A bottom hole rotating speed sensor based on centrifugal force

A speed sensor and centrifugal force technology, applied in drilling equipment, drilling measurement, devices using electric/magnetic methods, etc., can solve the problem of not fully adapting to the requirements of bottom-hole power machines, avoid temperature drift problems, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

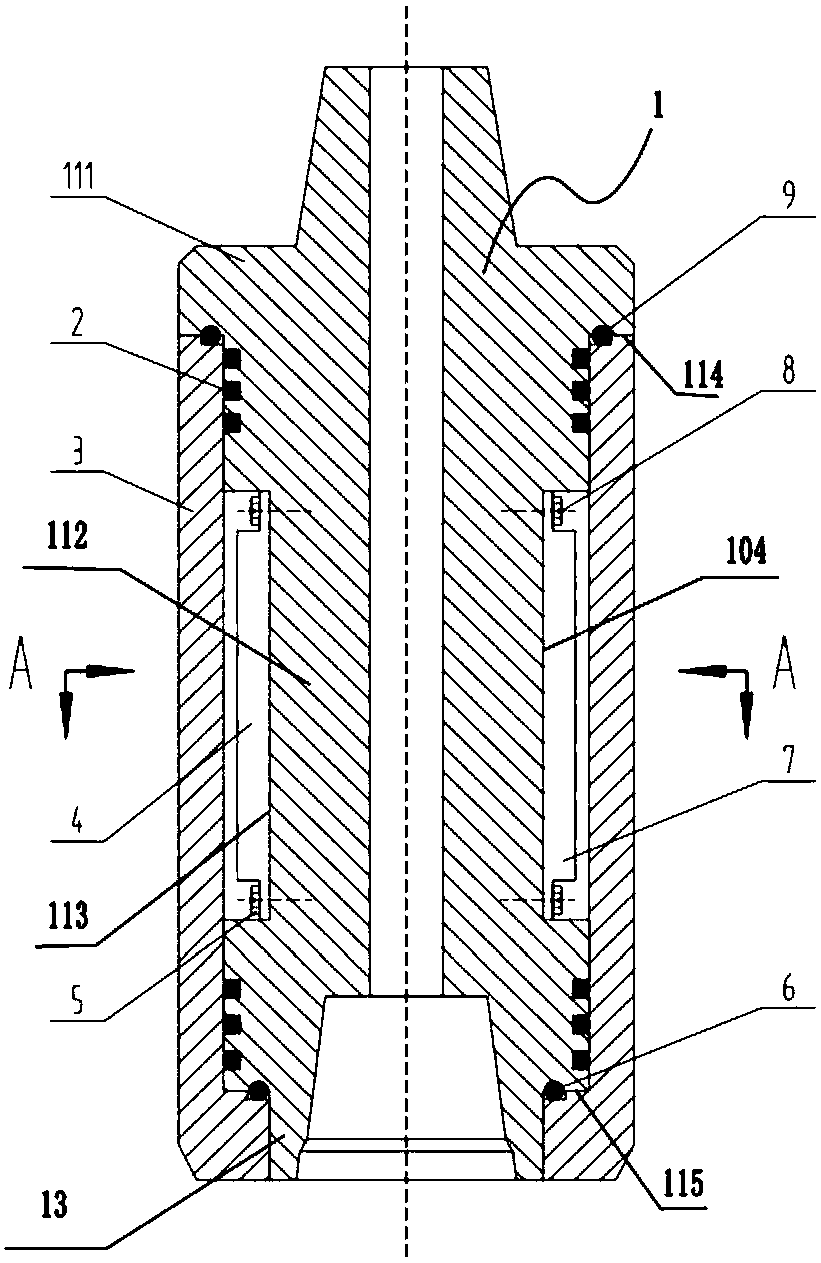

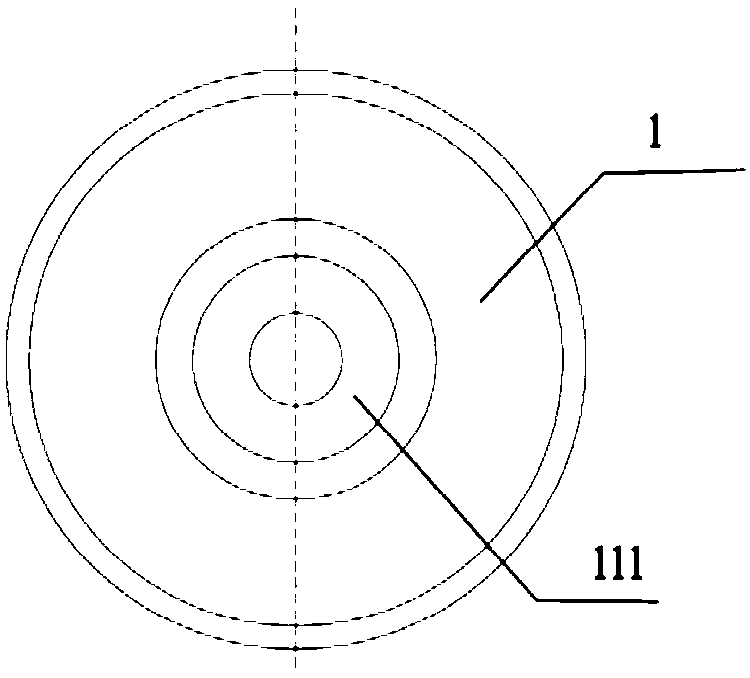

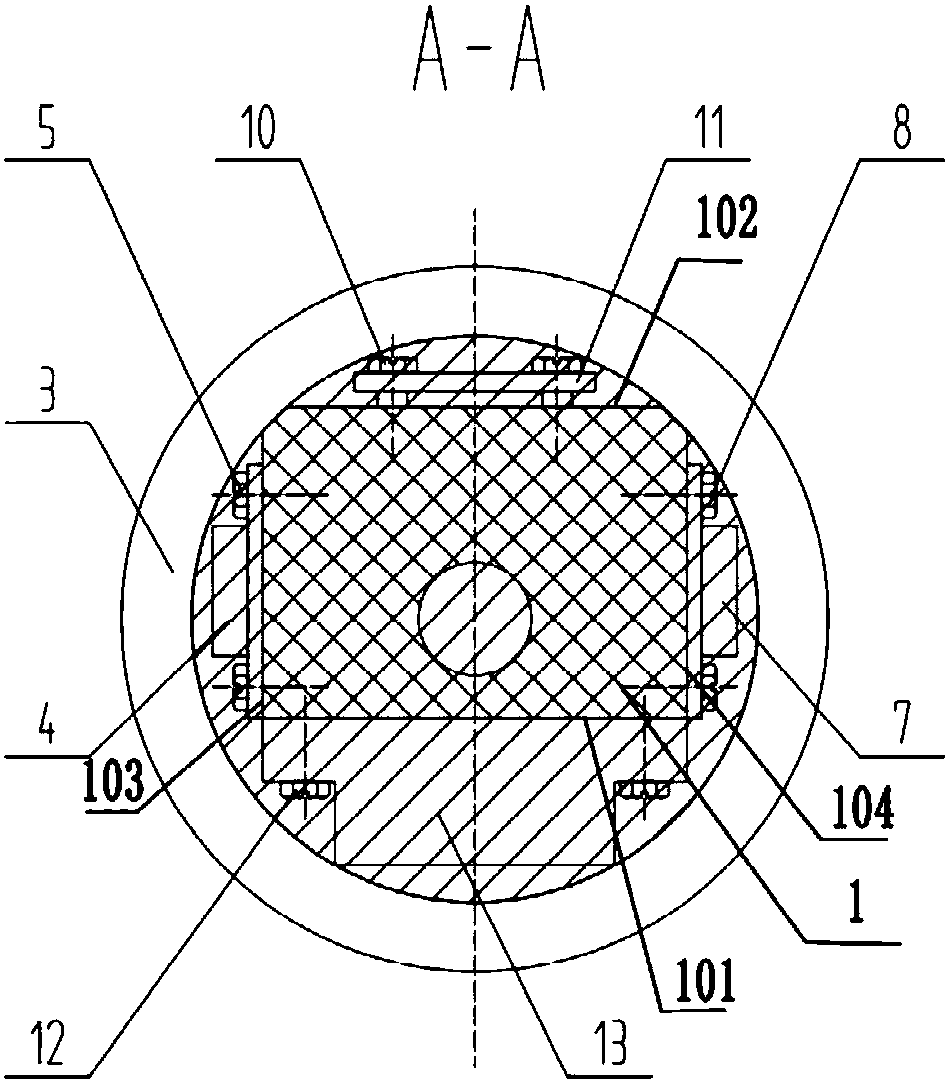

[0038] like Figure 1-3 As shown, the bottom hole speed sensor based on centrifugal force of the present invention includes: a main shaft 1, and a first plane part 101 is formed on the outer peripheral surface of the main shaft 1; a speed detection assembly, which is detachably mounted on the first plane part 101, used to obtain the rotational speed data of the rotating part (such as a power machine at the bottom of a deep hole, etc.); the housing 3, which is threaded outside the main shaft 1, is used to seal the rotational speed detection assembly in the housing 3 and the space between the main shaft 1.

[0039] In this embodiment, the rotational speed sensor can be used to obtain the rotational speed data of the power machine at the bottom of the deep hole. Specifically, the main shaft 1 includes: a head end 111, a middle end 112, and a tail end 113; and the head end 111 and the The middle end 112 is connected to form a first stepped portion 114, and the tail end 113 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com