A New Type of Vacuum Drying Oven

A vacuum drying oven and drying chamber technology, applied in drying chambers/containers, drying solid materials, drying gas layout, etc., can solve problems such as air leakage, reducing equipment utilization, and delaying equipment use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

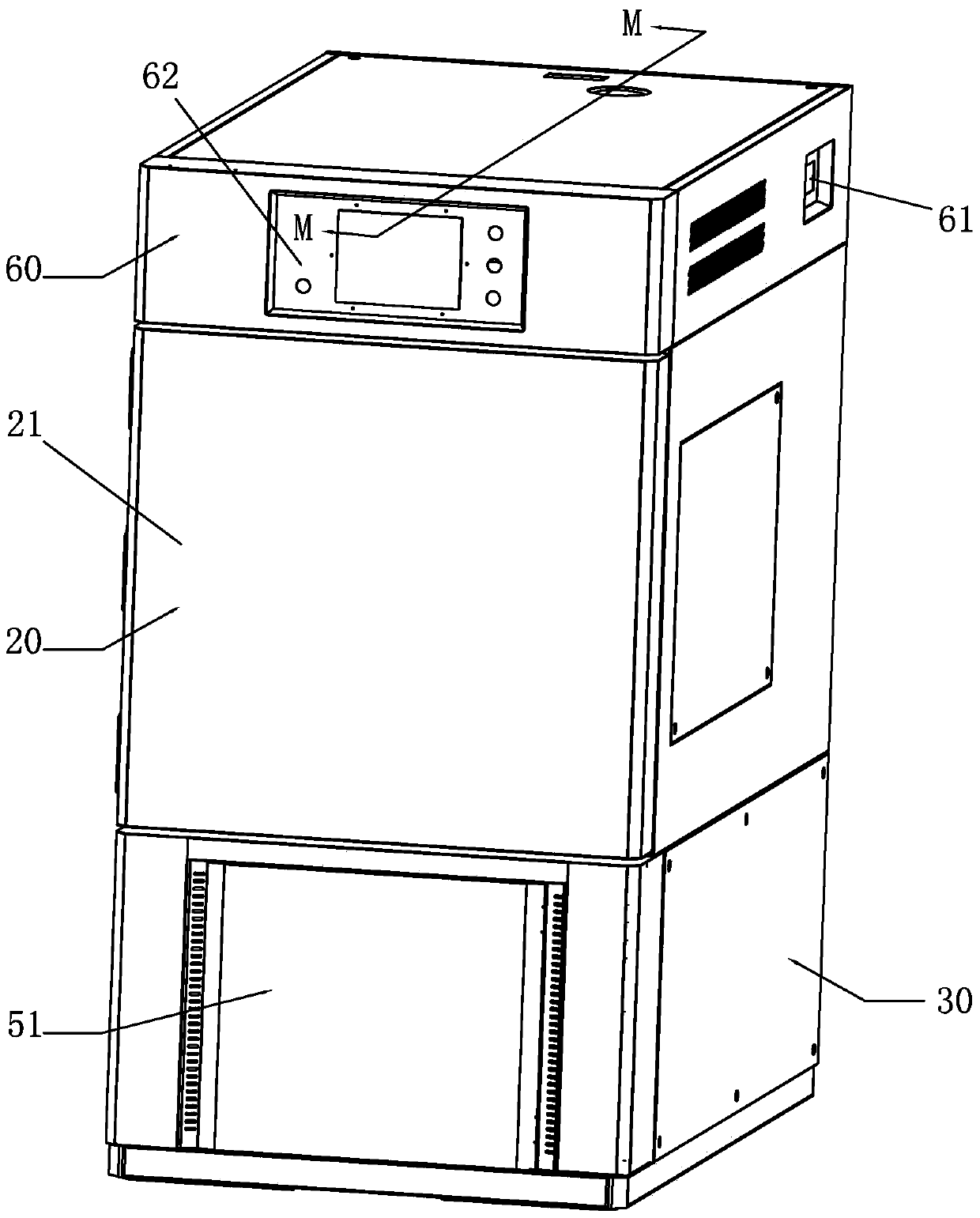

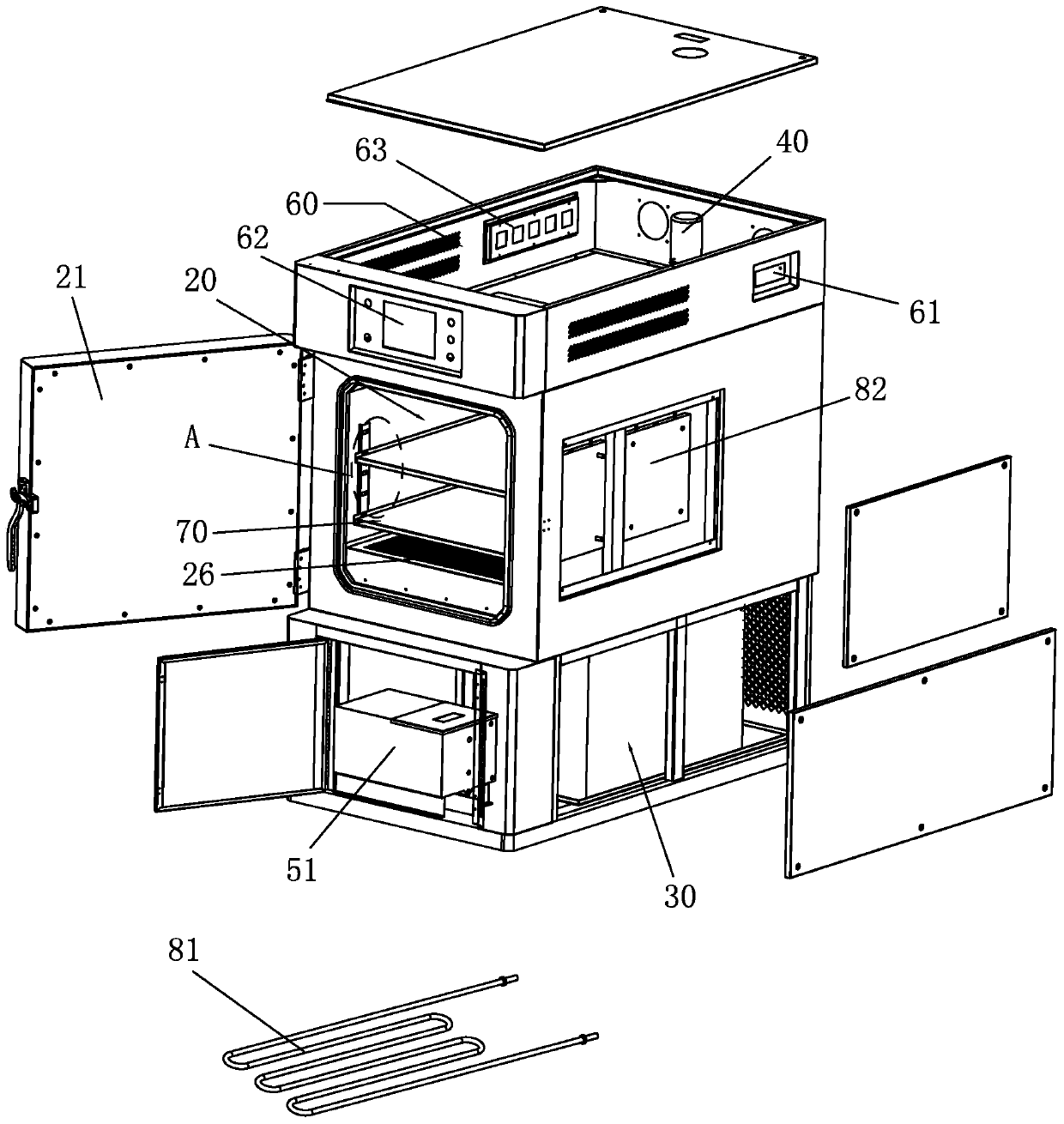

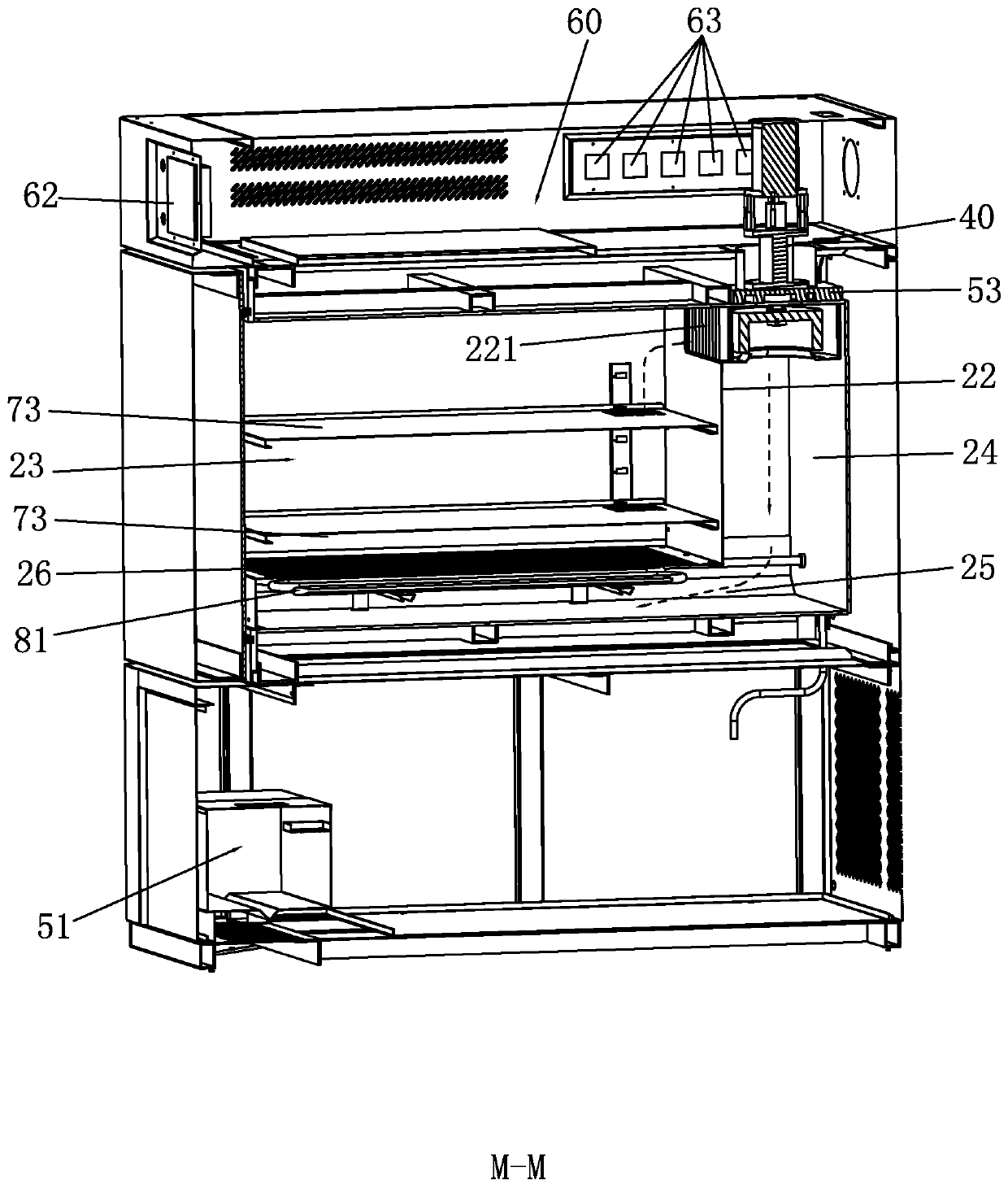

[0051] Please refer to Figure 1 to Figure 8 As shown, it has shown the concrete structure of the embodiment of the present invention, and this kind of novel vacuum drying box includes box body 10 and is arranged on box body 10 inside drying chamber 20, hot air circulation system and vacuum unit 30; The chamber 20 has an opening for taking and taking out items, and an openable safety box door 21 is arranged at the opening.

[0052]A vertical partition 22 is arranged in the drying chamber 20, and the vertical partition 22 divides the drying chamber 20 into a storage chamber 23 and an air outlet chamber 24. The upper end of the vertical partition 22 is connected to the inner top wall of the drying chamber 20, The lower end of the vertical partition 22 is kept at a distance from the inner bottom wall of the drying chamber 20 to form an air passage connecting port 25, and the bottom of the aforementioned air outlet chamber 24 communicates with the storage chamber 23 through the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com