Ultrahigh vacuum sealing flange structure for non-circular channel of large Tokamak vacuum chamber

A tokamak and ultra-high vacuum technology, applied in the field of tokamak vacuum chamber sealing flange structure, to achieve the effect of improving the ability of anti-vibration and shock, easy processing and maintenance, and improving the reliability of vacuum sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

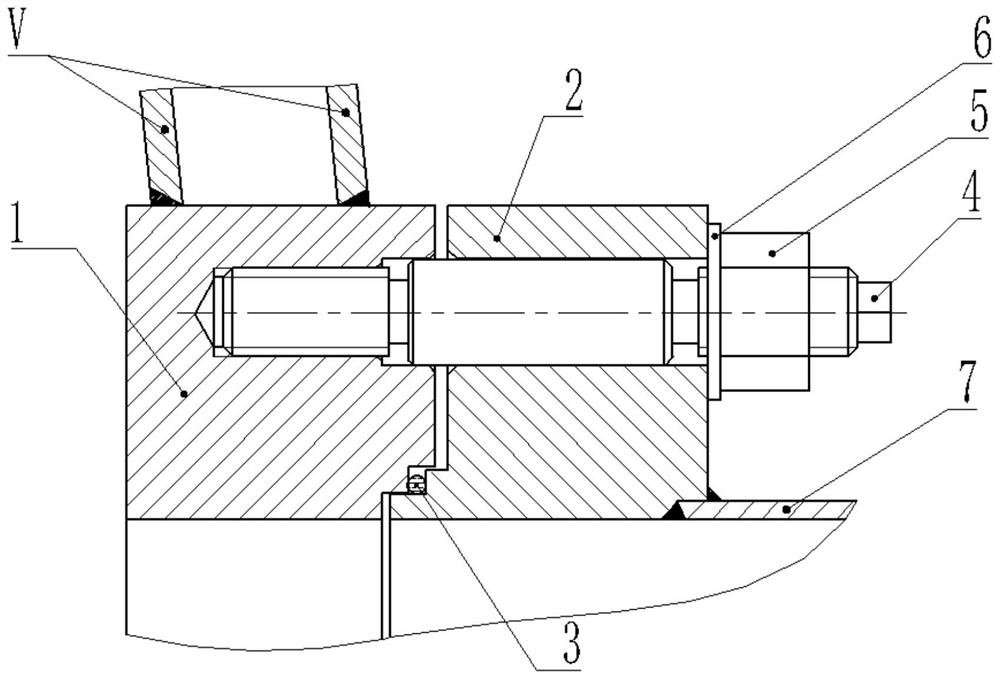

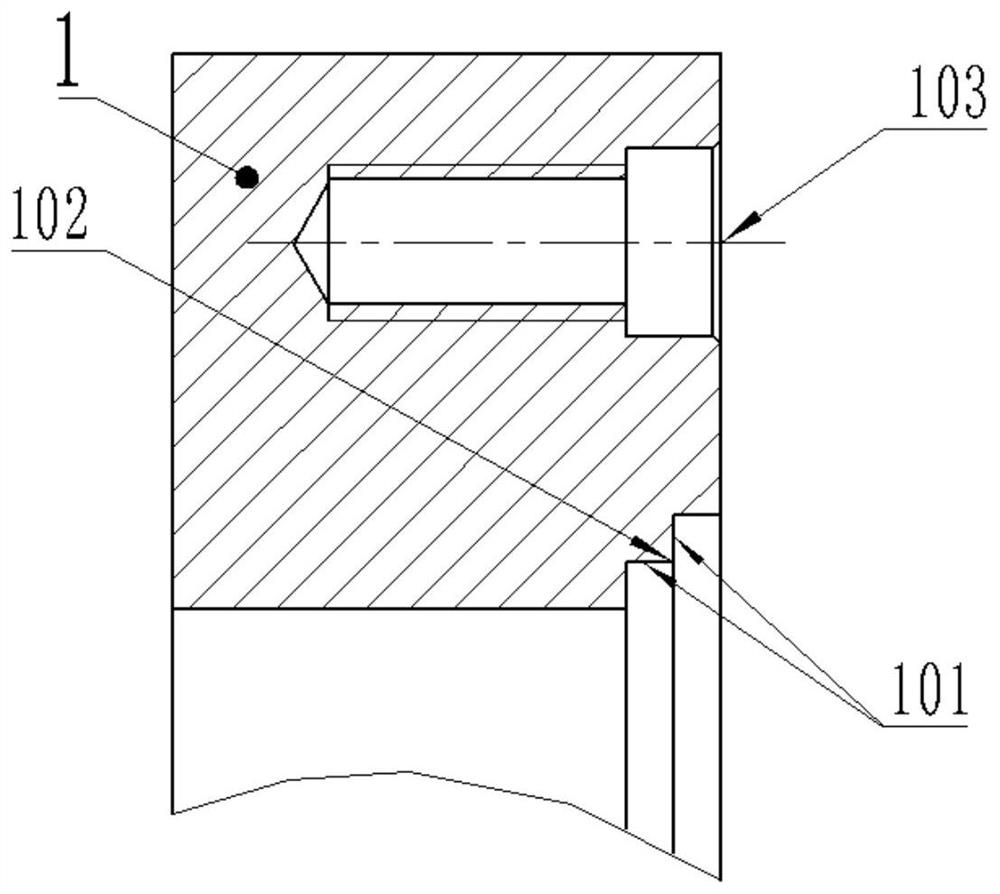

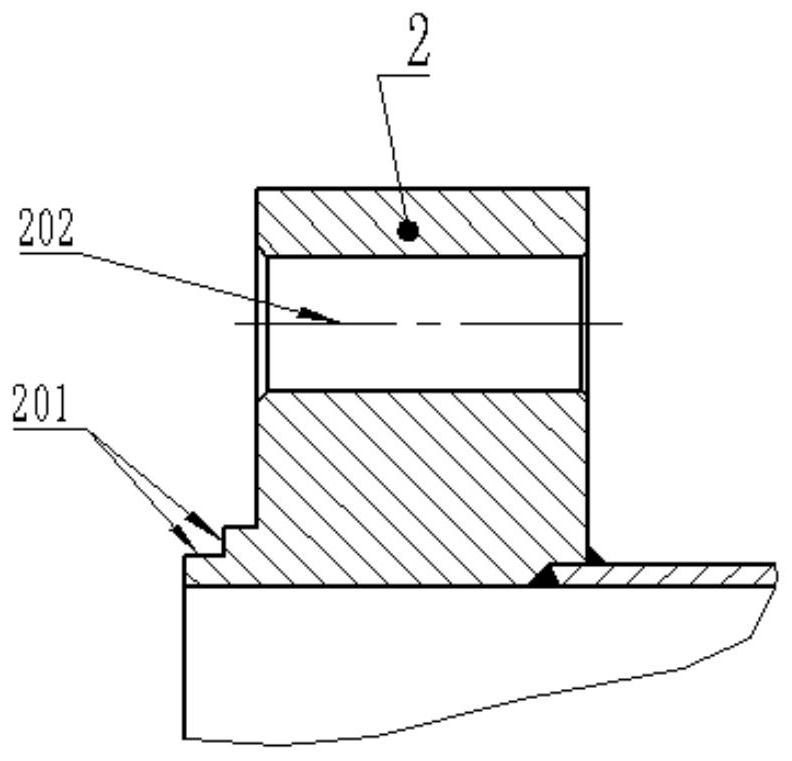

[0029] like figure 1 As shown, the concave flange 1 is welded on the shell of the vacuum chamber V, and the convex flange 2 is welded on the end of the connecting pipe 7 . The entire flange structure can be located in the upper, middle and lower regions of the outer casing of the vacuum chamber. If the connecting pipe of the flange can be drawn out from the neutral position of the coil, the flange structure can also be arranged at the position of the coil.

[0030] The role of connecting pipe 7 is to form an ultra-high vacuum boundary together with the vacuum chamber shell and flange, and to connect plasma diagnosis, heating and vacuum pumping equipment located outside the vacuum chamber of the tokamak device. A flange structure is designed between the vacuum chamber V and the connecting pipe 7 to form an ultra-high vacuum channel.

[0031] The conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com