Energy-saving shuttle vehicle capable of steering in all-around mode

A shuttle car, all-round technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of large current discharge of batteries, increase of electrolytic reaction, increase of polarization of plates, etc., and achieve strong energy saving and applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

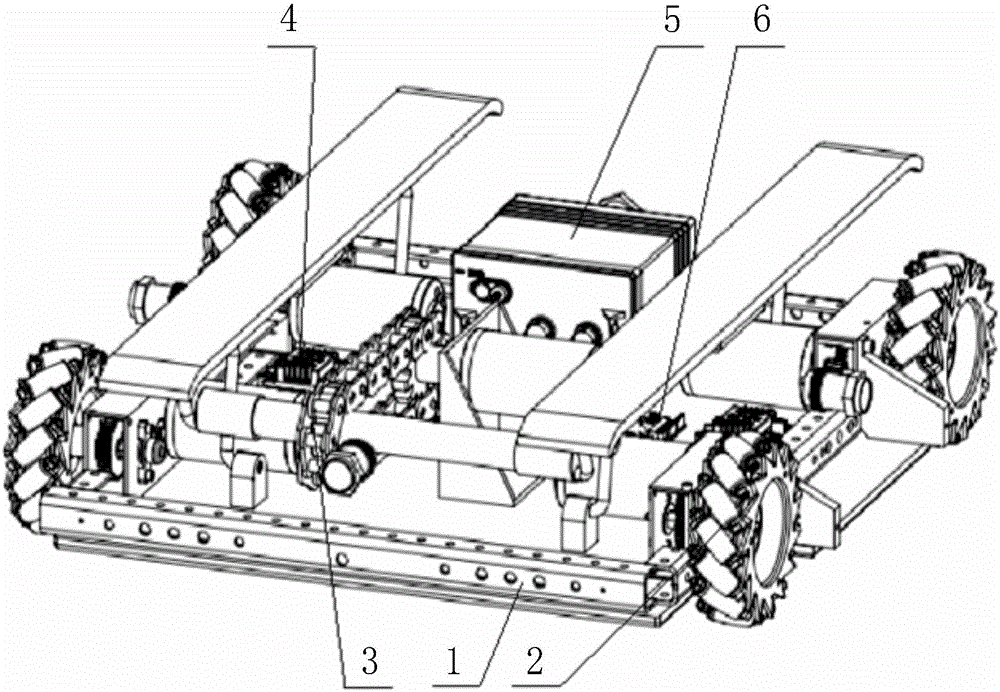

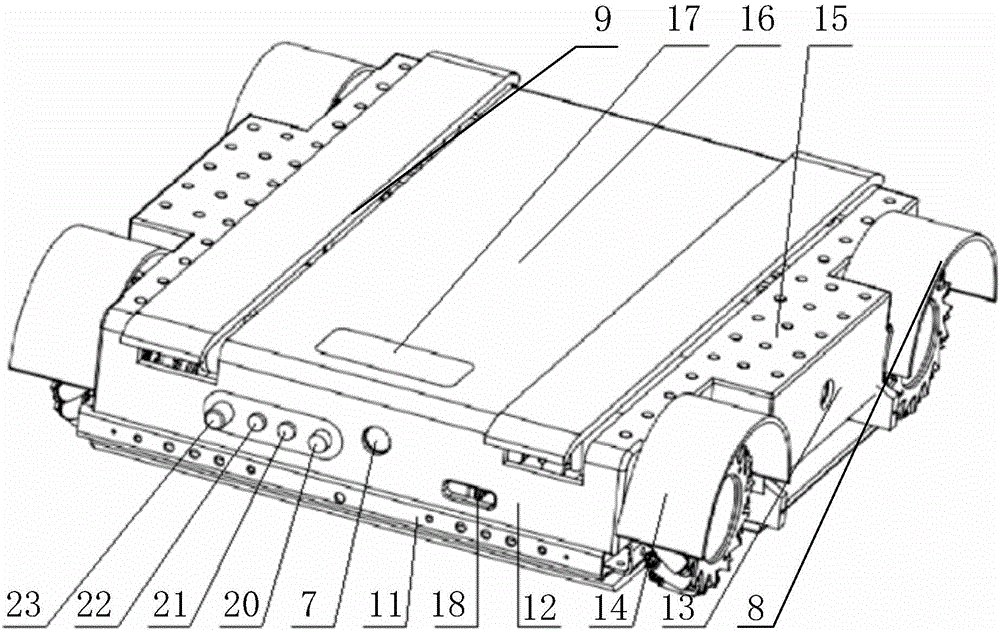

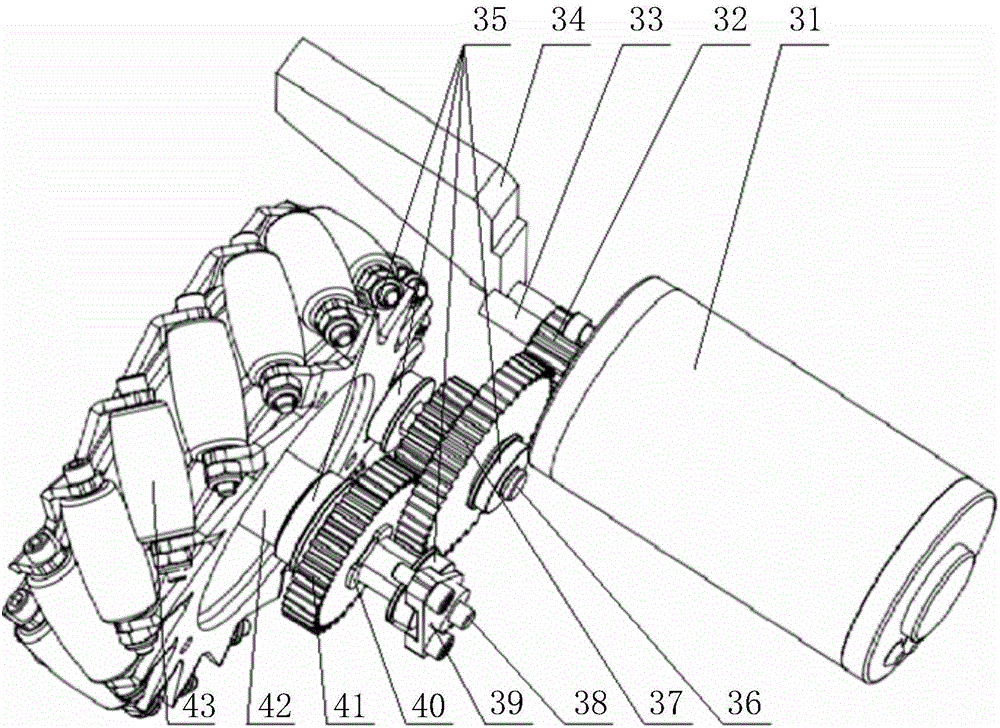

[0026] Such as figure 1 As shown, it is a structural schematic diagram of an energy-saving shuttle vehicle capable of omnidirectional steering in the present invention. The shuttle vehicle includes a vehicle body 1, a steering device 2 installed on the vehicle body, a lifting device 3, a control system 4, and a supercapacitor power source 5. Communication module 6. Sensor system, wherein the sensor system includes an infrared ranging sensor 7, an anti-collision sensor 8, and a pressure sensor 9:

[0027] The infrared ranging sensor 7 is used to measure the distance between the vehicle and the cargo box; the anti-collision sensor 8 is used to detect whether the shuttle car is collided; the pressure sensor 9 judges whether the goods are completely placed by detecting the pressure on the pallet on the shelf;

[0028] The supercapacitor power source 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com