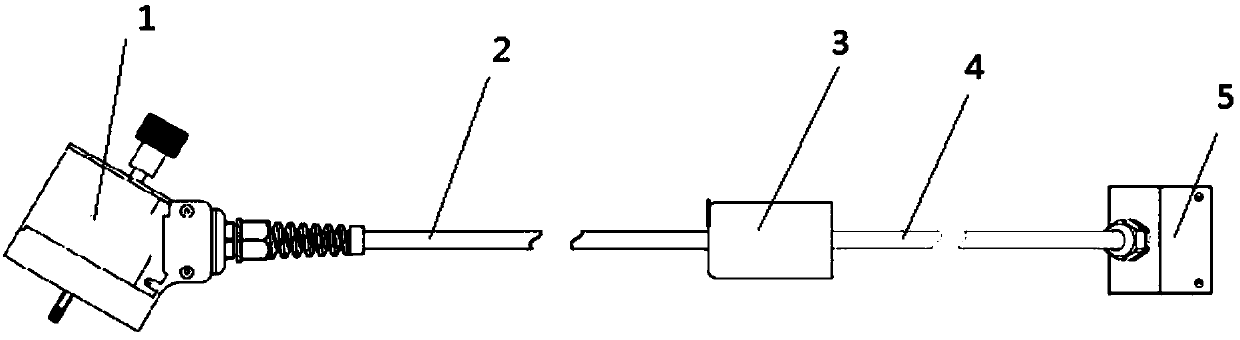

[0021] like figure 2 As shown, a phased array probe connection structure for automatic ultrasonic testing includes a tester connector 1, a cable A2, a waterproof adapter 3, a cable B4 and a phased array probe 5, wherein the detection unit connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com