Double-power-supply voltage detection circuit

A technology of voltage detection circuit and dual power supply, which is applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve the problems of increasing nonlinear error, nonlinear error affecting measurement and protection accuracy, and reducing reliability. Achieve the effects of resisting temperature drift, facilitating user wiring, and reducing process errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

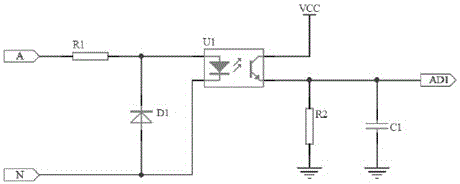

[0011] see figure 1 , which is a schematic diagram of a dual-supply voltage detection circuit with a traditional optocoupler as the core. Such as figure 1 As shown, there is only one optocoupler, which is like a general semiconductor device. Due to the change of ambient temperature, the transmitted signal will have temperature drift and certain nonlinear errors during use, which will affect the accuracy of measurement and protection, resulting in large voltage measurement. error.

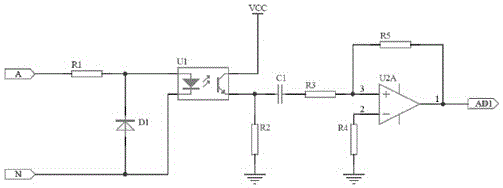

[0012] see figure 2 , which is a schematic diagram of a dual power supply voltage detection circuit with a traditional optocoupler as the core and an operational amplifier. Non-linear correction is achieved by using temperature compensation or the cooperation of operational amplifiers, but the general temperature compensation accuracy is poor, and some increase the nonlinear error; and the use of operational amplifiers cannot solve the temperature drift of the optocoupler.

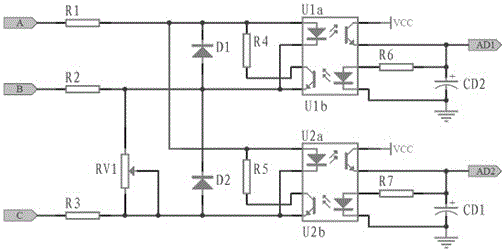

[0013] Please refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com