Electrodeless ultraviolet germicidal lamp

A technology of electrodeless ultraviolet and germicidal lamps, which is applied in the direction of discharge lamps, parts of gas discharge lamps, electrical components, etc. It can solve problems such as incomplete expansion coefficients, complicated processing of parts, and long start-up time, and reach the applicable power range. Wide, suitable for a wide temperature range, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

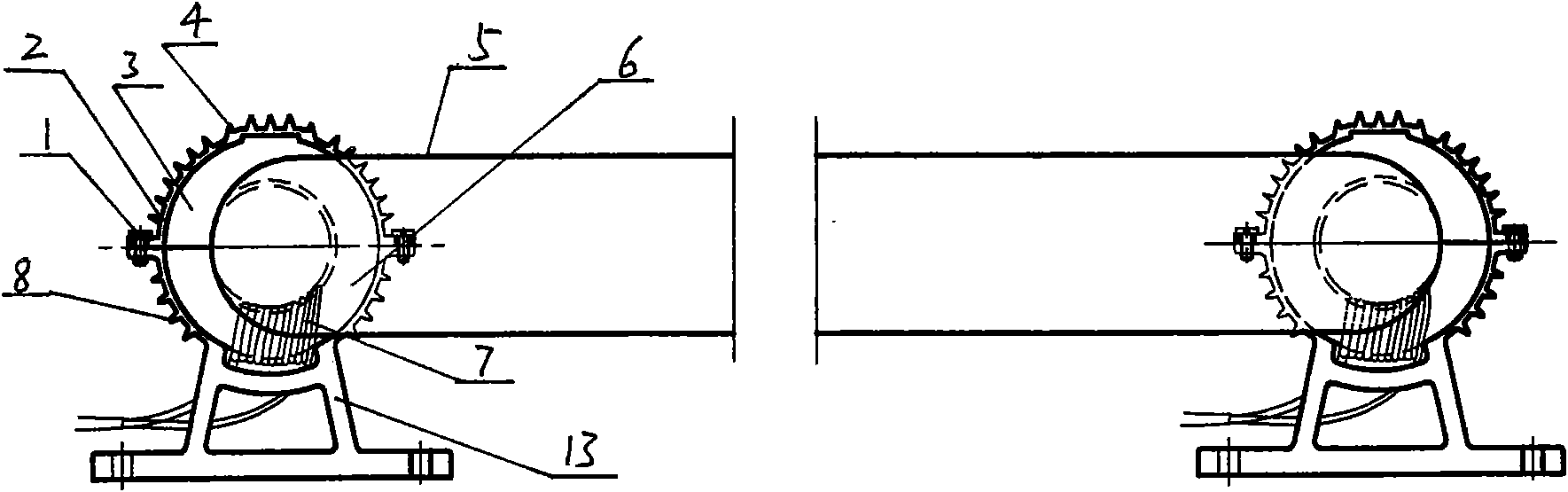

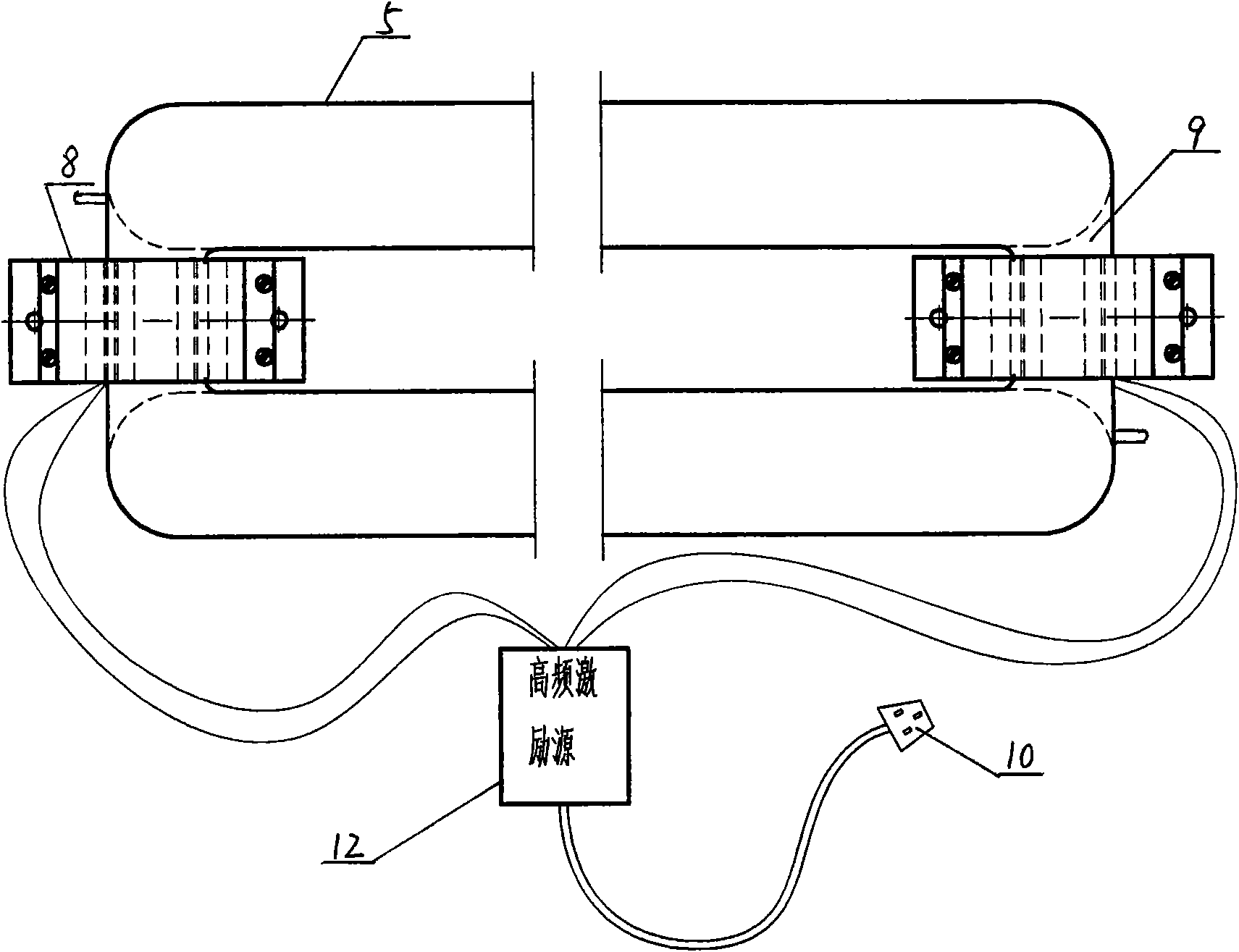

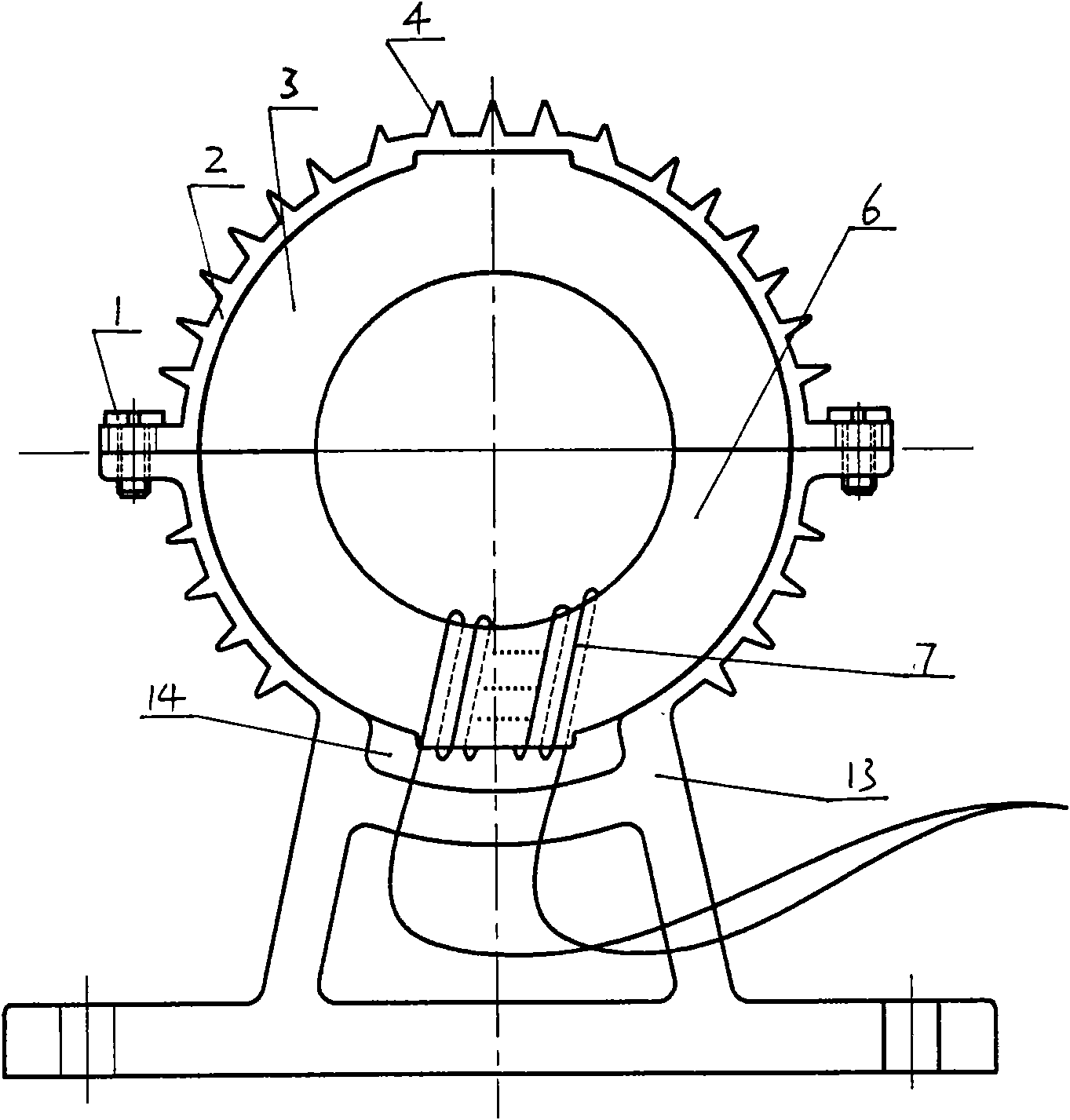

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment includes a frame-shaped lamp tube 5 made of HX-ultraviolet transparent quartz tube material, two power couplers 8 and a high-frequency excitation source 12 . The power coupler 8 includes a radiator and a high-frequency current transformer. The radiator is composed of a base 13 and a top cover 2, which is made of an aluminum alloy material with a model number of A006063. The upper end of the base 13 is combined with the top cover 2 to form a complete circle, and its outer edge 4 is serrated. . The junction of the base 13 and the top cover 2 has a convex edge fixed together, and the convex edge is provided with threaded holes, which are fixed together by bolts 1, nuts and gaskets. The high-frequency current transformer is composed of a magnetic ring made of manganese-zinc ferrite model N27 and a coil 7 made of AFT250 Teflon wire. The magnetic ring is composed of upper and lower semicircl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com