Vacuum sealing joint for low-temperature tubular heating tube

A tubular heating tube and vacuum sealing technology, which is applied to engine sealing, engine components, mechanical equipment, etc., can solve the problems of increasing the cost of decompression equipment, high cost, and unrealistic, etc., and achieves simple structure, simple assembly, and obvious effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

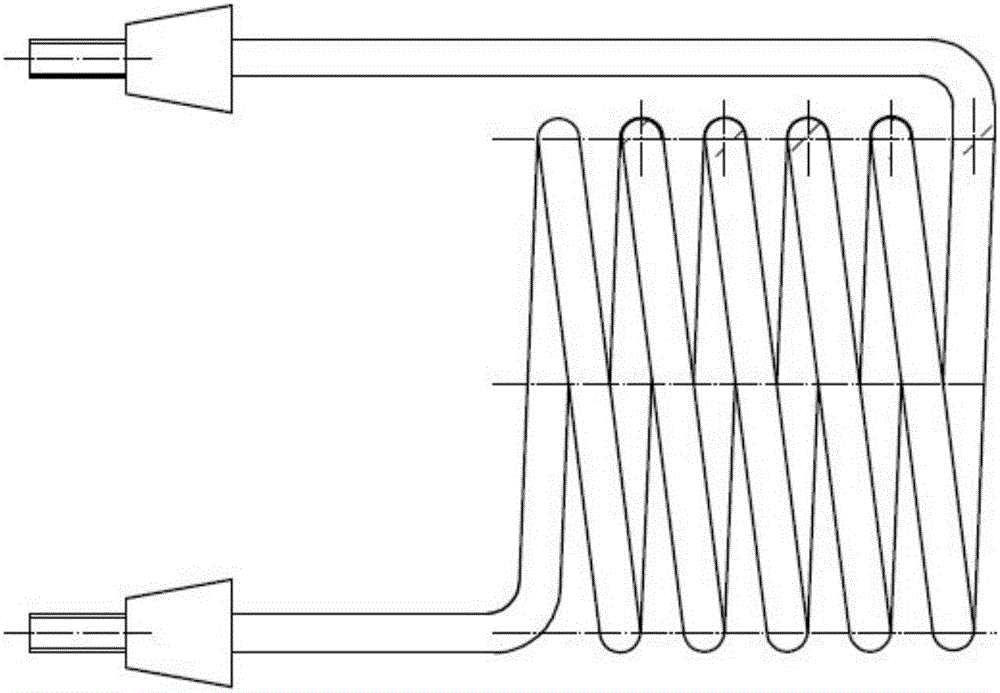

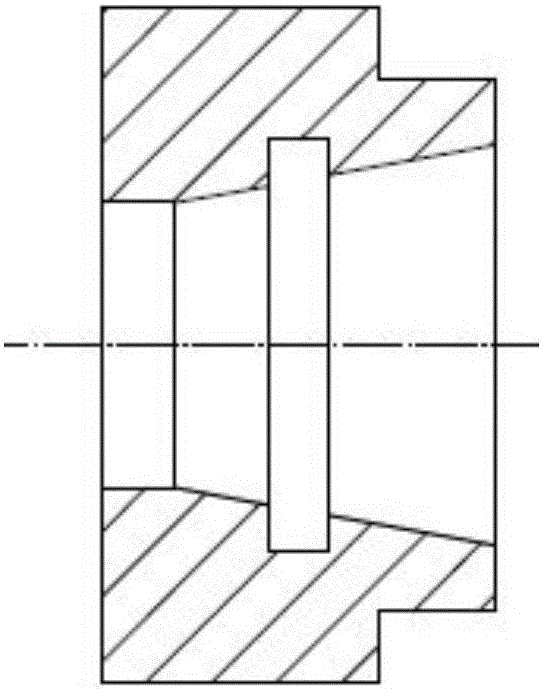

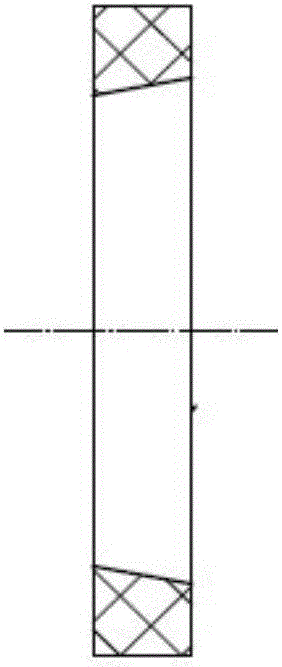

[0017] Such as Figure 1 to Figure 5 As shown, the low-temperature tubular heating tube vacuum sealing joint of the present invention includes a tubular spiral heating tube 201 , a vacuum joint 203 , a sealing ring 204 , and a compression nut 205 . Vacuum furnace wall 202 pre-machines the hole for installing vacuum joint 203. The vacuum joint is inserted into the hole from the outside of the furnace and welded on the vacuum furnace wall. The direction of the cone is the same. Insert the two conductive ends of the tubular spiral heating tube 201 into the vacuum joint from the furnace. 205 respectively screw on the two conductive ends of the tubular spiral heating tube 201, and tighten to make the tapered part of the tubular spiral heating tube compress the sealing ring 204 to achieve the vacuum sealing effect, screw on the other two compression nuts 205 and tighten the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com