Underwater connector capable of being plugged and unplugged wetly

A connector and wet plugging technology, applied in the field of electrical connector design, to achieve reliable water tightness and avoid the effect of losing electrons and being corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

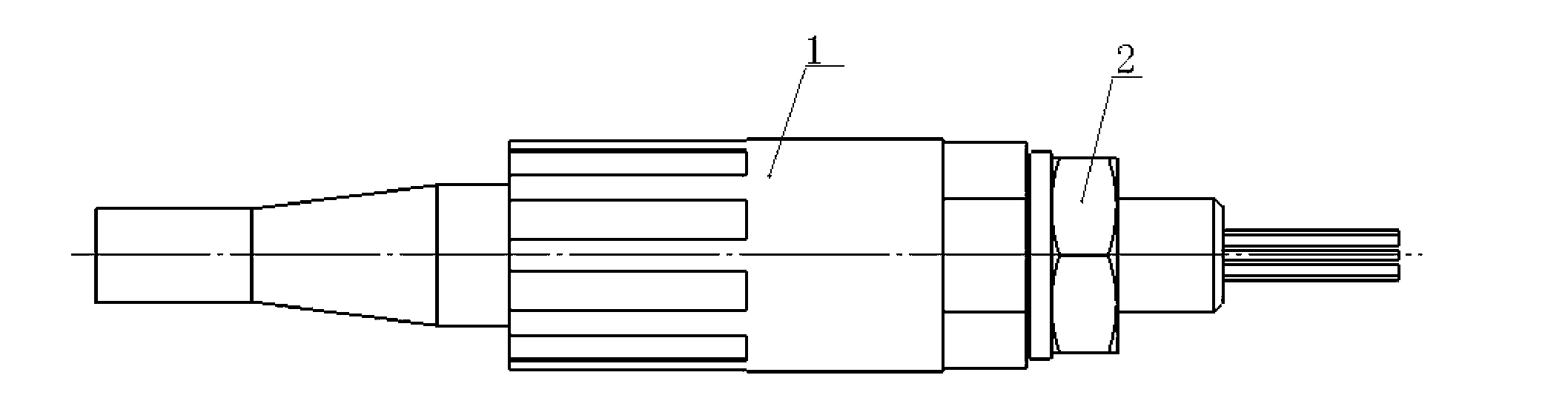

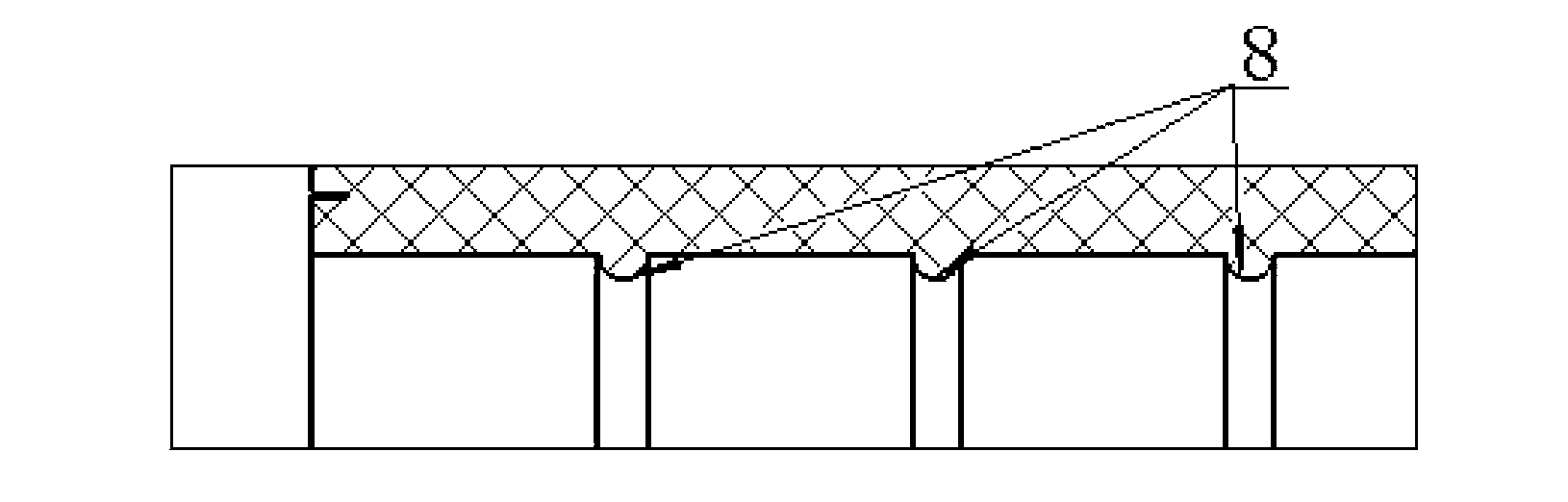

[0021] The wet-pluggable underwater connector in this embodiment includes a plug (1) and a socket (2), the plug (1) includes a jack (3), a connecting nut (10), and the socket ( 2) It includes pins (7), pin insulators (5), and socket housings (6), and the connecting nut (10) is connected and locked to the socket housing (6) through threads, wherein the pins (7) There are protruding cylindrical protrusions (4) on the surface, and sealing rings (8) are arranged in the holes that cooperate with the cylindrical protrusions (4) on the surface of the pins (7) in the sockets (3). (7) After mating with the socket (3), the sealing ring (8) is extruded on the cylindrical protrusion (4) on the surface of the pin (7) to realize the individual sealing function of a single contact body and play the role of isolating water, thereby Further played the role of electrical insulation.

[0022] The wet-pluggable underwater connector described in this embodiment, wherein, the plug (1) is formed by...

Embodiment 2

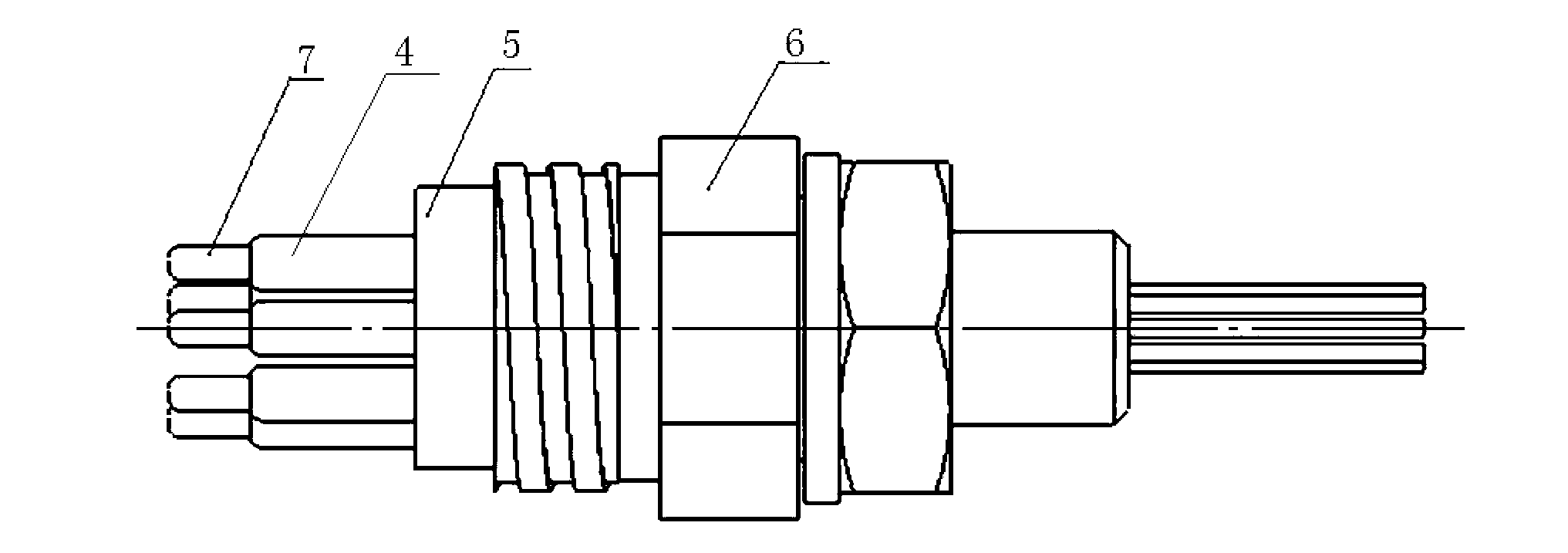

[0028] The wet-pluggable underwater connector in this embodiment includes a plug (1) and a socket (2), the plug (1) includes a jack (3), a connecting nut (10), and the socket ( 2) It includes pins (7), pin insulators (5), and socket housings (6), and the connecting nut (10) is connected and locked to the socket housing (6) through threads, wherein the pins (7) There are protruding cylindrical protrusions (4) on the surface, and sealing rings (8) are arranged in the holes that cooperate with the cylindrical protrusions (4) on the surface of the pins (7) in the sockets (3). (7) After mating with the socket (3), the sealing ring (8) is extruded on the cylindrical protrusion (4) on the surface of the pin (7) to realize the individual sealing function of a single contact body and play the role of isolating water, thereby Further played the role of electrical insulation.

[0029] The wet-pluggable underwater connector described in this embodiment, wherein the socket housing (6) is ...

Embodiment 3

[0035] The wet-pluggable underwater connector in this embodiment includes a plug (1) and a socket (2), the plug (1) includes a jack (3), a connecting nut (10), and the socket ( 2) It includes pins (4), pin insulators (5), and socket housings (6), and the connecting nut (10) is connected and locked to the socket housing (6) through threads, wherein the pins (7) There are protruding cylindrical protrusions (4) on the surface, and sealing rings (8) are arranged in the holes that cooperate with the cylindrical protrusions (4) on the surface of the pins (7) in the sockets (3). (7) After mating with the socket (3), the sealing ring (8) is squeezed on the cylindrical protrusion (4) on the surface of the pin (7) to realize the individual sealing function of a single contact body and play the role of isolating water. Thereby further playing the role of electrical insulation.

[0036] The wet-pluggable underwater connector described in this embodiment, wherein, the plug (1) is formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com