Motor device

A technology of motors and magnets, applied in the field of DC motor devices, can solve the problems of affecting the rotating force and speed of the rotor core 121, increasing the cost of production and assembly, reducing the magnetic absorption effect of the magnet, achieving a breakthrough in design concepts, reducing magnetic energy loss, The effect of increasing the number of coils or wire diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

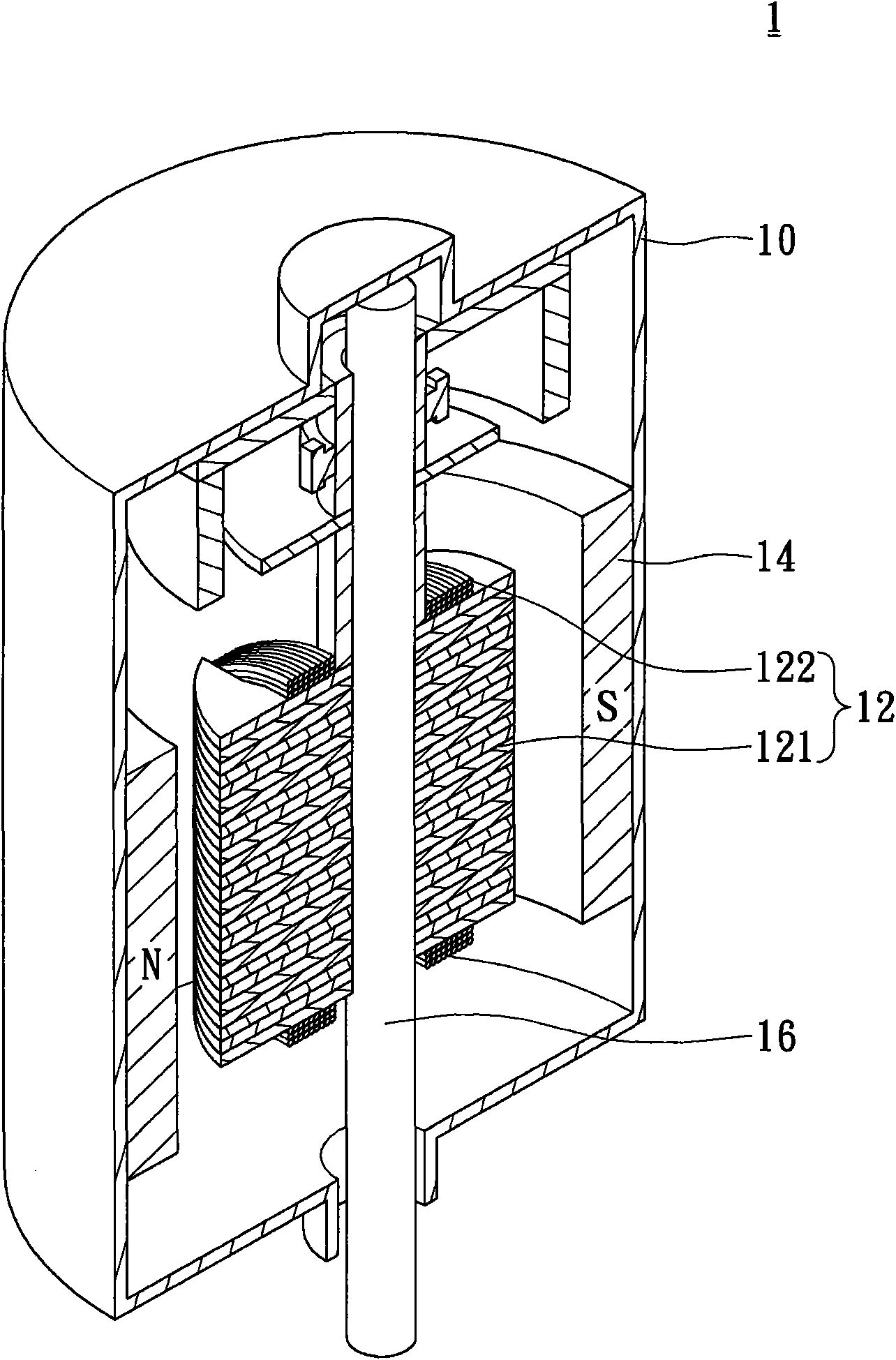

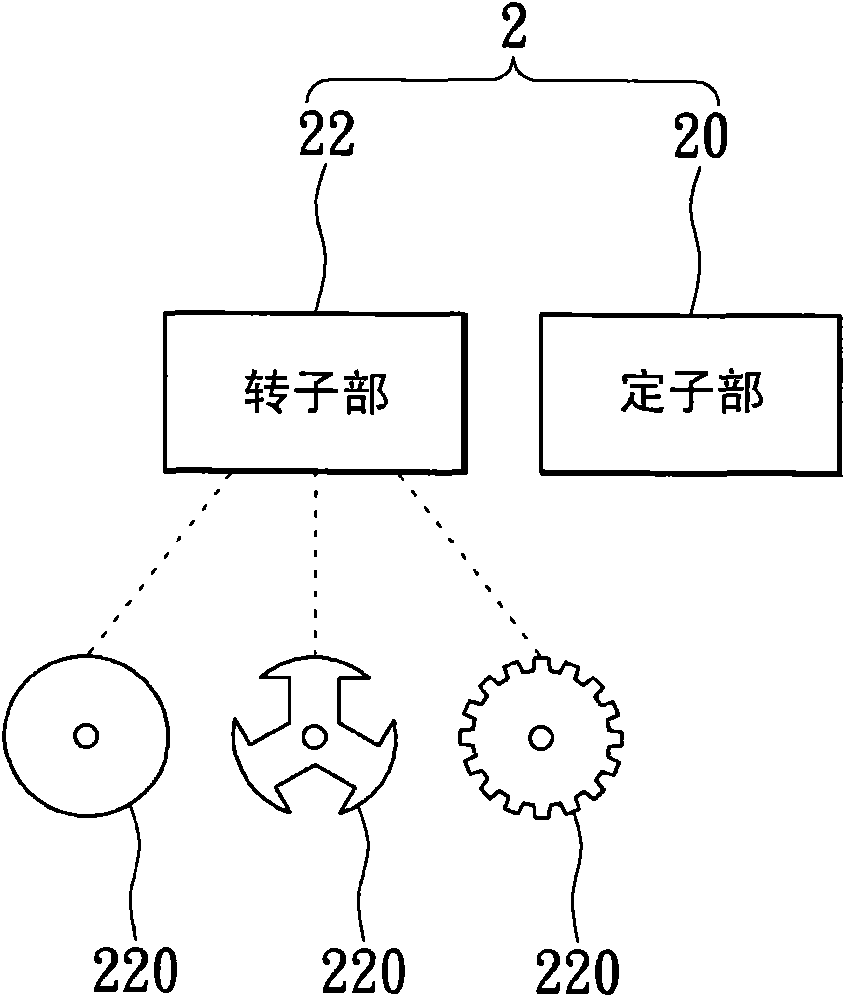

[0046] Please refer to image 3 . image 3 It is a structural schematic diagram of the motor device of the embodiment of the present invention. The motor device 2 of this embodiment includes a stator part 20 and a rotor part 22 . The structural design of the motor device 2 is that the rotor part 22 is arranged on the inner ring of the stator part 20. In this way, after the motor device 2 is energized, the rotor part 22 will interact magnetically with the stator part 20, and the inner ring of the stator part 20 Make a turn. In the foregoing cases, the motor device 2 may be a DC stepping motor, a DC series motor, a DC brushless motor or a DC brushed motor.

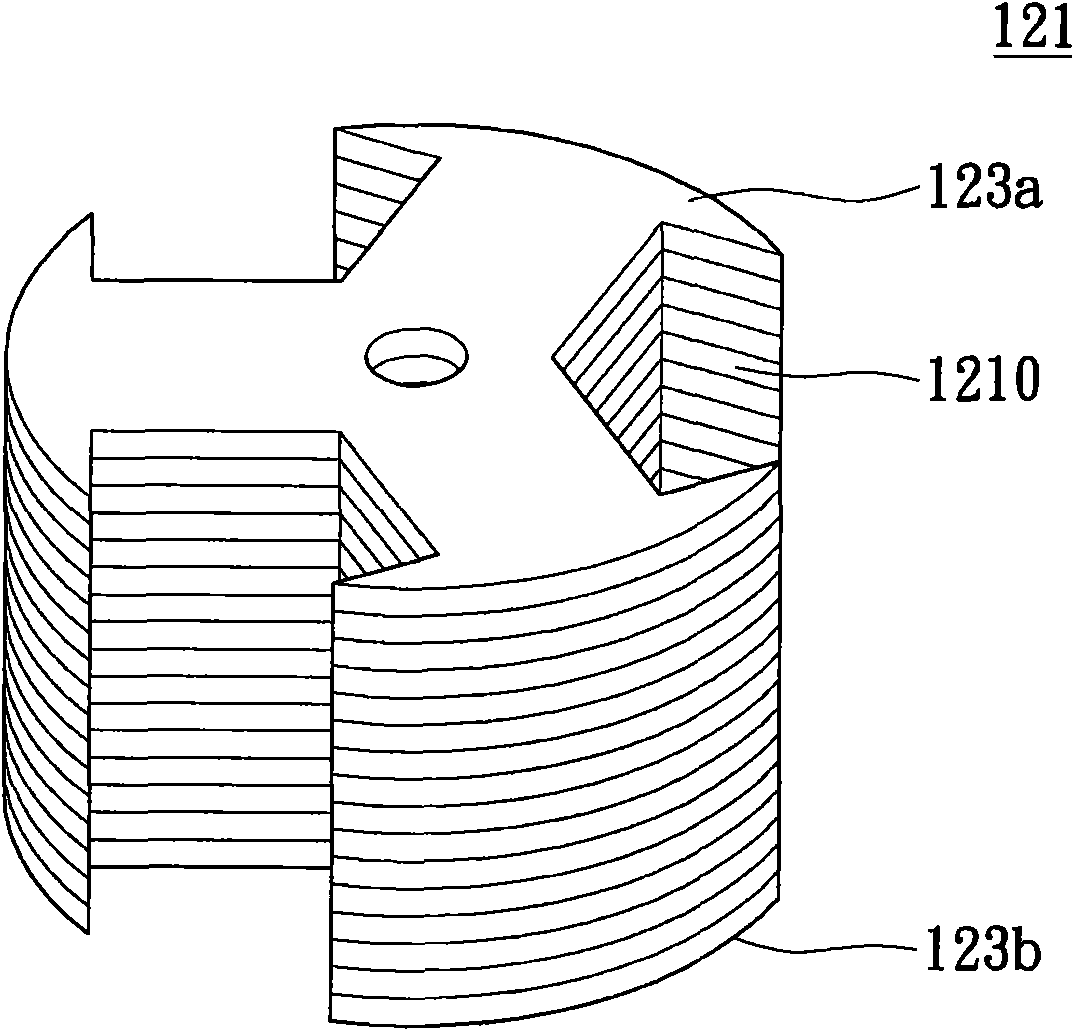

[0047] Refer again image 3 . The rotor part 22 includes a rotor core 220, and the appearance of the rotor iron core 220 can be designed as a cylindrical rotor iron core, a radial rotor iron core or a gear-shaped rotor iron core, however, the aforementioned various rotor iron core 220 shapes are embodiments of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com