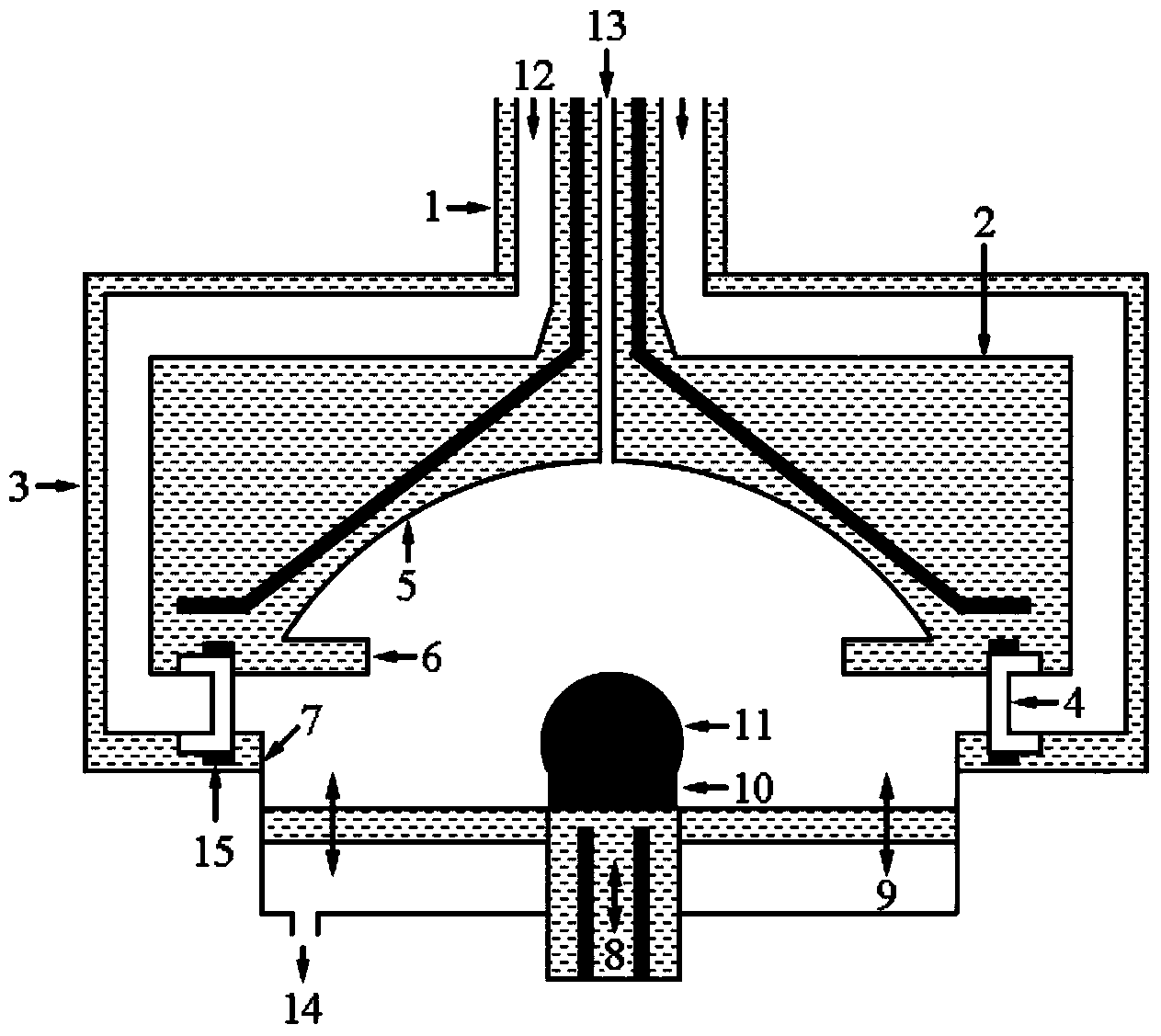

Domical microwave plasma chemical vapor deposition diamond film device

A chemical vapor deposition, microwave plasma technology, applied in gaseous chemical plating, electrical components, metal material coating processes, etc., to achieve the effect of helping uniform deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

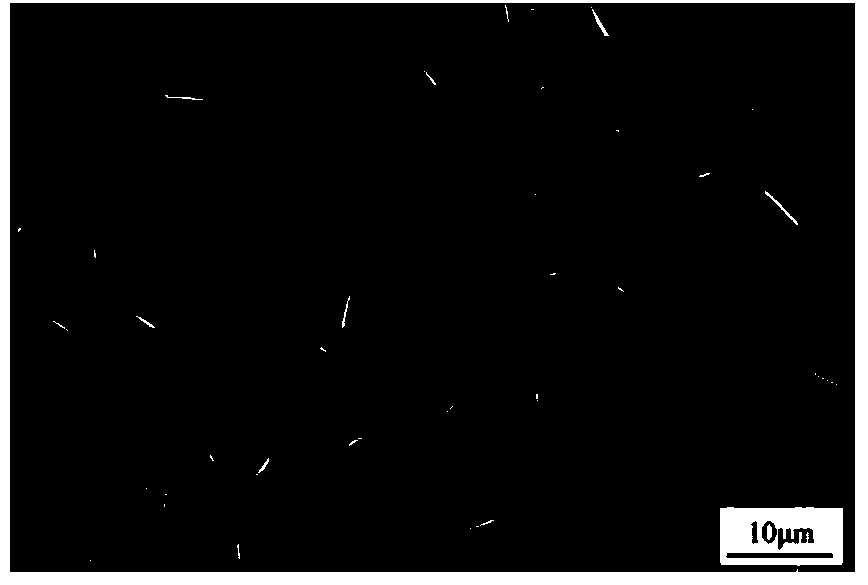

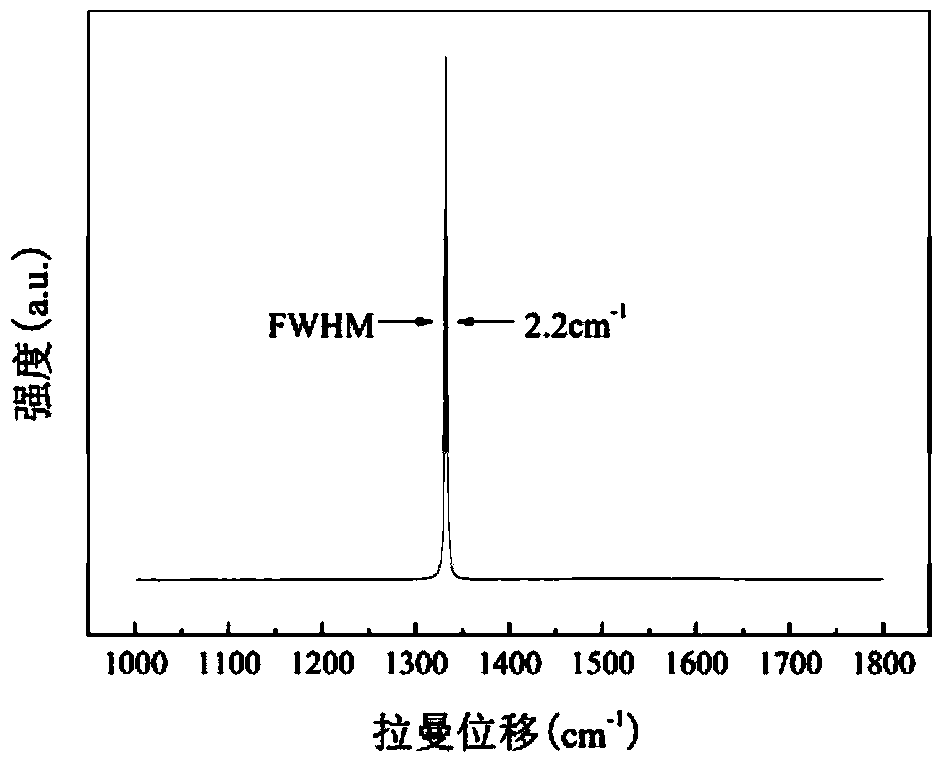

[0035] Utilize the dome type MPCVD diamond film deposition device that the present invention proposes, carried out the deposition of high-quality diamond film, experimental process is as follows:

[0036] (1) Turn on the chiller, from the top coaxial waveguide converter 1 to the middle cylindrical loop antenna 2 to the bottom adjustable center deposition table 8 and adjustable edge deposition table 9, and the entire cylindrical shell 3, All parts through which the microwave propagates are water-cooled;

[0037] (2) Turn on the mechanical pump to evacuate the resonance cavity to below 1Pa;

[0038] (3) The hydrogen gas and the methane gas with a flow rate of 400ml / min and 20ml / min are respectively introduced into the resonance cavity through the intake pipe 13;

[0039] (4) Adjust the valve size of the mechanical pump so that the gas pressure in the resonance chamber is around 800Pa;

[0040] (5) Turn on the microwave power supply, input the microwave 12 with a frequency of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com