Machine equipment of semiconductor or photovoltaic material

A technology for photovoltaic materials and processing equipment, applied in semiconductor devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve problems such as smoke from furnace doors, black edges on sheet materials, and poor sealing, and achieve flexible adjustment and control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

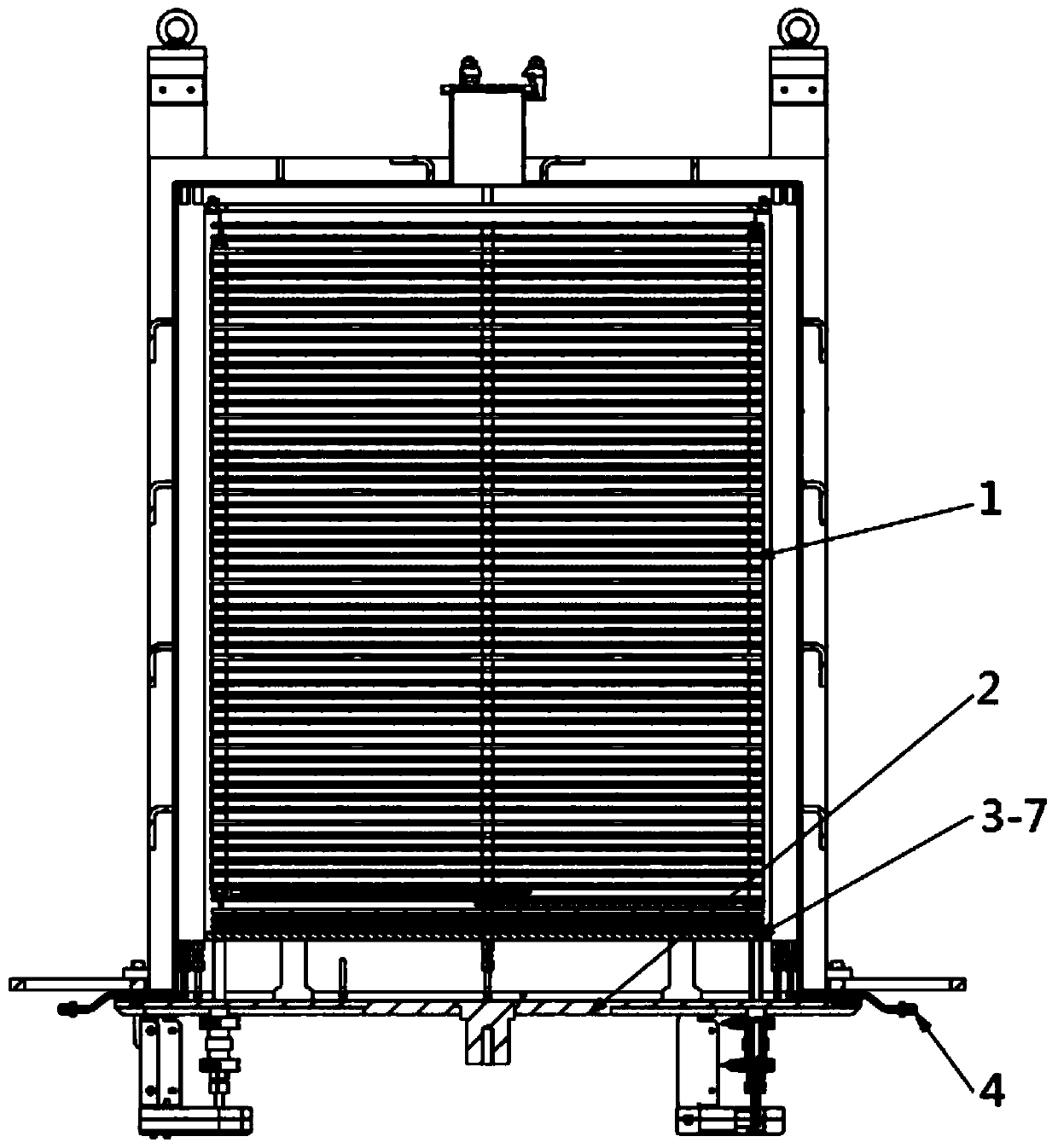

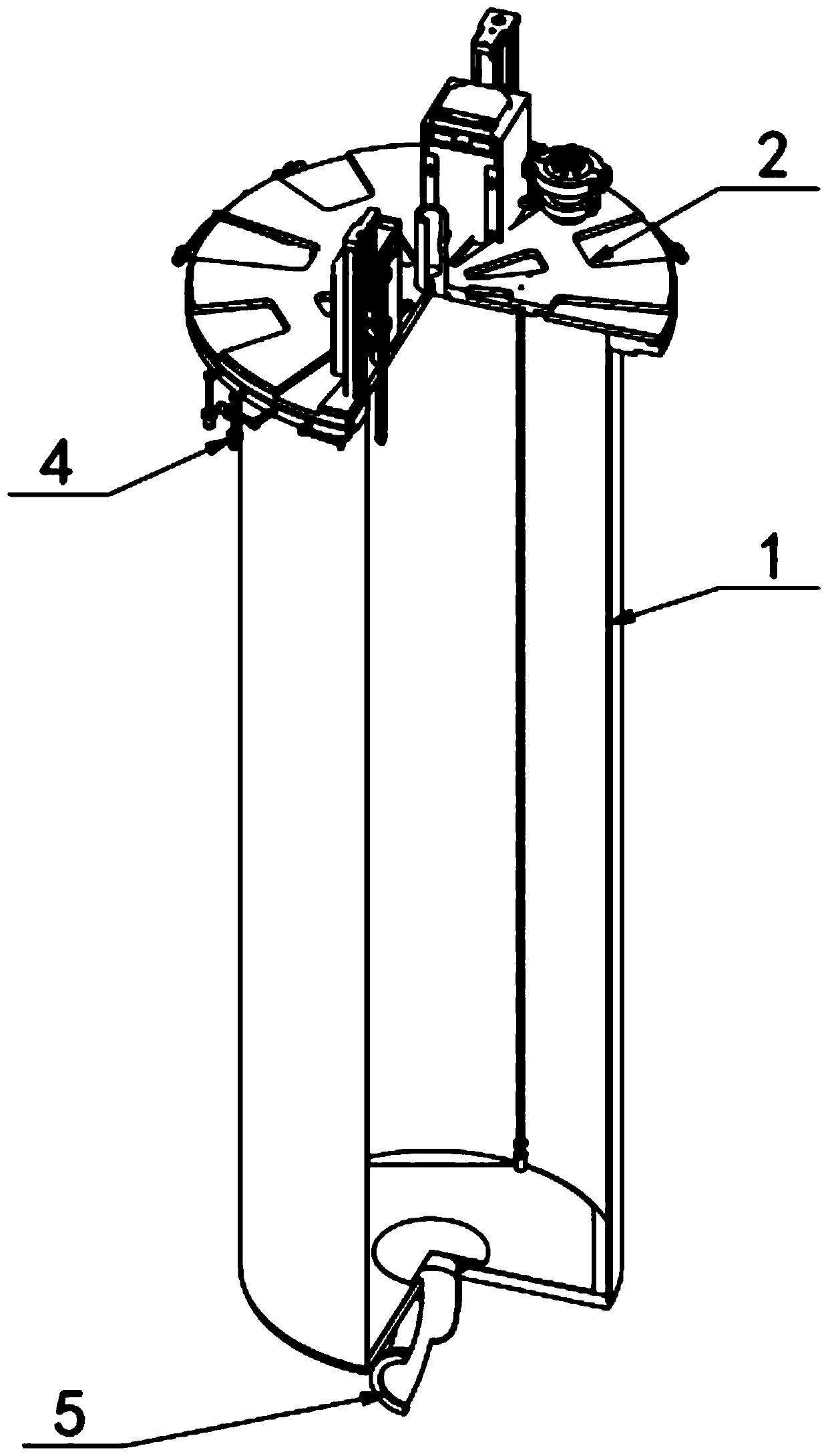

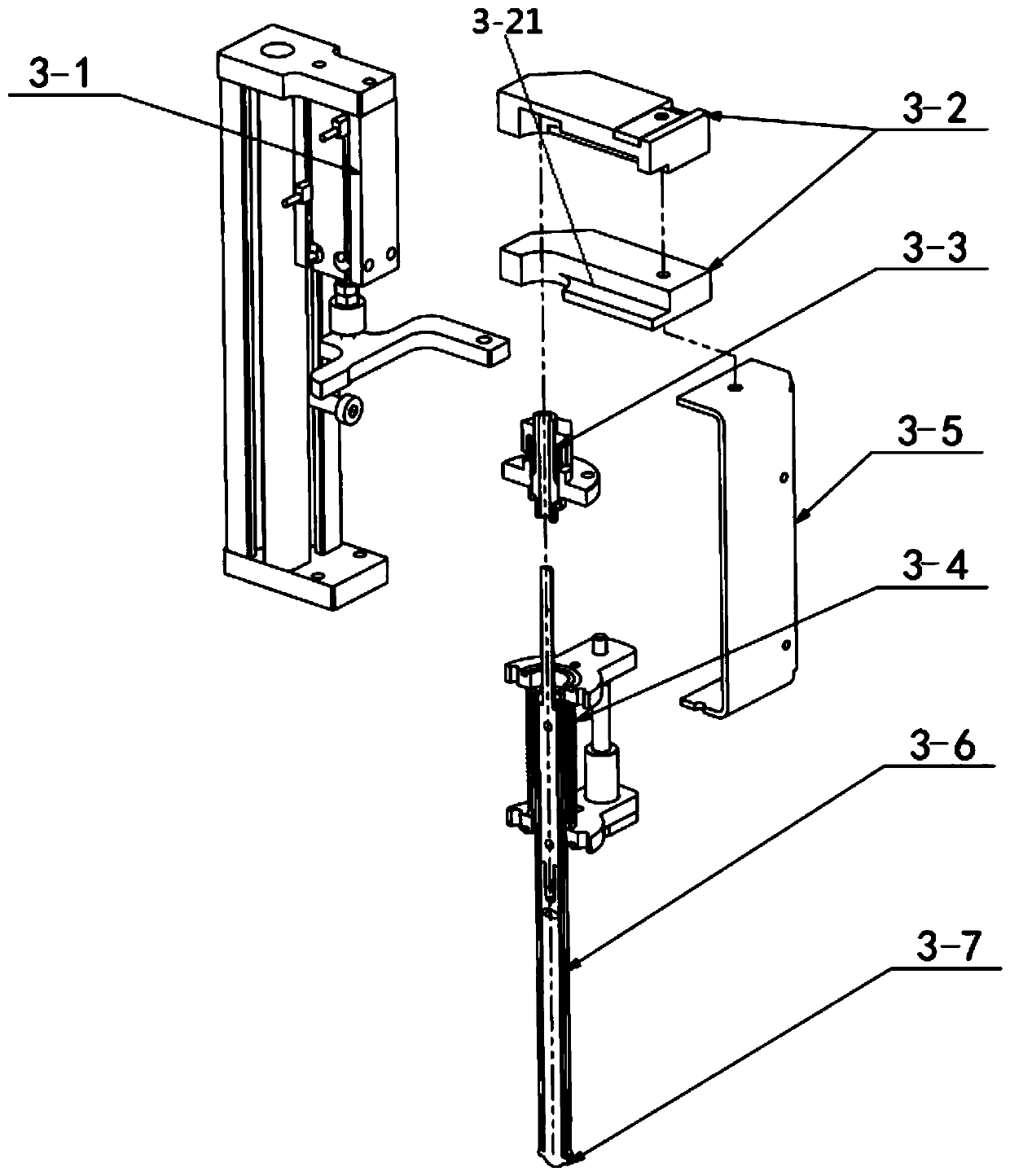

[0035] like Figure 1 to Figure 6 As shown, the semiconductor or photovoltaic material processing equipment includes a furnace body 1, a furnace door 2, and an electrode structure is arranged on the furnace door 2. The electrode structure includes an electrode column 3-7, an electrode body 3-5 and insulating materials. The electrode column 3-7 is connected with the electrode main body 3-5, and the insulating material covers the side of the electrode column 3-7. By insulating and covering the electrode columns, only two ends of the electrode columns 3-7 are exposed. It will be more convenient when the furnace door 2 is connected to the electrode structure in the graphite boat, and it will be easier to form a uniform electric field and realize plasma-enhanced chemical vapor phase. deposition. like figure 1 As shown, the graphite boat will be placed in parallel in the furnace body 1, and the silicon wafers on the graphite boat will also be placed in parallel. This placement st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com