High-temperature pulsed hot water spraying sterilizing method

A technology of high-temperature pulsation and hot water spraying, which is applied in the field of sterilization, can solve the problems that are difficult to achieve or fail to kill microorganisms, and achieve the effects of short time in the high-temperature zone, high temperature control accuracy, and good temperature distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

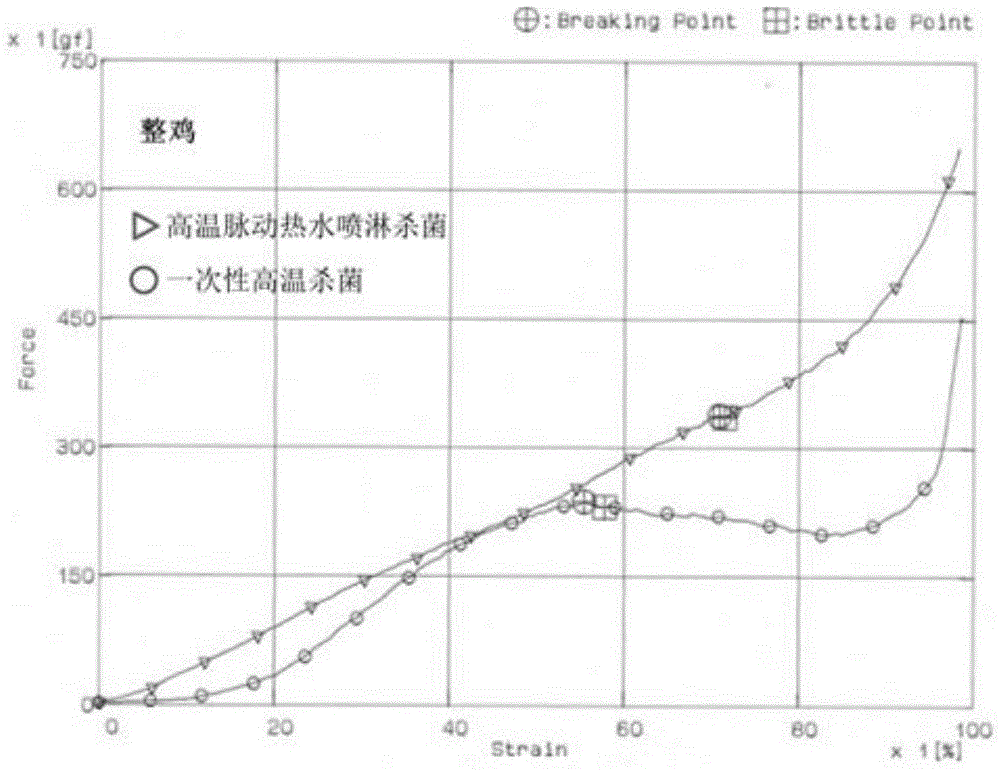

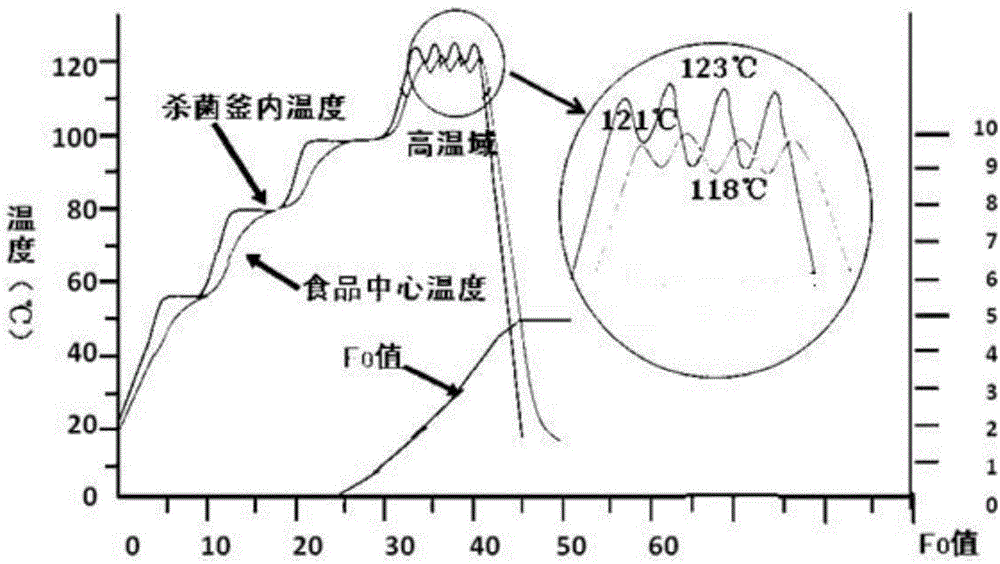

[0026] In the prior art, the pretreated whole chicken is subjected to high-temperature sterilization once, the sterilization temperature is 121°C, the total sterilization time is 52 minutes, F 0 The value is 4.18, the product is cultured at 37°C for 7 days, and the total number of microorganisms is tested. The amount of bacteria carried by the product is 1.12×10 2 . During high temperature pulsating hot water spray sterilization:

[0027] Preparation: Put the pretreated whole chicken into the sterilizer; open the valve on the water replenishment pipeline between the cold water tank and the hot water tank, replenish the cold water in the cold water tank to the hot water tank, and Water level; open the valve on the first heating circuit where the hot water tank and circulation pump are located, and circulate the cold water in the hot water tank through the circulation pump on the first heating circuit; open the valve on the steam pipeline, And heat the cold water in the first ...

Embodiment 2

[0038] In the prior art, the pretreated whole chicken is sterilized once at high temperature, the sterilization temperature is 121°C, and the total sterilization time is 45 minutes. The product is cultured at 37°C for 7 days, and the total number of microorganisms is tested. The bacteria carrying amount of the product is 5.87 ×10 4 .

[0039] High-temperature pulsating hot water spray sterilization: preparation: put the pretreated whole chicken into the sterilizer; open the valve on the water supply pipeline between the cold water tank and the hot water tank, and replenish the cold water in the cold water tank into the hot water tank, and to the upper limit water level; open the valve on the first heating circuit where the hot water tank and circulation pump are located, and make the cold water in the hot water tank go through the circulation pump on the first heating circuit Circulation; open the valve on the steam pipeline, and heat the cold water in the first heating circu...

Embodiment 3

[0051] In the prior art, the pretreated whole chicken is sterilized once at high temperature, the sterilization temperature is 121°C, and the total sterilization time is 45 minutes. The product is cultured at 37°C for 7 days, and the total number of microorganisms is tested. The bacteria carrying amount of the product is 5.87 ×10 4 .

[0052] During high temperature pulsating hot water spray sterilization:

[0053] Preparation: Put the pretreated whole chicken into the sterilizer; open the valve on the water replenishment pipeline between the cold water tank and the hot water tank, replenish the cold water in the cold water tank to the hot water tank, and Water level; open the valve on the first heating circuit where the hot water tank and circulation pump are located, and circulate the cold water in the hot water tank through the circulation pump on the first heating circuit; open the valve on the steam pipeline, And heat the cold water in the first heating circuit to 100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com