Load-bearing watertight electrical connector

A connector and dense electricity technology, applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of unusable, watertight connectors do not have load-bearing function, etc., and achieve the effect of reliable watertightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

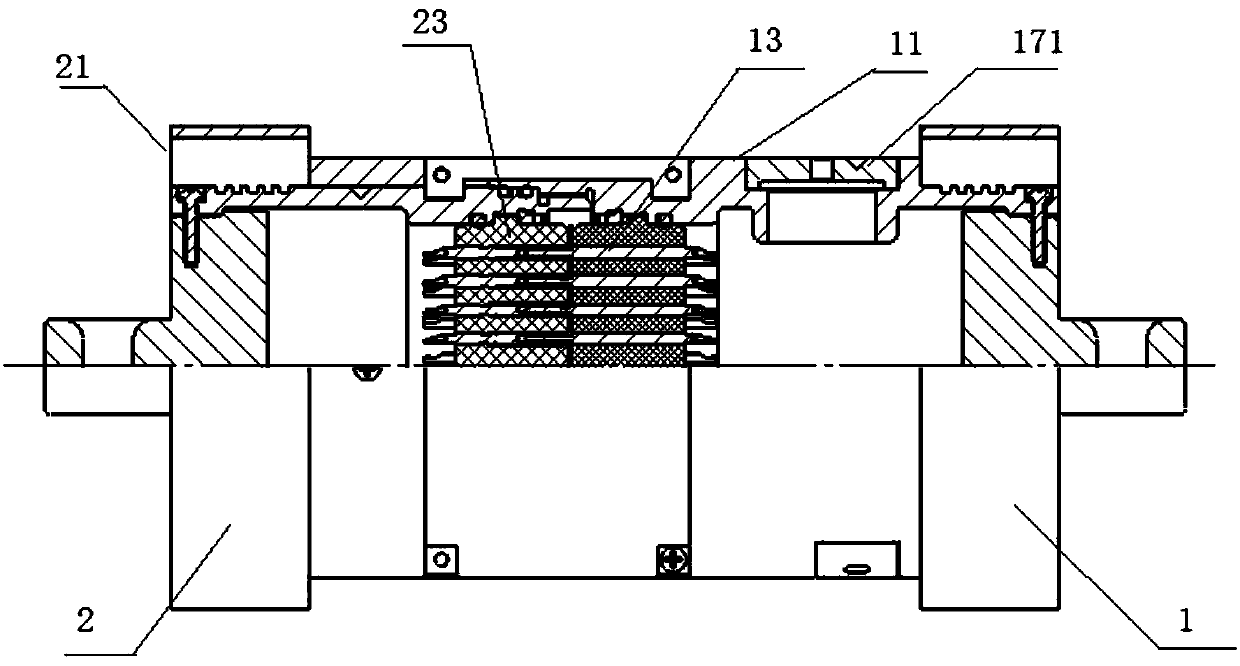

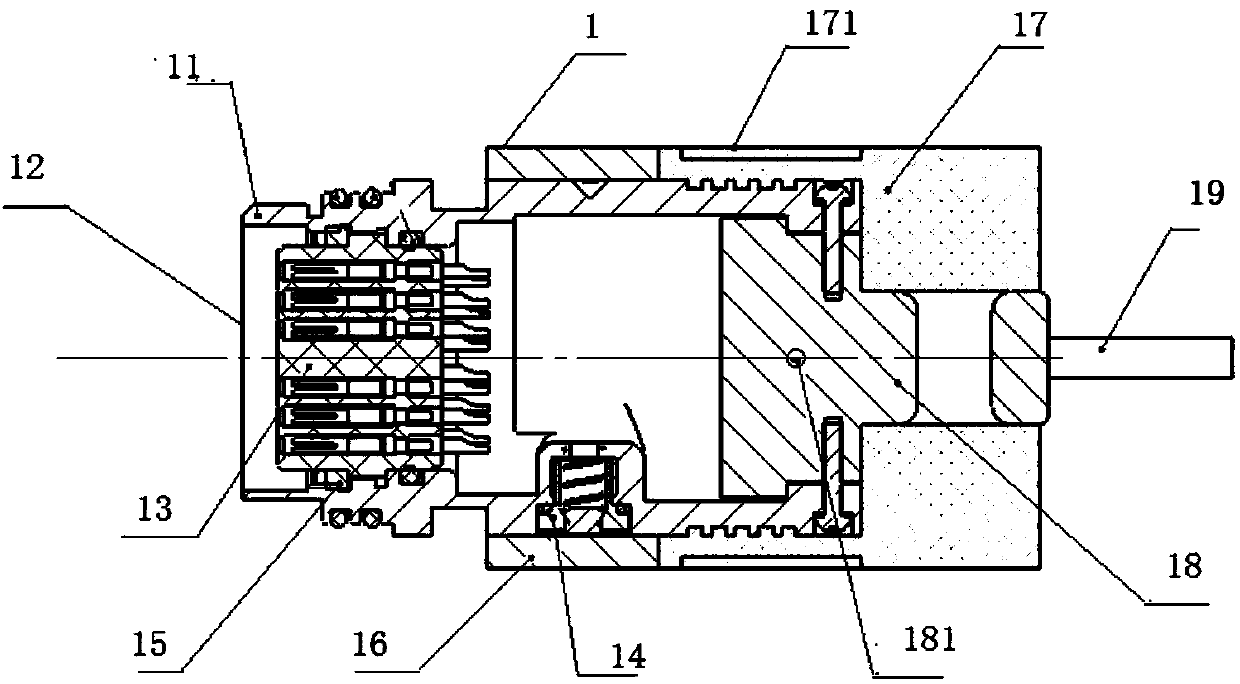

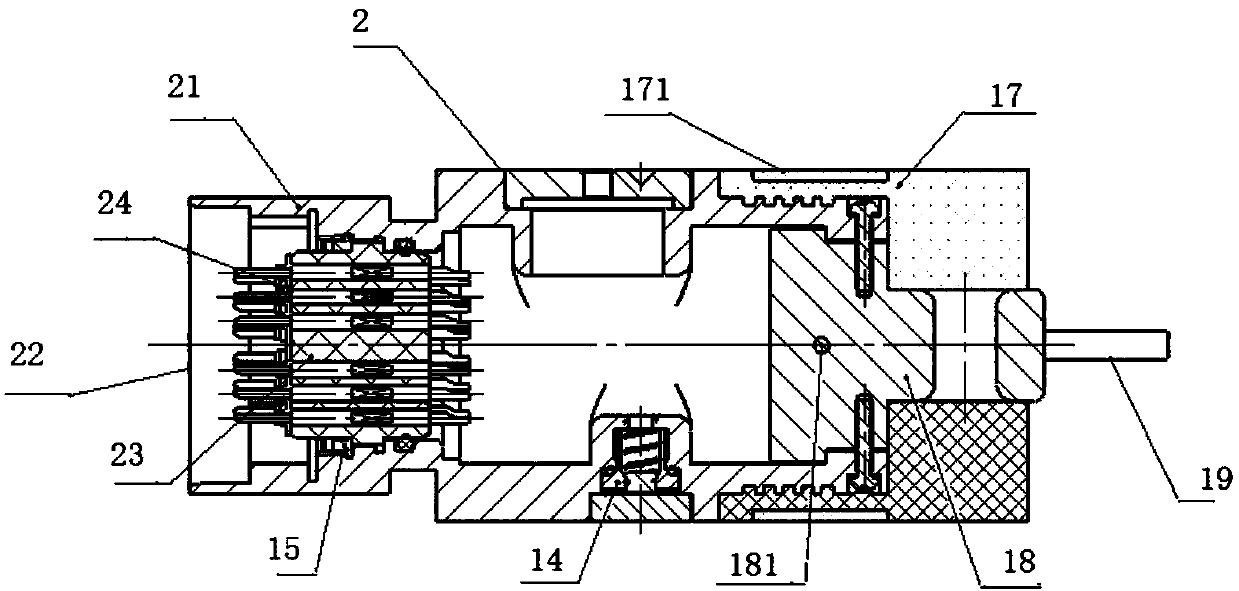

[0022] The load-bearing watertight electrical connector will be further described below with reference to the accompanying drawings.

[0023] The overall structure

[0024] In this load-bearing watertight electrical connector, the plug 1 and the socket 2 of the electrical connector are plugged and mated in the form of direct plugging and unplugging, and the half-flange structure locks the mated plug and socket. There is an O-ring at the interface between the plug and the socket. The O-ring will be deformed under the action of the medium pressure in the groove, and "flow" to the gap to achieve the sealing effect. When the O-ring is working, a seal can be formed on the inner and outer diameters, the end face or any other surface, and a single O-ring can achieve horizontal and vertical bidirectional sealing. Such as figure 1 shown.

[0025] The half-type flange structure is used to axially position the docked electrical connector, and then the half-type structure is fastened w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com