Preparation method of aluminum-based ceramic composite material

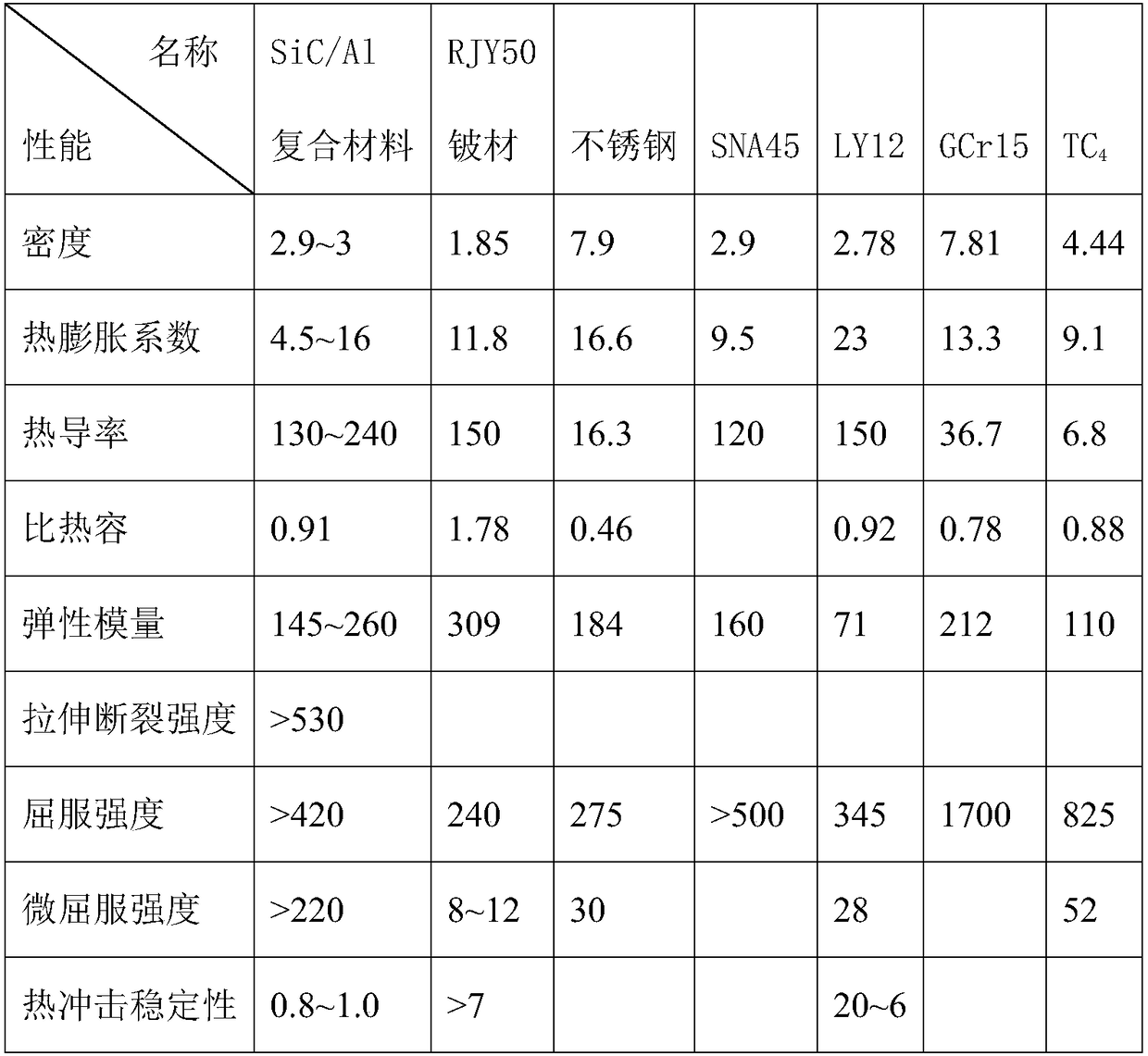

A technology of composite materials and aluminum-based ceramics, applied in the field of metal composite materials, can solve problems such as low density, low thermal expansion coefficient, and immature technology, and achieve the effect of increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of aluminum-based ceramic composite material of the present invention, concrete steps are as follows:

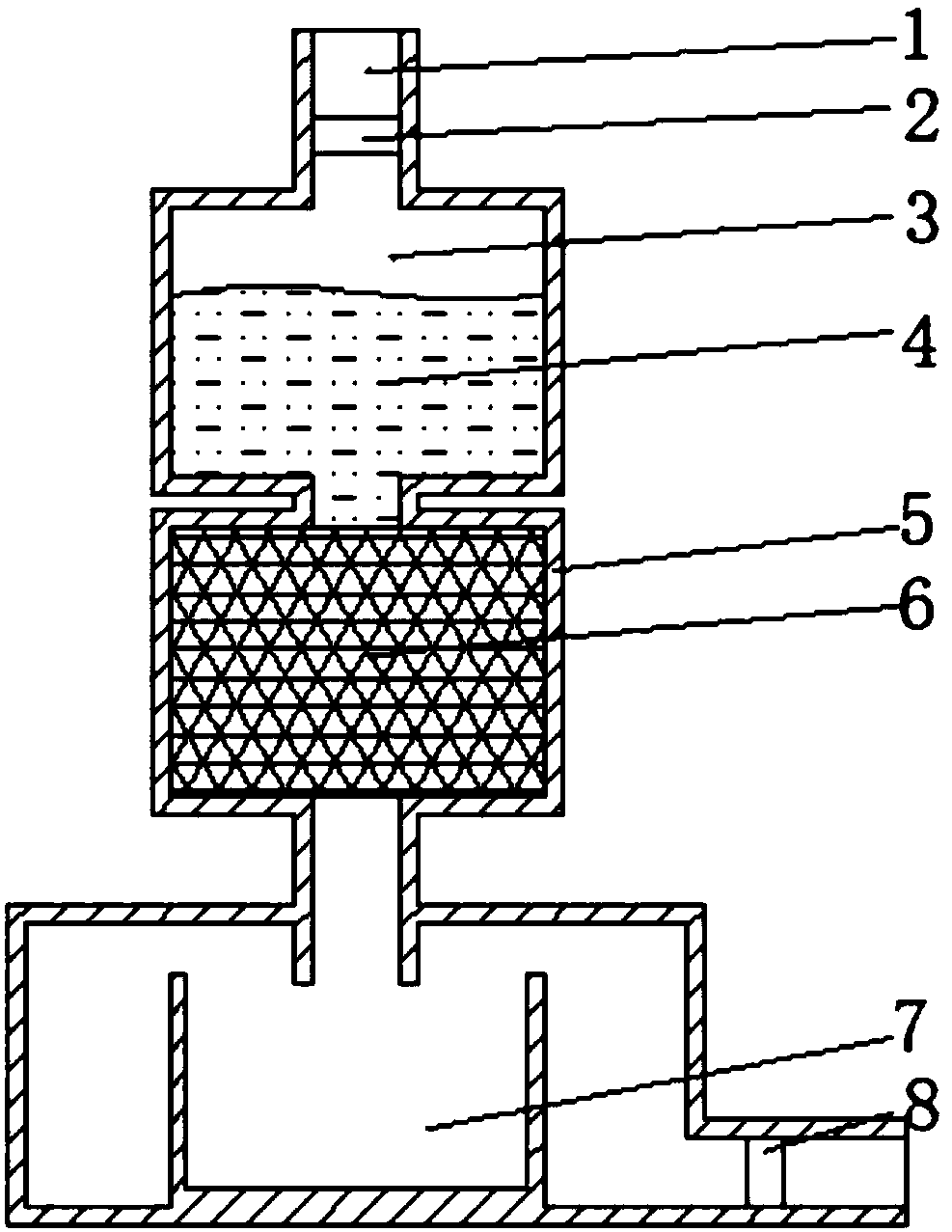

[0028] S1. Using vacuum pressureless impregnation, first place the aluminum ingot 4 in the upper chamber 3 of the furnace, then place the porous ceramic blank 6 in the lower chamber 5 to closely fit the inner wall of the furnace chamber, and then close the manual valve to close the sintering furnace To ensure its airtightness, open the rough pumping valve to vacuumize for 10-15 minutes, then open the vacuum valve and molecular pump until the vacuum degree reaches 0.008-0.01Pa;

[0029] The rough pumping valve and the molecular pump of the vacuum valve are mutually cut off. When the rough pumping valve is opened, the molecular pump of the vacuum valve is closed. When the vacuum valve and the molecular pump are opened, the rough pumping valve is closed.

[0030] The diameter of the aluminum ingot 4 is 5-600mm, and the height is 50-55mm.

[...

Embodiment

[0035] Such as figure 1 As mentioned above, the preparation equipment of this embodiment is a vacuum hot-press sintering furnace, wherein the sealing equipment includes an upper pressure head 1, a graphite tube 2, a graphite backing plate 5; an aluminum ingot 3 for impregnation, and a product mold 4. Among them, the SiC preform The size is 1~500mm in length, 1~500mm in width, and 1~1000mm in height, according to figure 1 way equipped.

[0036] The preparation steps of aluminum-based ceramic materials are as follows:

[0037] Step S1, first place the aluminum ingot in the upper chamber of the furnace, then place the porous ceramic blank in the lower chamber of the furnace to closely adhere to the inner wall of the furnace chamber, then close the manual valve to close the sintering furnace, and open the roughing valve for 10 to 15 minutes Then open the molecular pump and vacuum valve for 1-1.5 hours to a vacuum degree of 0.008-0.01;

[0038] Step S2, when the vacuum degree re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com