Method for reinforcing spoke structural strength of bicycle and motor vehicle

A technology for structural strength and bicycles, applied in bicycle accessories, transportation and packaging, etc., can solve the problems of inability to balance, limited lightweight achievements, and high processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

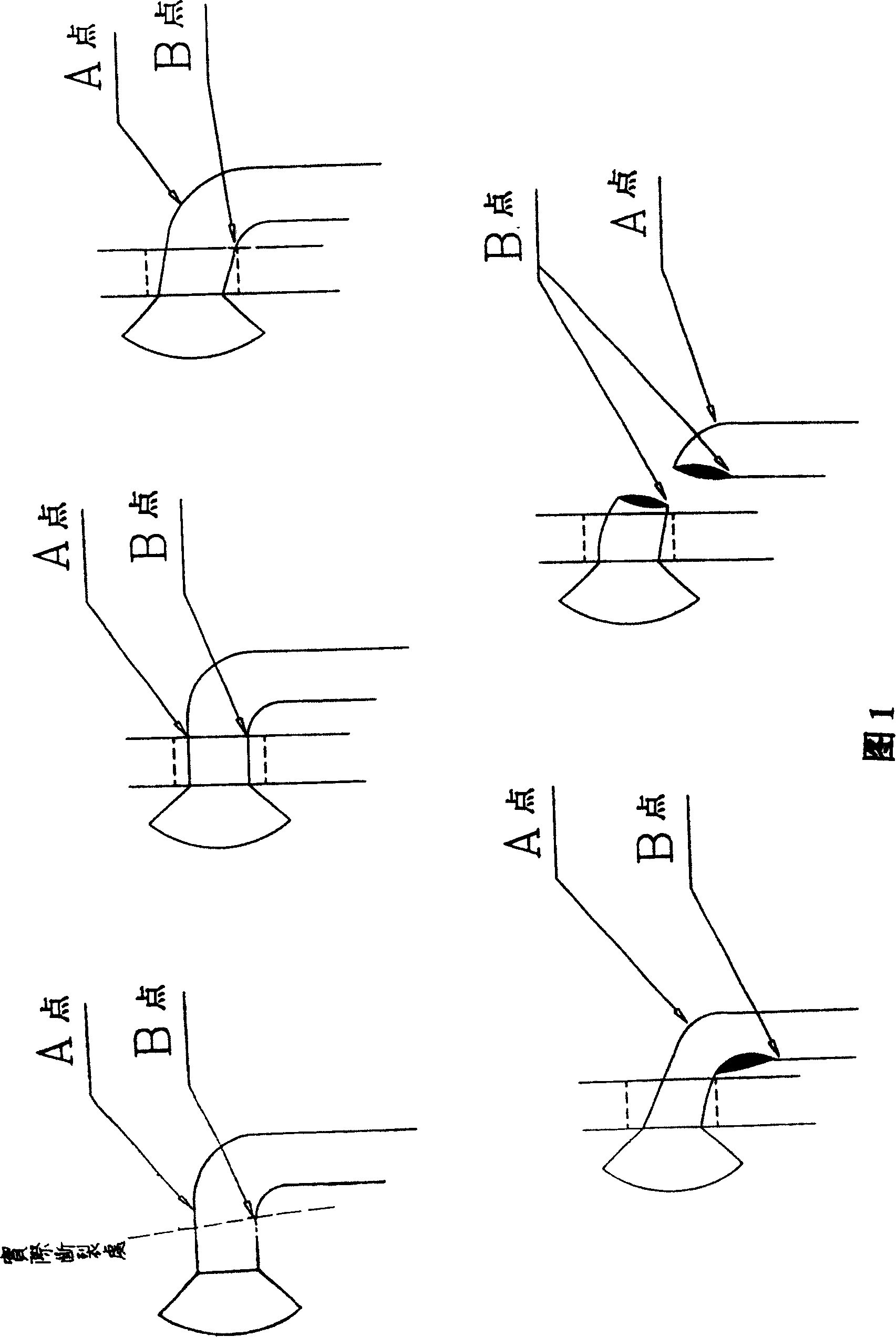

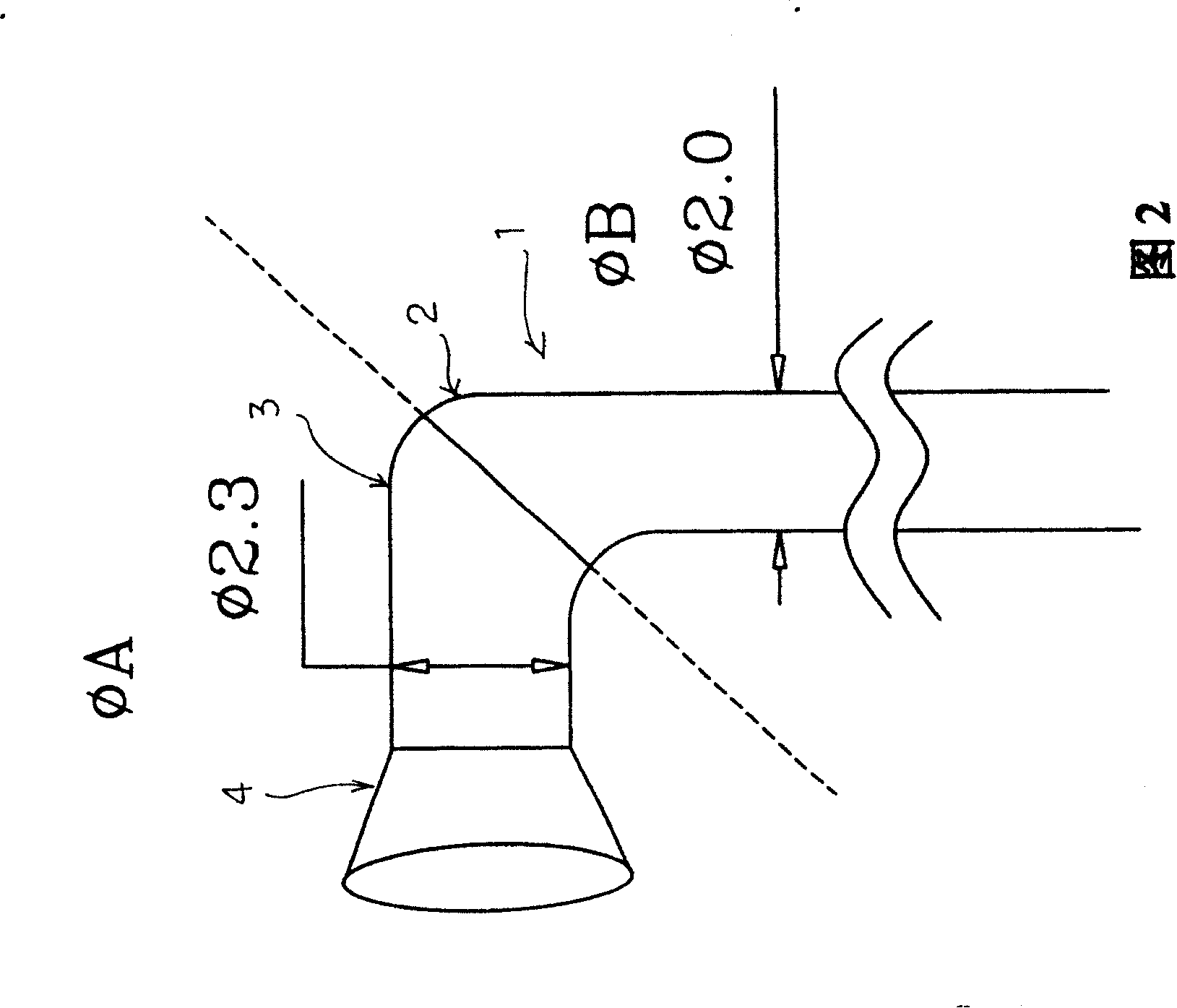

[0020] The present invention provides a method for strengthening the structural strength of the spokes of bicycles and motorcycles. The method adopts mechanical processing to improve the structural strength of the neck 3 and the bending part 2 of the spoke 1 body; The spokes after the inventive method processing are compared and explained:

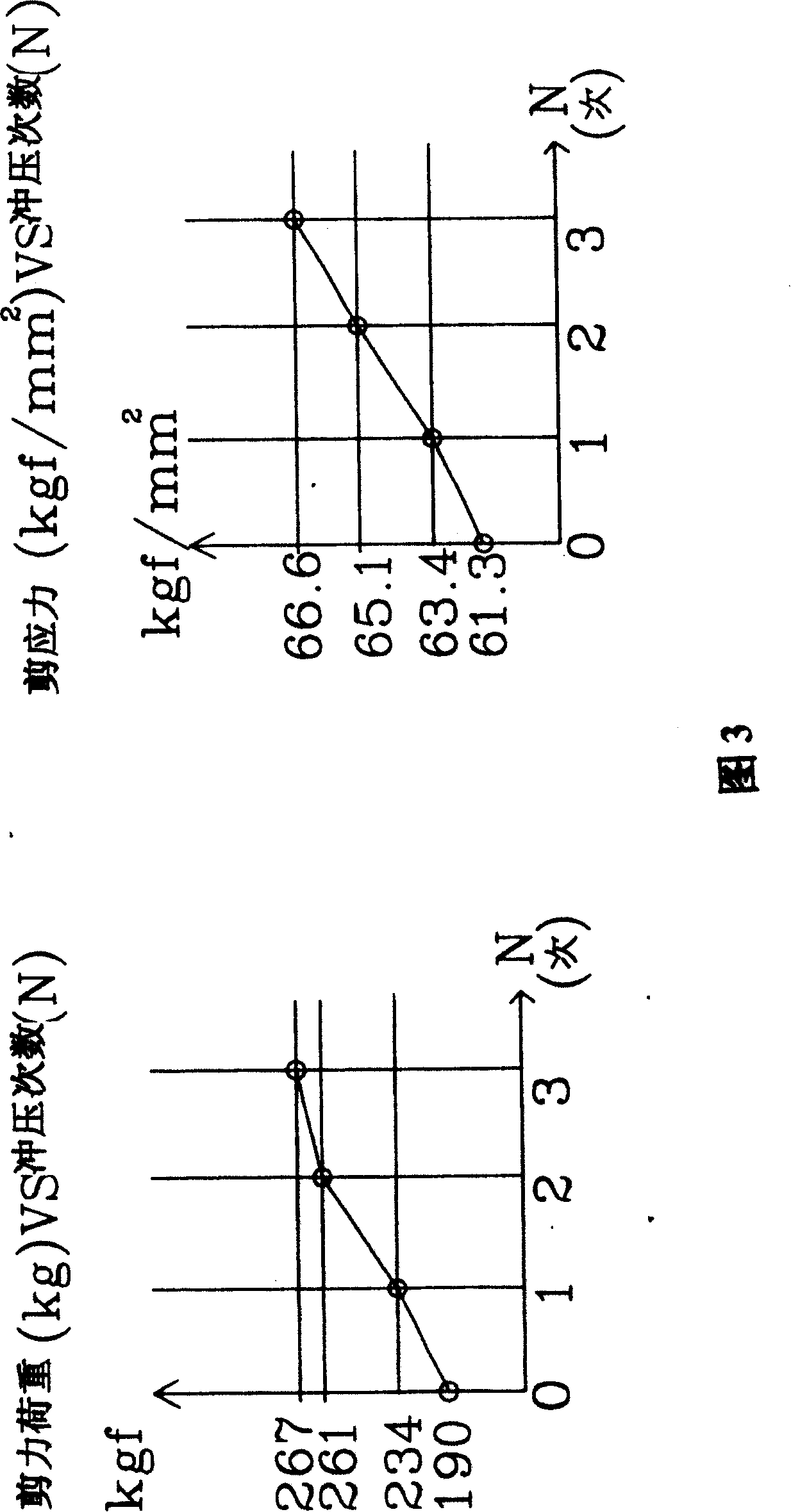

[0021] Taking the spoke body 1 made of stainless steel SS 304 by conventional technology as an example, the shear stress is about 60kgf / mm 2 , pulling force about 110kgf / mm 2 , therefore, if the wire diameter of the spoke is 2.0mm, then:

[0022] 1. The maximum tensile force that the spokes can withstand is

[0023] 110kgf / mm 2 ·[(2.0 / 2) 2 ·π]mm 2 =345kgf

[0024] 2. The maximum shear force that the spokes can withstand is (the actual spokes are not cut vertically, the section is approximately equal to 4.5~5.0)

[0025] 60kgf / mm 2 ·[4.5~5.0]mm 2 =270~300kgf

[0026] From the above calculation results, it can be seen that although...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com