Oxygen-free copper composite welding method

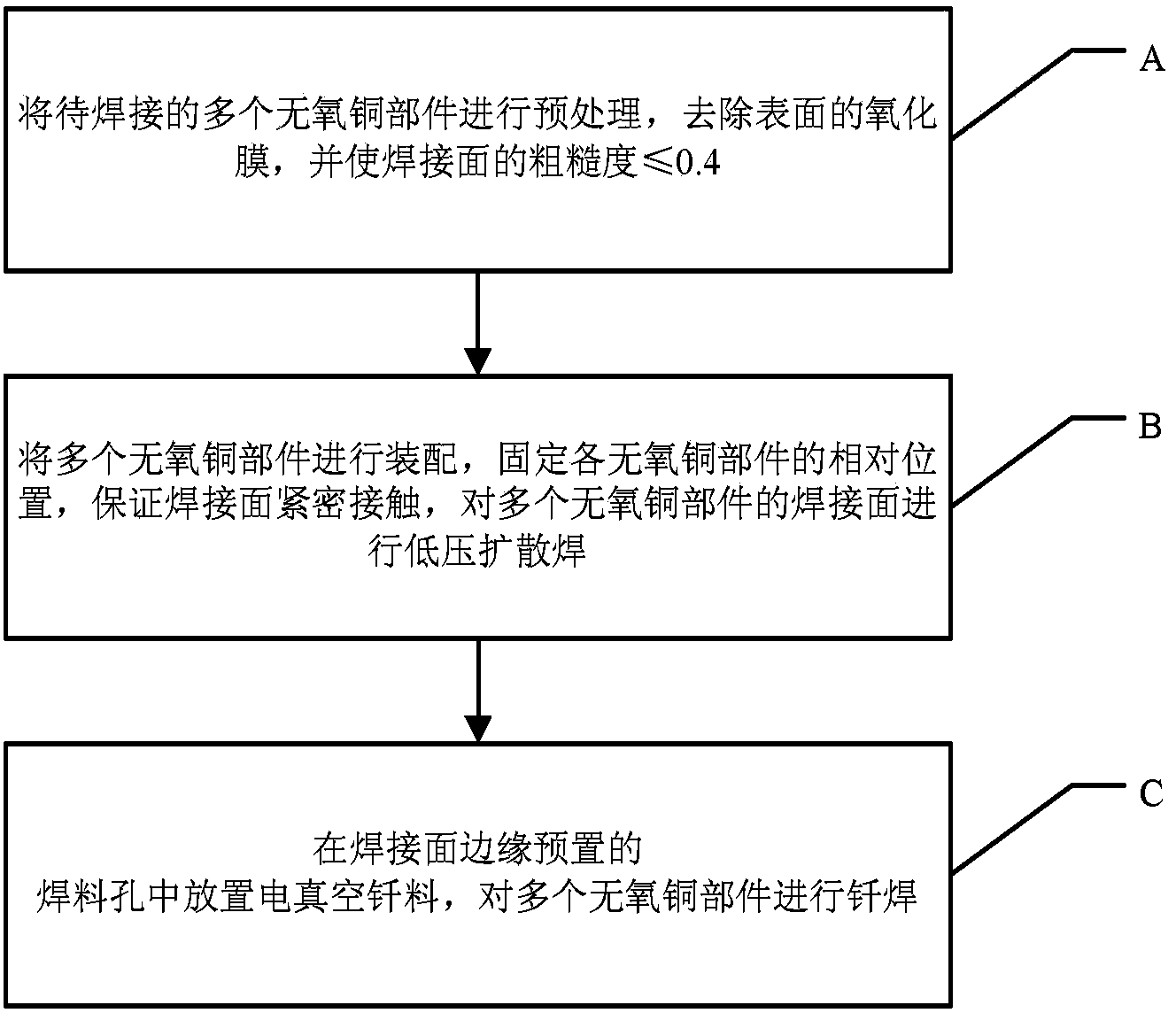

A composite welding and oxygen-free copper technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of large deformation, solder overflow, etc., and achieve good vacuum sealing, high welding precision and tight combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] The oxygen-free copper precision welding method in this example is as follows: the contact surface roughness of the welded parts is 0.4, the parts are immersed in acetone solution and ultrasonically cleaned for 30 minutes, and then put into a hydrogen furnace for hydrogen annealing treatment. The hydrogen burning temperature is 550 ° C. The holding time is 60min. Then assemble the oxygen-free copper parts to ensure that the joint surfaces are in close contact, and use methods such as centering rods to fix the relative positions. Into a vacuum furnace, and apply a 0.2MP diffusion pressure by means of heavy objects, the vacuum degree is always better than 1×10 during the diffusion welding process -3 Pa, heat up to 950°C at a heating rate of 15°C / min, hold for 60 minutes, then cool to 300°C at a rate of 10°C / min, and then cool to room temperature with the furnace, that is, low-pressure diffusion welding is completed; Put the electric vacuum solder in the solder hole, the ...

example 2

[0028] The difference between this example and Example 1 is that the roughness of the contact surface of the workpiece to be welded is 0.2, and the others are the same as Example 1.

example 3

[0030] The difference between this example and Example 1 is that the low-pressure diffusion welding pressure is 0.08MPa, and the others are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com