Gas-phase deposition coating and vacuum heat-treatment on-line combined composite coating equipment

A technology of vapor deposition coating and vacuum heat treatment, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of pollution in the intermediate transmission link, and achieve improved cleanliness, channel rules, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

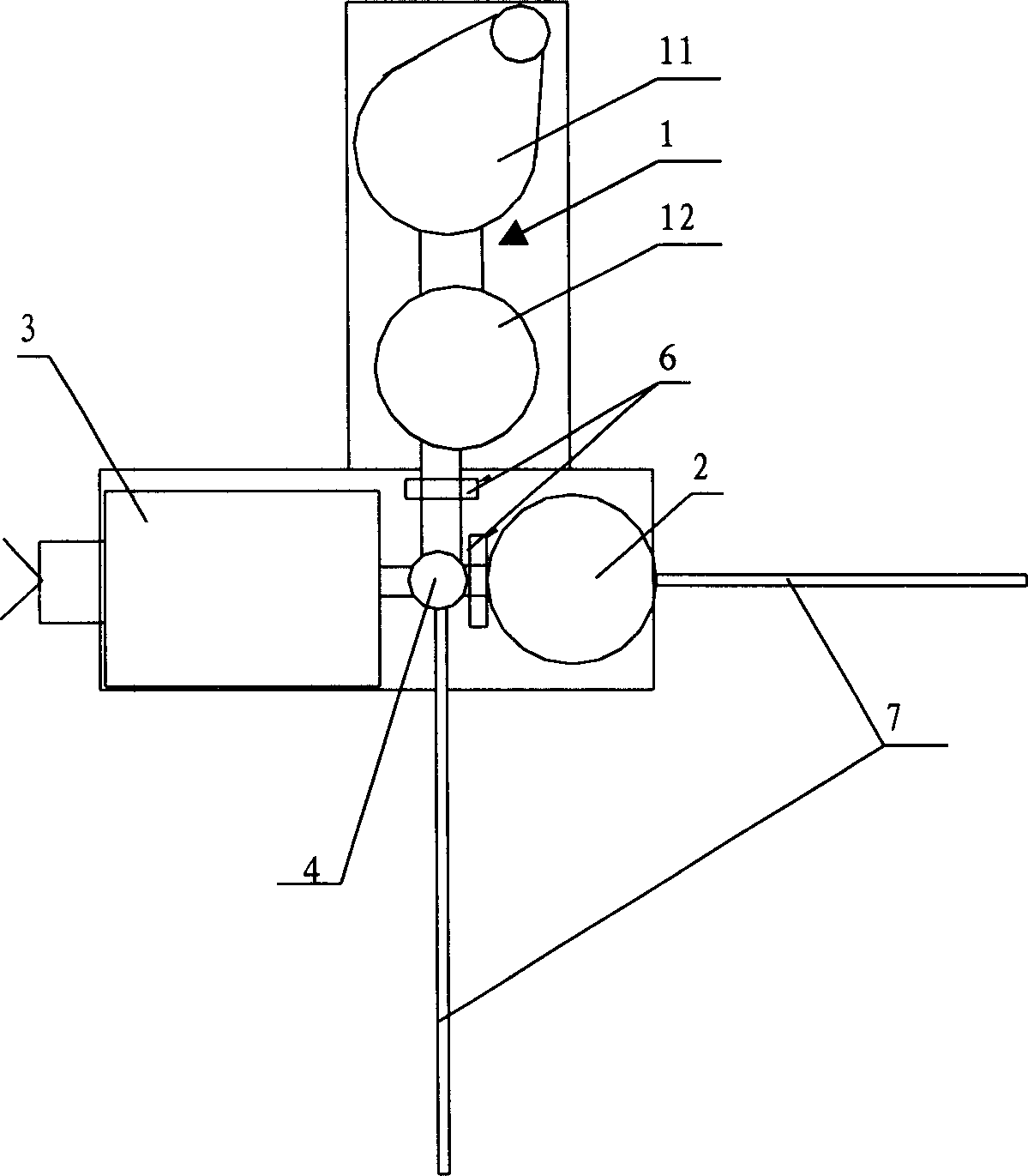

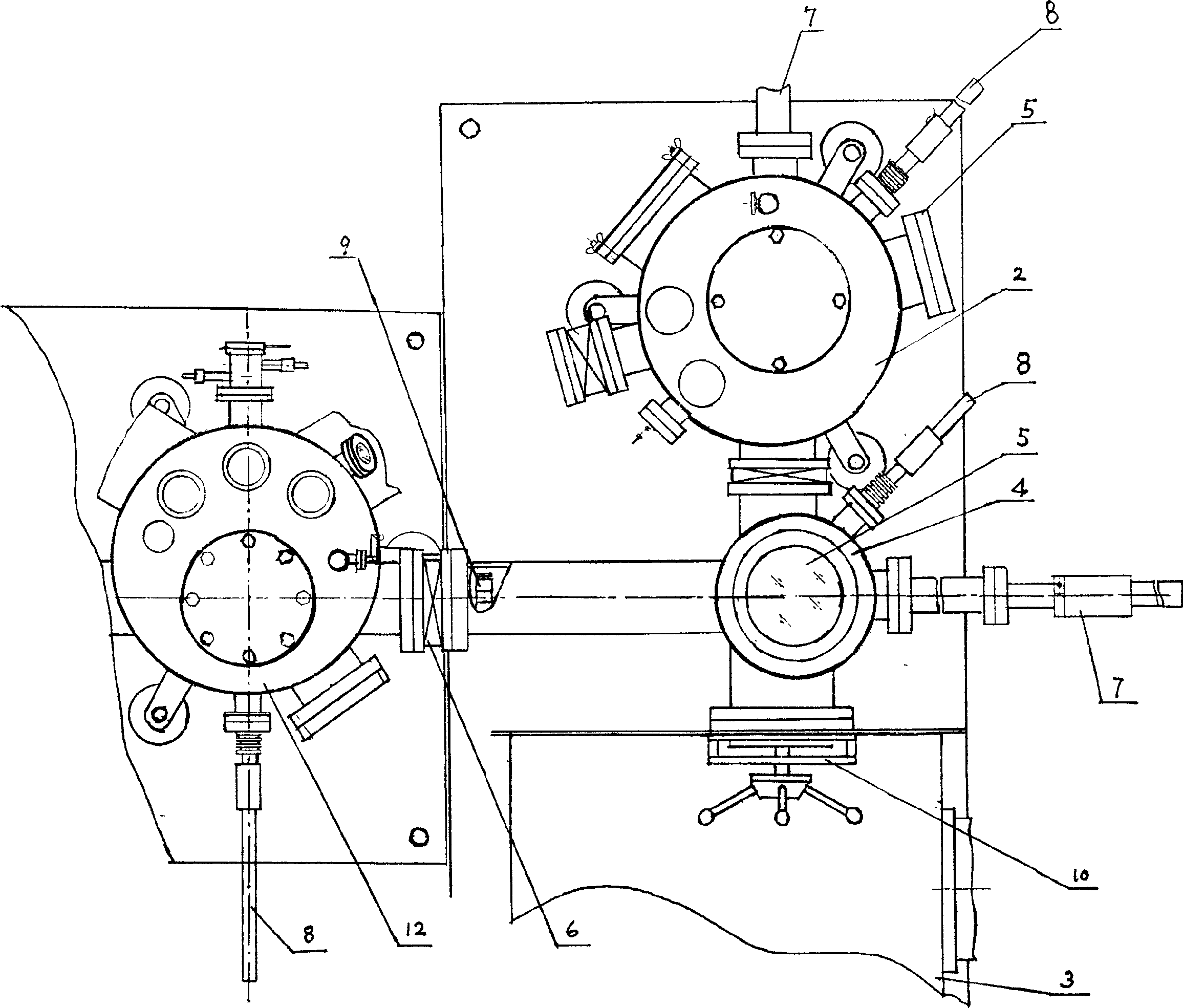

[0021] The structure of the present invention is attached figure 1 , 2 As shown, it includes a coating chamber 1, a heat treatment chamber 2 and a glove box 3, and is characterized in that: it also includes a transfer chamber 4, which is a stainless steel cylindrical structure, and is arranged in the coating chamber 1, the heat treatment chamber 2 and the glove box. Between the boxes 3, it is connected with the coating chamber 1, the heat treatment chamber 2 and the glove box 3 through stainless steel pipes, and a stainless steel high vacuum plug valve 6 is arranged on the stainless steel pipes. The sheet or film is transferred between the three functional positions of the heat treatment sample stage, the coating substrate stage and the glove box; where:

[0022] Described transfer chamber 4 has loam cake, is provided with observation window 5 on it, and the pipe internal diameter size is suitable for sample to pass through; A support roller 9 is set to prevent the transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com