Microwave continuous freeze-drying device

A microwave and freeze-drying technology, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of increasing manufacturing difficulty and cost, reducing the probability of discharge and release, and uneven drying of materials, so as to protect the vacuum characteristics and avoid Glow discharge, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] As the simplest embodiment of the present invention, on the basis of the existing microwave continuous freeze-drying device, such as the two existing freeze-drying devices listed in the background technology, the left and right walls of the freeze-drying warehouse are The walls of the tank and the bottom chamber are made of non-metallic wave-transparent materials such as polytetrafluoroethylene, polyethylene, polypropylene or quartz glass.

Embodiment 2

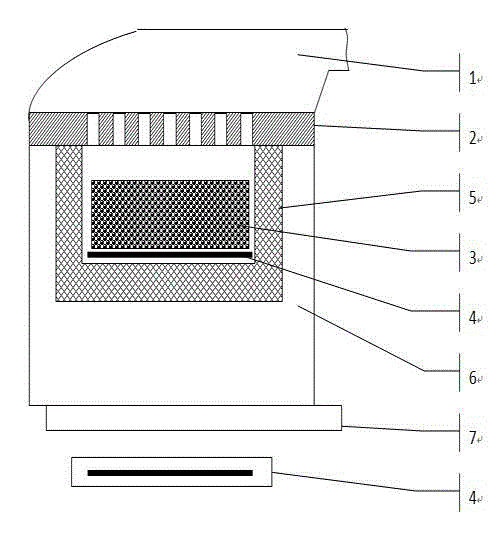

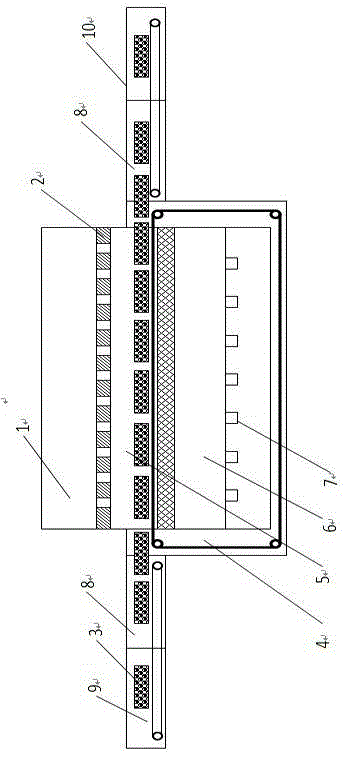

[0035] As the best embodiment of the present invention, such as figure 1 , 2 As shown, the vacuum continuous feeding mechanism 9, the vacuum continuous discharging mechanism 10, the microwave system 7, the microwave suppressor 8, the vacuum water catch system 1, the microwave chamber 6, the material transmission system 4, the freeze-drying chamber 5 and the microwave shielding plate 2 composition.

[0036] Among them, the freeze-drying chamber 5 is made of non-metallic wave-transparent materials, such as polytetrafluoroethylene, etc., which are non-toxic, odorless, have certain strength, wave penetration, low microwave loss, and certain temperature resistance;

[0037] The microwave shielding plate 2 is made of metal and has uniform through holes, which can inhibit the passage of microwaves and ensure the passage of water vapor;

[0038] The freeze-drying chamber 5 has a "concave" cross-sectional shape, on which a microwave shielding plate 2 is installed, and then connected ...

Embodiment 3

[0046] Depend on figure 1 , 2 Shown constitutes a microwave continuous freeze-drying device.

[0047] The microwave system adopts a microwave source with a frequency of 2450MHz and a slit antenna feeding method. The power of a single wave source is 2kW, and the total power of multiple sets reaches 30kW; the freeze-drying chamber 5 is made of polytetrafluoroethylene; Fluorine-coated glass fiber tape; Material 3 is a material with a moisture content of 65% that has been frozen below the eutectic point.

[0048] The main operation process is as follows:

[0049] Vacuumize the vacuum water catch system 1 so that the air pressure in the freeze-drying chamber 5 drops below 133Pa;

[0050] The material 3 is continuously sent to the conveyor belt in the material conveying system 4 by the continuous feeding system 9 and the microwave suppressor 8;

[0051] The material system 4 continuously sends the material 3 into the freeze-drying bin 5;

[0052] The microwave system 7 feeds mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com