Skid-mounted rocket tank pressure annunciator flight vacuum environment simulator

A technology of vacuum environment simulation and pressure signal, applied in the testing of measuring devices, instruments, machines/structural components, etc., can solve the problems of lack of mature experience, etc., to achieve improved maintainability, good vacuum sealing effect, and enhanced effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

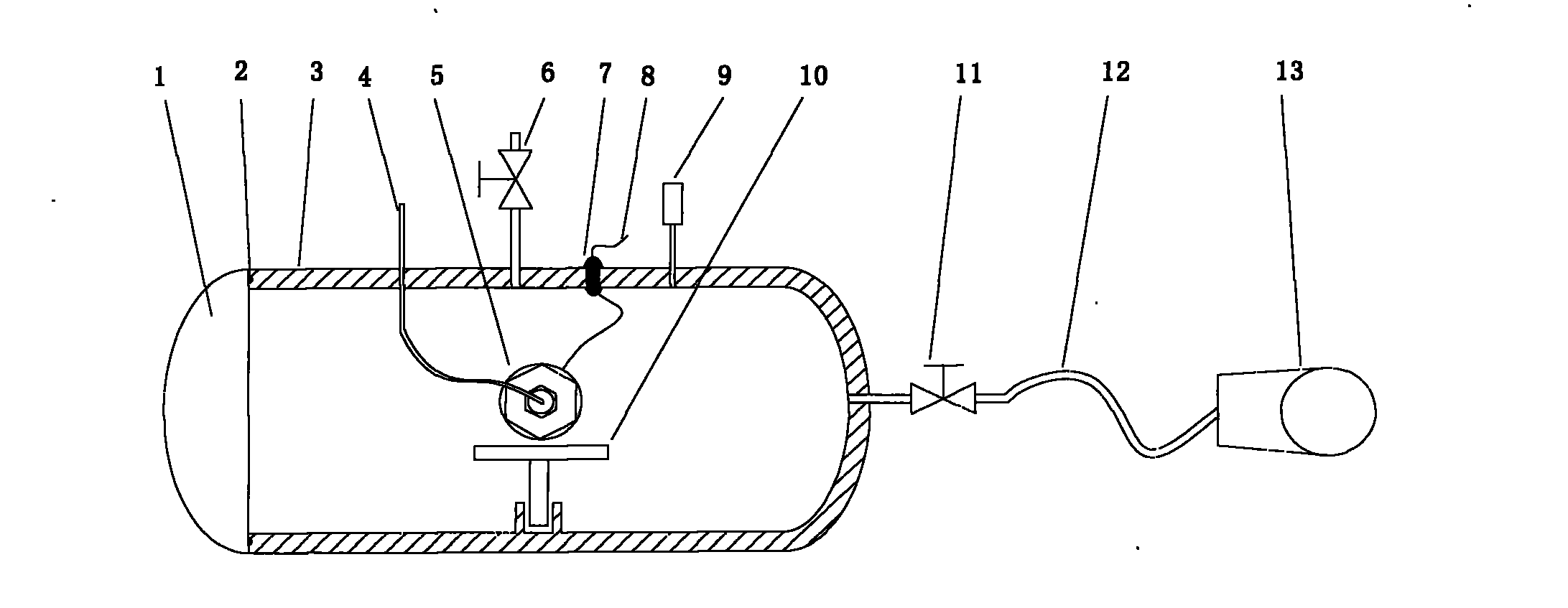

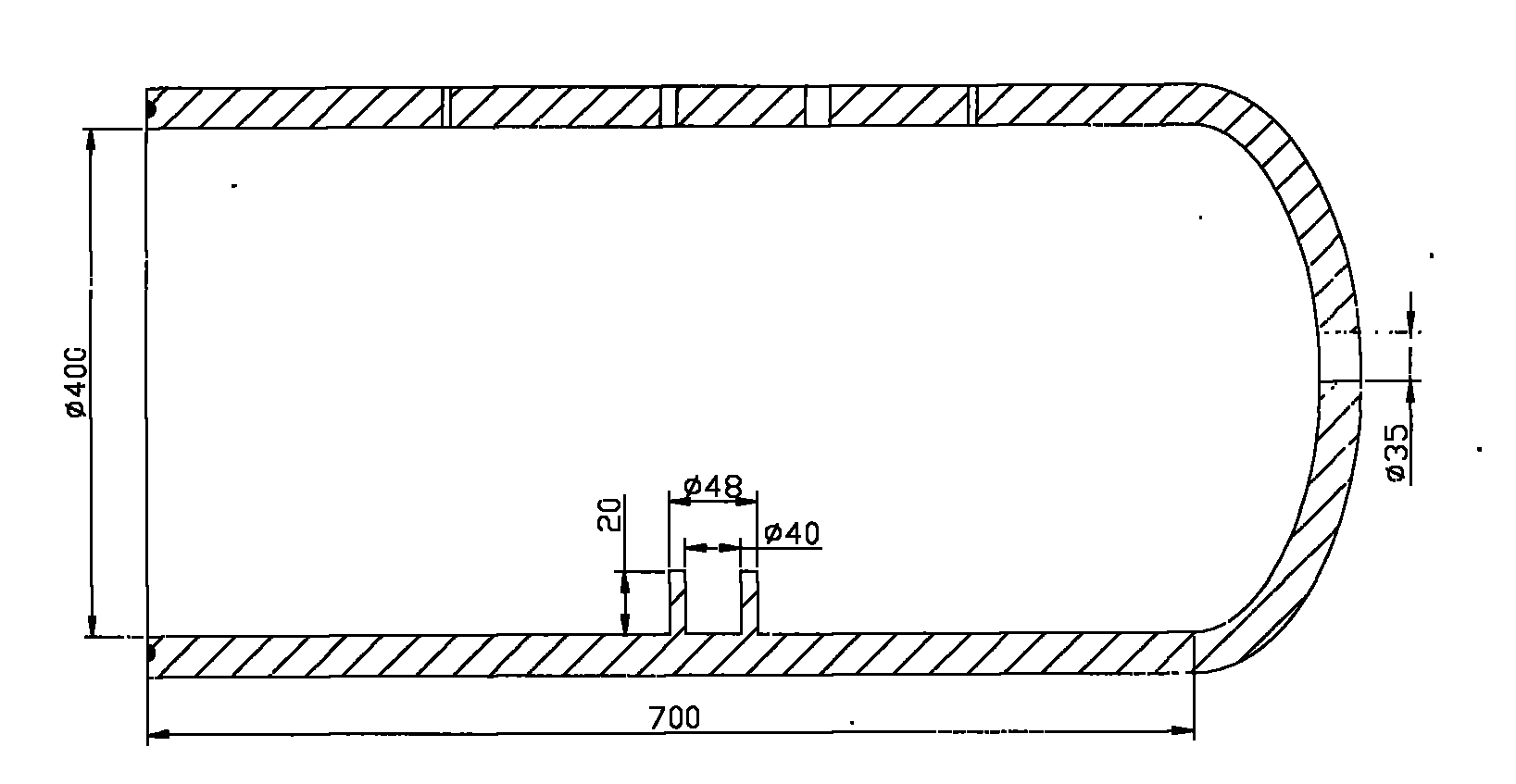

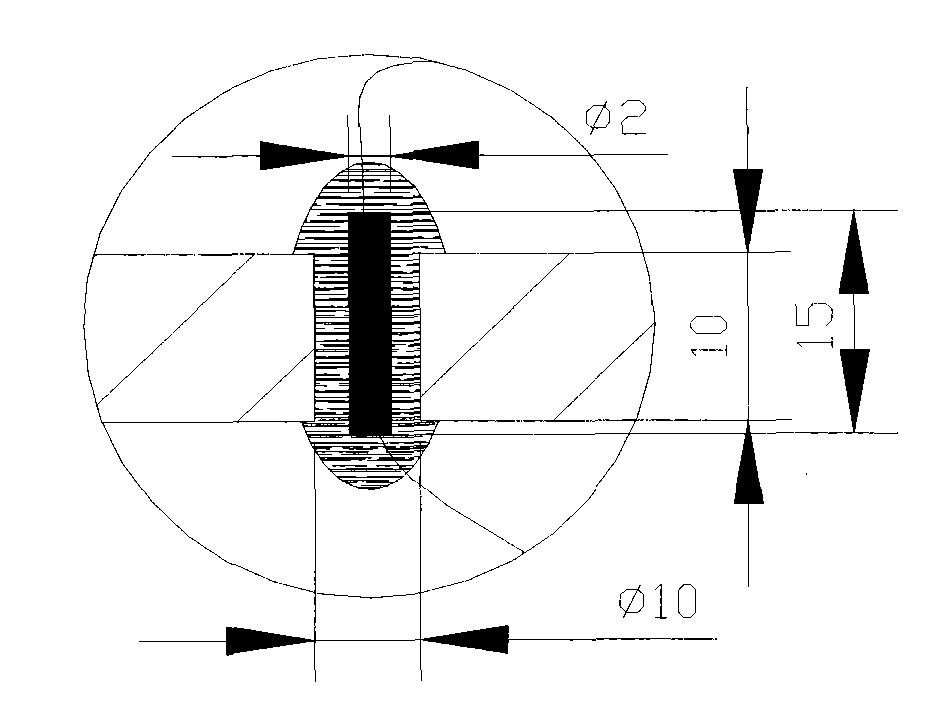

[0016] like figure 1 As shown, the present invention is mainly composed of a vacuum chamber door 1, an O-ring seal 2, a vacuum chamber 3, a box pressure conduit 4, a manual valve 6, a cable sealing and insulating structure 7, a cable wire 8, a vacuum gauge 9, a candle holder 10, and a vacuum valve. 11. It is composed of metal hose 12 and vacuum pump 13. The vacuum chamber door 1, O-ring 2, vacuum chamber 3, manual valve 6, and vacuum valve 11 form a sealed space for maintaining the vacuum environment and accommodating equipment such as the pressure signal device 5 and the candle holder 10; the connection of the box pressure conduit 4 requires The propellant storage tank and the pressure signaler 5 for controlling the pressure are made of stainless steel pipes with a diameter of 8mm and a wall thickness of 1mm, and are connected with the nozzle welded on the wall of the vacuum chamber 3 by threads; the manual valve 6 starts when the atmospheric pressure in the vacuum chamber 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com