An electrostatic chuck and its gas supply method

An electrostatic chuck and helium technology, which is applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve problems such as changes in reaction conditions, leakage, inconsistent effects between the center and edge areas of the substrate 30, and achieve good temperature distribution. , to ensure the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

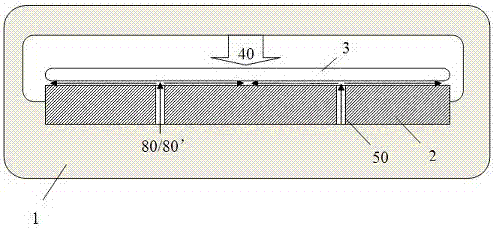

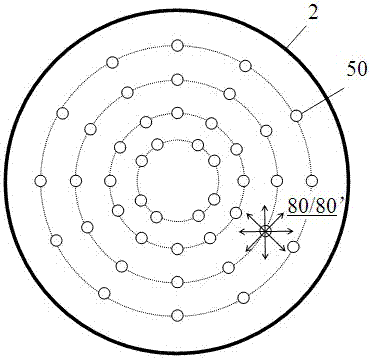

[0027] Such as figure 2 As shown, in the first embodiment of the present invention, the first process gas 40 is introduced into the vacuum processing chamber 1 to etch or otherwise process the surface of the substrate 3, and the bottom of the vacuum processing chamber 1 is provided with static electricity. The chuck 2 fixes and supports the substrate 3 placed on the electrostatic chuck 2 . A number of gas passages 50 are opened in the electrostatic chuck 2 to introduce cooling gas from the bottom of the electrostatic chuck 2 to its top surface. Afterwards, the cooling gas is blown through the gap between the back surface of the substrate 3 and the top surface of the electrostatic chuck 2 , so as to flow through the entire back surface of the substrate 3 for heat transfer, thereby cooling the substrate 3 .

[0028] Wherein, the diameter of the electrostatic chuck 2 in this embodiment is equal to or greater than the diameter of the substrate 3 . At the same time, the gas comp...

Embodiment 2

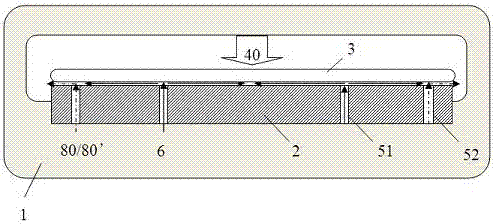

[0034] Such as Figure 4 As shown, in the second embodiment of the present invention, the electrostatic chuck 2 is located at the bottom of the vacuum processing chamber 1, and is used to fix and support the substrate 3 placed on it, and the first process gas 40 is introduced from above to the substrate. 3 The surface is etched or otherwise treated. The diameter of the electrostatic chuck 2 is equal to or larger than that of the substrate 3 . Moreover, two groups of gas channels, the first channel 51 and the second channel 52 , are provided in the electrostatic chuck 2 , which are respectively used to transport gas to the gap between the back surface of the substrate 3 and the top surface of the electrostatic chuck 2 .

[0035] Wherein, the first channel 51 is located in the central area 91 of the electrostatic chuck 2, and is used to transport cooling gas, preferably helium 60; The second process gas 80 or 80' with the same or very close composition ratio, which separates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com