Production process for left-rear side inner car door panel assembly

A production process and assembly technology, which is applied in the production process field of the left rear side door inner panel assembly, can solve the problems of unfavorable door outer panel processing, complex production process, and large fit gap, so as to facilitate assembly processing and avoid fit gaps The effect of large and small process error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

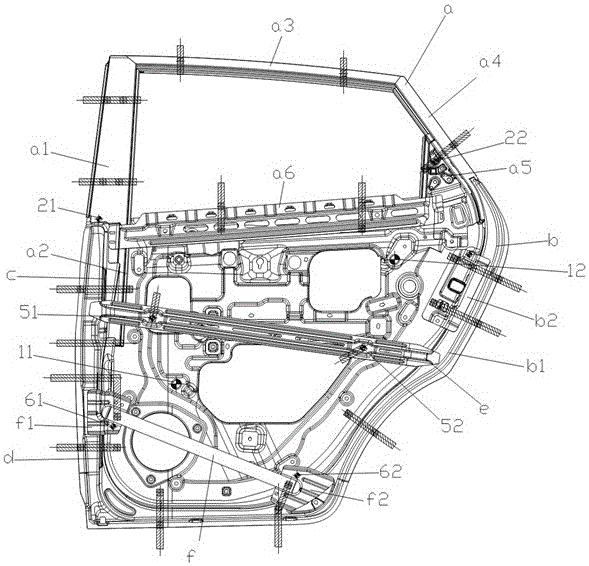

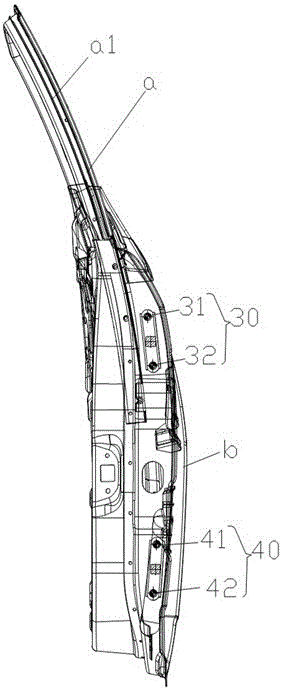

[0022] With reference to the accompanying drawings, a production process of the left rear side door inner panel assembly includes the following steps:

[0023] Step 1: Welding of the upper frame assembly a; the door B-pillar a1 and the glass lift guide rail a2 located in front of the upper frame assembly a, the upper bar a3 located above the upper frame assembly a, and the upper frame assembly a The rear door C-pillar a4, the triangular window panel a5, and the outer panel reinforcement plate a6 located below the upper frame assembly a are assembled into one body, and the contact points where the above six are in contact with each other are welded by a welding machine;

[0024] The second step: welding of the anti-collision bar assembly f: arrange the front and rear connecting plates f1 and f2 of the anti-collision bar at both ends of the anti-collision bar, and weld the contact points between the three;

[0025] Step 3: Welding of the door inner panel assembly b: Weld the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com